Slurry is a valuable source of nitrogen (N), phosphorus (P) and potassium (K) and its effective use on farms can help reduce fertiliser costs. To maximise the nutrient value of either cattle or pig slurry, a number of decisions should be made over the coming weeks as to where on the farm slurry is required and consider application timing and techniques to maximise N recovery.

Targeted early application of slurry based on soil test results will ensure efficient use of slurry N and that early-season P and K requirements are satisfied.

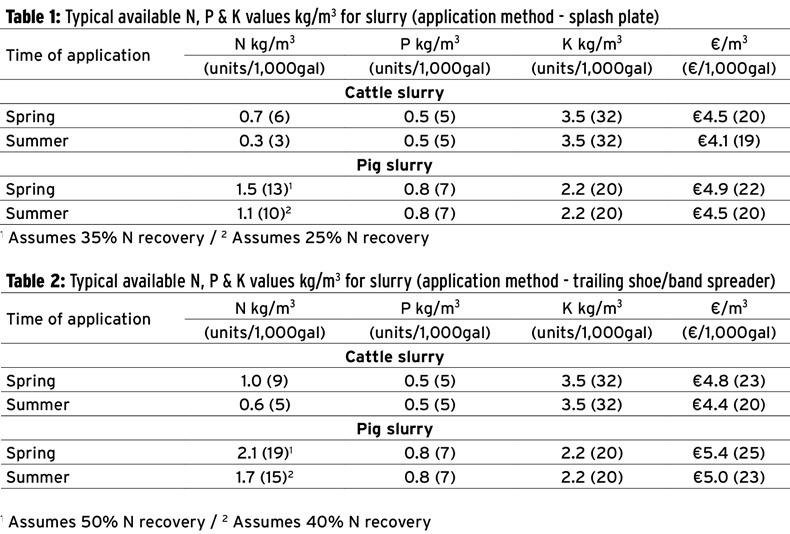

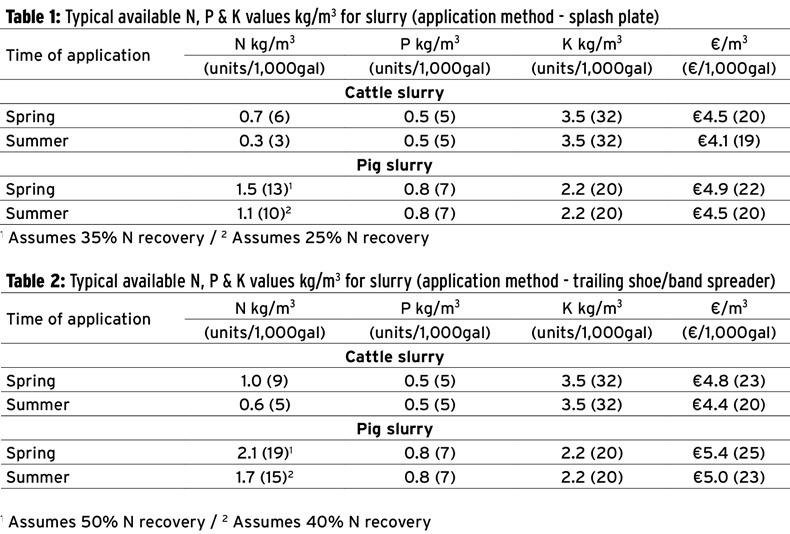

The typical value of 1,000 gallons of cattle or pig slurry applied by splash plate in springtime has an available N-P-K content equivalent to a 50kg bag of 6:5:32 and 13:7:20 respectively.

The nutrient content of slurry will vary with animal type and diet, and especially with slurry dilution with water.

Knowing the nutrient content will help ensure that crops receive the planned levels of N, P and K to maximise grass growth for either silage or grazing.

Laboratory analysis of slurry is a must to determine the precise nutrient values for the slurries being applied. However, in practice, this is rarely done. A more practical approach may be to estimate the slurry dry matter on farm using a slurry hydrometer. This is a low-cost and useful tool to estimate the N-P-K value based on the dry matter of the slurry.

