The seed you put in the ground is one of the most important inputs. Aside from your seedbed, it has the potential to leave you with a great crop or a bad crop.

You need to be sure that your seed is good quality, that it will germinate, be free of seed-borne disease and is free of weeds so that it does not bring unwanted problems on to your farm.

Ireland has extremely high standards when it comes to seed, something that is often under-appreciated.

On a recent visit to the Department of Agriculture, Food and the Marine’s official seed testing laboratory, the huge level of work that goes into producing that high-quality seed is clear to see.

Lab director Brian O’Connor facilitated a tour of the lab and the Irish Farmers Journal met an enthusiastic team along the way.

Some of the team in the Department of Agriculture's seed lab.

No stone is left unturned to ensure quality the whole way along the chain. After all, if something goes wrong, it will affect massive tonnes of seed. Ireland produces over 40,000t of certified seed each year.

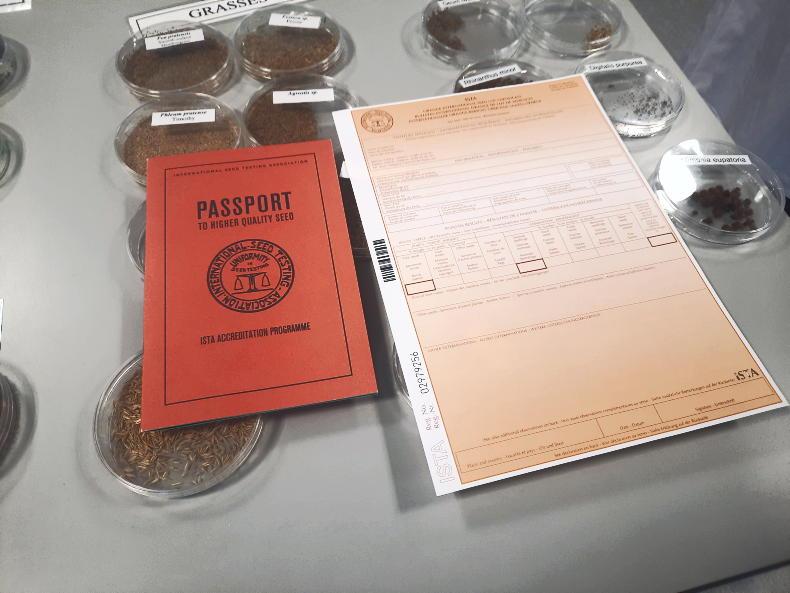

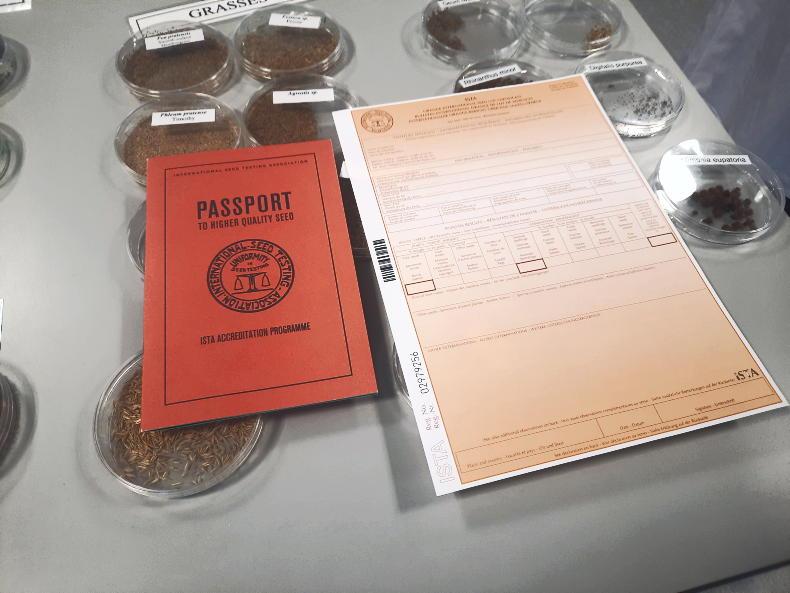

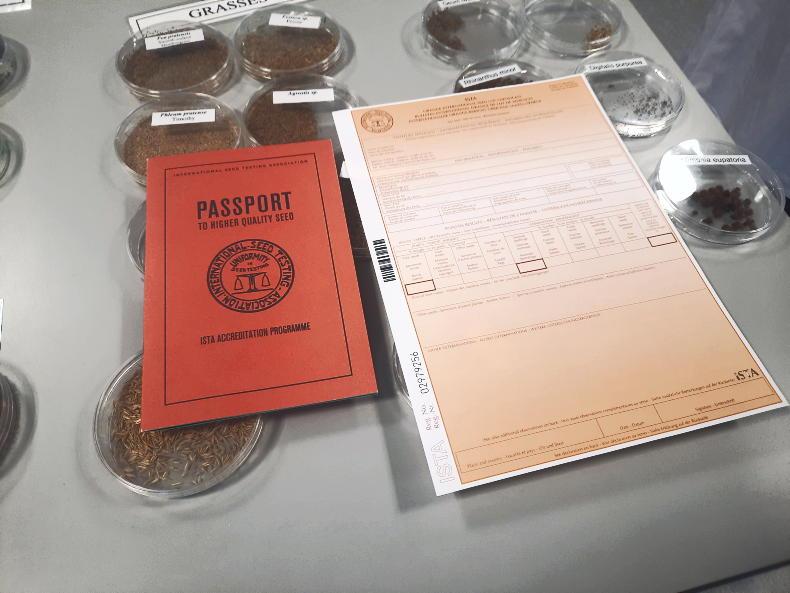

The laboratory is accredited by the International Seed Testing Association (ISTA); it is the only ISTA accredited seed testing laboratory in Ireland and is one of only 150 ISTA accredited laboratories worldwide.

This means the Department can issue orange international certificates (OICs) to go with seed for export.

The laboratory is audited every three years by ISTA, but throughout the year, up to 30 internal audits are completed. Everything from the weighing scales to the substrates used to test and analyse are quality checked before use.

About 10,000 samples tested

About 10,000 tests are conducted on samples annually. The majority of these are on cereals, grasses and beans, but numerous other species are also tested.

