The revival in the fortunes of butter, the success of their German model and problems delivering a consistent product from multiple sites are the main reasons behind the recent Irish Dairy Board (IDB) decision to invest €30m building a state-of-the-art butter-packing plant in Mitchelstown.

After years of being unfairly denigrated using dubious science promoted by margarine makers, butter sales are bouncing back. Irish butter, with its unique colour and taste, has the potential to be a global star.

To fulfill that potential, it needs to get the supply chain fit for purpose.

Why is the project required? The IDB has plans to double sales of Kerrygold butter from around 20,000t to 40,000t by 2020. Speaking at the results announcement last week, IDB chairman Aaron Forde admitted that the company cannot currently meet demand for branded Kerrygold butter. One of the main problems is that the IDB has no control over manufacturing, ultimately depending on a range of processors to service their customers. It is clearly not an optimum structure for a branded business.

Kerrygold butter remains the number one butter in the German market, with a 17% market share and sales approaching €300m per year.

The challenge for IDB executives is to replicate that success in other markets, the US being a clear target. IDB branded sales to the US grew by 15% to €62m in 2013, with butter sales up 48%. The market can’t get enough of the stuff. Irish butter is yellow and grass-fed; US butter is white and corn-fed. As the global dairy industry becomes increasingly large-scale and corn-fed, the marketing strengths of grass-fed “meadow milk” from family farms increases. After making its debut on US television screens last year, the IDB could not meet demand.

Russia, Africa and the Middle East also offer real potential.

What the IDB wants to do in Ireland is to replicate the model that is delivering so successfully in Germany – a modern well-invested factory with state-of-the-art logistics and packaging technology.

The accompanying map shows the six locations where Kerrygold is currently packed into a limited number of retail formats. Additional sites also produce bulk 25kg butter blocks which are shipped to Germany for packaging. In future, many of these sites will continue to make butter, but their packing operations are likely to be scaled back in favour of IDB Cork.

Being blunt, butter packing in Ireland today is a mess, occurring at multiple sites, most of which have not been modernised. Basic foil-wrapped 1lb packs dominate output.

There has been little investment in packing technology and most plants are sub-optimal in scale.

In fact, apart from IDB Germany, as much as 60% of Kerrygold butter is currently packed outside of Ireland – in Britain, France and Belgium. The facilities are simply not here to meet the required demand at the right specifications.

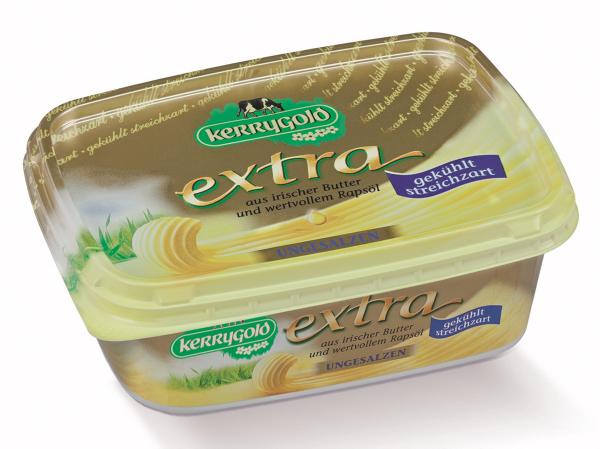

Kerrygold Extra, which is a spreadable tub format, has been a huge success in Germany. It was recently launched in Britain. Irish butter is sent to Germany in order to make the product.

Speaking last week, IDB chief executive Kevin Lane said Irish farmers produce the best butter in the world; they have the best brand in the world; the missing link is the world-class supply chain to match. IDB Germany has all three. IDB Cork aims to replicate that success.

In the 1800s, the Cork Butter Exchange was the world’s leading butter market. If the Irish Dairy Board get it right, Cork will again become a global leader in branded butter product.

SHARING OPTIONS