Since selling his dairy farm and purchasing the cows.ie farm in 1998,David Clarke has invested heavily in farm infrastructure, particularly in the last seven to eight years as the business continues to grow. Cows.ie supplies livestock to customers in Ireland, Europe and other countries.

The farmyard, located outside the village of Loughnavalley, Mullingar, Co Westmeath, holds an impressive array of cubicle sheds, silage stores and calving and calf areas.

The cows.ie model is based on sourcing of livestock (mainly dairy) for farmers in Ireland, the UK and throughout Europe.

Most livestock travel directly from the farm they are sourced at to the purchasing farmer’s yard. However, a portion of stock remain on the Clarke farm where they may be calved down or milked, so the farm has a 16-unit herringbone parlour and a network of paddocks for what David describes as a “transient” herd.

There is a 1:10 slope on the ramps exiting and entering, with the banks sloped at a ratio of 1:1 to prevent slippage.

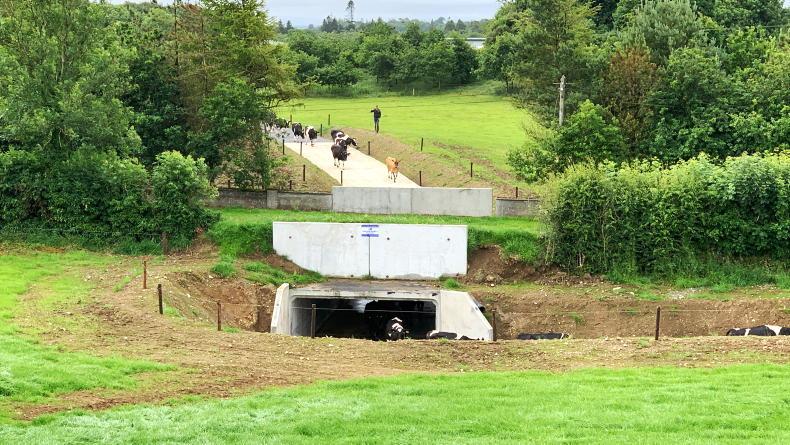

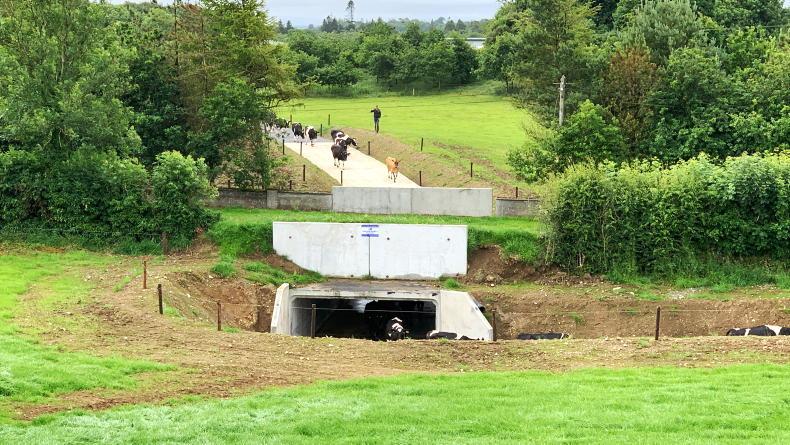

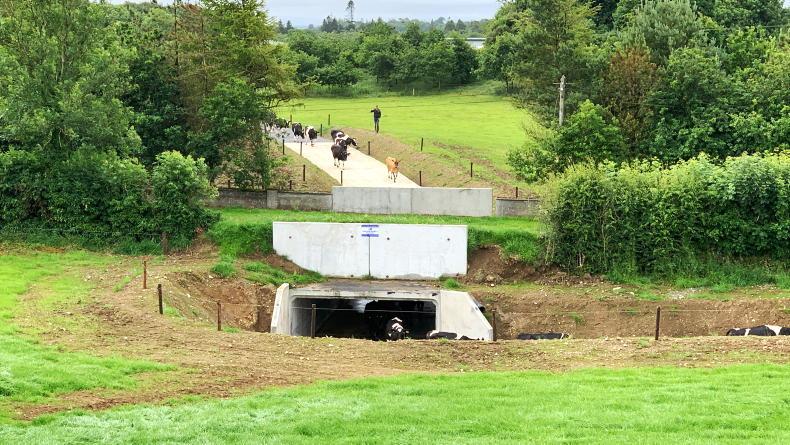

In recent years, as the number of milking cows awaiting sale has increased on the farm, the Clarkes have been availing of grazing some of their land that resides on the Hill of Uisneach, across the R390 road going from the village of Loughnavalley to Killare.

Although it is a regional road, there is a high volume of traffic, with cows having to travel down a stretch of the road before turning off. Cows had to be held in the yard after milking with additional help needed to safely get cows across.

Cathal Clarke (David’s son), Rachel Miller (dairy assistant) and Ciaran Dowdall (farm manager).

The decision was therefore made to invest in an underpass to link the two blocks of land together.

Work on the site began in early April. The farm received permission to close the stretch of road between 11 and 22 April, but due to the project progressing well, the road was back open by 15 April.

The precast culverts were supplied by Drumderry Precast and lowered in to place by crane.

Hexagonal grips were installed using a roller at time of pouring to improve grip to cows entering and exiting the underpass.

A total of eight culverts were used, with each one 2m in length giving an overall underpass length of 16m.

The culverts are 2.1m in height and 5m in width, with the farm Land Cruiser and RTV both able to pass through the culverts. The wall thickness of the culverts is 300mm. There are precast parapet walls either side of the road as well as precast wing walls funnelling cows into the underpass each side.

The road on the yard side is concreted, with a hexagonal grip finish to prevent slips or falls as cows enter the underpass.

