Year on year, there is a growing requirement for more and more farmers to transition towards the use of low-emission slurry spreading (LESS) technology to comply with regulations.

This year, another group of farmers will be faced with new slurry-spreading rules. It is estimated that in the region of 15,000 farmers in Ireland may have to change the way in which their slurry is applied in 2025. New rules under the Good Agricultural Practice for Protection of Waters Regulations which have come into effect since 1 January 2025 require farmers with a grassland stocking rate of between 100kg/ha and 129kg/ha organic nitrogen to apply all slurry on their holding (produced and imported) using LESS equipment.

Prior to this, the use of LESS equipment was already mandatory for farmers with a grassland stocking rate of 130kg/ha and higher organic nitrogen (including derogation farmers), pig farmers and for slurry applied to arable lands, where the slurry is not being incorporated into the soil within 24 hours.

Forward speed is key

Farmers and machine drivers relatively new to using LESS applicators such as a dribble bar or a trailing shoe, should be aware that the forward speed when applying slurry through these systems needs to be significantly increased compared when using a traditional splash plate, in order to achieve the same application rate.

If you use a LESS application system for the first time, one of the first things you will notice is how quick you will empty the tanker in comparison to when using the splash plate.

Slurry calibration calculator

A few years ago, Teagasc launched a very basic and easy-to-use online slurry spreader calibration calculator to help farmers and agricultural contractors using tankers to set accurate application rates.

