The defining point in the completion of many new farm buildings is often how animals settle into their new environment and the ease in which animals can be handled and cared for. David and Nicola Whelehan have recently completed an impressive new suckler unit in Lemongrove, Gaybrook, Co Westmeath.

A lot of thought and planning went into designing the unit, with David keen to construct a shed that would focus on ease of use, as the suckler farm is operated on a part-time basis. Health and safety was also high on the agenda, as was providing an environment that underpins optimum animal performance.

Photo 1

The Whelehans also wanted the shed to blend into the site selected and not be overly intrusive. As detailed in photo 1, the design for the four-bay slatted shed with creep area is an A-framed structure open on the most sheltered side. The height at the eaves is approximately 4m, while the height at the apex is in the region of 5.8m. The green cladding works great in blending the shed with its surrounds.

The tank was constructed with an internal width of 4.1m and a slat width of 4.67m (14’6”). It is also a foot deeper than normal at 2.85m (9’).

The wider and deeper tank provides surplus storage capacity and reduces the pressure to apply slurry in early spring, while also accommodating additional slurry produced by autumn-born calves.

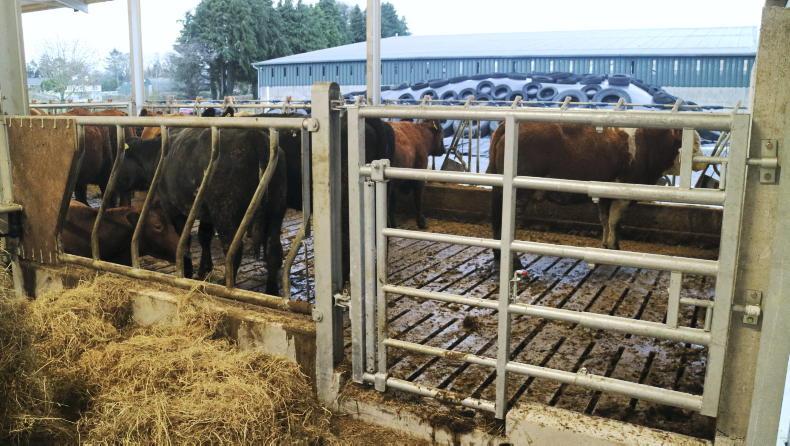

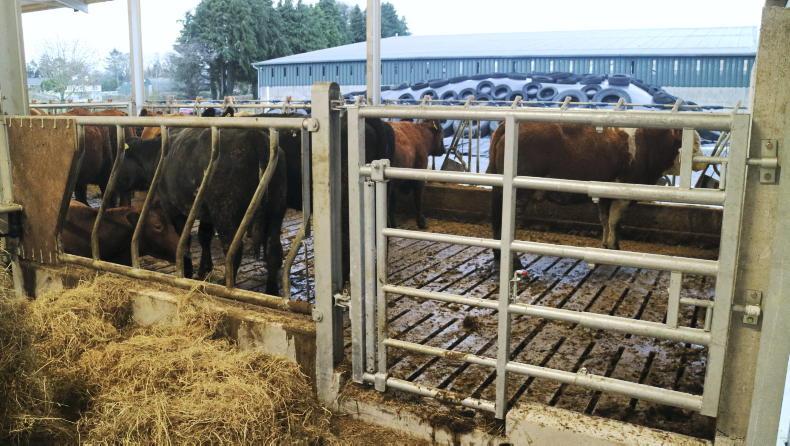

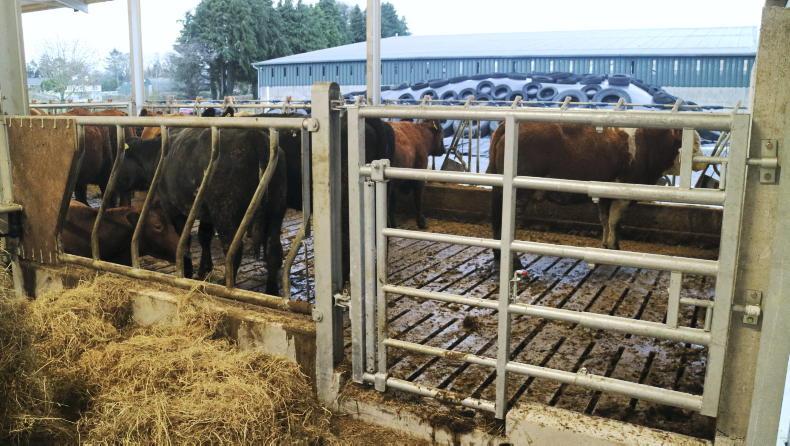

Photo 2

Photo 2

The shed differs from conventional suckler sheds with a creep area, in that the width of the creep is broader than normal at 7.3m (24’). David explains that there were a number of reasons for selecting this width. The farm has a split calving spread and is transitioning to a higher percentage of cows calving in late summer. Therefore, the focus is on providing calves with ample room in the creep area and avoiding calves being stocked tightly come springtime.

David says there were differing views given by farmers when exploring the merits of including a crush in the creep area, with most views cautioning against restricting available space. The fact that the creep is wider than normal does not hinder the creep area, with ample space available.

A crush runs the length of the two middle bays, with a head gate extending out into one bay at the end of the shed at an angle. The positioning of the crush allows the shed to be used as a large animal handling unit, with animal movement flowing in a clockwise manner.

Photo 3

Photo 3

The reasoning for extending the head unit out at an angle was to provide an opportunity to work at both sides of an animal. The head gate itself is the Condon Warrior head gate, which allows the gate to be manually closed from the rear of the animal. A head scoop was also fitted with health and safety in mind, as well as being in a position to easily restrain suckler cows.

