Almost every farm in the country has a use for a jeep- or car-drawn trailer, be it a livestock, flatbed or plant trailer.

These trailers, although used all year round, tend to be among the most neglected pieces of equipment on any farm.

It is vital that trailers are routinely maintained. This goes beyond the visuals such as lights and number plates, and should include brakes and other wear parts.

Not only is this to remain road legal, but for safety too.

We travelled to Ifor Williams dealer Whites Trailers outside Abbeyshrule, Co Longford, to get the lowdown on a standard service procedure.

While it was a horsebox being worked on, its running gear is identical to most livestock, flatbed and plant trailers.

Cian Nolan, Whites Trailers, Longford.

Start by inspecting the hitch head. Some hitches have a wear indicator on the side. Once hitched, you shouldn’t be able to lift the hitch head past the indicator.

Alternatively, place a ball into the head and check for wear. There should be a small degree of movement but nothing excessive.

Check the hitch head for wear by inserting a ball and checking for play. Alternatively, some hitches have wear indicators.

If wear is present, a new hitch head should be fitted, checking it’s either the 2.7t or 3.5t rated type first. The common 3.5t hitch head will cost about €110 plus VAT.

There are two types of hitch head, 2.7t and 3.5t rated. The 3.5T head is priced around €110 plus VAT.

The hitch body which is bolted to the chassis should have its bolts checked for tightness. Depending on the brand of hitch it may have one or two grease nipples.

These should receive a pump of grease regularly. Grease allows the hitch barrel to move freely while the brakes are being applied. Lack of grease will have the opposite effect and cause wear.

A full hitch replacement (including head) will cost in the region of €300 plus VAT.

A complete new hitch will cost in the region of €300 plus VAT.

The rubber bellow protects the barrel and retains grease. A cut or missing bellow will allow water and dirt to ingress.

Remove or pull back to inspect barrel condition. A replacement will only cost €15-€20 plus VAT.

If the hitch barrel is easily pushed back or the trailer ‘slaps’ forward while on the road, then it’s in need of replacement. A new damper will cost ball park €70-85 plus VAT.

Damper condition should be checked, ideally you shouldn’t be able to compress it.

“A worn damper is often an indication that there is an underlying brake issue, ie seized cables or worn shoes. It shouldn’t be replaced without further investigation as it will likely fail again prematurely,” Cian said.

Similarly, a damaged or worn damper will stop the trailer brakes from working and result in car or jeep having to do all the braking. This is dangerous (especially loaded) and will also result in increased vehicle maintenance.

Described by Cian as a “cheap insurance policy”, the breakaway cable is not only a legal requirement but an important safety feature. In the unfortunate event that a trailer becomes uncoupled from its vehicle on the move, the breakaway cable will pull, engage the handbrake and bring the trailer to a halt before snapping.

A proper breakaway is a legal requirement and should be fitted to every trailer.

Cian explained that the worst possible thing to do is use a chain in its place as it will probably not snap. This means the vehicle and trailer will remain connected and potentially cause the vehicle to crash too. A breakaway cable costs €10 plus VAT. Handbrake grease points should be lubricated frequently, ensuring the brake fork is free-moving. It is required to move once the handbrake is applied or when the breakaway is pulled in the event of an emergency.

Every trailer should be fitted with a free moving jockey wheel.

Ensure it is lowered as much as possible before winding starts.

A damaged or broken jockey wheel is a common sight on many trailers.

Jockey wheels tend to range from €45 to €65 plus VAT depending if they are 2.7t or 3.5t rated. If the actual wheel itself is damaged it can itself be replaced, wheels cost in the region of €20-€25 plus VAT.

While servicing it is important to remove each hub and check brake condition. Start by checking each wheel bearing while wheels are off the ground.

Spin each wheel listening for roughness, then look/feel for movement. Hub bearings cost between €50 and €60 each plus VAT depending on type. A press tends to be required for replacement.

Alongside the brake fork, other handbrake grease points should be lubricated routinely.

Modern Ifor Williams’s examples use a sealed bearing while other manufacturers use tapered bearings. Since the latter are not sealed, they need to be greased regularly.

If gone unnoticed for too long, a failed bearing can lead to hub damage and result in the hub needing to be replaced, costing €135-175 plus VAT depending on size (eight- or 10-stud).

