specific Earlier this summer, Claas announced its all-new Jaguar 1000 lineup.

Having pushed the current generation 900 to the limit in terms of power and throughput, the company returned to the drawing board in search of new limits.

The result was a new platform and a new starting point, with scope for future growth. To get here, everything aside from the MAN V12 engine and cab controls, has been redesigned or enlarged.

At the European launch in Ferdinandshof, located in Germany’s northeast, Conor Trimble UK and Irish Jaguar product manager pointed out that the new series contains 90% new components and a 20% larger feed channel right the way through to the spout.

Upgrades include a higher capacity pickup, feed rollers, chopping cylinder, crop accelerator and a larger spout. The result is a claimed throughput of up to 480t/hour in maize.

To put the scale of the development into context, Claas shared an interesting comparison, where a Jaguar 1200 achieved 24.9% higher throughput than a Jaguar 990 in whole-crop wheat, while using 15% less fuel.

1000+hp journey

With more than 50 years of forager development, increasing power and capacity has long been Claas’s goal. A 1,000hp+ Jaguar series has been decades in the making. In 1999, Claas tested a crude looking 1,130hp dual-engine test mule, running a Mercedes V8 and straight-six engine. It was fitted with a standard 750mm chopping cylinder.

The Jaguar 1000 nods to the earlier generation Jaguar models with the green spout and 'boxy' design style with new 'Y' styling on the side panels.

In 2007, a larger 1,250hp test model powered by twin V8 Mercedes engines was tested, this time powering a much wider 1,100mm wide chopping cylinder.

Roll the clock forward 18 years, Claas has brought to market what has been one of its largest ever development projects, at a time it now feels is right, based on market trends. The new four-model lineup includes the Jaguar 1080 (850hp), 1090 (935hp), 1100 (1,020hp) and 1200 (1,110hp).

Despite the increase in performance, the drive concept has been fully integrated to maintain the same external width as the Jaguar 800 and 900, while a new family of headers has been developed to match the higher throughput.

