Given the time, cost and level of complexity around the discussion, I hear some agri trading bosses are threatening to delist protected urea.

Teagasc recently sent letters to milk companies discounting any potential residues in milk around the use of protected urea.

This is just the latest in a list of the issues that seems to be causing a ripple of discomfort to farmers using protected urea. However, we all know widespread advice to change always brings more questions than answers.

What is protected urea?

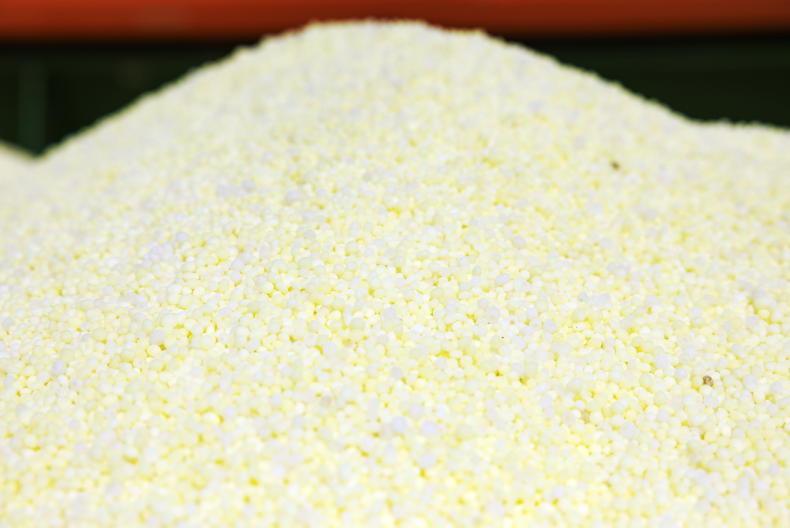

Protected urea is urea, as we know it, with a urease inhibitor chemical coating or incorporation to help reduce ammonia loss to the atmosphere.

There are a number of different commercial products that are used to make the coating. The majority of protected urea products on offer use the NBPT coating (Table 1).

Teagasc and the Department of Agriculture’s climate change division suggest the roadmap for farmers is that we need to replace 100% of the urea (46% N) sold in Ireland with protected urea. Remember urea as a product makes up only 10% of the nitrogen sold in Ireland. In addition, the plan is to replace 50% of the CAN (27% N) with protected urea to meet targets set by the Teagasc MACC curve on reducing national emissions.

Sales of protected urea have been rising steadily for the last three years. Along the way, there have been speed bumps with some questioning residue levels in product (meat or milk) with long-term continued usage.

The letter from Teagasc to processors this week goes some of the way to alleviating residue concerns

More question the impact on soil biology. Others question while the NBPT might not have a residue the reagents that bind the NBPT might have negative long-term implications.

The letter from Teagasc to processors this week goes some of the way to alleviating residue concerns.

Leaving aside the chemistry, there have been practical considerations with some farmers not adjusting spreaders when moving from CAN to urea and ending up with stripes in silage fields.

The issues farmers are reporting

Fear of change and additional cost: if farmers are using ordinary urea successfully for the last 10 years, then where is the need to change? The research results suggest there is no added response benefit using protected urea so the €40/t additional cost is effectively a farmer pulling on a green jersey to reduce national emissions. However, the practical reality is replacing CAN (27% N) with protected urea (46% N) will more or less be a breakeven decision for the farmer with no additional cost incurred. The bag or label should state “urea with urease inhibitor” and also the type of inhibitor. Coating differences: one of the main reasons for variation in products is there are varying levels of coatings applied to the different products with some coatings degrading at different rates. The less coating, the less protection to ammonia losses by the urease inhibitor. The standard coating degradation rate talked about in the industry is 2% per month. Think about coating degradation like this. Someone in the farmhouse makes chocolate-covered Rice Krispie buns. You take them out of the fridge and place them on a rack beside the cooker. They are dark brown when they come out of the fridge with lots of chocolate. Every time you turn on the cooker and the heat rises, more of the chocolate drips off the Rice Krispie buns that are sitting beside the cooker until eventually you are left with very little chocolate on the buns and they turn a pale yellow colour. In the same way, when the protected urea lands in the farmer’s yard, it has a level of coating on the urea. Let’s put a number on it – say 500ppb.

Then, over time, as the urea sits in the yard before it gets into the spinner the coating degrades and it could be down at 400ppb before it is actually spread in late April or May.

The EU regulation suggests that the company selling the product just needs to have the required coating when the product lands in the yard. The Department will be doing product spot checks during the year to check this.