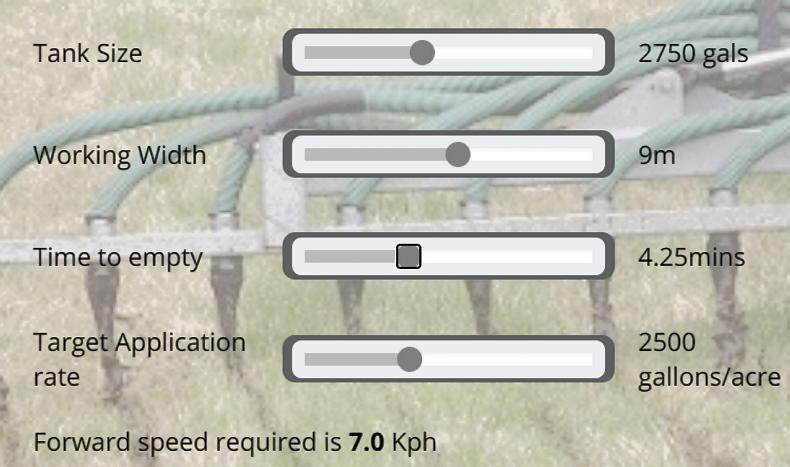

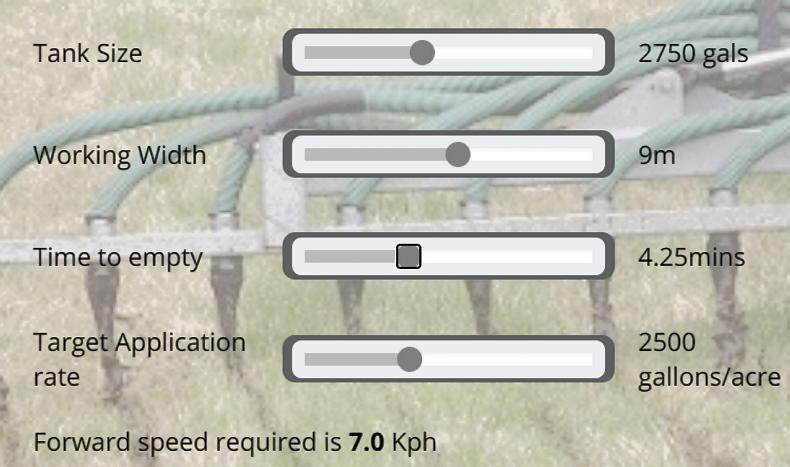

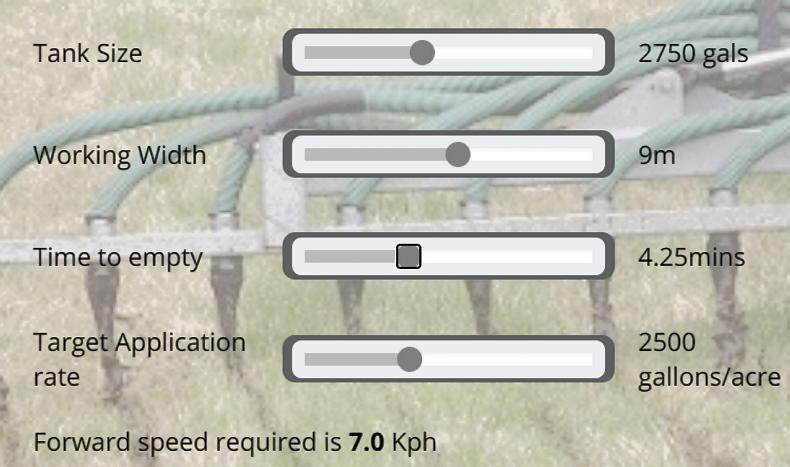

The online calibration calculator requires four key pieces of information in order to determine the forward speed required to apply the desired rate. The user fills in this information by adjusting a number of sliders on the calculator. The details required include the size of the tanker being used (gallons), the working width of the applicator system (metres), the time taken to empty the tanker and the targeted application rate. The calculator will then indicate the required forward speed in km/h to achieve the desired rate. The Irish Farmers Journal found this calculator to be one of the most simple available. It removes the guesswork, can be used on your mobile phone and is available for free online.

The Teagasc online slurry spreader calibration calculator is simple and free to use.

Trial

To test the system in a very basic demonstration, we used a 2,750-gallon tanker with an 11,000-litre pump and a nine-metre trailing shoe. When using the splash plate, the average working width of the application was measured at approximately 13.5m, while the time to empty was noted as approximately 6 minutes and 25 seconds.

Next, we trialled applying slurry through the trailing shoe, using the same tanker. The nine-metre trailing shoe distributed the slurry through 40 outlets which were fed by a Vogelsang macerator. Its time to empty was noted as approximately 4 minutes and 25 seconds.

Why did the tanker

empty quicker?

Slurry being applied through the splash plate had to be fed out through the one narrow gap, measured at approximately 55mm wide. Meanwhile, when we moved to the LESS system, the opening feeding the macerator is increased two-fold and in some cases, this goes up three-fold, in addition to far more outlets. The working width is significantly reduced, while the flow of slurry to feed the large number of outlets is increased, so naturally the tanker will empty far quicker.

The point to note is that when using LESS systems, the tractors forward speed needs to be significantly increased to match the splash plate’s application rate. A factor often overlooked by many; forward speed is key to an even application at the correct rate.

Target application rate

Once we had the information we needed, we entered the data into the Teagasc slurry calibration calculator. The calculator advised operating at a forward speed of 3.2km/h when using the splash plate, and over twice that speed of 7km/h when applying slurry with the dribble bar.

Although a 2,750-gallon tanker is larger than what most farmers are running, so too is the 9m trailing shoe. The most common working width LESS system being sold to farmers in Ireland continues to be 7.5m. Despite this, the concept of the increased forward speed remains the same. When moving to a new application method, it is important to ensure that you are applying slurry evenly and at the correct rate.

If your land type, tractor power and hydraulics, the tankers ballast setup and budget allow, we would recommend opting for a wider LESS applicator in a bid to be able to hit the desired application rates at slower forward speeds.

When moving to a LESS application method, ensure that you are applying the slurry evenly and at the correct rate.LESS systems (particularly the common 7.5m attachments) require an increased forward speed to maintain the same application rate as a splash plate.Teagasc have a free online calibration calculator which advises users of the correct forward speed to achieve their desired application rate.The calculator requires the tank size, the working width, the time to empty and the desired application rate, before providing you with the forward speed needed.

Year on year, there is a growing requirement for more and more farmers to transition towards the use of low-emission slurry spreading (LESS) technology to comply with regulations.

