Amazone has added a new model to its self-propelled sprayer offering, namely the Pantera 7004. Prior to this, Amazone offered one self-propelled model, namely the 4504 ,with a 4,500l tank and boom widths from 21m to 42m.

With a maximum spray tank capacity of 7,000l and a nominal volume of 6,600l, the 7004’s tank is made of fibre-glass reinforced plastic. Amazone says it has exceptionally smooth inner and outer walls with no nooks and crannies, for perfect cleaning.

The Pantera gains Claas’s latest cab, which Amazone says is tailored specifically to the functionality of a self-propelled sprayer.

Offset track driving is available, in which the front wheels can be set at the minimum track width and the rear wheels at maximum, meaning the soil is travelled over just once.

The layout of the four high-pressure cleaning nozzles, agitation and outlet sump are based on the tried-and-tested existing current model and guarantee cleaning with minimal residual volumes. A 500l tank positioned at the rear of the machine provides fresh water for cleaning.

With an empty weight of 12t, it features a 306hp Deutz engine under the hood and transfers power hydraulically to the wheels. Amazone claims the new running gear with independent trailing arm suspension is unique. The hydro-pneumatic suspension is adaptive, whereby the characteristics are tailored to the driving situation.

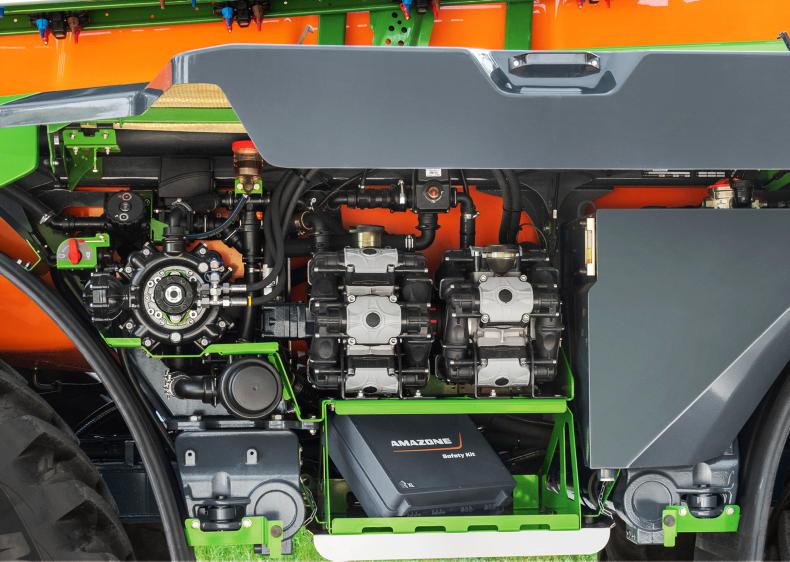

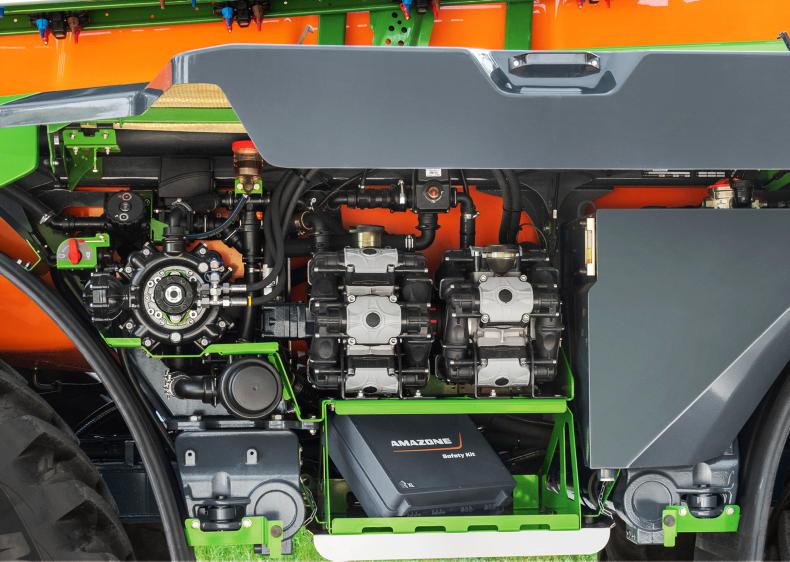

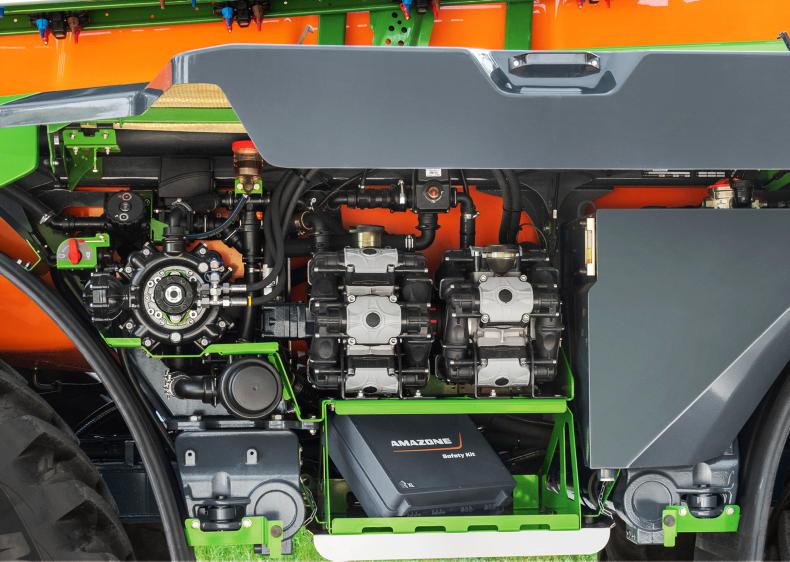

The piston diaphragm pumps are designed for a constant total output of 610l/min for maximum work rates.

Amazone is using its own precision boom technology, with the aircraft wing design enabling working widths from 24m to 48m.

Hydraulic track width adjustment, with a standard track width from 2m to 2.75m, is fitted as standard. Track widths from 2.25m to 3m are also available. The ground clearance is 1.3m. Offset track driving is available, in which the front wheels can be set at the minimum track width and the rear wheels at maximum, meaning the soil is travelled over just once. Amazone is using its own precision boom technology with the aircraft wing design enabling working widths from 24m to 48m.

Another feature is the integrated slope compensation. The inclination of the vehicle is detected via sensors and the machine is automatically kept horizontal to a certain gradient.

Twelve LED work lights are now incorporated in the roof as standard.

New cab

The Pantera gains Claas’s latest cab and is equipped with filtration which meets the category four standards. Amazone say the new armrest is tailored specifically to the functionality of a self-propelled sprayer. As part of the twin terminal strategy, the 7” AmaDrive terminal is responsible for the operation of the vehicle, whereas the spraying system is operated via an IsoBus terminal. Twelve LED work lights are now incorporated into the roof as standard. It comes with the option of individual nozzle lighting on the boom. The piston diaphragm pumps are designed for a constant total output of 610l/min. The injection principle provides a suction capacity of 700l/min for filling.

A bowser fill port is available as an option. This allows a filling speed of up to 1,000l/min with the 3” line. The DLG award-winning DirectInject system is available as an option. This enables additional products to be added when required in a matter of seconds from the cab at the touch of a button.

With an empty weight of 12t, it features a 306hp Deutz engine under the hood and transfers power hydraulically to the wheels.

The award-winning DirectInject system enables additional products to be added when required in a matter of seconds from the cab at the touch of a button.

Amazone has added a new model to its self-propelled sprayer offering, namely the Pantera 7004. Prior to this, Amazone offered one self-propelled model, namely the 4504 ,with a 4,500l tank and boom widths from 21m to 42m.

With a maximum spray tank capacity of 7,000l and a nominal volume of 6,600l, the 7004’s tank is made of fibre-glass reinforced plastic. Amazone says it has exceptionally smooth inner and outer walls with no nooks and crannies, for perfect cleaning.

The Pantera gains Claas’s latest cab, which Amazone says is tailored specifically to the functionality of a self-propelled sprayer.

Offset track driving is available, in which the front wheels can be set at the minimum track width and the rear wheels at maximum, meaning the soil is travelled over just once.

The layout of the four high-pressure cleaning nozzles, agitation and outlet sump are based on the tried-and-tested existing current model and guarantee cleaning with minimal residual volumes. A 500l tank positioned at the rear of the machine provides fresh water for cleaning.

With an empty weight of 12t, it features a 306hp Deutz engine under the hood and transfers power hydraulically to the wheels. Amazone claims the new running gear with independent trailing arm suspension is unique. The hydro-pneumatic suspension is adaptive, whereby the characteristics are tailored to the driving situation.

The piston diaphragm pumps are designed for a constant total output of 610l/min for maximum work rates.

Amazone is using its own precision boom technology, with the aircraft wing design enabling working widths from 24m to 48m.

Hydraulic track width adjustment, with a standard track width from 2m to 2.75m, is fitted as standard. Track widths from 2.25m to 3m are also available. The ground clearance is 1.3m. Offset track driving is available, in which the front wheels can be set at the minimum track width and the rear wheels at maximum, meaning the soil is travelled over just once. Amazone is using its own precision boom technology with the aircraft wing design enabling working widths from 24m to 48m.

Another feature is the integrated slope compensation. The inclination of the vehicle is detected via sensors and the machine is automatically kept horizontal to a certain gradient.

Twelve LED work lights are now incorporated in the roof as standard.

New cab

The Pantera gains Claas’s latest cab and is equipped with filtration which meets the category four standards. Amazone say the new armrest is tailored specifically to the functionality of a self-propelled sprayer. As part of the twin terminal strategy, the 7” AmaDrive terminal is responsible for the operation of the vehicle, whereas the spraying system is operated via an IsoBus terminal. Twelve LED work lights are now incorporated into the roof as standard. It comes with the option of individual nozzle lighting on the boom. The piston diaphragm pumps are designed for a constant total output of 610l/min. The injection principle provides a suction capacity of 700l/min for filling.

A bowser fill port is available as an option. This allows a filling speed of up to 1,000l/min with the 3” line. The DLG award-winning DirectInject system is available as an option. This enables additional products to be added when required in a matter of seconds from the cab at the touch of a button.

With an empty weight of 12t, it features a 306hp Deutz engine under the hood and transfers power hydraulically to the wheels.

The award-winning DirectInject system enables additional products to be added when required in a matter of seconds from the cab at the touch of a button.

SHARING OPTIONS