Pöttinger acquired the Rabe drill facility in Bernberg, Germany, in 2001, and has big plans to grow this part of its business. On a recent press trip to the facility, Pöttinger shared the history of the factory, which is one of Germany’s oldest, established in 1853.

As part of its state ownership, Bernburg produced seed drills under the Fortschritt name. After the reunification of Germany, the company was controlled by local trustees.

In 1992, Rabe purchased the factory and entered an agreement with Pöttinger to supply seed drills in the red and yellow colours. This agreement ended when Pöttinger assumed full control and ownership in 2001. So the company is not a newcomer in this area of drilling technology.

Pöttinger set a target to grow turnover from €301m to €450m in five years. It sees cultivation equipment as a big part of this growth, and has invested heavily in the Bernburg facility, with €10.3m spent in upgrades.

These upgrades are now yielding updated products – customised drills with direct ordering. In a week, the facility can roll out 40 drills on three production lines for the Terrasem, Aerosem, and Vitasem A.

Aerosem Duplex seeding system

A clever system from Pöttinger, the Aerosem drill now has the ability to plant dual rows of maize in a staggered pattern. Following on from the development of its Precision Combi Seeder (PCS), which enables Pöttinger’s Aerosem pneumatic drill to plant both cereal crops and maize, the machine is now capable of planting dual rows of maize in a staggered pattern.

As before, the Duplex system uses the same type of mechanical singulation metering units. The dual rows of maize are achieved by using pairs of the drill’s double-disc coulters.

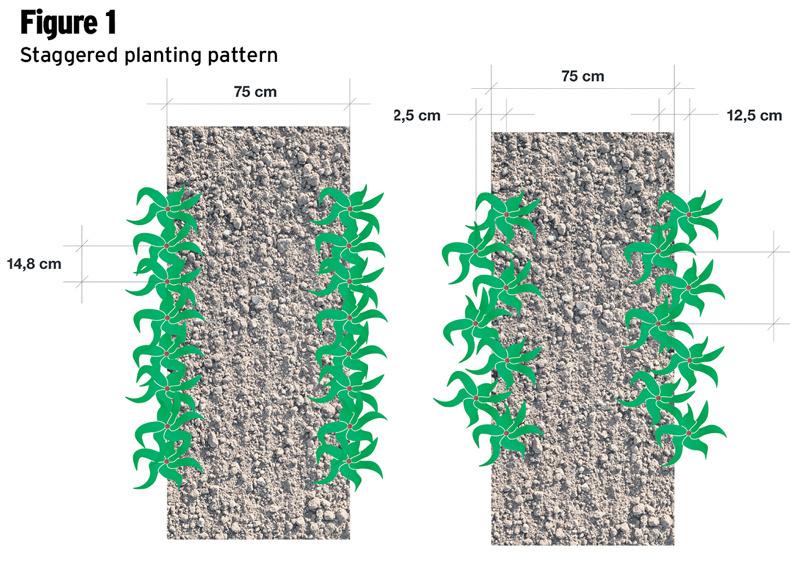

This plants the maize in a dual row at 12.5cm spacing, with a 75cm spacing to the next dual row. Staggered row spacing increases the distance between the plants, allowing for better light interception, more efficient nutrient use and more space for roots to develop, according to Diarmuid Claridge from Pöttinger Ireland.

Figure 1 shows the staggered planting pattern. Pöttinger says output is increased also, with single-row maize planting, forward speed is limited to about 8km/h, but with work shared between twice as many singulation units, forward speeds of the Duplex system are up to 12km/h. This method of sowing has enabled maize silage yield increases of 11%, the company claims.

Pöttinger also stressed to great lengths that planting the maize in this pattern will not affect harvesting with Kemper maize headers. The split hopper design is a novel feature and allows either a companion crop or fertiliser to be drilled with the maize crop.

Shaun Groom, the company’s UK general manager, said the ability to sow another crop either side of each row of maize improves soil conditions and trafficability at harvest time. For Ireland, this might be a welcome factor in poor autumn weather.

The limitation for this country is the temperature, and the perception that all maize plants need plastic cover. Diarmuid hopes to get a machine working in the south next year, and investigate the performance in the field of the maize plant.

“Where I see it this drill is not a giant stride away from having a facility to sow cereal grains and fertiliser together in a mounted unit,” says Diarmuid. The PCS system adds about €4,696 (£4,000) to an Aerosem or €9,367 (£8,000) for the PCS fitted with the Duplex version.

Terrasem trailed drills with a wave disc low disturbance design

Reduced power, shallow cultivating and reducing unwanted soil disturbance and hence spreading of the problematic blackgrass weed are the drivers of this design, according to Pöttinger.

The updated Terrasem takes 15 % less horsepower compared with the previous version, at a working depth of 5-6cm. It is not designed for deep cultivating, and works really well in stale seedbeds, Pöttinger says.

It is available with seed and fertiliser, in working widths of up to 9m.

The drill has a minimum working speed of 10km/h. The theory is only to cultivate the ground needed for seed planting. The low disturbance Terrasem is fitted with two rows of waved discs, with each disc lining up with a seed coulter at a 125mm or 167mm row spacing. Discs are mounted in pairs and do not run at an angle like the other designs.

SHARING OPTIONS