Brake cables can often seize or wear.

Once the hub has been removed, the brake assembly and axle stub is visible. Start by checking the condition of each brake cable right back to the handbrake rod.

Cian said cables tend to be left just sitting on the axles where they rub and wear. He recommends cable-tying each cable to the axle to prevent rubbing. Any seized or worn cable should be replaced. Often when going that far it makes most sense to replace the set (four on a twin axle). Brake cables tend to cost about €15 plus VAT.

Worn brake shoes need replaced, making sure to insert each spring the correct way around or the shoe will want to pull away from the hub. Replacement brake shoe kits cost between €100 and €130 plus VAT per axle depending on size.

Always ensure the expander on each is in its slackened position and the adjuster is freely moving for when the hub has been reassembled.

During reassembly, it’s recommended that sealed bearing hubs have a new nut fitted and be torqued to the manufacturer’s guidelines.

Now, tighten/loosen the adjuster nut (17mm or 19mm socket) while spinning the hub until it just locks up. Then loosen it half a turn and that’s it.

Cian strongly recommends where possible, that a parked trailer should not have its handbrake applied regardless of duration.

Otherwise the pads are left in contact with the hubs, the brakes can then stick-on once moved. What happens is the brake material becomes removed from the shoe and leads to total brake failure.

Most trailers are fitted with leaf springs. Some five-leaf, some twin-leaf and some single-leaf. Check spring condition and that the axle hasn’t moved – this would indicate a loose U-bolt.

If shoe springs are inserted incorrectly, the shoe will not want to sit flush like above.

Check their tightness. At either end of the spring there is a bushing where it mounts to the trailer. Check for signs of wear. A worn bushing will leave a trailer noisy.

The two bushings on each spring can be easily replaced.

If unnoticed for too long, fabrication work may be required to replace the mounting bracket. Bushings cost around €10-€15 plus VAT. Springs cost anywhere from €60-€100 each plus VAT.

Each set of U-bolts hold a bump stop in place. Replacements cost €6 plus VAT.

Before checking U-bolt tightness, ensure all rubber bump stops are present.