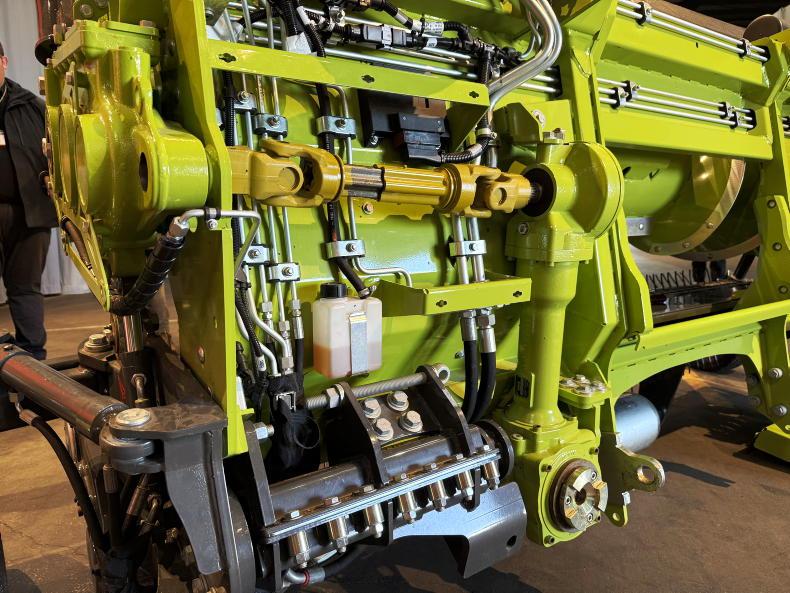

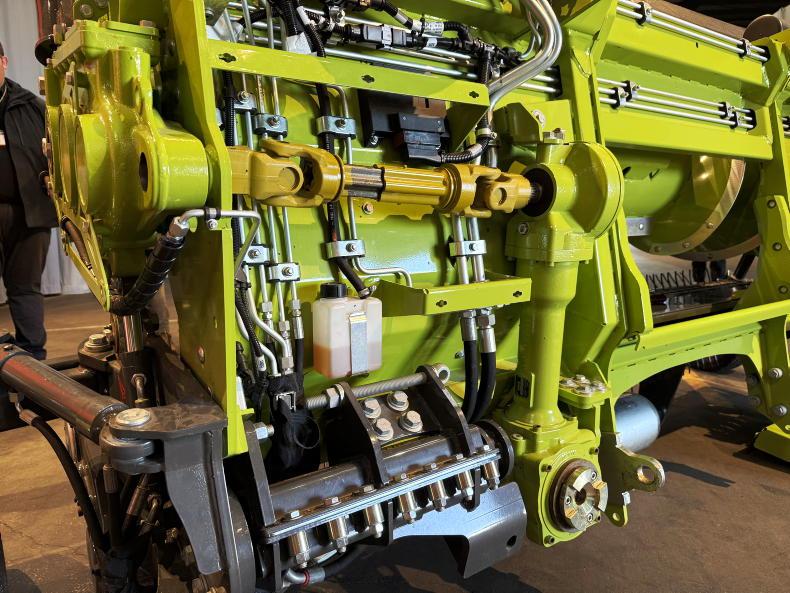

Hydraulic pre-compression

Before reaching the 910mm wide chopping cylinder, crop is dealt with by the new pre-compression system. Here, four 880mm wide pre-compression rollers and a fully hydraulic pre-compression system work to achieve uniform crop flow regardless of the layer thickness.

Claas says this delivers consistent feeding of the V-Flex chopping cylinder for maximum throughput and chop quality.

The new pre-compression system features four rollers which work with a fully hydraulic pre-compression system.

For maintenance, the pre-compression rollers can be raised hydraulically, while the Quick Access system allows the entire pre-compression unit to swivel out up to 80° in minutes. The header’s tilting frame with hydraulic centring is integrated into the pre-compression unit.

New V-Flex chopping cylinder

The Jaguar 1000 is equipped as standard with the V-Flex chopping cylinder, available with 20, 24, 28 and 36 knives. While, based on the Jaguar 900 design, the cylinder is significantly wider at 910mm compared with 750mm.

Knives, fastened from above with three bolts, automatically align in the drum stars. Setting the knives to the shear bar and readjusting them is not necessary. An optional water injection system is now offered to reduce fire risks when sharpening the chopping cylinder.

The pre-compression unit can be swiveled out up to 80 degrees for maintenance.

Being a blank canvas design, Claas is confident that this is only the start for the Jaguar 1000 in terms of horsepower and performance.

“When we set out to break the 1,000hp, we wanted to build a machine that was truly made for 1,000hp. With that, we wanted to build in headroom for future growth if and when its needed,” Conor Trimble explained.

The Jaguar 1000 can be equipped with the new Multi Crop Cracker XL, available either as the MCC XL Classic with a sawtooth profile with various teeth and a 40% speed difference, or as the MCC XL Shredlage with a 50% speed difference. It offers a large contact surface between the wider rollers, with a 310mm roller diameter (250mm in Jaguar 900).

New accelerator

The Jaguar 1000 adopts a new accelerator philosophy. In doing so, clearance between knives and wear liners has increased from 6mm-9mm to17mm to eliminate any potential bottlenecks and better utilise the additional horsepower.

The 900 series V-Flex chopping cylinder (left) vs the 1000 series V-Flex chopping cylinder.

Changes inside the grass box help crop acceleration up the spout, with the accelerator scale now ranging from 1 to 60 (1mm-60mm), up from 1-10 on the Jaguar 900.

This is achieved by moving the paddle wheel relative to the fixed back plate. A hydraulically powered bottom door also improves access when clearing blockages.

The familiar 24.24l MAN V12 engine benefits from a new cooling pack to deal with the increased power outputs.

One of our first impression was the sheer size of the spout. It is 20% larger and reshaped for improved performance. Depending on the size fitted, it is hydraulically foldable, with a quickly interchangeable end piece to suit the chosen header. Five spout options are offered; XS, S, M, XL, and 2XL.