In 2023, just over 10,500 tests were carried out. The majority of these come from seed assemblers through the Department’s Seed Certification Programme and go towards certifying seed for sale. Some come from the Department’s variety testing trials.

A certain number also come from seed processors, who dress homesaved seed for farmers, while a smaller amount come from farmers themselves.

Anyone can avail of the seed lab’s facilities, once they pay for the different tests being carried out.

Journey of a seed sample in the lab

Samples are delivered daily and those samples are immediately registered, scanned and given a barcode and entered into the system.

The sample is not recognisable as belonging to anyone, so there can be no bias towards a variety or customer.

Some samples just need one test carried out, while others may need a series of tests.

There are 11 lab analysts working all the time in the lab to complete these tests.

Cereals.Grasses.Oilseed seeds.Vegetable seeds.Pulses.Legumes.Trees.Cover crops.Wildflowers.What it’s tested for

Germination (gold standard).Rapid viability (Tz test).Purity.Other seed determination. Thousand grain weight.Hectolitre weight.Moisture. Seed health tests.The first thing that was emphasised in the lab was the importance of a representative sample.

Samples are mixed and divided three times when they enter the lab to make sure that all samples are equal for the test being carried out.

However, the mixing in the lab is of little value if a poor sample has been taken at the seed source.

Margaret Kavanagh, who has worked in the seed lab for many years, noted that when samples are being sent in by farmers, it is important they don’t just take a few handfuls from the same place in the grain heap, but that they sample from different areas and mix the sample. Guidelines are available on the Department’s website.