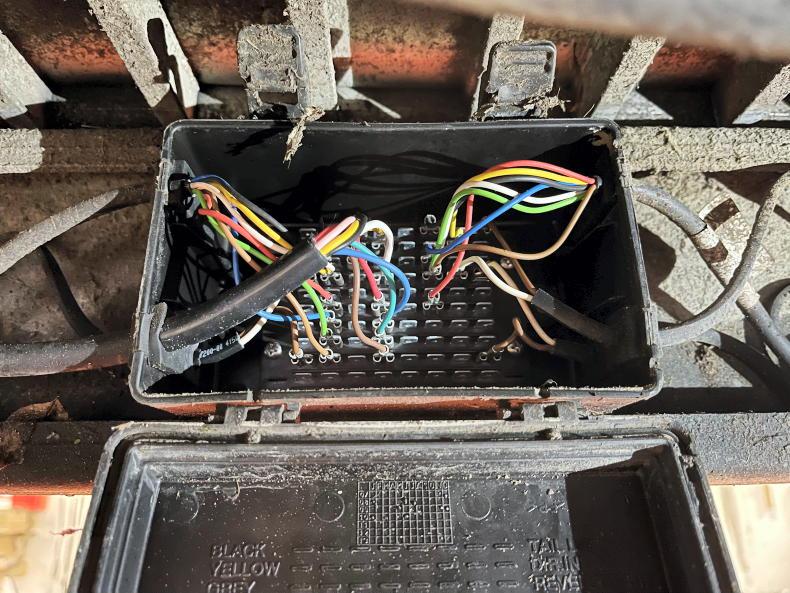

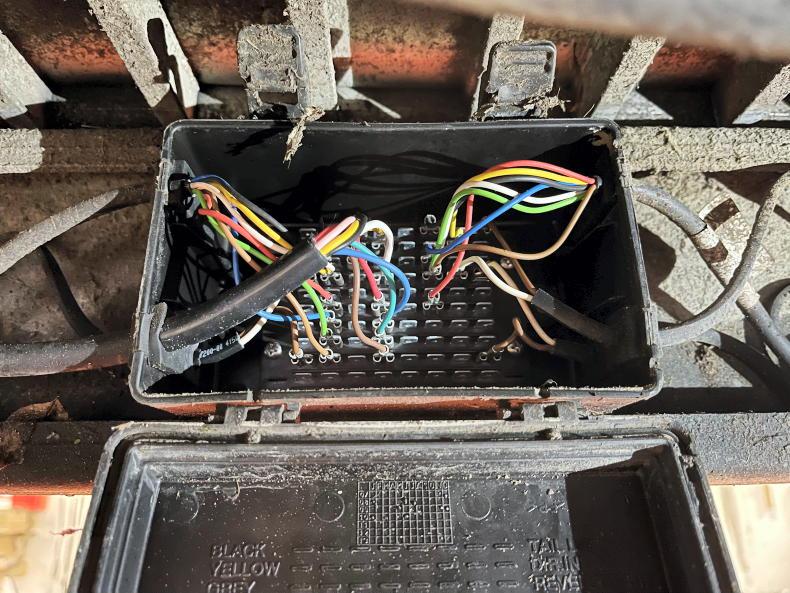

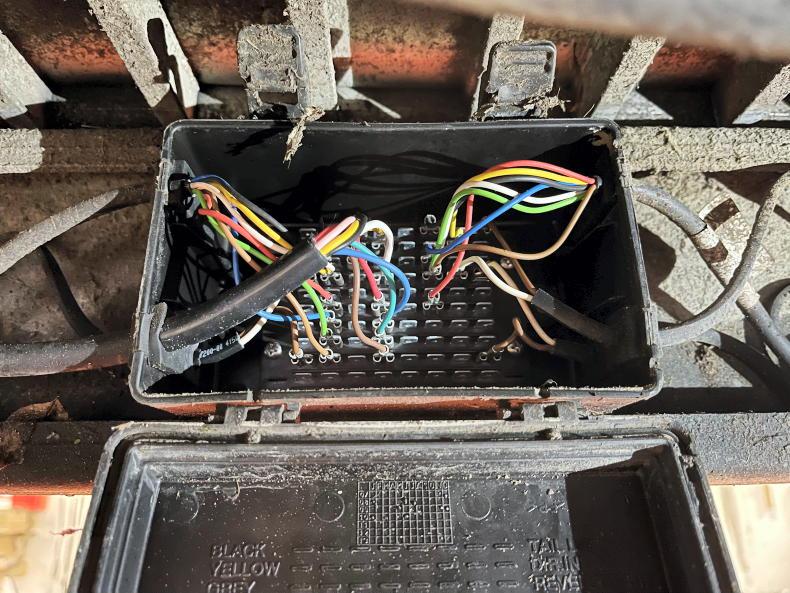

All lights should be functional. Beyond the bulb, there can be issues with the seven-pin plug or junction box(es).

A lighting issue that tends to go beyond the bulb or plug usually lies within the junction box.

Some manufacturers have one junction box while some have two. Corrosion is the most common issue. If the budget is there a full LED light conversion is worthwhile.

A full conversion using LEDs from a reputable brand will cost about €250 plus VAT.

A fully LED light conversion including side marker lights will cost in the region of €250 plus VAT for a reputable brand.

Tyre walls often tend to give way before thread proves an issue. Cian said that the most common rim size on livestock trailers today is 16in fitted with a 175mm or 185mm tyre. He said that 65psi tends to be the go-to pressure. The smaller the rim, the higher the tyre pressure generally.

Tyres often tend to perish or get damaged side walls before fully worn. However, they should still be replaced.

Aside from latch condition, all that may need seen to on a trailer ramp is its hinges. If a ramp proves difficult to close it may need its hinge bushings replaced. These tend to cost no more than €10 plus VAT each and just press into place.

Latch condition should be checked.

Spring fatigue may also occur with replacement being the only fix. Ensure the little spud on the inside gate is present, this holds the gate in place helping prevent an animal pushing it back while closing the ramp.

Older trailers may need the ramps hinge bushings replaced. Bushings cost no more than €10 plus VAT each.

1 Insure your trailer and record its serial number.2 Avoid parking with the handbrake on where possible.3 Have the trailer serviced routinely depending on usage. Hitch head (€100+VAT).Complete hitch assembly (€300+VAT).Breakaway cable (€10+VAT).Damper (€70-85+VAT).Rubber bellow (€15-20+ VAT).Brake cables (€15+VAT each).Brake shoe kit (€100-€130+VAT per axle).Hub bearing (€50-60+VAT).Complete hub and bearing (€135+VAT each).Spring bushings (€10-15+VAT each).Springs (€60-100+VAT).Jockey wheel (€45-65+VAT).