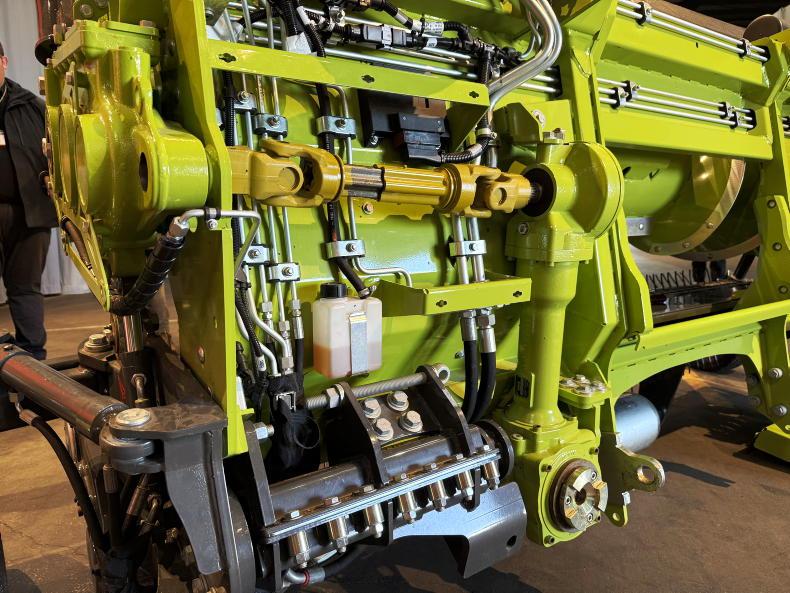

New drive concept

In the 1000 series, power from the 24L MAN V12 engine is transferred via a powerband to the chopping cylinder, throwing accelerator, and corn cracker. The engine is AdBlue only, without an EGR valve or DPF.

A flat radiator screen replaces the previous conical design, creating more space for fitting and removing the now larger processor. Opposite to the Jaguar 900, the radiator screens hoover arm remains fixed and instead the screen rotates.

The familiar 24.24l MAN V12 engine benefits from a new cooling pack to deal with the increased power outputs.

A rear-left pump transfer case drives the hydraulic motors powering the ground drive, pre-compression rollers, and two independent variable attachment drives. To suit specific harvest conditions, the independent variable attachment drives, allow independent speed adjustment of the pickup reel and intake auger on the Pick Up header range and the knife, transport discs and feed drums on the Orbis maize headers.

During road travel, only the ground drive is active, the drive for the chopping unit, intake and front attachments is decoupled in the pump transfer case.

The new pickup range of headers is specific to the Jaguar 1000 and is fully mechanically driven via gearboxes and PTO shafts.

Four-wheel drive and intelligent all-wheel management is standard while front and rear differential locks are optional as is a tyre pressure control system for the front and rear axles.

Remaining within an overall transport width of 3.3m, the drive design allows for 800/70 R42 (2.05m) front tyres as standard (38in standard on Jaguar 900), with the largest possible front tyre being 900/60 R42 (2.15m). In addition, tyres up to 710/60 R30 can be selected for the rear axle.

Quieter cab

The Jaguar 1000 cab is larger and similar to that fitted to the Lexion combines. Multiple seat options are available, including a swivelling heated and ventilated leather option.

The right-hand armrest features the familiar Cmotion ground speed control lever and 12in Cebis terminal. The GPS Pilot Cemis 1200 is available for auto steering and smart farming tasks that fall under the Claas Connect umbrella, such as fleet management, live yield data, etc.

The quick release multi-coupler connects all electric and hydraulic supplies.

Optional joystick steering offers two modes and adjustable intensity for field use, with three armrest buttons for assignable functions like raising the discharge spout, horn, or work lights.

Nutrimeter

With the new series, Claas has introduced the option of its latest NIR 2.0 system. Through real-time determination of the dry matter content, chop length can be automatically adjusted based on the desired length.

In addition to dry matter content, the Nutrimeter also records other ingredients, such as starch, crude protein and sugar content. A new feature is the mobile use of the NIR sensor as an IsoBus device, which enables easy conversion from machine to machine.

The five-tine bar cam track pickup remains, however, it is now integrated into the gearbox drive.

The data collected by the Nutrimeter is stored, analysed and put together with the machine data from the Jaguar in Claas connect, the firm’s online machine platform.

New generation pick-up

To match its output, Claas has developed a range of front attachments specific to the new Jaguar, leaving the current range of headers for the 800 and 900 series uncompatible.

The new Pick Up features independent variable speed drives for the reel and auger, as already mentioned. Both the crop roller and main auger are 20% larger than on the Jaguar 900 Pick Up too.

For the first time on a Claas pickup reel, there are no chain drives or slip clutches; the tines and auger are driven mechanically via PTO drive shafts and gearboxes. While the five tine bar cam track pickup remains, it is now integrated into an oil lubricated gearbox drive.

The new Pick Up header features nylon strippers and removable tine bars.

A dog-clutch quick-coupler automatically engages once the head is fitted, transferring the mechanical drive to the pickup, while the multi-coupler connects hydraulics and electrics. Cemos Auto Header automatically adjusts auger and pickup speeds to the length of the cut and forward speed. With its constant hydraulic pre-press pressure, Claas says the intake auger ensures even crop flow to the feeder unit

In addition, the strippers are now quick release and made from nylon, while tine bars are also easily removable, leaving tine replacement easy and with minimal tools. A new range of Orbis heads are available with working widths of 9m,10.5m and 12m (12,14 and 16 rows). As already mentioned, feature of which include an independent variable drive of the knife and transport discs, as well as the feed drums.