The underpass runs underneath the busy R390 road between Loughnavalley and Killare.

While cows enter the underpass directly from the yard side, the exit ramp is at a right angle on the opposite side of the road.

David Clarke reported that there was no issue with cows transitioning to using the underpass.

David explained that due to the historical value of the Hill of Uisneach, they did not wish to cut into the hill unnecessarily, so opted to have cows turn away from the hill when entering/exiting the underpass.

A precast 3,000-gallon tank collects all dirty water from both ramps. Drumderry Precast was responsible for the supply and fit of the precast panels and associated works.

The sides of the ground leading into and out of the underpass are sloped at a rate of 1:1 to prevent any slippage of soil, with grasses and wildflowers sown to increase biodiversity.

There is a 1:10 slope on the ramps exiting and entering, with the banks sloped at a ratio of 1:1 to prevent slippage.

David mentioned that a number of ecologists pointed out the benefits of the underpass to wildlife, particularly hedgehogs, who can now use the underpass to cross the road.

The concreted ramps for the cows have a fall of 1:10, and combined with the hexagonal grip, cows will be able to safely exit and enter the underpass.

David plans to keep these concreted ramps clean using a hydraulic tractor sweeper. Oliver Dowdall Construction & Plant Hire was the contractor used for installing the ramps and roadways.

The total cost of the project is shown in the table.

The underpass poses a significant investment to the farm, but David and his team are delighted with the results. It has allowed them to avail more of the land across the road without posing a risk to staff, livestock or other road users.

The farm had zero-grazed in the past but this to had its associated costs. David and his team were very appreciative of the local and wider community for their understanding during the road closures.

As well as the benefit of being able to let cows out as they are being milked, David also now plans to install timed latches on paddocks so that cows can be waiting in the yard come milking time to save time for him and his busy team.

The underpass is an investment in the health and safety of livestock, David’s team and that of road users.It will allow for better grass utilisation by being able to graze across the road more frequently.A saving on labour and time for fetching or letting out cows.

Since selling his dairy farm and purchasing the cows.ie farm in 1998,David Clarke has invested heavily in farm infrastructure, particularly in the last seven to eight years as the business continues to grow. Cows.ie supplies livestock to customers in Ireland, Europe and other countries.