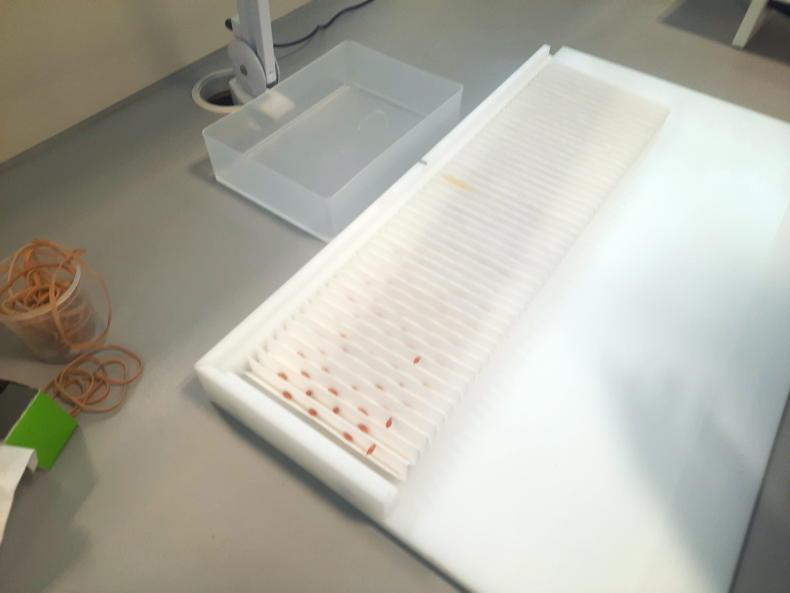

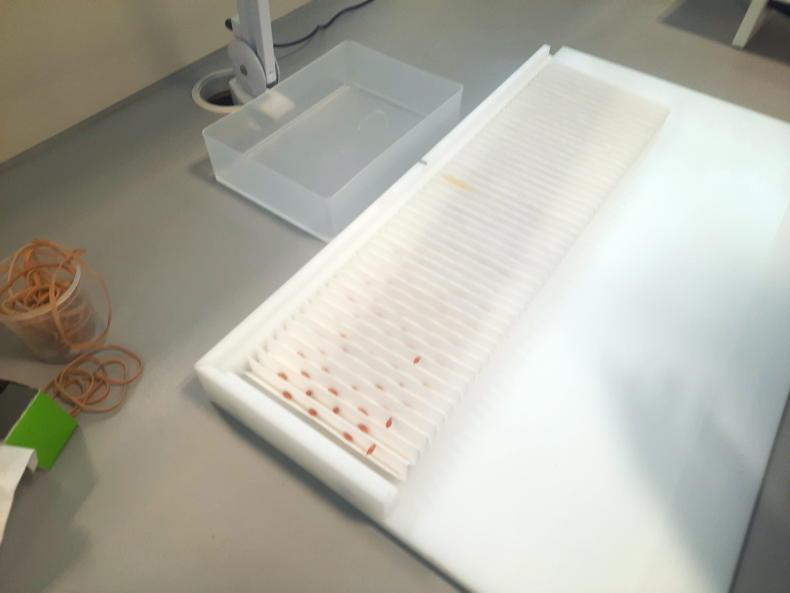

Margaret Kavanagh checking on germination tests in the lab.

Germination

Germination is probably the most common test carried out in the lab, and one of the most important, as if the seed cannot germinate then it is not viable to process. The gold standard is when seeds are allowed to grow or germinate. The second is a rapid test using chemicals to check the seeds’ viability.

Beans going through a germination test.

Beans going through a germination test.

Beans going through a germination test.

The rapid test is very important at certain times of the year, eg for winter cereal seed. This is often a very quick turn-around to get seed assembled, so a rapid test helps to eliminate some seed quickly and allow for the longer test to be carried out afterwards.