From the quick coupler power is transferred through a series of shafts and gearboxes to power the main auger and reel.

specific Earlier this summer, Claas announced its all-new Jaguar 1000 lineup.

Having pushed the current generation 900 to the limit in terms of power and throughput, the company returned to the drawing board in search of new limits.

The result was a new platform and a new starting point, with scope for future growth. To get here, everything aside from the MAN V12 engine and cab controls, has been redesigned or enlarged.

At the European launch in Ferdinandshof, located in Germany’s northeast, Conor Trimble UK and Irish Jaguar product manager pointed out that the new series contains 90% new components and a 20% larger feed channel right the way through to the spout.

Upgrades include a higher capacity pickup, feed rollers, chopping cylinder, crop accelerator and a larger spout. The result is a claimed throughput of up to 480t/hour in maize.

To put the scale of the development into context, Claas shared an interesting comparison, where a Jaguar 1200 achieved 24.9% higher throughput than a Jaguar 990 in whole-crop wheat, while using 15% less fuel.

1000+hp journey

With more than 50 years of forager development, increasing power and capacity has long been Claas’s goal. A 1,000hp+ Jaguar series has been decades in the making. In 1999, Claas tested a crude looking 1,130hp dual-engine test mule, running a Mercedes V8 and straight-six engine. It was fitted with a standard 750mm chopping cylinder.

The Jaguar 1000 nods to the earlier generation Jaguar models with the green spout and 'boxy' design style with new 'Y' styling on the side panels.

In 2007, a larger 1,250hp test model powered by twin V8 Mercedes engines was tested, this time powering a much wider 1,100mm wide chopping cylinder.

Roll the clock forward 18 years, Claas has brought to market what has been one of its largest ever development projects, at a time it now feels is right, based on market trends. The new four-model lineup includes the Jaguar 1080 (850hp), 1090 (935hp), 1100 (1,020hp) and 1200 (1,110hp).

Despite the increase in performance, the drive concept has been fully integrated to maintain the same external width as the Jaguar 800 and 900, while a new family of headers has been developed to match the higher throughput.

Hydraulic pre-compression

Before reaching the 910mm wide chopping cylinder, crop is dealt with by the new pre-compression system. Here, four 880mm wide pre-compression rollers and a fully hydraulic pre-compression system work to achieve uniform crop flow regardless of the layer thickness.

Claas says this delivers consistent feeding of the V-Flex chopping cylinder for maximum throughput and chop quality.

The new pre-compression system features four rollers which work with a fully hydraulic pre-compression system.

For maintenance, the pre-compression rollers can be raised hydraulically, while the Quick Access system allows the entire pre-compression unit to swivel out up to 80° in minutes. The header’s tilting frame with hydraulic centring is integrated into the pre-compression unit.

New V-Flex chopping cylinder

The Jaguar 1000 is equipped as standard with the V-Flex chopping cylinder, available with 20, 24, 28 and 36 knives. While, based on the Jaguar 900 design, the cylinder is significantly wider at 910mm compared with 750mm.

Knives, fastened from above with three bolts, automatically align in the drum stars. Setting the knives to the shear bar and readjusting them is not necessary. An optional water injection system is now offered to reduce fire risks when sharpening the chopping cylinder.

The pre-compression unit can be swiveled out up to 80 degrees for maintenance.

Being a blank canvas design, Claas is confident that this is only the start for the Jaguar 1000 in terms of horsepower and performance.

“When we set out to break the 1,000hp, we wanted to build a machine that was truly made for 1,000hp. With that, we wanted to build in headroom for future growth if and when its needed,” Conor Trimble explained.

The Jaguar 1000 can be equipped with the new Multi Crop Cracker XL, available either as the MCC XL Classic with a sawtooth profile with various teeth and a 40% speed difference, or as the MCC XL Shredlage with a 50% speed difference. It offers a large contact surface between the wider rollers, with a 310mm roller diameter (250mm in Jaguar 900).

New accelerator

The Jaguar 1000 adopts a new accelerator philosophy. In doing so, clearance between knives and wear liners has increased from 6mm-9mm to17mm to eliminate any potential bottlenecks and better utilise the additional horsepower.

The 900 series V-Flex chopping cylinder (left) vs the 1000 series V-Flex chopping cylinder.

Changes inside the grass box help crop acceleration up the spout, with the accelerator scale now ranging from 1 to 60 (1mm-60mm), up from 1-10 on the Jaguar 900.

This is achieved by moving the paddle wheel relative to the fixed back plate. A hydraulically powered bottom door also improves access when clearing blockages.