A walkway was also constructed along the crush section and this gives the operator more power in handling animals from a height. Condon Engineering provided all penning for the shed, including the head-locking feed barriers.

All gates provided are hinged at both sides and can be quickly dismantled and erected. David says this is already proving useful to quickly alter the layout of the shed.

Photo 4

Photo 4

The shed is currently set-up to have the gate removed between the middle two pens of the creep area, with calves mixing from the slatted pens at the front.

Allowing the calves to become accustomed to mixing provides an opportunity to let calves out by day to adjoining fields.

This will be particularly beneficial in autumn to help break the cow-calf bond and promote faster resumption to cyclic activity and also in spring to get calves to grass quicker. The head-locking barriers work excellently in regard to easily split cows and calves.

There is also a gate removed between the two slatted pens on the front right when looking at photo 4.

This allows two pens of cows to be run together with the farm’s stock bull and cuts down on the need to move the bull between pens.

In a scenario where a bull is not being run with cows, having a larger number of cows mixing promotes greater activity when cows are in heat.

Photo 5

Photo 5

The two pens at either end of the slatted area also have a part feeding barrier (along with a creep area) between the slatted area and the creep area, and this provides additional feed space for cows.

The fact that a higher number of calves can be accommodated in the two centre creep pens affords David the opportunity to leave the end creep areas out of use for feeding, if required. It also allows hay or straw to be offered to in-calf heifers or cows at this area.

The creep gates work by means of the gate section expanding or contracting easily, with the potential to set the opening at various widths.

There are a number of other well-designed features in the shed that stand out.

There is additional lighting in the creep area along by the crush, which provides the potential to work with animals at any time. This is important when the farm is operated part-time.

There are extra spotlights at the front of the shed, which also provide additional lighting along the feed barrier for feeding in darkness.

There are additional safety sockets at the entry point to the creep area and at the crush to allow equipment to be used easily, without requiring the use of leads.

The sliding door on the left of the shed has a small in-built door, which allows easy access to the creep area without having to open sliding doors.

A short stub wall between the creep area and slatted shed prevents straw from entering the slatted area and allows quicker cleaning with a front loader, while high-resolution calving cameras, provided by Easy Cam and linked to David’s mobile phone, allow regular monitoring of animals.