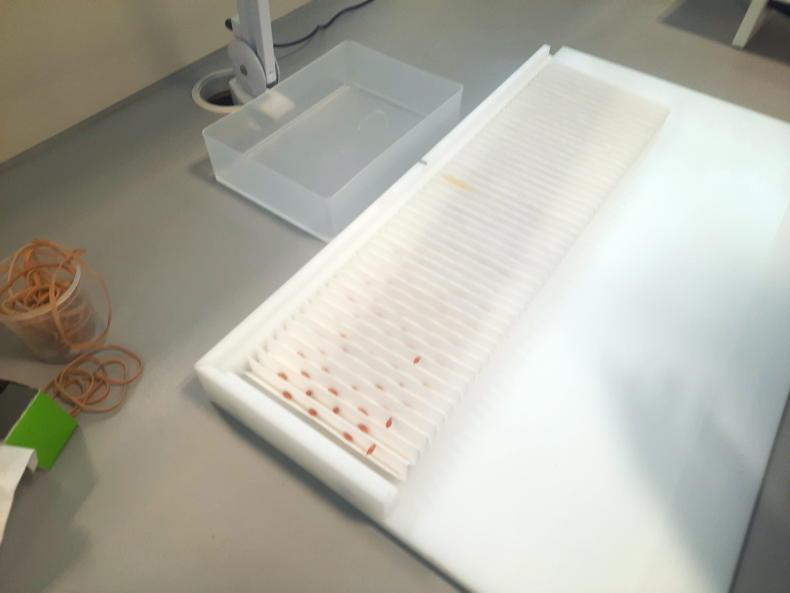

Germination – gold standard

This test involves taking 400 pure seeds and placing them on paper along with 60ml of water and allowing the seeds to grow.

Once planted, the seeds are chilled before being moved to an incubator, but sometimes procedures are required to break physiological dormancy in winter seeds (eg Gibberellic acid may be added).

They are analysed seven to 14 days after planting. The longer test time is for samples that have dormancy present. Early harvests have helped with getting samples turned around and lessen the pressure with winter seed.

A germination test being carried out on barley.

A barley sample going through a germination test.

Preliminary wheat samples are generally split into a dressed and undressed test; 200 seeds are chemically treated in the lab and sown alongside 200 untreated seeds.

This help to advise customers before making decisions on dressing seed that may be unsuitable. The same dressing is used for all tests.

Margaret said that there was a big difference between dressed and undressed seed for this year’s seed, most likely due to the poor weather of 2023.

Seed viability can be tested quickly, in 24 hours, with a tetrazolium (Tz) test. This test is not as accurate, as certain seed issues can only be used as a quick test with a follow-up of a full germination test afterwards.

Eoin O’Connor explained that 200 grains are split and treated with the chemical tetrazolium chloride.

A viable wheat seed in a Tz test.

A healthy embryo in the seed stains red, while damaged or dead embryonic tissue will not stain. This test can indicate the presence of heat damage and sprouting and is useful with winter seed, in particular.

Many farmers will be familiar with the test for malting barley, but when carried out to seed testing standards this test takes a lot longer to complete.

The sprouted seed in this image which has undergone a Tz test is not viable.

Disease and purity testing

Damien Browne works on disease testing and explained that the main things they look for are fusarium, microdochium, loose smut, net blotch, leaf stripe on cereals and Ascochyta and Botrytis on beans.

Inoculum from the seed is placed on agar in a petri dish in the lab and allowed to grow in an incubator for seven days. Weather preharvest and during harvest can have a big effect on the seed quality.

Disease will impact on germination and seed viability, so this is an essential step along the way.

Purity

This is all highly skilled work and analysts need great patience.

A particularly meticulious test is purity. The team weighs out a sample of seed and goes through the entire sample. For example, if it is a sample of barley seed, they will separate the barley from other things. There be small stones. Weed seeds need to be looked out for as well as things like chaff and broken grains.

Once the sample has been separated, the barley seed, weeds and broken grains are weighed separately to identify a percentage or to deem a sample to be able to be certified or not.

If the sample contains blackgrass, sterile brome or wild oats, for example, it would not pass for certified seed.

Analysts are trained in seed identification to help them identify weeds quickly and have seed collections on hand to assist in this. Across the hall is a very impressive reference collection of seed from Ireland and all over the world. These seeds are not viable, but are preserved so that weed seeds can be identified if anything unusual comes in in a sample.