Phosphorus and potassium

Cattle or pig slurry is a good source of P and K fertiliser and should be applied to parts of the farm that have either low soil P or K levels, or to crops with high P and K demands such as grass or maize silage.

Targeting these areas will help reduce fertiliser bills and replenish soil P and K reserves.

Research shows that fields around the farmyard tend to have higher levels of both P and K due to more regular applications of manures.

Silage fields tend to be the furthest fields away from the yard and tend to have low soil fertility levels plus the largest demand for both P and K.

Slurry is a valuable fertiliser and the extra transport costs in moving slurry to fields further from the farm may offset the extra spreading charges associated with extra transport.

The P to K ratio in cattle slurry is more suitable for grass silage crops. Pig slurry has a better P to K ratio for grazing ground, depending on the stocking rate and soil test results.

The P in organic manures is 100% available relative to chemical fertiliser at soil P index 3 and 4. However, if a soil is P Index 1 or 2, the availability of the P will be only 50%. This means that you can use organic manures as a good source of P if soil P levels are low.

A soil test will confirm the P status of the soil and help with targeting slurry to Index 1 and 2 soils for more efficient crop fertilisation and P utilisation.

New slurry K value

Higher levels of K content in cattle slurry were assumed in the past compared to the levels shown in Table 1. Newly updated advice in the Teagasc Green Book shows that the level of K in slurry has fallen by approximately 20% compared with levels that were previously assumed based on older studies from the early 1990s. This reduction in K content is not surprising given the decline in K fertiliser inputs over the same period.

Nitrogen content

The form of N in cattle or pig slurry is ammonium-N and is similar to the form of N in urea fertiliser. This form of N is readily available for plant uptake provided soil and weather conditions are favourable.

Losses of ammonium-N occur when there are drying conditions such as warm, sunny and windy days (good drying days). To maximise N uptake, apply slurry on cool, overcast or misty days. It is recommended to apply as much slurry as possible in the springtime to maximise the fertiliser N value of slurry.

Spring-applied slurry is worth approximately three units of N per 1,000 gallons extra compared with summer application, due to better N recovery at that time of the year (Table 1). However, irrespective of timing, applying slurry in the right weather conditions (cool, overcast, misty conditions) is advised rather than hot dry weather.

Slurry dilution will also improve the N uptake as the slurry will infiltrate faster into the soil and the crop root zone compared with thick slurry. Diluted slurry will also be washed off the grass faster, resulting in reduced grass contamination.

Remember that dilution will increase the N efficiency, but will reduce the P and K content of the slurry and this needs to be accounted for in balancing the P and K requirements of crops.

Pig slurry has an advantage over cattle, with a typical dry matter content of 4% compared with 7% for good-quality cattle slurry. Many farmers have seen the benefits of diluting cattle slurry with pig slurry rather than water. Before importing pig slurry, check your farm fertiliser plan to determine the volume that can be imported on to the whole farm.

Slurry application equipment

The method of slurry application (splashplate or trailing shoe / band spreader) will have a large effect on nitrogen losses. The splashplate technique broadcasts slurry across the full spread width and, depending on timing and weather conditions, high levels of N loss may occur as a result.