The suckler unit cost €77,000 plus VAT to construct, or €89,000 including VAT. David was eligible for 60% grant aid as a young trained farmer, meaning the shed had a net cost of €30,800. David commended the availability of TAMS funding provided by the Department of Agriculture:

“There is no way the farm could justify such an investment without TAMS funding. At the same time, investments like this are essential to allow farms to be operated on a part-time basis. The shed has only been in use a few weeks, but I can already see the major benefits it will bring in terms of allowing a better work-life balance, which is vital with a young family.”

From his experience, David highlights a number of useful tips that may benefit other farmers. There is a relatively tight time frame to complete work and the advice is to organise and plan service providers well in advance of when they will be required.

Experience in submitting the initial TAMS application for grant aid and the submission for payment is also critical to get right for swift payment, and this was completed by Carton Rural Consultants.

An investment such as this can also put huge pressure on cashflow, so it is important to have a good plan in place to allow the farm to continue to make normal investments. When approaching financial institutions for bridging loans, it is important to do this well in advance of when funding is required.

The final tip is to take advantage of the years of experience those working on sheds can bring: “We could not be happier with the quality of work completed and the experience of everyone who worked on the shed added to its finish. Dowdall Groundworks and Plant Hire got the tank and groundworks completed quickly, which put the shed on the front foot.

“We tried to utilise local providers where possible and got the slats from William Maxwell Pre-Cast Ltd and concrete from BD Floods Concrete. The workmanship in the shed structure erected by Tommy Dillon is second to none, while lighting installed by Liam Lynam Electrical provides a safe environment to work late at night, with safety also to the fore in sliding doors manufactured by Daniel Coffey. The Condon Engineering penning allows the shed layout to be quickly altered and the Easy Cam cameras fit in perfectly with working off the farm.”

The defining point in the completion of many new farm buildings is often how animals settle into their new environment and the ease in which animals can be handled and cared for. David and Nicola Whelehan have recently completed an impressive new suckler unit in Lemongrove, Gaybrook, Co Westmeath.

A lot of thought and planning went into designing the unit, with David keen to construct a shed that would focus on ease of use, as the suckler farm is operated on a part-time basis. Health and safety was also high on the agenda, as was providing an environment that underpins optimum animal performance.

Photo 1

The Whelehans also wanted the shed to blend into the site selected and not be overly intrusive. As detailed in photo 1, the design for the four-bay slatted shed with creep area is an A-framed structure open on the most sheltered side. The height at the eaves is approximately 4m, while the height at the apex is in the region of 5.8m. The green cladding works great in blending the shed with its surrounds.

The tank was constructed with an internal width of 4.1m and a slat width of 4.67m (14’6”). It is also a foot deeper than normal at 2.85m (9’).

The wider and deeper tank provides surplus storage capacity and reduces the pressure to apply slurry in early spring, while also accommodating additional slurry produced by autumn-born calves.

Photo 2

Photo 2

The shed differs from conventional suckler sheds with a creep area, in that the width of the creep is broader than normal at 7.3m (24’). David explains that there were a number of reasons for selecting this width. The farm has a split calving spread and is transitioning to a higher percentage of cows calving in late summer. Therefore, the focus is on providing calves with ample room in the creep area and avoiding calves being stocked tightly come springtime.

David says there were differing views given by farmers when exploring the merits of including a crush in the creep area, with most views cautioning against restricting available space. The fact that the creep is wider than normal does not hinder the creep area, with ample space available.

A crush runs the length of the two middle bays, with a head gate extending out into one bay at the end of the shed at an angle. The positioning of the crush allows the shed to be used as a large animal handling unit, with animal movement flowing in a clockwise manner.

Photo 3

Photo 3

The reasoning for extending the head unit out at an angle was to provide an opportunity to work at both sides of an animal. The head gate itself is the Condon Warrior head gate, which allows the gate to be manually closed from the rear of the animal. A head scoop was also fitted with health and safety in mind, as well as being in a position to easily restrain suckler cows.