An orange certificate which allows seed to be exported around the world.

The other seed determination (OSD) test, as the name suggests, determines if other species than those listed on the label are present in the sample.

This test is more useful than a purity test for a customer wishing to determine weed seed levels in a sample, as it is conducted on a larger sample (eg cereals 1kg) than a purity test.

OSD analysis is also part of seed certification requirements.

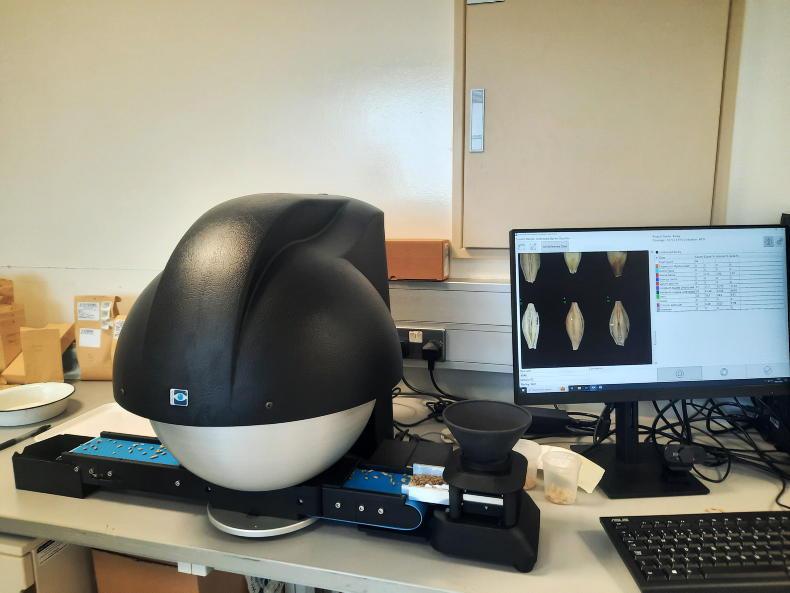

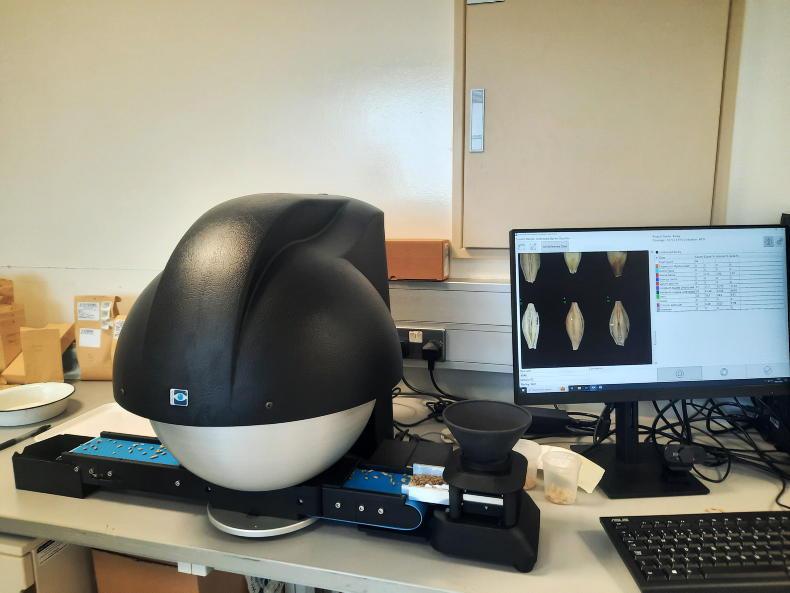

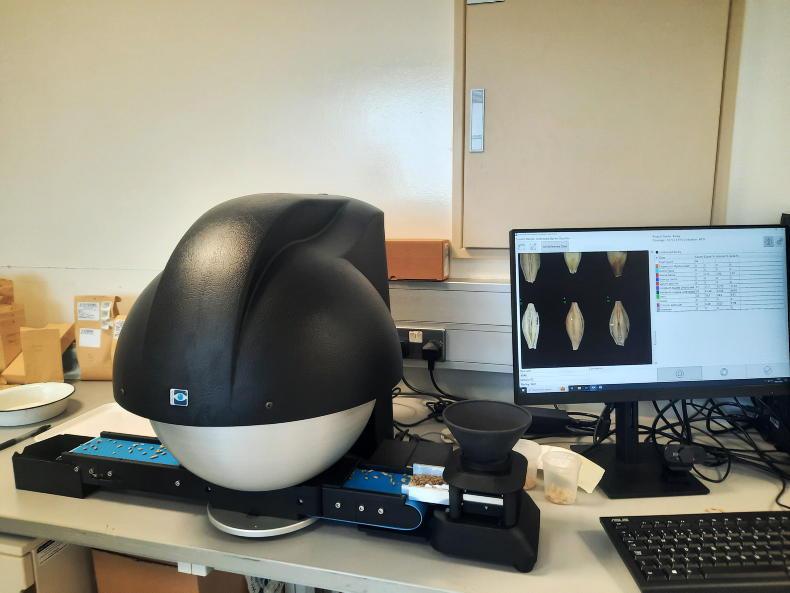

Along the route we met Shaileen McGovern, who was training a machine to identify weeds, stones and other species, along with barley, wheat, oats and other plants.

Artificial intelligence could play a big part in identifying weeds and testing for purity in the seed lab.

This machine, which is on trial, may help to reduce workload, as it could identify species which should not be in the sample. Shaileen had samples of blackgrass, sterile brome, wild oat, stones and chaff to see if it was identifying everything correctly.

The Department runs an independent variety evaluation and seed certification scheme.

Working with seed breeders and agents, it trials varieties and compiles recommended lists with varieties it recommends to Irish farmers to plant which suit our growing conditions.

The seed testing lab tests all of the seed in these trials before planting. In parallel to the trialling system, the new varieties will often enter the seed certification system to ensure seed is available and once varieties make it on to the list, the seed has to be multiplied.

Seed assemblers find farmers with suitable land in their rotation to grow over 40,000t of seed and the Department then inspects these crops to ensure varietal purity and that it meets the other standards required in the field throughout the year.

After harvest, Department inspectors supervise the processing of the seed and these samples are sent to the seed lab for testing.

These tests include: disease, purity, OSD and germination.