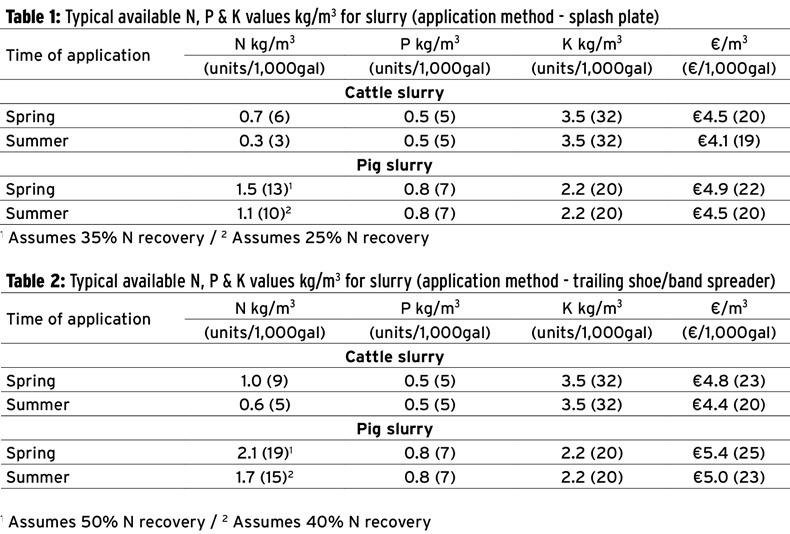

The trailing shoe places the slurry in lines below the grass canopy, while the band spreader places the slurry in narrow bands which reduces the slurries’ exposure to drying conditions and thus reduces the risk of N loss (see table 2).

Other benefits include improved flexibility with applications as a result of reduced contamination of herbage leading to quicker return to grazing, the opportunity to apply slurry into larger grass covers which creates a wider window of opportunity for application in better soil conditions particularly in spring and more even application of slurry across the spread width. The odours released during and after application are also usually reduced with a trailing shoe or band spreader compared with splash plate.

Investment by an individual farmer in a trailing shoe or band spreader may be cost prohibitive as the savings in N fertiliser may not cover the extra costs associated with farmer-owned equipment.

This will depend on the volume of slurry on farm and the value placed on potential other benefits, such as flexibility of timing into taller grass covers, reduced odours and more even nutrient application.

However, where a farmer is already using a contractor for applying slurry by splashplate, using a contractor with a band spreader or trailing shoe may be cost effective.

The contractor price is usually higher per hour, but the value of slurry is increased by approximately €3 per 1,000 gallons (cattle / pig slurry) by these methods, so depending on the volume spread per hour, a higher cost per hour of the contractor can be justified for using the modern techniques.

Authors: Mark Plunkett and William Burchill from Teagasc, Johnstown Castle, Wexford, and Gerard McCutcheon from Teagasc, Oak Park, Carlow.

Slurry is a valuable source of nitrogen (N), phosphorus (P) and potassium (K) and its effective use on farms can help reduce fertiliser costs. To maximise the nutrient value of either cattle or pig slurry, a number of decisions should be made over the coming weeks as to where on the farm slurry is required and consider application timing and techniques to maximise N recovery.

Targeted early application of slurry based on soil test results will ensure efficient use of slurry N and that early-season P and K requirements are satisfied.

The typical value of 1,000 gallons of cattle or pig slurry applied by splash plate in springtime has an available N-P-K content equivalent to a 50kg bag of 6:5:32 and 13:7:20 respectively.

The nutrient content of slurry will vary with animal type and diet, and especially with slurry dilution with water.

Knowing the nutrient content will help ensure that crops receive the planned levels of N, P and K to maximise grass growth for either silage or grazing.

Laboratory analysis of slurry is a must to determine the precise nutrient values for the slurries being applied. However, in practice, this is rarely done. A more practical approach may be to estimate the slurry dry matter on farm using a slurry hydrometer. This is a low-cost and useful tool to estimate the N-P-K value based on the dry matter of the slurry.

Phosphorus and potassium

Cattle or pig slurry is a good source of P and K fertiliser and should be applied to parts of the farm that have either low soil P or K levels, or to crops with high P and K demands such as grass or maize silage.

Targeting these areas will help reduce fertiliser bills and replenish soil P and K reserves.

Research shows that fields around the farmyard tend to have higher levels of both P and K due to more regular applications of manures.

Silage fields tend to be the furthest fields away from the yard and tend to have low soil fertility levels plus the largest demand for both P and K.

Slurry is a valuable fertiliser and the extra transport costs in moving slurry to fields further from the farm may offset the extra spreading charges associated with extra transport.

