Cattle slurry is a valuable resource on livestock farms. When used effectively, it can supply significant amounts of nutrients for grass production, and help offset fertiliser costs.

Slurries and manures can vary in quality and nutrient content, particularly due to different dilution rates with water. The typical NPK fertiliser value of a range of organic fertilisers is shown in Table 1.

Where to spread?

Most of the fertiliser value of manures and slurries is in the P and K content. Therefore, the most important thing to decide is what fields on the farm have the highest P and K requirements, and put the slurry on those fields. These are the fields that will have the highest fertiliser P and K costs, so try to save some of the cost by using slurry.

The P and K requirements will be based on soil tests and crop requirements. Target fields for slurry that are low in P and K. Silage fields will have higher requirements than grazed fields, especially for K.

How much to spread?

Although a number of fields might have a requirement for some slurry, the levels of requirement may vary. The advice is to carry out soil analysis and base slurry application rates on the soil nutrient status and nutrient management plan for the farm. In practice this bit is easy to get accurate results, getting the tanker to perform to this level of accuracy could be another story.

Slurry tanker calibration

The application rate of slurry is determined by the slurry discharge rate, the forward speed of the tractor and the spreading width. In order to apply the target application rate (TAR), you must determine the discharge rate and calculate the forward speed. The discharge rate is usually in the order of 1.5-2.5m3/minute. To determine your actual discharge rate you can measure the time required to empty the tank and apply it to the following formula.

Step one

Measuring the discharge is a relatively simple process. The tanker must be completely full of slurry. What affects the discharge rate of slurry is the dry matter content. Wet slurry will naturally flow faster out of the tank.

Drive in to the field and set up as normal for spreading.Have a stopwatch ready to start timing when the tanker is actually spreading slurry.Do not time headland turns when the slurry discharge is turned off.What is needed is how many minutes it has taken to empty the slurry tank while in work.Step two