EU laws mean that uncertified seed cannot be traded.

Some of the old seed samples in the Department.

Requirements of certified seed

85% germination (cereals).98% purity C1, basic and prebasic 99% (wheat, oats, barley).Completely free of wild oats, blackgrass, sterile brome and darnel grass.Once the lab has completed the seed tests, it issues analysis reports to Department officials in the seed certification section, who then issue certified seed labels to seed processors.

All certified seed will carry a label from the Department of Agriculture to say that it meets certified seed standards.

The original seed collection in the Department of Agriculture.

The seed testing laboratory dates back as far as 1895 and came under the control of the Department of Agriculture in 1901. It was the first official control laboratory in the State, which shows the importance of agriculture at the time.

It was originally situated in what is now the Taoiseach’s office on Merrion Street. Around 1990, Taoiseach Charlie Haughey moved the lab to Abbotstown and it was moved to Backweston in Co Kildare in 2005.

The seed you put in the ground is one of the most important inputs. Aside from your seedbed, it has the potential to leave you with a great crop or a bad crop.

You need to be sure that your seed is good quality, that it will germinate, be free of seed-borne disease and is free of weeds so that it does not bring unwanted problems on to your farm.

Ireland has extremely high standards when it comes to seed, something that is often under-appreciated.

On a recent visit to the Department of Agriculture, Food and the Marine’s official seed testing laboratory, the huge level of work that goes into producing that high-quality seed is clear to see.

Lab director Brian O’Connor facilitated a tour of the lab and the Irish Farmers Journal met an enthusiastic team along the way.

Some of the team in the Department of Agriculture's seed lab.

No stone is left unturned to ensure quality the whole way along the chain. After all, if something goes wrong, it will affect massive tonnes of seed. Ireland produces over 40,000t of certified seed each year.

