Operating a suckler farm and working full time off farm is a challenging prospect and one that in today’s environment requires efficient handling facilities to minimise the labour input required. This was the focus of last week’s Teagasc cattle handling facilities event on the farm of John Flynn, Curraghduff, Newbridge, Ballinasloe, Co Galway.

John runs a 24-cow suckler-to-weanling store enterprise with his wife Joanne and children Sarah and James while working full time off farm. Sarah also has a dairy-beef enterprise, purchasing and rearing 10 calves annually and bringing through to beef. The farm has built up an efficient housing and handling system in recent years with a new cattle handling unit and investment in mobile handling facilities the most recent investment.

The farm’s handling facility for over a decade was a cattle crush spanning along the back of a creep area which was originally designed for handling cows at calving or small numbers.

While John says the unit worked OK, it did have limitations for the smooth flow of animals while working with animals in the race while there is animals around you in the pen was also far from ideal.

John adds that the challenge of working with animals limited the appetite for regular weighing and performance

recording.

While the new unit is only in operation a few months, the benefits are already clear.

About 90 animals moved through the unit in less than an hour for the herd’s annual TB test while the weighing of animals is an easy task and will open up the opportunity of monitoring performance much more frequently.

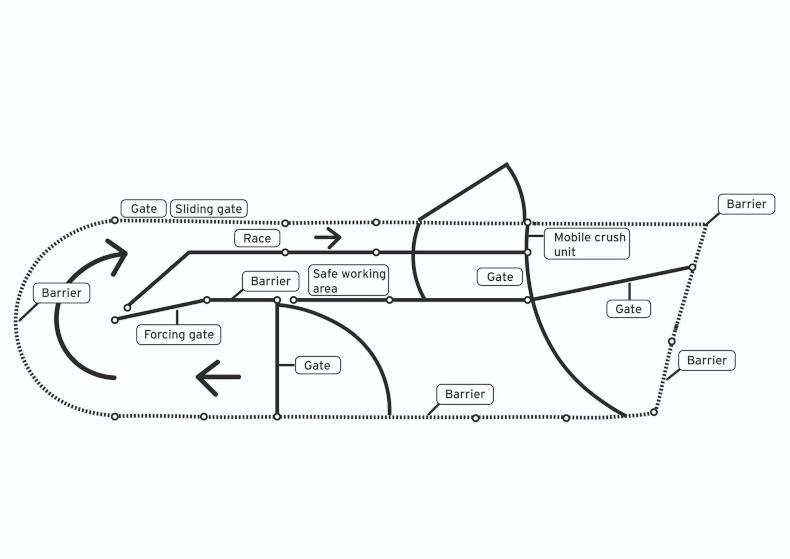

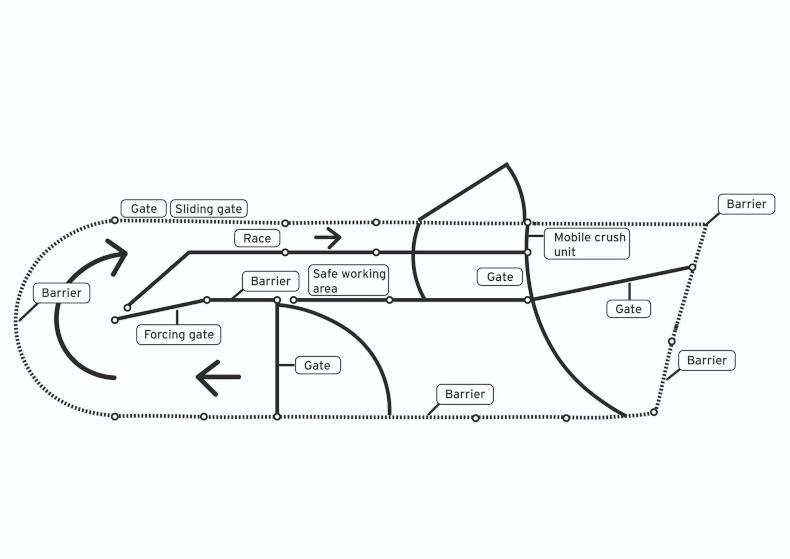

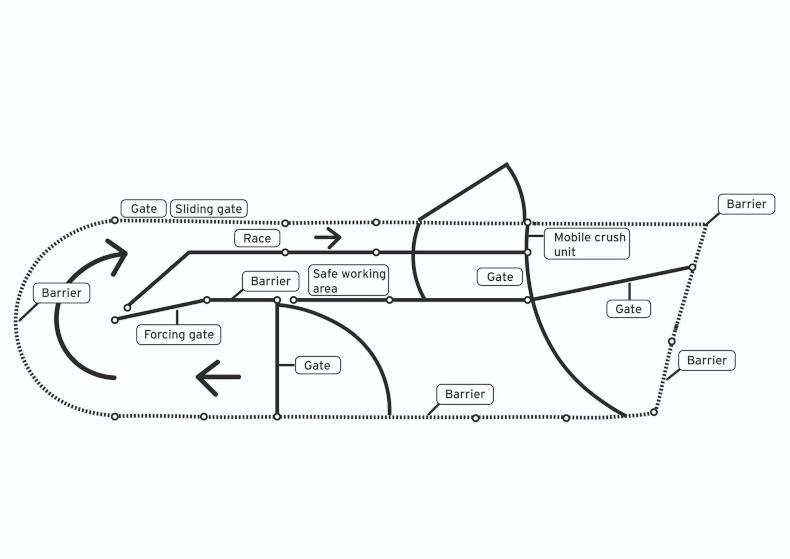

As can be seen in the main picture and Figure 1, the unit comprises a holding pen which can be divided in the middle and a curved section with a forcing gate.

The premises of the curved unit is that animals move smoothly where they are returning in the direction from where they came.

John and Joanne Flynn with their children Sarah and James, hosts of the recent Teagasc cattle handling event.

John explains that a lot of thought was put in to the unit and applauded the experience and expertise of Niall Barrett, Barrett Engineering, in delivering a unit that had safety to the fore. There is a safe animal handling area between the holding pen and race. The holding pen can be accessed easily by a safe entry and exit point with the gate dividing the holding pen closing at this point allowing safe access to either pen.

A mobile crush unit sits at the front of the race and just behind this are two small gates which John says also works excellently in allowing safe passage without having to enter any of the animal holding areas.

These also work excellently in allowing restrained animals in the mobile unit to be artificially inseminated, scanned etc safe in the knowledge that animals in the race cannot come in contact.

The mobile crush unit has a built in weighing platform and a Trutest reader with Bluetooth technology. John explains that he can weigh and upload weights to ICBF in the press of a button from his phone.

The mobile crush unit sits on front of the fixed race and can be moved when required.

The head gate is fitted with a head scoop while there is also a leg hoist fitted to the unit. The mobile unit can be moved during the summer months to other land blocks with land fragmentation a challenge and used with mobile penning.

The forcing gate is already a firm favourite with the automatic locking mechanism preventing animals from pushing the gate back on top of the operator. The floor of the unit was already 90% in place as it was an existing concrete apron on front of a slatted unit. A small area of concrete was added and a channel was inserted in this section to divert any soiled water to an existing dungstead and tank. When not in use, the rainfall can be diverted to a clean water run-off.

The mobile handling facilities includes the mobile weighing scales, leg hoist and head scoop while 45m of mobile penning was also purchased.

The TAMS reference cost of this element was almost €7,000 ex-VAT with the actual cost close to €1,650 ex-VAT higher equating to grant aid of about 48.5%.

The fixed unit has not been submitted for TAMS payment with a few costs still to confirm. It is estimated that the total cost of the unit including erection and associated concrete works will be upwards of €10,000 ex VAT with TAMS grant aid expected to be in the region of 50% of costs.

The circular forcing pen and gate gives great power to the operator to move animals safely with the gate fixed in place every few inches.

John explains that the cost can be justified not only in the labour saving element but more so in the safety that it provides.

“I am working full-time off farm. If I break a hand, leg etc – which I had a lot of near misses with the old crush – and am out of work for six months or left with a long-term injury then the costs would be a multiple of the investment.

"Suckler farming is becoming increasingly reliant on part-time operators and they will only be enticed if the system is manageable.

"Sarah can do any of the tasks that have to be done easily. I am also fortunate to be able to rely on help from great neighbours and my father, Vincent, when cows are calving and cattle need to be handled, and you want to be sure that you have their interests looked after.”

Cattle handling facilities tips

Seamus Nolan, Teagasc business and technology adviser based in Castlerea, Co Roscommon, delivered tips for farmers applying for grant aid for cattle handling facilities under TAMS III.

Enclosure boundary

The enclosure of cattle handling facilities must comprise a mass concrete wall or barrier. For example, a feed barrier or a shed wall built from blocks will not suffice. The race or cattle crush can form the barrier on one side of the enclosure with gates (as per specification) sufficing at the point of entry to the enclosure.

Mobile head units

Seamus told farmers that the Department will allow a mobile cattle crush unit to form part of a permanent enclosure. The unit is eligible once it sits in front of the race section. The unit must have a head gate that can restrain animals. Where applying for grant aid this must be applied for under the heading of mobile cattle crush which has a reference cost of €2,272.03.

Crush exit

There must be a 4m clearing for animals to exit the crush unit, ie, 4m from the head gate to a barrier/wall section. This can be reduced to 3m where the enclosure facing the head gate is a gate or sliding door which can be opened.

Reference costs

Seamus told farmers that the Department’s reference cost cover standard items. In reference to the mobile cattle crush unit he stated that “the Department have costed [this] without all the bells and whistles”, and that where units cost above the reference costs it will be up to farmers to cover this portion in full.

Revenue v TAMS

Seamus also cautioned farmers that there is a difference between what the Department of Agriculture defines as fixed and mobile equipment and what revenue defines as such in terms of being able to claim back VAT on.

Farmers need to take account of this in funding the investment as not being in a position to claim back vat may significantly increase the cost of the investment.

The suckler-to-weanling/store enterprise is impressive with a 374-day calving interval and calves per cow figure of 0.98 calves putting it among the top performing herds in the county.

Mortality at birth and 28 days was zero for the last two seasons.

John explains that sires are selected to complement or address a cow’s strengths and weaknesses with calving ease a big consideration and delivering in low mortality at birth.

Calving takes place from January to April with artificial insemination used for nine weeks and a stock bull used for a maximum of six weeks.

A cross section of the race with two small gates for ease of access when inseminating, scanning cows or completing other tasks or simly entering and exiting the safe working area.

John adds that the focus at present is to reduce cow size marginally with some older cows in the herd weighing upwards of 800kg.

The main breed of choice is Limousin with Salers genetics used in the last year for heifers and Belgian Blue for an odd cow that suits to produce high-value weanlings.

Padraig Glynn, Teagasc business and technology adviser, explained that the herd is also well above the national average when it comes to calving at 22 to 26 months or age with 75% of first calvers falling within this age range compared to 19% nationally.

The mobile crush unit incorporates a weighing platform.

TruTest technology allows weights to be recorded automatically and transferred via bluetooth to the operators phone.

The headscoop in position when not in use.

The curved unit promotes easier movement of animals.

Mobile penning can be used to handle cattle on fragmented land parcels. John and Joanne Flynn with their children Sarah and James, hosts of the recent Teagasc cattle handling event.

The external perimeter of the unit is a fixed barrier.

The holding pen area can be divided in two for different batches of animals.

Operating a suckler farm and working full time off farm is a challenging prospect and one that in today’s environment requires efficient handling facilities to minimise the labour input required. This was the focus of last week’s Teagasc cattle handling facilities event on the farm of John Flynn, Curraghduff, Newbridge, Ballinasloe, Co Galway.

John runs a 24-cow suckler-to-weanling store enterprise with his wife Joanne and children Sarah and James while working full time off farm. Sarah also has a dairy-beef enterprise, purchasing and rearing 10 calves annually and bringing through to beef. The farm has built up an efficient housing and handling system in recent years with a new cattle handling unit and investment in mobile handling facilities the most recent investment.

The farm’s handling facility for over a decade was a cattle crush spanning along the back of a creep area which was originally designed for handling cows at calving or small numbers.

While John says the unit worked OK, it did have limitations for the smooth flow of animals while working with animals in the race while there is animals around you in the pen was also far from ideal.

John adds that the challenge of working with animals limited the appetite for regular weighing and performance

recording.

While the new unit is only in operation a few months, the benefits are already clear.

About 90 animals moved through the unit in less than an hour for the herd’s annual TB test while the weighing of animals is an easy task and will open up the opportunity of monitoring performance much more frequently.

As can be seen in the main picture and Figure 1, the unit comprises a holding pen which can be divided in the middle and a curved section with a forcing gate.

The premises of the curved unit is that animals move smoothly where they are returning in the direction from where they came.

John and Joanne Flynn with their children Sarah and James, hosts of the recent Teagasc cattle handling event.

John explains that a lot of thought was put in to the unit and applauded the experience and expertise of Niall Barrett, Barrett Engineering, in delivering a unit that had safety to the fore. There is a safe animal handling area between the holding pen and race. The holding pen can be accessed easily by a safe entry and exit point with the gate dividing the holding pen closing at this point allowing safe access to either pen.

A mobile crush unit sits at the front of the race and just behind this are two small gates which John says also works excellently in allowing safe passage without having to enter any of the animal holding areas.

These also work excellently in allowing restrained animals in the mobile unit to be artificially inseminated, scanned etc safe in the knowledge that animals in the race cannot come in contact.

The mobile crush unit has a built in weighing platform and a Trutest reader with Bluetooth technology. John explains that he can weigh and upload weights to ICBF in the press of a button from his phone.

The mobile crush unit sits on front of the fixed race and can be moved when required.

The head gate is fitted with a head scoop while there is also a leg hoist fitted to the unit. The mobile unit can be moved during the summer months to other land blocks with land fragmentation a challenge and used with mobile penning.

The forcing gate is already a firm favourite with the automatic locking mechanism preventing animals from pushing the gate back on top of the operator. The floor of the unit was already 90% in place as it was an existing concrete apron on front of a slatted unit. A small area of concrete was added and a channel was inserted in this section to divert any soiled water to an existing dungstead and tank. When not in use, the rainfall can be diverted to a clean water run-off.

The mobile handling facilities includes the mobile weighing scales, leg hoist and head scoop while 45m of mobile penning was also purchased.

The TAMS reference cost of this element was almost €7,000 ex-VAT with the actual cost close to €1,650 ex-VAT higher equating to grant aid of about 48.5%.

The fixed unit has not been submitted for TAMS payment with a few costs still to confirm. It is estimated that the total cost of the unit including erection and associated concrete works will be upwards of €10,000 ex VAT with TAMS grant aid expected to be in the region of 50% of costs.

The circular forcing pen and gate gives great power to the operator to move animals safely with the gate fixed in place every few inches.

John explains that the cost can be justified not only in the labour saving element but more so in the safety that it provides.

“I am working full-time off farm. If I break a hand, leg etc – which I had a lot of near misses with the old crush – and am out of work for six months or left with a long-term injury then the costs would be a multiple of the investment.

"Suckler farming is becoming increasingly reliant on part-time operators and they will only be enticed if the system is manageable.

"Sarah can do any of the tasks that have to be done easily. I am also fortunate to be able to rely on help from great neighbours and my father, Vincent, when cows are calving and cattle need to be handled, and you want to be sure that you have their interests looked after.”

Cattle handling facilities tips

Seamus Nolan, Teagasc business and technology adviser based in Castlerea, Co Roscommon, delivered tips for farmers applying for grant aid for cattle handling facilities under TAMS III.

Enclosure boundary

The enclosure of cattle handling facilities must comprise a mass concrete wall or barrier. For example, a feed barrier or a shed wall built from blocks will not suffice. The race or cattle crush can form the barrier on one side of the enclosure with gates (as per specification) sufficing at the point of entry to the enclosure.

Mobile head units

Seamus told farmers that the Department will allow a mobile cattle crush unit to form part of a permanent enclosure. The unit is eligible once it sits in front of the race section. The unit must have a head gate that can restrain animals. Where applying for grant aid this must be applied for under the heading of mobile cattle crush which has a reference cost of €2,272.03.

Crush exit

There must be a 4m clearing for animals to exit the crush unit, ie, 4m from the head gate to a barrier/wall section. This can be reduced to 3m where the enclosure facing the head gate is a gate or sliding door which can be opened.

Reference costs

Seamus told farmers that the Department’s reference cost cover standard items. In reference to the mobile cattle crush unit he stated that “the Department have costed [this] without all the bells and whistles”, and that where units cost above the reference costs it will be up to farmers to cover this portion in full.

Revenue v TAMS

Seamus also cautioned farmers that there is a difference between what the Department of Agriculture defines as fixed and mobile equipment and what revenue defines as such in terms of being able to claim back VAT on.

Farmers need to take account of this in funding the investment as not being in a position to claim back vat may significantly increase the cost of the investment.

The suckler-to-weanling/store enterprise is impressive with a 374-day calving interval and calves per cow figure of 0.98 calves putting it among the top performing herds in the county.

Mortality at birth and 28 days was zero for the last two seasons.

John explains that sires are selected to complement or address a cow’s strengths and weaknesses with calving ease a big consideration and delivering in low mortality at birth.

Calving takes place from January to April with artificial insemination used for nine weeks and a stock bull used for a maximum of six weeks.

A cross section of the race with two small gates for ease of access when inseminating, scanning cows or completing other tasks or simly entering and exiting the safe working area.

John adds that the focus at present is to reduce cow size marginally with some older cows in the herd weighing upwards of 800kg.

The main breed of choice is Limousin with Salers genetics used in the last year for heifers and Belgian Blue for an odd cow that suits to produce high-value weanlings.

Padraig Glynn, Teagasc business and technology adviser, explained that the herd is also well above the national average when it comes to calving at 22 to 26 months or age with 75% of first calvers falling within this age range compared to 19% nationally.

The mobile crush unit incorporates a weighing platform.

TruTest technology allows weights to be recorded automatically and transferred via bluetooth to the operators phone.

The headscoop in position when not in use.

The curved unit promotes easier movement of animals.

Mobile penning can be used to handle cattle on fragmented land parcels. John and Joanne Flynn with their children Sarah and James, hosts of the recent Teagasc cattle handling event.

The external perimeter of the unit is a fixed barrier.

The holding pen area can be divided in two for different batches of animals.

SHARING OPTIONS