The familiar 24.24l MAN V12 engine benefits from a new cooling pack to deal with the increased power outputs.

One of our first impression was the sheer size of the spout. It is 20% larger and reshaped for improved performance. Depending on the size fitted, it is hydraulically foldable, with a quickly interchangeable end piece to suit the chosen header. Five spout options are offered; XS, S, M, XL, and 2XL.

New drive concept

In the 1000 series, power from the 24L MAN V12 engine is transferred via a powerband to the chopping cylinder, throwing accelerator, and corn cracker. The engine is AdBlue only, without an EGR valve or DPF.

A flat radiator screen replaces the previous conical design, creating more space for fitting and removing the now larger processor. Opposite to the Jaguar 900, the radiator screens hoover arm remains fixed and instead the screen rotates.

The familiar 24.24l MAN V12 engine benefits from a new cooling pack to deal with the increased power outputs.

A rear-left pump transfer case drives the hydraulic motors powering the ground drive, pre-compression rollers, and two independent variable attachment drives. To suit specific harvest conditions, the independent variable attachment drives, allow independent speed adjustment of the pickup reel and intake auger on the Pick Up header range and the knife, transport discs and feed drums on the Orbis maize headers.

During road travel, only the ground drive is active, the drive for the chopping unit, intake and front attachments is decoupled in the pump transfer case.

The new pickup range of headers is specific to the Jaguar 1000 and is fully mechanically driven via gearboxes and PTO shafts.

Four-wheel drive and intelligent all-wheel management is standard while front and rear differential locks are optional as is a tyre pressure control system for the front and rear axles.

Remaining within an overall transport width of 3.3m, the drive design allows for 800/70 R42 (2.05m) front tyres as standard (38in standard on Jaguar 900), with the largest possible front tyre being 900/60 R42 (2.15m). In addition, tyres up to 710/60 R30 can be selected for the rear axle.

Quieter cab

The Jaguar 1000 cab is larger and similar to that fitted to the Lexion combines. Multiple seat options are available, including a swivelling heated and ventilated leather option.

The right-hand armrest features the familiar Cmotion ground speed control lever and 12in Cebis terminal. The GPS Pilot Cemis 1200 is available for auto steering and smart farming tasks that fall under the Claas Connect umbrella, such as fleet management, live yield data, etc.

The quick release multi-coupler connects all electric and hydraulic supplies.

Optional joystick steering offers two modes and adjustable intensity for field use, with three armrest buttons for assignable functions like raising the discharge spout, horn, or work lights.

Nutrimeter

With the new series, Claas has introduced the option of its latest NIR 2.0 system. Through real-time determination of the dry matter content, chop length can be automatically adjusted based on the desired length.

In addition to dry matter content, the Nutrimeter also records other ingredients, such as starch, crude protein and sugar content. A new feature is the mobile use of the NIR sensor as an IsoBus device, which enables easy conversion from machine to machine.

The five-tine bar cam track pickup remains, however, it is now integrated into the gearbox drive.

The data collected by the Nutrimeter is stored, analysed and put together with the machine data from the Jaguar in Claas connect, the firm’s online machine platform.

New generation pick-up

To match its output, Claas has developed a range of front attachments specific to the new Jaguar, leaving the current range of headers for the 800 and 900 series uncompatible.

The new Pick Up features independent variable speed drives for the reel and auger, as already mentioned. Both the crop roller and main auger are 20% larger than on the Jaguar 900 Pick Up too.

For the first time on a Claas pickup reel, there are no chain drives or slip clutches; the tines and auger are driven mechanically via PTO drive shafts and gearboxes. While the five tine bar cam track pickup remains, it is now integrated into an oil lubricated gearbox drive.

The new Pick Up header features nylon strippers and removable tine bars.

A dog-clutch quick-coupler automatically engages once the head is fitted, transferring the mechanical drive to the pickup, while the multi-coupler connects hydraulics and electrics. Cemos Auto Header automatically adjusts auger and pickup speeds to the length of the cut and forward speed. With its constant hydraulic pre-press pressure, Claas says the intake auger ensures even crop flow to the feeder unit

In addition, the strippers are now quick release and made from nylon, while tine bars are also easily removable, leaving tine replacement easy and with minimal tools. A new range of Orbis heads are available with working widths of 9m,10.5m and 12m (12,14 and 16 rows). As already mentioned, feature of which include an independent variable drive of the knife and transport discs, as well as the feed drums.

From the quick coupler power is transferred through a series of shafts and gearboxes to power the main auger and reel.

SHARING OPTIONS