Michael and Conor Murphyfarm 121.4ha (300 acres) in partnership just outside Kilmanagh, Co Kilkenny.

They own 36.4ha (90 acres) and rent the remaining 85ha (210 acres). The land area is all under grass, except for 18 acres which they use to grow maize to feed the winter-milking cows, with cows milked year-round.

After Conor finished a level six advanced dairy course in Piltown in Kildalton, he decided that he wanted to stay at home farming. Michael and Conor decided that the best option was to go into partnership.

They both work full-time on the farm and Conor does some silage work with a local contractor during the summer.

However, this summer Conor is taking a few months off to work and play hurling in San Francisco.

“My two daughters, Caoimhe, who just finished first year in agricultural science in UCD, and Aoibhe, always help out on the farm, so I won’t be alone during the summer,” says Michael.

They have 70 spring-calving cows and milk roughly 60 cows through the winter. The herd is predominantly Holstein.

Suitable female progeny are used as herd replacements, with the remainder carried through to slaughter. Male progeny are killed as bulls at 17 months of age, with heifers killed at 20 months.

New cubicle shed

I visited the farm recently to view a new cubicle shed that they finished in January 2017. The Murphys decided to build the shed to have somewhere to house all of the milkers in one place at one time.

Before this, the milking cows were split up into a couple of smaller cubicle sheds that were just getting too awkward to work with.

The shed has the capacity to hold 129 cows – 100 cows can feed comfortably at any one time.

There are 11 feeding barriers in total on two sides of the shed, perpendicular to each other. Michael felt by doing this it would keep the shed and yard more compact.

The cubicles, which are a standard-size cubicle with Easy Fix Cow Comfort mats and a brisket board to stop the cows from lying too far forward in the cubicle. The cubicles are bedded with sawdust.

The cubicles, which are a standard-size cubicle with Easy Fix Cow Comfort mats and a brisket board to stop the cows from lying too far forward in the cubicle. The cubicles are bedded with sawdust.

“The brisket boards really keep the cubicles clean, they’re a great job,” says Michael.

The cubicle area is split into three by 8ft passageways with a Dairymaster scrapper in each aisle.

Michael says they decided to go with Corbett concrete dairy grip slats from Cahir, Co Tipperary, instead of covering the slats with rubber.

Their argument for this decision was that when the rubber mats wear and when they get wet, they can be just as slippy as the concrete.

The dairy grip slats worked out about €25 dearer per slat. After having to put down a bull that was fit for slaughter because it slipped on slats and broke its leg, Michael felt they were worth the cost.

There are two tractor slats at the corner of the shed where the tractor and diet feeder have to drive over to feed.

These were slightly more expensive.

Another additional cost was the pre-cast cubicles that came out over the slatted tank. The tank in the shed is 116ft x 28ft x 8ft and has a 170,000-gallon capacity. The tank has four agitation points, two at either end.

Full troughs with no stub wall under the barrier worked out cheaper than a half-U trough and a separate stub wall.

Even with the barriers and troughs, Michael found that the cows were still flicking the beet out over the side, so he got a local man to make some lightweight removable covers to stop this. The concrete feeding troughs were sourced from Murphy’s Concrete, Enniscorthy, Co Wexford.

To combat the need to move cows between sheds for handling, a crush was installed at the back so that all work could be performed in the shed.

All the gates and barriers in the crush and shed were attached with bolts and pins rather than welded, so if anything ever goes wrong or an animal goes down they can be taken out easily. The two gates at either side of the slats were made adjustable between 14ft and 16ft so that they could be used in two different areas.

All the gates and barriers in the crush and shed were attached with bolts and pins rather than welded, so if anything ever goes wrong or an animal goes down they can be taken out easily. The two gates at either side of the slats were made adjustable between 14ft and 16ft so that they could be used in two different areas.

The shed structure was supplied and erected by O’Dwyer Steel. All steelwork is galvanised. The roof is fibre cement sheets and this was selected to prevent drip.

The Jordain gates and feed barriers were built for purpose and imported from France. One of the more distinctive features of the shed is the quick-release guillotine gates.

To open the gate, you simply release the pin and the gate is drawn up on a weighted pulley system.

Handy if the pen is full with cows as you don’t have to swing the gate around through the cows. It also means there are no swinging gates or doors in the shed, which is an added safety bonus.

The drinking troughs, supplied by Teemore Engineering, were equipped with fast-empty valves, so they are easily emptied when they get soiled.

There are also three sliding doors installed for extra shelter at the sides and back of the shed. The levels and ground work was done by Podge Dearmody.

Michael and Conor built the shed through the Young Farmer Capital Investment Scheme and because they are in a registered farm partnership they will be able to double the investment ceiling of €80,000 (excluding VAT) to a new ceiling of €160,000. The new grant rate in this scenario will be 50% of the average (maximum grant of €80,000).They are also able to claim the VAT back.

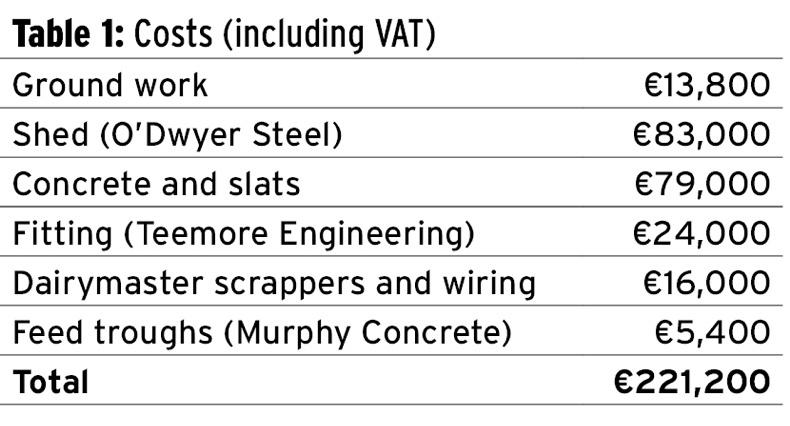

All of the features and dimensions were to Department standards. They are currently waiting for their application for payment to be approved. The costs of the shed are detailed in Table 1.