Almost every farm in the country has a use for a jeep- or car-drawn trailer, be it a livestock, flatbed or plant trailer.

These trailers, although used all year round, tend to be among the most neglected pieces of equipment on any farm.

It is vital that trailers are routinely maintained. This goes beyond the visuals such as lights and number plates, and should include brakes and other wear parts.

Not only is this to remain road legal, but for safety too.

We travelled to Ifor Williams dealer Whites Trailers outside Abbeyshrule, Co Longford, to get the lowdown on a standard service procedure.

While it was a horsebox being worked on, its running gear is identical to most livestock, flatbed and plant trailers.

Cian Nolan, Whites Trailers, Longford.

Start by inspecting the hitch head. Some hitches have a wear indicator on the side. Once hitched, you shouldn’t be able to lift the hitch head past the indicator.

Alternatively, place a ball into the head and check for wear. There should be a small degree of movement but nothing excessive.

Check the hitch head for wear by inserting a ball and checking for play. Alternatively, some hitches have wear indicators.

If wear is present, a new hitch head should be fitted, checking it’s either the 2.7t or 3.5t rated type first. The common 3.5t hitch head will cost about €110 plus VAT.

There are two types of hitch head, 2.7t and 3.5t rated. The 3.5T head is priced around €110 plus VAT.

The hitch body which is bolted to the chassis should have its bolts checked for tightness. Depending on the brand of hitch it may have one or two grease nipples.

These should receive a pump of grease regularly. Grease allows the hitch barrel to move freely while the brakes are being applied. Lack of grease will have the opposite effect and cause wear.

A full hitch replacement (including head) will cost in the region of €300 plus VAT.

A complete new hitch will cost in the region of €300 plus VAT.

The rubber bellow protects the barrel and retains grease. A cut or missing bellow will allow water and dirt to ingress.

Remove or pull back to inspect barrel condition. A replacement will only cost €15-€20 plus VAT.

If the hitch barrel is easily pushed back or the trailer ‘slaps’ forward while on the road, then it’s in need of replacement. A new damper will cost ball park €70-85 plus VAT.

Damper condition should be checked, ideally you shouldn’t be able to compress it.

“A worn damper is often an indication that there is an underlying brake issue, ie seized cables or worn shoes. It shouldn’t be replaced without further investigation as it will likely fail again prematurely,” Cian said.

Similarly, a damaged or worn damper will stop the trailer brakes from working and result in car or jeep having to do all the braking. This is dangerous (especially loaded) and will also result in increased vehicle maintenance.

Described by Cian as a “cheap insurance policy”, the breakaway cable is not only a legal requirement but an important safety feature. In the unfortunate event that a trailer becomes uncoupled from its vehicle on the move, the breakaway cable will pull, engage the handbrake and bring the trailer to a halt before snapping.

A proper breakaway is a legal requirement and should be fitted to every trailer.

Cian explained that the worst possible thing to do is use a chain in its place as it will probably not snap. This means the vehicle and trailer will remain connected and potentially cause the vehicle to crash too. A breakaway cable costs €10 plus VAT. Handbrake grease points should be lubricated frequently, ensuring the brake fork is free-moving. It is required to move once the handbrake is applied or when the breakaway is pulled in the event of an emergency.

Every trailer should be fitted with a free moving jockey wheel.

Ensure it is lowered as much as possible before winding starts.

A damaged or broken jockey wheel is a common sight on many trailers.

Jockey wheels tend to range from €45 to €65 plus VAT depending if they are 2.7t or 3.5t rated. If the actual wheel itself is damaged it can itself be replaced, wheels cost in the region of €20-€25 plus VAT.

While servicing it is important to remove each hub and check brake condition. Start by checking each wheel bearing while wheels are off the ground.

Spin each wheel listening for roughness, then look/feel for movement. Hub bearings cost between €50 and €60 each plus VAT depending on type. A press tends to be required for replacement.

Alongside the brake fork, other handbrake grease points should be lubricated routinely.

Modern Ifor Williams’s examples use a sealed bearing while other manufacturers use tapered bearings. Since the latter are not sealed, they need to be greased regularly.