The farmyard, located outside the village of Loughnavalley, Mullingar, Co Westmeath, holds an impressive array of cubicle sheds, silage stores and calving and calf areas.

The cows.ie model is based on sourcing of livestock (mainly dairy) for farmers in Ireland, the UK and throughout Europe.

Most livestock travel directly from the farm they are sourced at to the purchasing farmer’s yard. However, a portion of stock remain on the Clarke farm where they may be calved down or milked, so the farm has a 16-unit herringbone parlour and a network of paddocks for what David describes as a “transient” herd.

There is a 1:10 slope on the ramps exiting and entering, with the banks sloped at a ratio of 1:1 to prevent slippage.

In recent years, as the number of milking cows awaiting sale has increased on the farm, the Clarkes have been availing of grazing some of their land that resides on the Hill of Uisneach, across the R390 road going from the village of Loughnavalley to Killare.

Although it is a regional road, there is a high volume of traffic, with cows having to travel down a stretch of the road before turning off. Cows had to be held in the yard after milking with additional help needed to safely get cows across.

Cathal Clarke (David’s son), Rachel Miller (dairy assistant) and Ciaran Dowdall (farm manager).

The decision was therefore made to invest in an underpass to link the two blocks of land together.

Work on the site began in early April. The farm received permission to close the stretch of road between 11 and 22 April, but due to the project progressing well, the road was back open by 15 April.

The precast culverts were supplied by Drumderry Precast and lowered in to place by crane.

Hexagonal grips were installed using a roller at time of pouring to improve grip to cows entering and exiting the underpass.

A total of eight culverts were used, with each one 2m in length giving an overall underpass length of 16m.

The culverts are 2.1m in height and 5m in width, with the farm Land Cruiser and RTV both able to pass through the culverts. The wall thickness of the culverts is 300mm. There are precast parapet walls either side of the road as well as precast wing walls funnelling cows into the underpass each side.

The road on the yard side is concreted, with a hexagonal grip finish to prevent slips or falls as cows enter the underpass.

The underpass runs underneath the busy R390 road between Loughnavalley and Killare.

While cows enter the underpass directly from the yard side, the exit ramp is at a right angle on the opposite side of the road.

David Clarke reported that there was no issue with cows transitioning to using the underpass.

David explained that due to the historical value of the Hill of Uisneach, they did not wish to cut into the hill unnecessarily, so opted to have cows turn away from the hill when entering/exiting the underpass.

A precast 3,000-gallon tank collects all dirty water from both ramps. Drumderry Precast was responsible for the supply and fit of the precast panels and associated works.

The sides of the ground leading into and out of the underpass are sloped at a rate of 1:1 to prevent any slippage of soil, with grasses and wildflowers sown to increase biodiversity.

There is a 1:10 slope on the ramps exiting and entering, with the banks sloped at a ratio of 1:1 to prevent slippage.

David mentioned that a number of ecologists pointed out the benefits of the underpass to wildlife, particularly hedgehogs, who can now use the underpass to cross the road.

The concreted ramps for the cows have a fall of 1:10, and combined with the hexagonal grip, cows will be able to safely exit and enter the underpass.

David plans to keep these concreted ramps clean using a hydraulic tractor sweeper. Oliver Dowdall Construction & Plant Hire was the contractor used for installing the ramps and roadways.

The total cost of the project is shown in the table.

The underpass poses a significant investment to the farm, but David and his team are delighted with the results. It has allowed them to avail more of the land across the road without posing a risk to staff, livestock or other road users.

The farm had zero-grazed in the past but this to had its associated costs. David and his team were very appreciative of the local and wider community for their understanding during the road closures.

As well as the benefit of being able to let cows out as they are being milked, David also now plans to install timed latches on paddocks so that cows can be waiting in the yard come milking time to save time for him and his busy team.

The underpass is an investment in the health and safety of livestock, David’s team and that of road users.It will allow for better grass utilisation by being able to graze across the road more frequently.A saving on labour and time for fetching or letting out cows.

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: