Two Offaly-based apprentices have joined the Tullamore Dew cooperage – which reopened last year – becoming the first coopers trained at Tullamore Dew in 66 years. The Tullamore Dew Irish whiskey distillery was first established in 1829 but ceased production on the Offaly site in 1954. It reopened in Tullamore in 2014. Between 1954 and 2014, Tullamore Dew sourced their products from other distilleries such as Irish Distillers.

Dylan Healion and Corey Bracken have begun a four-year apprenticeship in Tullamore Dew. The ancient craft of coopering involves making and repairing barrels and casks used to store alcohol. Until now, the craft had nearly died out in Ireland but Tullamore Dew are attempting to keep the tradition alive.

A rarity

Dylan and Corey account for two of only four cooper apprentices in Ireland and will soon join the ranks of only five qualified coopers in a nation with 38 distilleries. The apprentices were hired due to their appreciation of the heritage, knowledge and skills required to keep the coopering tradition alive. Upon completion of the apprenticeship, they will receive their qualification under the National Cooper Federation.

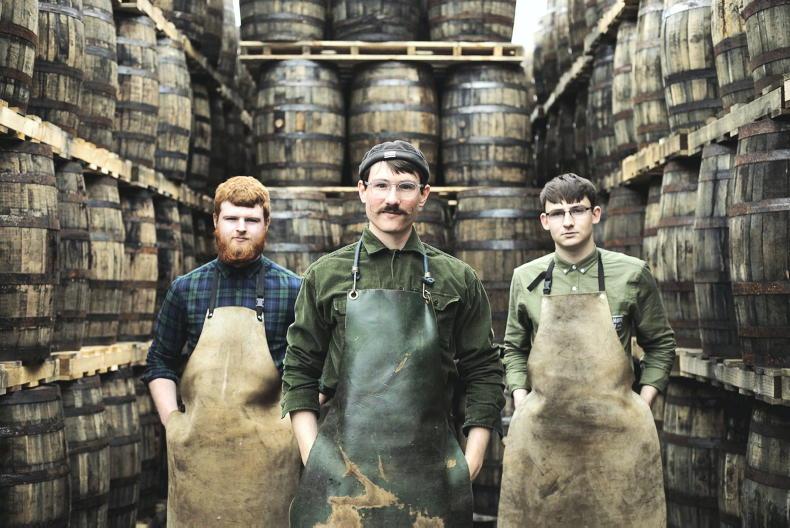

Corey Bracken, Dylan Healion and Enguerrand Vandenbossche at the Tullamore Dew Cooperage. \ Hazel Coonagh

The apprentices are trained under the watchful eye of Enguerrand Vandenbossche, Tullamore Dew’s head cooper. Enguerrand has amassed a decade of experience in the area. First trained in France in champagne cooperage, Enguerrand then worked as a cooper throughout Normandy for cider, calvados, cognac and wine. He later worked in Scotland, before moving to Ireland to take the opportunity as head cooper with Tullamore Dew.

The apprenticeship will teach Dylan and Corey the cooper trade; repairing barrels to store whiskey. Up to 80% of the character of a whiskey comes from the cask, therefore coopers are extremely important to the distilling process. Before the cask production facility reopened, there was only one cooperage in Ireland and the majority of Irish barrels were sent for repair to Scotland. The re-establishment of the cooperage at Tullamore Dew will continue the tradition and allow for barrel repair for the growing whiskey trade in Ireland.

Irish Country Living spoke with Dylan, Corey and Enguerrand about this unique apprenticeship.

The apprentices are both local to the distillery: Dylan hails from Kilurin and Corey is from Tullamore. Corey outlined the benefits of availing of the unique opportunity in his home county. “There’s no travelling. I only live 10 minutes down the road.”

Dylan described the apprenticeship in Tullamore as “a once-in-a-lifetime opportunity; a chance you wouldn’t get anywhere else”. Speaking about why he chose to pursue a career in cooperage, Dylan says:

“It’s a great trade – it’s very traditional, something that hasn’t changed for centuries.”

Enguerrand Vandenbossche working at the Tullamore Dew Cooperage. \ Hazel Coonagh

Dylan was working in Tullamore as a bottler when he first heard of the apprenticeship opportunity. He worked for a day with Enguerrand to get a taste for the industry, and researched the role before applying for the apprenticeship.

Corey was also working as a bottler with Tullamore Dew when the apprenticeship opportunity arose. Corey says he “really enjoyed working with the company and wanted to go for the cooperage ever since I started”.

A great achievement

Corey described it as a great achievement, having a unique apprenticeship, and outlined that he would love to see it growing, with more apprentices doing this kind of trade. “Hopefully in Ireland, it will pick up and there will be more coopers.”

Enguerrand outlined that he was working for William Grant & Sons in Scotland, the owners of Tullamore Dew, when he heard of the job opportunity in the new cooperage. When offered the job he says he wanted to be part of the adventure.

“I didn’t hesitate at all and I just moved country,” he explains.

Enguerrand described the re-establishment of the cooperage as a “very exciting opportunity”, saying Tullamore Dew can now complete the entire distillery process on site.

“We have everything here; we do everything from distilling to the bottling. All that was missing was the cooperage, which is a big part of the distillery.”

A lot to learn

The coopers will repair approximately 23 barrels a day, as well as create speciality casks for premium blends. Discussing the apprenticeship, Enguerrand it’s all about knowing how to prepare the casks, first of all.

“Then, it’s having a good understanding of the woods – how to read the wood and how the wood is reacting with the spirit, or the maturation.” He describes cooperage as “a long adventure”.

“There’s a lot to learn,” he says. “As coopers, you never stop – even after the apprenticeship. Even me, I’m still learning a lot of stuff.”

Dylan and Corey will someday train future apprentices in the trade, but Enguerrand says they must amass a lot of experience before reaching that level. He emphasises the importance of developing the coopering trade in Ireland.

“We need more coopers in Ireland,” he explains. “The whiskey industry is growing fast, there are now almost 40 distilleries.”

Enguerrand outlined that there will be many barrels needed to sustain this industry, and barrels will need to be repaired. Therefore, there will be an increased demand for Dylan and Corey, as well as new coopers, in Ireland.

Discussing how the tradition can be encouraged and kept alive in Ireland, Enguerrand says he would “love to see more people interested in the job”, however, “a lot of people don’t know this trade still exists”.

Two Offaly-based apprentices have joined the Tullamore Dew cooperage – which reopened last year – becoming the first coopers trained at Tullamore Dew in 66 years. The Tullamore Dew Irish whiskey distillery was first established in 1829 but ceased production on the Offaly site in 1954. It reopened in Tullamore in 2014. Between 1954 and 2014, Tullamore Dew sourced their products from other distilleries such as Irish Distillers.

Dylan Healion and Corey Bracken have begun a four-year apprenticeship in Tullamore Dew. The ancient craft of coopering involves making and repairing barrels and casks used to store alcohol. Until now, the craft had nearly died out in Ireland but Tullamore Dew are attempting to keep the tradition alive.

A rarity

Dylan and Corey account for two of only four cooper apprentices in Ireland and will soon join the ranks of only five qualified coopers in a nation with 38 distilleries. The apprentices were hired due to their appreciation of the heritage, knowledge and skills required to keep the coopering tradition alive. Upon completion of the apprenticeship, they will receive their qualification under the National Cooper Federation.

Corey Bracken, Dylan Healion and Enguerrand Vandenbossche at the Tullamore Dew Cooperage. \ Hazel Coonagh

The apprentices are trained under the watchful eye of Enguerrand Vandenbossche, Tullamore Dew’s head cooper. Enguerrand has amassed a decade of experience in the area. First trained in France in champagne cooperage, Enguerrand then worked as a cooper throughout Normandy for cider, calvados, cognac and wine. He later worked in Scotland, before moving to Ireland to take the opportunity as head cooper with Tullamore Dew.

The apprenticeship will teach Dylan and Corey the cooper trade; repairing barrels to store whiskey. Up to 80% of the character of a whiskey comes from the cask, therefore coopers are extremely important to the distilling process. Before the cask production facility reopened, there was only one cooperage in Ireland and the majority of Irish barrels were sent for repair to Scotland. The re-establishment of the cooperage at Tullamore Dew will continue the tradition and allow for barrel repair for the growing whiskey trade in Ireland.

Irish Country Living spoke with Dylan, Corey and Enguerrand about this unique apprenticeship.

The apprentices are both local to the distillery: Dylan hails from Kilurin and Corey is from Tullamore. Corey outlined the benefits of availing of the unique opportunity in his home county. “There’s no travelling. I only live 10 minutes down the road.”

Dylan described the apprenticeship in Tullamore as “a once-in-a-lifetime opportunity; a chance you wouldn’t get anywhere else”. Speaking about why he chose to pursue a career in cooperage, Dylan says:

“It’s a great trade – it’s very traditional, something that hasn’t changed for centuries.”

Enguerrand Vandenbossche working at the Tullamore Dew Cooperage. \ Hazel Coonagh

Dylan was working in Tullamore as a bottler when he first heard of the apprenticeship opportunity. He worked for a day with Enguerrand to get a taste for the industry, and researched the role before applying for the apprenticeship.

Corey was also working as a bottler with Tullamore Dew when the apprenticeship opportunity arose. Corey says he “really enjoyed working with the company and wanted to go for the cooperage ever since I started”.

A great achievement

Corey described it as a great achievement, having a unique apprenticeship, and outlined that he would love to see it growing, with more apprentices doing this kind of trade. “Hopefully in Ireland, it will pick up and there will be more coopers.”

Enguerrand outlined that he was working for William Grant & Sons in Scotland, the owners of Tullamore Dew, when he heard of the job opportunity in the new cooperage. When offered the job he says he wanted to be part of the adventure.

“I didn’t hesitate at all and I just moved country,” he explains.

Enguerrand described the re-establishment of the cooperage as a “very exciting opportunity”, saying Tullamore Dew can now complete the entire distillery process on site.

“We have everything here; we do everything from distilling to the bottling. All that was missing was the cooperage, which is a big part of the distillery.”

A lot to learn

The coopers will repair approximately 23 barrels a day, as well as create speciality casks for premium blends. Discussing the apprenticeship, Enguerrand it’s all about knowing how to prepare the casks, first of all.

“Then, it’s having a good understanding of the woods – how to read the wood and how the wood is reacting with the spirit, or the maturation.” He describes cooperage as “a long adventure”.

“There’s a lot to learn,” he says. “As coopers, you never stop – even after the apprenticeship. Even me, I’m still learning a lot of stuff.”

Dylan and Corey will someday train future apprentices in the trade, but Enguerrand says they must amass a lot of experience before reaching that level. He emphasises the importance of developing the coopering trade in Ireland.

“We need more coopers in Ireland,” he explains. “The whiskey industry is growing fast, there are now almost 40 distilleries.”

Enguerrand outlined that there will be many barrels needed to sustain this industry, and barrels will need to be repaired. Therefore, there will be an increased demand for Dylan and Corey, as well as new coopers, in Ireland.

Discussing how the tradition can be encouraged and kept alive in Ireland, Enguerrand says he would “love to see more people interested in the job”, however, “a lot of people don’t know this trade still exists”.

SHARING OPTIONS