The laboratory is accredited by the International Seed Testing Association (ISTA); it is the only ISTA accredited seed testing laboratory in Ireland and is one of only 150 ISTA accredited laboratories worldwide.

This means the Department can issue orange international certificates (OICs) to go with seed for export.

The laboratory is audited every three years by ISTA, but throughout the year, up to 30 internal audits are completed. Everything from the weighing scales to the substrates used to test and analyse are quality checked before use.

About 10,000 samples tested

About 10,000 tests are conducted on samples annually. The majority of these are on cereals, grasses and beans, but numerous other species are also tested.

In 2023, just over 10,500 tests were carried out. The majority of these come from seed assemblers through the Department’s Seed Certification Programme and go towards certifying seed for sale. Some come from the Department’s variety testing trials.

A certain number also come from seed processors, who dress homesaved seed for farmers, while a smaller amount come from farmers themselves.

Anyone can avail of the seed lab’s facilities, once they pay for the different tests being carried out.

Journey of a seed sample in the lab

Samples are delivered daily and those samples are immediately registered, scanned and given a barcode and entered into the system.

The sample is not recognisable as belonging to anyone, so there can be no bias towards a variety or customer.

Some samples just need one test carried out, while others may need a series of tests.

There are 11 lab analysts working all the time in the lab to complete these tests.

Cereals.Grasses.Oilseed seeds.Vegetable seeds.Pulses.Legumes.Trees.Cover crops.Wildflowers.What it’s tested for

Germination (gold standard).Rapid viability (Tz test).Purity.Other seed determination. Thousand grain weight.Hectolitre weight.Moisture. Seed health tests.The first thing that was emphasised in the lab was the importance of a representative sample.

Samples are mixed and divided three times when they enter the lab to make sure that all samples are equal for the test being carried out.

However, the mixing in the lab is of little value if a poor sample has been taken at the seed source.

Margaret Kavanagh, who has worked in the seed lab for many years, noted that when samples are being sent in by farmers, it is important they don’t just take a few handfuls from the same place in the grain heap, but that they sample from different areas and mix the sample. Guidelines are available on the Department’s website.

Margaret Kavanagh checking on germination tests in the lab.

Germination

Germination is probably the most common test carried out in the lab, and one of the most important, as if the seed cannot germinate then it is not viable to process. The gold standard is when seeds are allowed to grow or germinate. The second is a rapid test using chemicals to check the seeds’ viability.

Beans going through a germination test.

Beans going through a germination test.

Beans going through a germination test.

The rapid test is very important at certain times of the year, eg for winter cereal seed. This is often a very quick turn-around to get seed assembled, so a rapid test helps to eliminate some seed quickly and allow for the longer test to be carried out afterwards.

Germination – gold standard

This test involves taking 400 pure seeds and placing them on paper along with 60ml of water and allowing the seeds to grow.

Once planted, the seeds are chilled before being moved to an incubator, but sometimes procedures are required to break physiological dormancy in winter seeds (eg Gibberellic acid may be added).

They are analysed seven to 14 days after planting. The longer test time is for samples that have dormancy present. Early harvests have helped with getting samples turned around and lessen the pressure with winter seed.

A germination test being carried out on barley.

A barley sample going through a germination test.

Preliminary wheat samples are generally split into a dressed and undressed test; 200 seeds are chemically treated in the lab and sown alongside 200 untreated seeds.

This help to advise customers before making decisions on dressing seed that may be unsuitable. The same dressing is used for all tests.

Margaret said that there was a big difference between dressed and undressed seed for this year’s seed, most likely due to the poor weather of 2023.

Seed viability can be tested quickly, in 24 hours, with a tetrazolium (Tz) test. This test is not as accurate, as certain seed issues can only be used as a quick test with a follow-up of a full germination test afterwards.

Eoin O’Connor explained that 200 grains are split and treated with the chemical tetrazolium chloride.

A viable wheat seed in a Tz test.