A walkway was also constructed along the crush section and this gives the operator more power in handling animals from a height. Condon Engineering provided all penning for the shed, including the head-locking feed barriers.

All gates provided are hinged at both sides and can be quickly dismantled and erected. David says this is already proving useful to quickly alter the layout of the shed.

Photo 4

Photo 4

The shed is currently set-up to have the gate removed between the middle two pens of the creep area, with calves mixing from the slatted pens at the front.

Allowing the calves to become accustomed to mixing provides an opportunity to let calves out by day to adjoining fields.

This will be particularly beneficial in autumn to help break the cow-calf bond and promote faster resumption to cyclic activity and also in spring to get calves to grass quicker. The head-locking barriers work excellently in regard to easily split cows and calves.

There is also a gate removed between the two slatted pens on the front right when looking at photo 4.

This allows two pens of cows to be run together with the farm’s stock bull and cuts down on the need to move the bull between pens.

In a scenario where a bull is not being run with cows, having a larger number of cows mixing promotes greater activity when cows are in heat.

Photo 5

Photo 5

The two pens at either end of the slatted area also have a part feeding barrier (along with a creep area) between the slatted area and the creep area, and this provides additional feed space for cows.

The fact that a higher number of calves can be accommodated in the two centre creep pens affords David the opportunity to leave the end creep areas out of use for feeding, if required. It also allows hay or straw to be offered to in-calf heifers or cows at this area.

The creep gates work by means of the gate section expanding or contracting easily, with the potential to set the opening at various widths.

There are a number of other well-designed features in the shed that stand out.

There is additional lighting in the creep area along by the crush, which provides the potential to work with animals at any time. This is important when the farm is operated part-time.

There are extra spotlights at the front of the shed, which also provide additional lighting along the feed barrier for feeding in darkness.

There are additional safety sockets at the entry point to the creep area and at the crush to allow equipment to be used easily, without requiring the use of leads.

The sliding door on the left of the shed has a small in-built door, which allows easy access to the creep area without having to open sliding doors.

A short stub wall between the creep area and slatted shed prevents straw from entering the slatted area and allows quicker cleaning with a front loader, while high-resolution calving cameras, provided by Easy Cam and linked to David’s mobile phone, allow regular monitoring of animals.

The suckler unit cost €77,000 plus VAT to construct, or €89,000 including VAT. David was eligible for 60% grant aid as a young trained farmer, meaning the shed had a net cost of €30,800. David commended the availability of TAMS funding provided by the Department of Agriculture:

“There is no way the farm could justify such an investment without TAMS funding. At the same time, investments like this are essential to allow farms to be operated on a part-time basis. The shed has only been in use a few weeks, but I can already see the major benefits it will bring in terms of allowing a better work-life balance, which is vital with a young family.”

From his experience, David highlights a number of useful tips that may benefit other farmers. There is a relatively tight time frame to complete work and the advice is to organise and plan service providers well in advance of when they will be required.

Experience in submitting the initial TAMS application for grant aid and the submission for payment is also critical to get right for swift payment, and this was completed by Carton Rural Consultants.

An investment such as this can also put huge pressure on cashflow, so it is important to have a good plan in place to allow the farm to continue to make normal investments. When approaching financial institutions for bridging loans, it is important to do this well in advance of when funding is required.

The final tip is to take advantage of the years of experience those working on sheds can bring: “We could not be happier with the quality of work completed and the experience of everyone who worked on the shed added to its finish. Dowdall Groundworks and Plant Hire got the tank and groundworks completed quickly, which put the shed on the front foot.

“We tried to utilise local providers where possible and got the slats from William Maxwell Pre-Cast Ltd and concrete from BD Floods Concrete. The workmanship in the shed structure erected by Tommy Dillon is second to none, while lighting installed by Liam Lynam Electrical provides a safe environment to work late at night, with safety also to the fore in sliding doors manufactured by Daniel Coffey. The Condon Engineering penning allows the shed layout to be quickly altered and the Easy Cam cameras fit in perfectly with working off the farm.”

SHARING OPTIONS