If gone unnoticed for too long, a failed bearing can lead to hub damage and result in the hub needing to be replaced, costing €135-175 plus VAT depending on size (eight- or 10-stud).

Brake cables can often seize or wear.

Once the hub has been removed, the brake assembly and axle stub is visible. Start by checking the condition of each brake cable right back to the handbrake rod.

Cian said cables tend to be left just sitting on the axles where they rub and wear. He recommends cable-tying each cable to the axle to prevent rubbing. Any seized or worn cable should be replaced. Often when going that far it makes most sense to replace the set (four on a twin axle). Brake cables tend to cost about €15 plus VAT.

Worn brake shoes need replaced, making sure to insert each spring the correct way around or the shoe will want to pull away from the hub. Replacement brake shoe kits cost between €100 and €130 plus VAT per axle depending on size.

Always ensure the expander on each is in its slackened position and the adjuster is freely moving for when the hub has been reassembled.

During reassembly, it’s recommended that sealed bearing hubs have a new nut fitted and be torqued to the manufacturer’s guidelines.

Now, tighten/loosen the adjuster nut (17mm or 19mm socket) while spinning the hub until it just locks up. Then loosen it half a turn and that’s it.

Cian strongly recommends where possible, that a parked trailer should not have its handbrake applied regardless of duration.

Otherwise the pads are left in contact with the hubs, the brakes can then stick-on once moved. What happens is the brake material becomes removed from the shoe and leads to total brake failure.

Most trailers are fitted with leaf springs. Some five-leaf, some twin-leaf and some single-leaf. Check spring condition and that the axle hasn’t moved – this would indicate a loose U-bolt.

If shoe springs are inserted incorrectly, the shoe will not want to sit flush like above.

Check their tightness. At either end of the spring there is a bushing where it mounts to the trailer. Check for signs of wear. A worn bushing will leave a trailer noisy.

The two bushings on each spring can be easily replaced.

If unnoticed for too long, fabrication work may be required to replace the mounting bracket. Bushings cost around €10-€15 plus VAT. Springs cost anywhere from €60-€100 each plus VAT.

Each set of U-bolts hold a bump stop in place. Replacements cost €6 plus VAT.

Before checking U-bolt tightness, ensure all rubber bump stops are present.

All lights should be functional. Beyond the bulb, there can be issues with the seven-pin plug or junction box(es).

A lighting issue that tends to go beyond the bulb or plug usually lies within the junction box.

Some manufacturers have one junction box while some have two. Corrosion is the most common issue. If the budget is there a full LED light conversion is worthwhile.

A full conversion using LEDs from a reputable brand will cost about €250 plus VAT.

A fully LED light conversion including side marker lights will cost in the region of €250 plus VAT for a reputable brand.

Tyre walls often tend to give way before thread proves an issue. Cian said that the most common rim size on livestock trailers today is 16in fitted with a 175mm or 185mm tyre. He said that 65psi tends to be the go-to pressure. The smaller the rim, the higher the tyre pressure generally.

Tyres often tend to perish or get damaged side walls before fully worn. However, they should still be replaced.

Aside from latch condition, all that may need seen to on a trailer ramp is its hinges. If a ramp proves difficult to close it may need its hinge bushings replaced. These tend to cost no more than €10 plus VAT each and just press into place.

Latch condition should be checked.

Spring fatigue may also occur with replacement being the only fix. Ensure the little spud on the inside gate is present, this holds the gate in place helping prevent an animal pushing it back while closing the ramp.

Older trailers may need the ramps hinge bushings replaced. Bushings cost no more than €10 plus VAT each.

1 Insure your trailer and record its serial number.2 Avoid parking with the handbrake on where possible.3 Have the trailer serviced routinely depending on usage. Hitch head (€100+VAT).Complete hitch assembly (€300+VAT).Breakaway cable (€10+VAT).Damper (€70-85+VAT).Rubber bellow (€15-20+ VAT).Brake cables (€15+VAT each).Brake shoe kit (€100-€130+VAT per axle).Hub bearing (€50-60+VAT).Complete hub and bearing (€135+VAT each).Spring bushings (€10-15+VAT each).Springs (€60-100+VAT).Jockey wheel (€45-65+VAT).

SHARING OPTIONS