A healthy embryo in the seed stains red, while damaged or dead embryonic tissue will not stain. This test can indicate the presence of heat damage and sprouting and is useful with winter seed, in particular.

Many farmers will be familiar with the test for malting barley, but when carried out to seed testing standards this test takes a lot longer to complete.

The sprouted seed in this image which has undergone a Tz test is not viable.

Disease and purity testing

Damien Browne works on disease testing and explained that the main things they look for are fusarium, microdochium, loose smut, net blotch, leaf stripe on cereals and Ascochyta and Botrytis on beans.

Inoculum from the seed is placed on agar in a petri dish in the lab and allowed to grow in an incubator for seven days. Weather preharvest and during harvest can have a big effect on the seed quality.

Disease will impact on germination and seed viability, so this is an essential step along the way.

Purity

This is all highly skilled work and analysts need great patience.

A particularly meticulious test is purity. The team weighs out a sample of seed and goes through the entire sample. For example, if it is a sample of barley seed, they will separate the barley from other things. There be small stones. Weed seeds need to be looked out for as well as things like chaff and broken grains.

Once the sample has been separated, the barley seed, weeds and broken grains are weighed separately to identify a percentage or to deem a sample to be able to be certified or not.

If the sample contains blackgrass, sterile brome or wild oats, for example, it would not pass for certified seed.

Analysts are trained in seed identification to help them identify weeds quickly and have seed collections on hand to assist in this. Across the hall is a very impressive reference collection of seed from Ireland and all over the world. These seeds are not viable, but are preserved so that weed seeds can be identified if anything unusual comes in in a sample.

An orange certificate which allows seed to be exported around the world.

The other seed determination (OSD) test, as the name suggests, determines if other species than those listed on the label are present in the sample.

This test is more useful than a purity test for a customer wishing to determine weed seed levels in a sample, as it is conducted on a larger sample (eg cereals 1kg) than a purity test.

OSD analysis is also part of seed certification requirements.

Along the route we met Shaileen McGovern, who was training a machine to identify weeds, stones and other species, along with barley, wheat, oats and other plants.

Artificial intelligence could play a big part in identifying weeds and testing for purity in the seed lab.

This machine, which is on trial, may help to reduce workload, as it could identify species which should not be in the sample. Shaileen had samples of blackgrass, sterile brome, wild oat, stones and chaff to see if it was identifying everything correctly.

The Department runs an independent variety evaluation and seed certification scheme.

Working with seed breeders and agents, it trials varieties and compiles recommended lists with varieties it recommends to Irish farmers to plant which suit our growing conditions.

The seed testing lab tests all of the seed in these trials before planting. In parallel to the trialling system, the new varieties will often enter the seed certification system to ensure seed is available and once varieties make it on to the list, the seed has to be multiplied.

Seed assemblers find farmers with suitable land in their rotation to grow over 40,000t of seed and the Department then inspects these crops to ensure varietal purity and that it meets the other standards required in the field throughout the year.

After harvest, Department inspectors supervise the processing of the seed and these samples are sent to the seed lab for testing.

These tests include: disease, purity, OSD and germination.

EU laws mean that uncertified seed cannot be traded.

Some of the old seed samples in the Department.

Requirements of certified seed

85% germination (cereals).98% purity C1, basic and prebasic 99% (wheat, oats, barley).Completely free of wild oats, blackgrass, sterile brome and darnel grass.Once the lab has completed the seed tests, it issues analysis reports to Department officials in the seed certification section, who then issue certified seed labels to seed processors.

All certified seed will carry a label from the Department of Agriculture to say that it meets certified seed standards.

The original seed collection in the Department of Agriculture.

The seed testing laboratory dates back as far as 1895 and came under the control of the Department of Agriculture in 1901. It was the first official control laboratory in the State, which shows the importance of agriculture at the time.

It was originally situated in what is now the Taoiseach’s office on Merrion Street. Around 1990, Taoiseach Charlie Haughey moved the lab to Abbotstown and it was moved to Backweston in Co Kildare in 2005.

SHARING OPTIONS