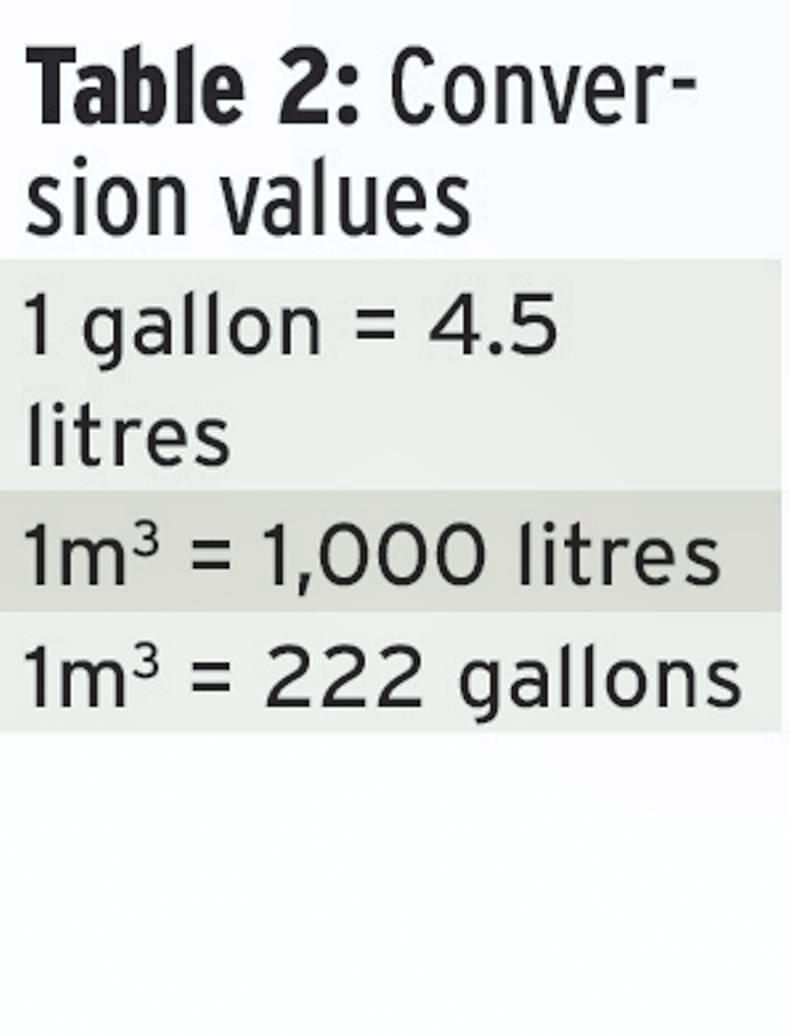

Calculating the slurry tanker’s capacity in cubic meters is the next task. Approximately 1,000 litres of slurry is equal to one cubic meter. For a 2,500-gallon tanker that works out at 11,250 litres and 11.25m³ capacity for the tanker.

Step three

After working out the time to unload the slurry tanker, and the capacity of the tanker in cubic meters the following formula can be used to calculate the discharge rate:

Discharge Rate (m³/minute) = tanker size (m³) / time to empty (mins)

Example: Tanker size 11.25m³/ 5.6 minutes = Discharge rate of 2m³ per minute.

Step four

The bout width of the spreader must then be measured, if using a splash plate. Trailing shoe and dribble bars will have a set working width. When measuring the bout width, simply measure the slurry coverage on the grass in metres for one run.

Step five

The bout width of the spreader must then be measured and applied with the discharge rate and TAR into the following formula to determine forward speed:

Forward Speed (kph) = 600 x discharge rate (cubic m/min)

_________________________________

TAR (m³/ha) x Bout Width (m).

A farmer wants a target application rate of 22m³/ha or 2,000 gallons per acre after first-cut silage.

A farmer wants a target application rate of 22m³/ha or 2,000 gallons per acre after first-cut silage.

Assuming the discharge rate = 2m3/min, and a bout width of 10m. The forward speed that the tractor must travel at to achieve this can be calculated using the above formula:

600 (constant) x 2 (discharge rate m³) = 1,200.

The next part to work out is the following:

22 (TAR m³/ha) x 10 (bout width m) = 220.

Divide 1,200 by 220, and the result is the forward speed of 5.4km/h.

The farmers can assume with that type of slurry travelling at 5.4 km/hr forward speed.

The target application rate (TAR) of 22m³/ha or 2,000 gallons per acre will be achieved.

Even coverage will also depend on the condition of the splash plate and avoidance of over and under lapping in operation.

Read more

Focus: slurry management 2016

Cattle slurry is a valuable resource on livestock farms. When used effectively, it can supply significant amounts of nutrients for grass production, and help offset fertiliser costs.

Slurries and manures can vary in quality and nutrient content, particularly due to different dilution rates with water. The typical NPK fertiliser value of a range of organic fertilisers is shown in Table 1.

Where to spread?

Most of the fertiliser value of manures and slurries is in the P and K content. Therefore, the most important thing to decide is what fields on the farm have the highest P and K requirements, and put the slurry on those fields. These are the fields that will have the highest fertiliser P and K costs, so try to save some of the cost by using slurry.

The P and K requirements will be based on soil tests and crop requirements. Target fields for slurry that are low in P and K. Silage fields will have higher requirements than grazed fields, especially for K.

How much to spread?

Although a number of fields might have a requirement for some slurry, the levels of requirement may vary. The advice is to carry out soil analysis and base slurry application rates on the soil nutrient status and nutrient management plan for the farm. In practice this bit is easy to get accurate results, getting the tanker to perform to this level of accuracy could be another story.

Slurry tanker calibration

The application rate of slurry is determined by the slurry discharge rate, the forward speed of the tractor and the spreading width. In order to apply the target application rate (TAR), you must determine the discharge rate and calculate the forward speed. The discharge rate is usually in the order of 1.5-2.5m3/minute. To determine your actual discharge rate you can measure the time required to empty the tank and apply it to the following formula.

