The range of machines have been designed and built in-house at its Cornwall base. The firm last built its own Titan rear-discharge spreaders in the 1970s, before switching production to concentrate on side-discharge machines and its range of other products, including the Tomahawk.

More recently, it re-entered the rear-discharge spreader market through an agreement with French maker Le Boulch to sell its machines in Teagle livery. This deal, which was primarily for the British market, ended just last year following the purchase of Le Boulch by Joskin.

Retaining the Titan name, the line comprises five models with nominal load capacities from 4.1m3 to 8.2m3, rising to 6.3m3 to 12.1m3 when heaped to the level of the slurry gate.

Teagle says its designers have focused on the need for greater precision in manure application, brought about by the environmental and economic drivers behind today’s farming.

To this end, the firm claims it has applied fertilizer spreader design thinking to the muck spreader sector. It claims that even feeding and spreading evenness was the subject of a great deal of research in terms of rotor design and pitch.

“Our field trials indicated that a pitch that’s too steep causes muck to be discharged too early, before it’s sufficiently shredded, while one that’s too shallow adversely affects discharge rate and spread width,” explains the firm’s Tom Teagle.

“But if it’s sufficiently shallow, it gives the rotor a greater effective working length and puts more beater tips in contact with the material.

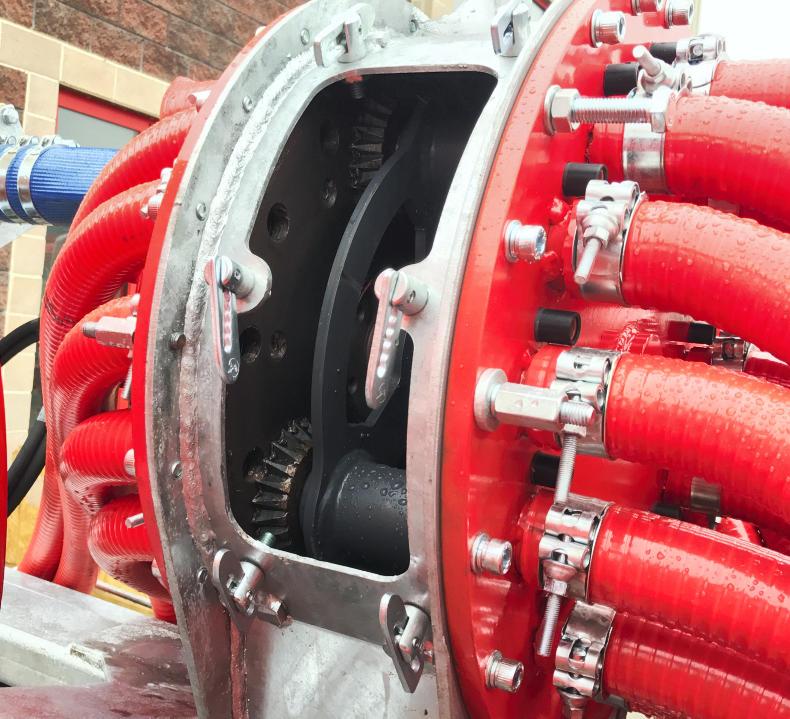

“Our research also showed the importance of a smooth and continuous rotor face to consistent and even shredding. We have engineered the new machines with rotors that have a 40% larger diameter than most competitors.

“This has been made possible because of the design that means the beater system is wider than the spreader’s body. This increases the tip speed of the flails, which are a swinging type for reduced gearbox and driveline shock loading.”

As part of a focus on limiting the number of wearing parts, the spreaders have been designed with twin-chain bed systems rather than a four-chain design, and there are just two tension adjusters.

Bed slats are attached with U-bolts to ease removal when necessary.

While the entry-level Titan 6 and 8 models are targeted particularly at farmers looking to replace side-discharge machines, Teagle says it recognises that not all farms benefit from having a telehandler.

All of the new Titans have been designed to allow easy filling with tractor loaders. The Titan 9 benefits from larger floor chains of 14mm rather than the 12mm on the two smaller models, plus a 5mm thicker bed shaft drive, up from 50mm.

Meanwhile, Titan 10 and 12 versions gain a thicker floor (5mm up from 4mm) and bigger diameter rotors. Standard features include side plates at the rear to keep the spreader flanks clean, and flip down covers for the road lights which work in conjunction with the slurry gate. Options on all models include electric bed chain control, sprung drawbar and a wide angle pto and cam clutch. Teagle is back in the market with machines made at its own factory, and has expanded its muck spreader offering to include Ireland, where it retails machines through Nolan’s Garage, Tralee, Co Kerry; Agriband, Bandon, Co Cork; Byrne Machinery, Roscrea, Co Tipperary; Joe O’Toole and Sons, Tullow, Co Carlow; and PJ Callan, Ardee, Co Louth.

SHARING OPTIONS