With the recent announcement that the nitrates derogation has been extended for three years, dairy farmers across the country could breathe a sigh of relief.

It’s not perfect, but at least it means farms can budget for until the end of 2028 in some comfort.

The extension is likely to have a big impact on attitude towards investment in the industry.

Uncertainty had restrained farms over the last 12 months. Few were willing to spend money on developing additional facilities when they were unsure if the cows would be there to fill them the following year.

This worry has been eased for now at least and future planning can re-commence with caution.

Investment

When planning an investment in a dairy business, parlours and milking equipment should always be high up on the priority list. The parlour is an essential component in the day-to-day running of the farm and it’s where over a third of the operator’s day is spent.

New entrant levels are well down on where they were five years ago, meaning a lot of the investment that is taking place in milking equipment currently being done by existing dairy farmers.

For that reason, parlour upgrades, modernisation and technology are much more of a focus than the greenfield constructions of previous times. The costs associated with any developments have risen significantly post COVID-19. Therefore, making systems as efficient as possible is crucial to generate a solid return.

In keeping with this idea, Teagasc’s John Upton gives his insight into how milking facilities can be made more energy efficient in the future on page 37.

Aidan Brennan gives his top three tips to consider when planning an investment in the parlour on page 36 and Daire Cregg reports from a recent visit to the DeLaval headquarters in Sweden on pages 34 and 35.

Technology has developed rapidly over the last ten years and this is reflected in some of the advancements being made at DeLaval, both on their R&D farm and across the factory floor.

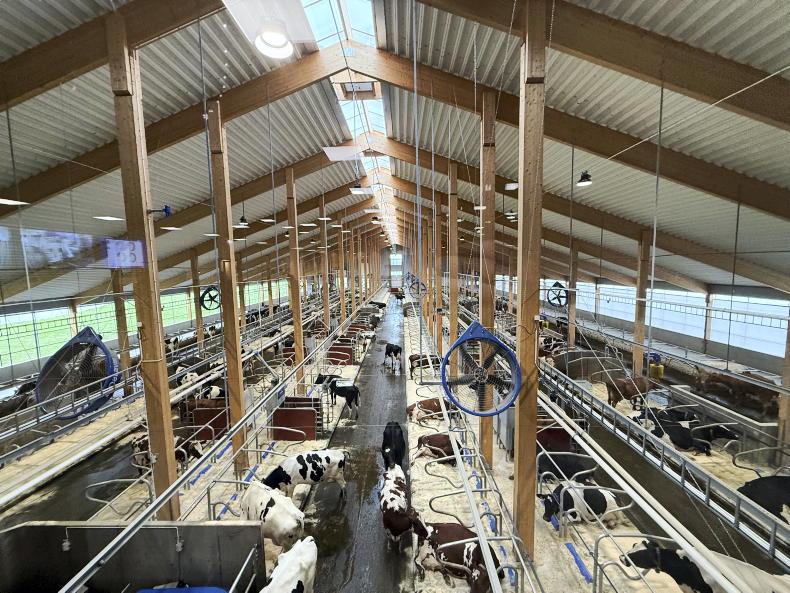

A rotary parlour.

With the recent announcement that the nitrates derogation has been extended for three years, dairy farmers across the country could breathe a sigh of relief.

It’s not perfect, but at least it means farms can budget for until the end of 2028 in some comfort.

The extension is likely to have a big impact on attitude towards investment in the industry.

Uncertainty had restrained farms over the last 12 months. Few were willing to spend money on developing additional facilities when they were unsure if the cows would be there to fill them the following year.

This worry has been eased for now at least and future planning can re-commence with caution.

Investment

When planning an investment in a dairy business, parlours and milking equipment should always be high up on the priority list. The parlour is an essential component in the day-to-day running of the farm and it’s where over a third of the operator’s day is spent.

New entrant levels are well down on where they were five years ago, meaning a lot of the investment that is taking place in milking equipment currently being done by existing dairy farmers.

For that reason, parlour upgrades, modernisation and technology are much more of a focus than the greenfield constructions of previous times. The costs associated with any developments have risen significantly post COVID-19. Therefore, making systems as efficient as possible is crucial to generate a solid return.

In keeping with this idea, Teagasc’s John Upton gives his insight into how milking facilities can be made more energy efficient in the future on page 37.

Aidan Brennan gives his top three tips to consider when planning an investment in the parlour on page 36 and Daire Cregg reports from a recent visit to the DeLaval headquarters in Sweden on pages 34 and 35.

Technology has developed rapidly over the last ten years and this is reflected in some of the advancements being made at DeLaval, both on their R&D farm and across the factory floor.

A rotary parlour.

SHARING OPTIONS