Step one

Measuring the discharge is a relatively simple process. The tanker must be completely full of slurry. What affects the discharge rate of slurry is the dry matter content. Wet slurry will naturally flow faster out of the tank.

Drive in to the field and set up as normal for spreading.Have a stopwatch ready to start timing when the tanker is actually spreading slurry.Do not time headland turns when the slurry discharge is turned off.What is needed is how many minutes it has taken to empty the slurry tank while in work.Step two

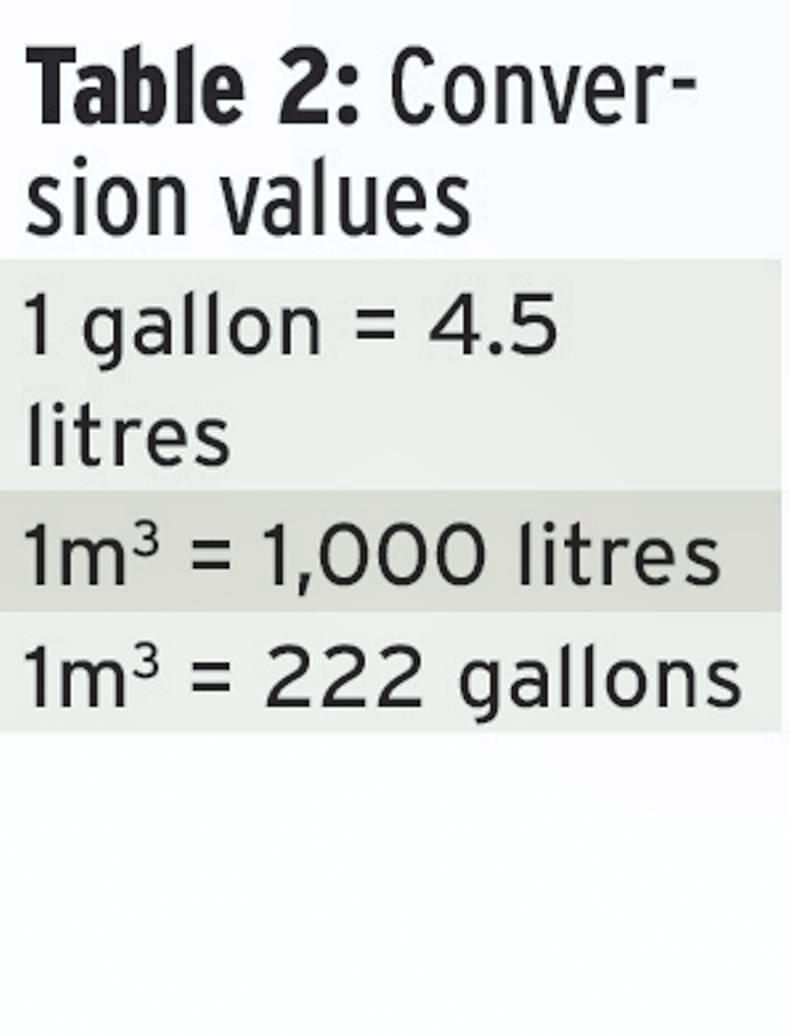

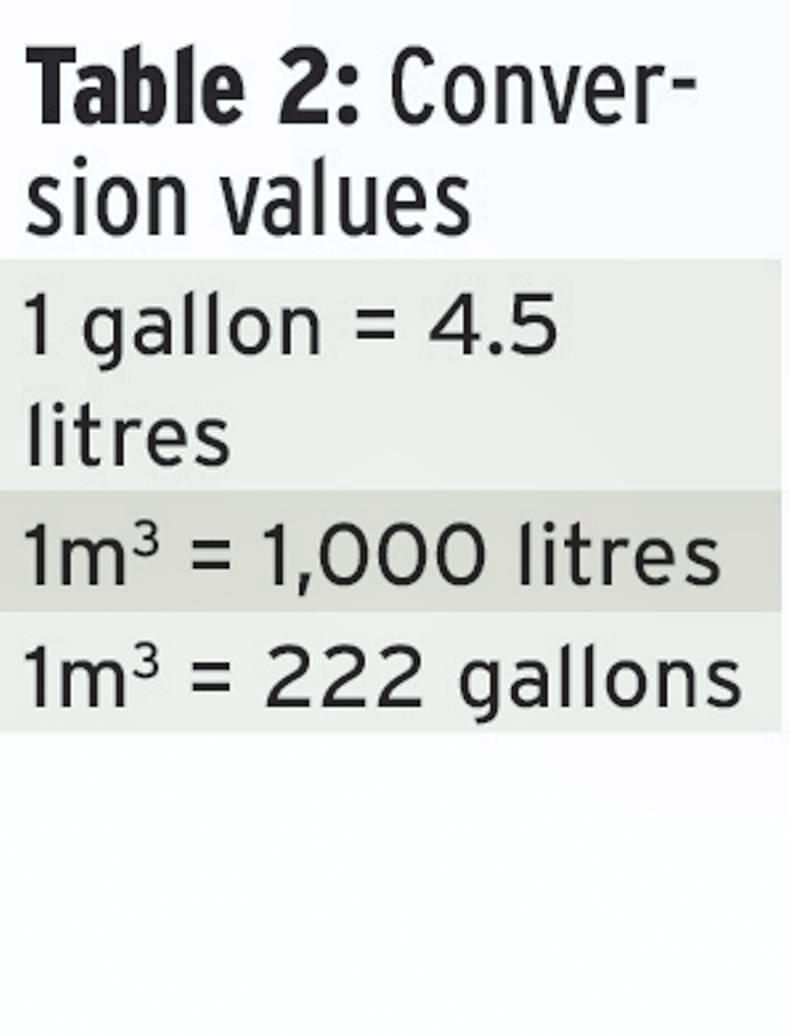

Calculating the slurry tanker’s capacity in cubic meters is the next task. Approximately 1,000 litres of slurry is equal to one cubic meter. For a 2,500-gallon tanker that works out at 11,250 litres and 11.25m³ capacity for the tanker.

Step three

After working out the time to unload the slurry tanker, and the capacity of the tanker in cubic meters the following formula can be used to calculate the discharge rate:

Discharge Rate (m³/minute) = tanker size (m³) / time to empty (mins)

Example: Tanker size 11.25m³/ 5.6 minutes = Discharge rate of 2m³ per minute.

Step four

The bout width of the spreader must then be measured, if using a splash plate. Trailing shoe and dribble bars will have a set working width. When measuring the bout width, simply measure the slurry coverage on the grass in metres for one run.

Step five

The bout width of the spreader must then be measured and applied with the discharge rate and TAR into the following formula to determine forward speed:

Forward Speed (kph) = 600 x discharge rate (cubic m/min)

_________________________________

TAR (m³/ha) x Bout Width (m).

A farmer wants a target application rate of 22m³/ha or 2,000 gallons per acre after first-cut silage.

A farmer wants a target application rate of 22m³/ha or 2,000 gallons per acre after first-cut silage.

Assuming the discharge rate = 2m3/min, and a bout width of 10m. The forward speed that the tractor must travel at to achieve this can be calculated using the above formula:

600 (constant) x 2 (discharge rate m³) = 1,200.

The next part to work out is the following:

22 (TAR m³/ha) x 10 (bout width m) = 220.

Divide 1,200 by 220, and the result is the forward speed of 5.4km/h.

The farmers can assume with that type of slurry travelling at 5.4 km/hr forward speed.

The target application rate (TAR) of 22m³/ha or 2,000 gallons per acre will be achieved.

Even coverage will also depend on the condition of the splash plate and avoidance of over and under lapping in operation.

Read more

Focus: slurry management 2016

A farmer wants a target application rate of 22m³/ha or 2,000 gallons per acre after first-cut silage.

A farmer wants a target application rate of 22m³/ha or 2,000 gallons per acre after first-cut silage.

SHARING OPTIONS