The P to K ratio in cattle slurry is more suitable for grass silage crops. Pig slurry has a better P to K ratio for grazing ground, depending on the stocking rate and soil test results.

The P in organic manures is 100% available relative to chemical fertiliser at soil P index 3 and 4. However, if a soil is P Index 1 or 2, the availability of the P will be only 50%. This means that you can use organic manures as a good source of P if soil P levels are low.

A soil test will confirm the P status of the soil and help with targeting slurry to Index 1 and 2 soils for more efficient crop fertilisation and P utilisation.

New slurry K value

Higher levels of K content in cattle slurry were assumed in the past compared to the levels shown in Table 1. Newly updated advice in the Teagasc Green Book shows that the level of K in slurry has fallen by approximately 20% compared with levels that were previously assumed based on older studies from the early 1990s. This reduction in K content is not surprising given the decline in K fertiliser inputs over the same period.

Nitrogen content

The form of N in cattle or pig slurry is ammonium-N and is similar to the form of N in urea fertiliser. This form of N is readily available for plant uptake provided soil and weather conditions are favourable.

Losses of ammonium-N occur when there are drying conditions such as warm, sunny and windy days (good drying days). To maximise N uptake, apply slurry on cool, overcast or misty days. It is recommended to apply as much slurry as possible in the springtime to maximise the fertiliser N value of slurry.

Spring-applied slurry is worth approximately three units of N per 1,000 gallons extra compared with summer application, due to better N recovery at that time of the year (Table 1). However, irrespective of timing, applying slurry in the right weather conditions (cool, overcast, misty conditions) is advised rather than hot dry weather.

Slurry dilution will also improve the N uptake as the slurry will infiltrate faster into the soil and the crop root zone compared with thick slurry. Diluted slurry will also be washed off the grass faster, resulting in reduced grass contamination.

Remember that dilution will increase the N efficiency, but will reduce the P and K content of the slurry and this needs to be accounted for in balancing the P and K requirements of crops.

Pig slurry has an advantage over cattle, with a typical dry matter content of 4% compared with 7% for good-quality cattle slurry. Many farmers have seen the benefits of diluting cattle slurry with pig slurry rather than water. Before importing pig slurry, check your farm fertiliser plan to determine the volume that can be imported on to the whole farm.

Slurry application equipment

The method of slurry application (splashplate or trailing shoe / band spreader) will have a large effect on nitrogen losses. The splashplate technique broadcasts slurry across the full spread width and, depending on timing and weather conditions, high levels of N loss may occur as a result.

The trailing shoe places the slurry in lines below the grass canopy, while the band spreader places the slurry in narrow bands which reduces the slurries’ exposure to drying conditions and thus reduces the risk of N loss (see table 2).

Other benefits include improved flexibility with applications as a result of reduced contamination of herbage leading to quicker return to grazing, the opportunity to apply slurry into larger grass covers which creates a wider window of opportunity for application in better soil conditions particularly in spring and more even application of slurry across the spread width. The odours released during and after application are also usually reduced with a trailing shoe or band spreader compared with splash plate.

Investment by an individual farmer in a trailing shoe or band spreader may be cost prohibitive as the savings in N fertiliser may not cover the extra costs associated with farmer-owned equipment.

This will depend on the volume of slurry on farm and the value placed on potential other benefits, such as flexibility of timing into taller grass covers, reduced odours and more even nutrient application.

However, where a farmer is already using a contractor for applying slurry by splashplate, using a contractor with a band spreader or trailing shoe may be cost effective.

The contractor price is usually higher per hour, but the value of slurry is increased by approximately €3 per 1,000 gallons (cattle / pig slurry) by these methods, so depending on the volume spread per hour, a higher cost per hour of the contractor can be justified for using the modern techniques.

Authors: Mark Plunkett and William Burchill from Teagasc, Johnstown Castle, Wexford, and Gerard McCutcheon from Teagasc, Oak Park, Carlow.

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: