With each passing day we learn more about the challenges the agricultural sector faces and the need to transform our farming systems.

However, many other sectors must deal with the same task, with many now turning to farmers to help find solutions to decrease their carbon emissions. One such sector is aviation, which has a monumental challenge to reduce emissions.

While Ireland has been trailing behind its European counterparts in this area, a new study aims to demonstrate the feasibility of constructing a sustainable aviation fuel (SAF) production plant in Ireland, with farmers playing a crucial role in providing the ingredients, including slurry and grass silage.

Aviation and SAF

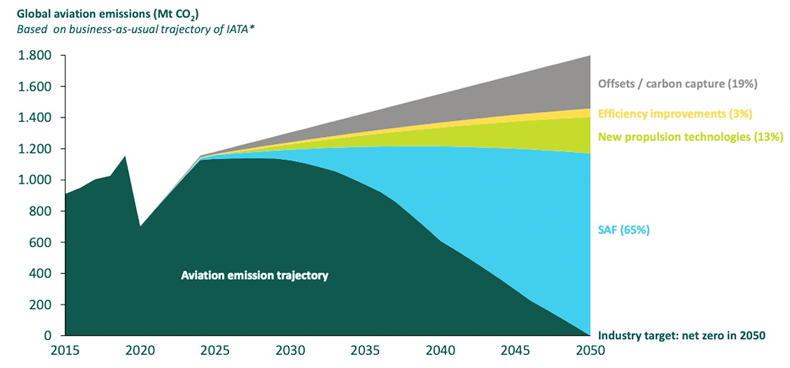

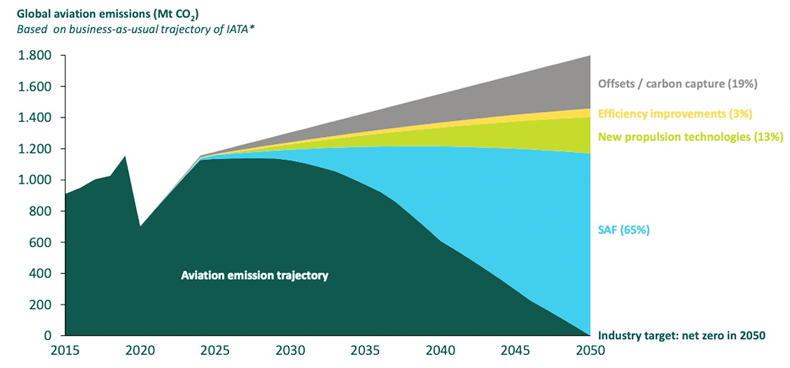

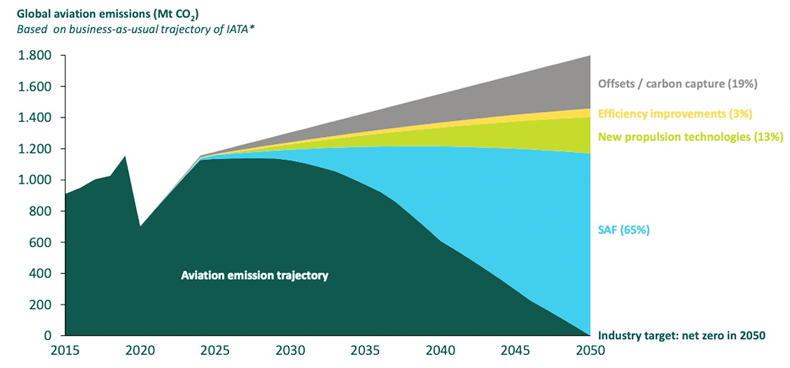

The aviation sector is responsible for approximately 2.3% of global emissions. The International Air Transport Association (IATA) has set a goal for the industry to achieve net-zero emissions by 2050.

While electric and hydrogen-powered aircraft can provide some emissions savings, these solutions are not practical for long-haul flights. This is where SAF comes into play.

SAF is a type of biofuel used to power aircraft that shares similar properties with conventional jet fuel, but has a carbon footprint that is typically 80% smaller. SAF blends can be used in aircraft without requiring any modifications while providing the same range and is expected to account for 65% of the required emissions reductions by 2050.

Jet powered with fuel made from slurry and grass could hold the key to decarbonising the aviation sector

SAF can be produced from both biological sources (such as biomass, wastes, fats, oils etc) and non-biological sources (such as hydrogen and CO2). Irish company Sustainable Flight Solutions Ireland (SFS) is currently conducting a study to determine the feasibility of developing a SAF facility in Ireland, using biomethane made from our emerging anaerobic digestion (AD) industry as a key ingredient.

Founded by Aer Lingus pilots Darren Carty and Agnes Thornton, the company has partnered with Dutch company SkyNRG, which has been working on SAF projects since 2009.

Biomethane

Biomethane gas is produced by cleaning and upgrading biogas produced by AD plants. Under Government plans, Ireland is required to produce 5.7 terawatt hour (TWh) of biomethane by 2030, which would require somewhere between 200 and 250 AD plants. This biomethane has been earmarked largely for the heat and haulage industries, which are difficult to decarbonise using electrification.

According to Darren, however, biomethane can be further processed to make SAF, which can then be blended with conventional jet fuel and used to power aircrafts.

Based on other commercial SAF plans in development, an Irish facility would have to be able to produce a minimum of 100 kilotonnes of SAF to be viable (less than 10% of the fuel requirements of Dublin airport). To put this in context, this would require about 2.2TWh of biomethane, nearly 40% of our 2030 target. Based on Ireland’s grass-slurry feedstock model, this would require around 44 large-scale AD plants (each producing 50GWh of gas output) and the equivalent of 110,000ac of grass silage and 1.7 million tonnes of slurry to feed the plants.

SAF will do the lions share of work in the aviation industries journey to net-zero

Darren believes a SAF facility would be able to provide much-needed long-term biomethane purchase agreements, as aircraft operators typically purchase fuel upwards of 10 years in advance.

Long-term gas purchase agreements are vital for securing finance for the construction of AD plants, and so far, Ireland’s high-energy-use sectors such as dairy and food processing, data centres, and manufacturing have not indicated that they would offer such an agreement.

So SAF could offer a route to development for the AD sector.

Issues with sustainability

Darren and Agnes want to engage with the Government early to develop a plan for SAF in Ireland, which ultimately depends on the development of an AD sector. They stress that time is of the essence.

In 2025, a proposed new SAF blending mandate will take effect in the EU. Under the European Commission’s proposal, 2% of fuel used in EU airports will have to come from SAF by 2025, increasing to 63% by 2050. The penalty for non-compliance could be twice the cost difference between SAF and jet fuel. SAF is typically four to five times more expensive than jet fuel. A separate mandate for synthetic SAF will also come into effect in 2025.

Left: conventional fossil jet fuel production pathway. Right: SAF production pathway.

However, questions remain about the sustainability criteria of the feedstock used in SAF production.

Under the Commission’s proposal, SAF made from biofuels can only be produced from EU-approved feedstocks, which include agricultural and forestry residues, cover crops, straw, and other waste streams such as animal slurries, used cooking oil, animal tallow etc. Food- and feed-based biofuels will not be allowed for SAF production due to the risk of competition for food and sustainability.

Although waste- and byproduct-based biofuels are generally preferred by environmentalists compared to crop-based biofuels, they are challenging to scale up.

Darren Carty,co-founder of SFS.

It remains unclear whether perennial grasses will be eligible for inclusion in the feedstock mix due to the potential risk of competition for food and fodder, despite performing well in carbon and sustainability life cycle assessments.

This clashes with the Irish Government’s vision for a grass- and slurry-based AD sector, where farmers can supply grass silage to an AD plant from some or all of their land base.

Darren said they must engage with the Government in order to fully determine this before an AD industry is formed that produces biomethane unsuitable for SAF production.

Study

In addition to assessing the feedstock and technology pathways, the SFS’s feasibility study will evaluate potential site locations. Earlier this month, Aircraft Leasing Ireland (ALI) and KPMG published another important report on SAF production in Ireland.

According to Jan Melgaard, chair of ALI’s sustainability committee: “Demand for SAF is growing, and while production is increasing globally, existing and planned projects alone cannot fully decarbonise the aviation sector or meet the rising demand.”

Agnes Thornton, co-founder of SFS.

Ireland is well-positioned to participate in the production of SAF, as most of the world’s largest aircraft leasing firms are based here and together own nearly 50% of the global aircraft fleet. The report also identified key challenges facing the sector, such as feedstock availability, green electricity cost, sustainability certification, investment, and competition for demand from other sectors such as road transport.

Disclaimer: The author Stephen Robb is currently involved in a family/community proposal for an anaerobic digestion facility in Co Donegal.

With each passing day we learn more about the challenges the agricultural sector faces and the need to transform our farming systems.

However, many other sectors must deal with the same task, with many now turning to farmers to help find solutions to decrease their carbon emissions. One such sector is aviation, which has a monumental challenge to reduce emissions.

While Ireland has been trailing behind its European counterparts in this area, a new study aims to demonstrate the feasibility of constructing a sustainable aviation fuel (SAF) production plant in Ireland, with farmers playing a crucial role in providing the ingredients, including slurry and grass silage.

Aviation and SAF

The aviation sector is responsible for approximately 2.3% of global emissions. The International Air Transport Association (IATA) has set a goal for the industry to achieve net-zero emissions by 2050.

While electric and hydrogen-powered aircraft can provide some emissions savings, these solutions are not practical for long-haul flights. This is where SAF comes into play.

SAF is a type of biofuel used to power aircraft that shares similar properties with conventional jet fuel, but has a carbon footprint that is typically 80% smaller. SAF blends can be used in aircraft without requiring any modifications while providing the same range and is expected to account for 65% of the required emissions reductions by 2050.

Jet powered with fuel made from slurry and grass could hold the key to decarbonising the aviation sector

SAF can be produced from both biological sources (such as biomass, wastes, fats, oils etc) and non-biological sources (such as hydrogen and CO2). Irish company Sustainable Flight Solutions Ireland (SFS) is currently conducting a study to determine the feasibility of developing a SAF facility in Ireland, using biomethane made from our emerging anaerobic digestion (AD) industry as a key ingredient.

Founded by Aer Lingus pilots Darren Carty and Agnes Thornton, the company has partnered with Dutch company SkyNRG, which has been working on SAF projects since 2009.

Biomethane

Biomethane gas is produced by cleaning and upgrading biogas produced by AD plants. Under Government plans, Ireland is required to produce 5.7 terawatt hour (TWh) of biomethane by 2030, which would require somewhere between 200 and 250 AD plants. This biomethane has been earmarked largely for the heat and haulage industries, which are difficult to decarbonise using electrification.

According to Darren, however, biomethane can be further processed to make SAF, which can then be blended with conventional jet fuel and used to power aircrafts.

Based on other commercial SAF plans in development, an Irish facility would have to be able to produce a minimum of 100 kilotonnes of SAF to be viable (less than 10% of the fuel requirements of Dublin airport). To put this in context, this would require about 2.2TWh of biomethane, nearly 40% of our 2030 target. Based on Ireland’s grass-slurry feedstock model, this would require around 44 large-scale AD plants (each producing 50GWh of gas output) and the equivalent of 110,000ac of grass silage and 1.7 million tonnes of slurry to feed the plants.

SAF will do the lions share of work in the aviation industries journey to net-zero

Darren believes a SAF facility would be able to provide much-needed long-term biomethane purchase agreements, as aircraft operators typically purchase fuel upwards of 10 years in advance.

Long-term gas purchase agreements are vital for securing finance for the construction of AD plants, and so far, Ireland’s high-energy-use sectors such as dairy and food processing, data centres, and manufacturing have not indicated that they would offer such an agreement.

So SAF could offer a route to development for the AD sector.

Issues with sustainability

Darren and Agnes want to engage with the Government early to develop a plan for SAF in Ireland, which ultimately depends on the development of an AD sector. They stress that time is of the essence.

In 2025, a proposed new SAF blending mandate will take effect in the EU. Under the European Commission’s proposal, 2% of fuel used in EU airports will have to come from SAF by 2025, increasing to 63% by 2050. The penalty for non-compliance could be twice the cost difference between SAF and jet fuel. SAF is typically four to five times more expensive than jet fuel. A separate mandate for synthetic SAF will also come into effect in 2025.

Left: conventional fossil jet fuel production pathway. Right: SAF production pathway.

However, questions remain about the sustainability criteria of the feedstock used in SAF production.

Under the Commission’s proposal, SAF made from biofuels can only be produced from EU-approved feedstocks, which include agricultural and forestry residues, cover crops, straw, and other waste streams such as animal slurries, used cooking oil, animal tallow etc. Food- and feed-based biofuels will not be allowed for SAF production due to the risk of competition for food and sustainability.

Although waste- and byproduct-based biofuels are generally preferred by environmentalists compared to crop-based biofuels, they are challenging to scale up.

Darren Carty,co-founder of SFS.

It remains unclear whether perennial grasses will be eligible for inclusion in the feedstock mix due to the potential risk of competition for food and fodder, despite performing well in carbon and sustainability life cycle assessments.

This clashes with the Irish Government’s vision for a grass- and slurry-based AD sector, where farmers can supply grass silage to an AD plant from some or all of their land base.

Darren said they must engage with the Government in order to fully determine this before an AD industry is formed that produces biomethane unsuitable for SAF production.

Study

In addition to assessing the feedstock and technology pathways, the SFS’s feasibility study will evaluate potential site locations. Earlier this month, Aircraft Leasing Ireland (ALI) and KPMG published another important report on SAF production in Ireland.

According to Jan Melgaard, chair of ALI’s sustainability committee: “Demand for SAF is growing, and while production is increasing globally, existing and planned projects alone cannot fully decarbonise the aviation sector or meet the rising demand.”

Agnes Thornton, co-founder of SFS.

Ireland is well-positioned to participate in the production of SAF, as most of the world’s largest aircraft leasing firms are based here and together own nearly 50% of the global aircraft fleet. The report also identified key challenges facing the sector, such as feedstock availability, green electricity cost, sustainability certification, investment, and competition for demand from other sectors such as road transport.

Disclaimer: The author Stephen Robb is currently involved in a family/community proposal for an anaerobic digestion facility in Co Donegal.

SHARING OPTIONS