Sulphur with nitrogen: there have been concerns around using sulphur with urea. Think about it – sulphur is acidic so it is difficult to manage. However, a number of products on the list have sulphur included in a compound. Low-fertility soils: if your soils are low in phosphorus (P) and potassium (K) and, let’s assume you can’t get P and K from slurry, you are probably going to have to use a round of 18:6:12 or diammonium phosphate (DAP) early in the season to get P and K on. There are no products with protected urea and phosphorus combined on the protected urea list (Table 1) so you need to use a compound if you need to get P and K on. The best advice for the last number of years is to get a dribble of P and K on little and often rather than a big autumn spread. Make an annual plan: plan your nitrogen purchase and usage now. Use products listed in Table 1 with confidence that research has been carried out in Ireland verifying environmental benefits and responses. Other products might well work but the response and environmental benefits have not been measured in Irish Teagasc research.Teagasc trials show protected urea (46% N) matches CAN (27% N) in terms of grass yield response.Urea protected with NBPT results in lower greenhouse gas emissions compared with CAN.A Teagasc review of the published literature suggests no meaningful risk of residues in milk under normal conditions of use on Irish farms. Read more

BETTER Farm: slurry and fertiliser this spring

Protected urea passes residue trial

Given the time, cost and level of complexity around the discussion, I hear some agri trading bosses are threatening to delist protected urea.

Teagasc recently sent letters to milk companies discounting any potential residues in milk around the use of protected urea.

This is just the latest in a list of the issues that seems to be causing a ripple of discomfort to farmers using protected urea. However, we all know widespread advice to change always brings more questions than answers.

What is protected urea?

Protected urea is urea, as we know it, with a urease inhibitor chemical coating or incorporation to help reduce ammonia loss to the atmosphere.

There are a number of different commercial products that are used to make the coating. The majority of protected urea products on offer use the NBPT coating (Table 1).

Teagasc and the Department of Agriculture’s climate change division suggest the roadmap for farmers is that we need to replace 100% of the urea (46% N) sold in Ireland with protected urea. Remember urea as a product makes up only 10% of the nitrogen sold in Ireland. In addition, the plan is to replace 50% of the CAN (27% N) with protected urea to meet targets set by the Teagasc MACC curve on reducing national emissions.

Sales of protected urea have been rising steadily for the last three years. Along the way, there have been speed bumps with some questioning residue levels in product (meat or milk) with long-term continued usage.

The letter from Teagasc to processors this week goes some of the way to alleviating residue concerns

More question the impact on soil biology. Others question while the NBPT might not have a residue the reagents that bind the NBPT might have negative long-term implications.

The letter from Teagasc to processors this week goes some of the way to alleviating residue concerns.

Leaving aside the chemistry, there have been practical considerations with some farmers not adjusting spreaders when moving from CAN to urea and ending up with stripes in silage fields.

The issues farmers are reporting

Fear of change and additional cost: if farmers are using ordinary urea successfully for the last 10 years, then where is the need to change? The research results suggest there is no added response benefit using protected urea so the €40/t additional cost is effectively a farmer pulling on a green jersey to reduce national emissions. However, the practical reality is replacing CAN (27% N) with protected urea (46% N) will more or less be a breakeven decision for the farmer with no additional cost incurred. The bag or label should state “urea with urease inhibitor” and also the type of inhibitor. Coating differences: one of the main reasons for variation in products is there are varying levels of coatings applied to the different products with some coatings degrading at different rates. The less coating, the less protection to ammonia losses by the urease inhibitor. The standard coating degradation rate talked about in the industry is 2% per month. Think about coating degradation like this. Someone in the farmhouse makes chocolate-covered Rice Krispie buns. You take them out of the fridge and place them on a rack beside the cooker. They are dark brown when they come out of the fridge with lots of chocolate. Every time you turn on the cooker and the heat rises, more of the chocolate drips off the Rice Krispie buns that are sitting beside the cooker until eventually you are left with very little chocolate on the buns and they turn a pale yellow colour. In the same way, when the protected urea lands in the farmer’s yard, it has a level of coating on the urea. Let’s put a number on it – say 500ppb.

Then, over time, as the urea sits in the yard before it gets into the spinner the coating degrades and it could be down at 400ppb before it is actually spread in late April or May.

The EU regulation suggests that the company selling the product just needs to have the required coating when the product lands in the yard. The Department will be doing product spot checks during the year to check this.

Sulphur with nitrogen: there have been concerns around using sulphur with urea. Think about it – sulphur is acidic so it is difficult to manage. However, a number of products on the list have sulphur included in a compound. Low-fertility soils: if your soils are low in phosphorus (P) and potassium (K) and, let’s assume you can’t get P and K from slurry, you are probably going to have to use a round of 18:6:12 or diammonium phosphate (DAP) early in the season to get P and K on. There are no products with protected urea and phosphorus combined on the protected urea list (Table 1) so you need to use a compound if you need to get P and K on. The best advice for the last number of years is to get a dribble of P and K on little and often rather than a big autumn spread. Make an annual plan: plan your nitrogen purchase and usage now. Use products listed in Table 1 with confidence that research has been carried out in Ireland verifying environmental benefits and responses. Other products might well work but the response and environmental benefits have not been measured in Irish Teagasc research.Teagasc trials show protected urea (46% N) matches CAN (27% N) in terms of grass yield response.Urea protected with NBPT results in lower greenhouse gas emissions compared with CAN.A Teagasc review of the published literature suggests no meaningful risk of residues in milk under normal conditions of use on Irish farms. Read more

BETTER Farm: slurry and fertiliser this spring

Protected urea passes residue trial

SHARING OPTIONS