This year, another group of farmers will be faced with new slurry-spreading rules. It is estimated that in the region of 15,000 farmers in Ireland may have to change the way in which their slurry is applied in 2025. New rules under the Good Agricultural Practice for Protection of Waters Regulations which have come into effect since 1 January 2025 require farmers with a grassland stocking rate of between 100kg/ha and 129kg/ha organic nitrogen to apply all slurry on their holding (produced and imported) using LESS equipment.

Prior to this, the use of LESS equipment was already mandatory for farmers with a grassland stocking rate of 130kg/ha and higher organic nitrogen (including derogation farmers), pig farmers and for slurry applied to arable lands, where the slurry is not being incorporated into the soil within 24 hours.

Forward speed is key

Farmers and machine drivers relatively new to using LESS applicators such as a dribble bar or a trailing shoe, should be aware that the forward speed when applying slurry through these systems needs to be significantly increased compared when using a traditional splash plate, in order to achieve the same application rate.

If you use a LESS application system for the first time, one of the first things you will notice is how quick you will empty the tanker in comparison to when using the splash plate.

Slurry calibration calculator

A few years ago, Teagasc launched a very basic and easy-to-use online slurry spreader calibration calculator to help farmers and agricultural contractors using tankers to set accurate application rates.

The online calibration calculator requires four key pieces of information in order to determine the forward speed required to apply the desired rate. The user fills in this information by adjusting a number of sliders on the calculator. The details required include the size of the tanker being used (gallons), the working width of the applicator system (metres), the time taken to empty the tanker and the targeted application rate. The calculator will then indicate the required forward speed in km/h to achieve the desired rate. The Irish Farmers Journal found this calculator to be one of the most simple available. It removes the guesswork, can be used on your mobile phone and is available for free online.

The Teagasc online slurry spreader calibration calculator is simple and free to use.

Trial

To test the system in a very basic demonstration, we used a 2,750-gallon tanker with an 11,000-litre pump and a nine-metre trailing shoe. When using the splash plate, the average working width of the application was measured at approximately 13.5m, while the time to empty was noted as approximately 6 minutes and 25 seconds.

Next, we trialled applying slurry through the trailing shoe, using the same tanker. The nine-metre trailing shoe distributed the slurry through 40 outlets which were fed by a Vogelsang macerator. Its time to empty was noted as approximately 4 minutes and 25 seconds.

Why did the tanker

empty quicker?

Slurry being applied through the splash plate had to be fed out through the one narrow gap, measured at approximately 55mm wide. Meanwhile, when we moved to the LESS system, the opening feeding the macerator is increased two-fold and in some cases, this goes up three-fold, in addition to far more outlets. The working width is significantly reduced, while the flow of slurry to feed the large number of outlets is increased, so naturally the tanker will empty far quicker.

The point to note is that when using LESS systems, the tractors forward speed needs to be significantly increased to match the splash plate’s application rate. A factor often overlooked by many; forward speed is key to an even application at the correct rate.

Target application rate

Once we had the information we needed, we entered the data into the Teagasc slurry calibration calculator. The calculator advised operating at a forward speed of 3.2km/h when using the splash plate, and over twice that speed of 7km/h when applying slurry with the dribble bar.

Although a 2,750-gallon tanker is larger than what most farmers are running, so too is the 9m trailing shoe. The most common working width LESS system being sold to farmers in Ireland continues to be 7.5m. Despite this, the concept of the increased forward speed remains the same. When moving to a new application method, it is important to ensure that you are applying slurry evenly and at the correct rate.

If your land type, tractor power and hydraulics, the tankers ballast setup and budget allow, we would recommend opting for a wider LESS applicator in a bid to be able to hit the desired application rates at slower forward speeds.

When moving to a LESS application method, ensure that you are applying the slurry evenly and at the correct rate.LESS systems (particularly the common 7.5m attachments) require an increased forward speed to maintain the same application rate as a splash plate.Teagasc have a free online calibration calculator which advises users of the correct forward speed to achieve their desired application rate.The calculator requires the tank size, the working width, the time to empty and the desired application rate, before providing you with the forward speed needed.

SHARING OPTIONS