The first two Triton strip till seed drills sold in Ireland broke ground here last week. We travelled to Clane in Co Kildare to catch up with tillage farmer David Weld as he was beginning to sow his winter crops with one of the new machines.

Mainly running a conventional plough system up to now, David sows 400 acres annually and has been carrying out some minimum tillage over the past few years. In doing so, he has tried various machines and systems such as the Duncan disc coulter drill and the Claydon strip till drill, but hadn’t completely settled on any one system prior to this.

However, he feels the Triton is the way forward for his farm, and intends on sowing all his crops with the machine.

According to Triton, its leading tine is designed to break compaction, aerate the soil and create drainage for the rooting zone in one pass.

Why Triton?

While browsing through the internet one night just over a year ago, he came across the Triton seed drills. He was very impressed, and decided to travel to England to see the machine in action for himself. He travelled to Cambridge, where he met Simon Chaplin, a tillage farmer who is also the owner of Triton drills.

Left: after one pass of the drill.

David said: “I was very impressed with the drill and decided to go look at it again in November when he was sowing with it. It was leaving a very nice finish with just one pass.

“Simon farms 4,000 acres of crops and sows all of it from November on using this drill. I returned to England in January and again in March to check out the crops I had seen planted and I was very happy with what I saw.

At the rear of the unit, a lightweight adjustable trash rake follows.

“I then decided to order one for my own farm, and shortly afterwards took on the agency to sell the drills in Ireland. I have demonstrated the machine to approximately 20 farmers so far, and feedback to date has been very good. People are genuinely interested.”

A relatively new player to the seed drill market, Triton built its first drill in the autumn of 2017.

The design

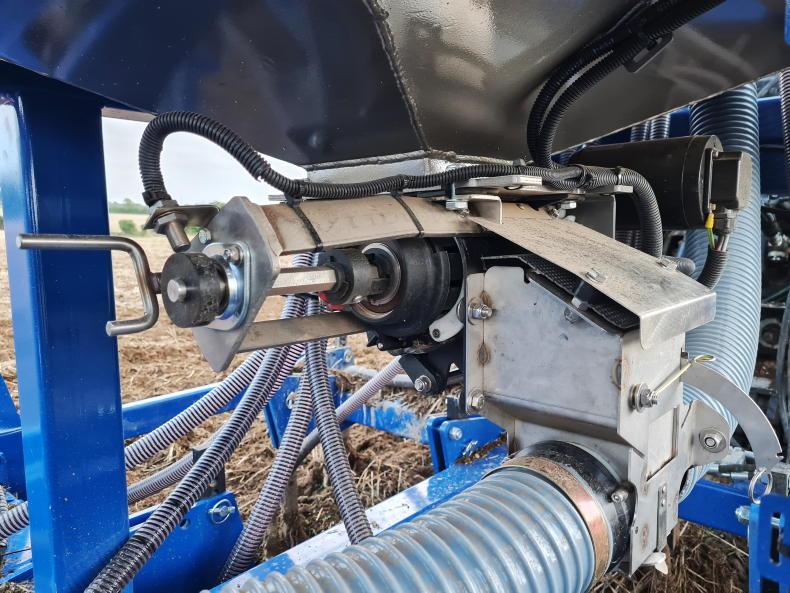

The manufacturer describes the Triton as an all-weather drill, saying it will perform well in any conditions once the tractor can travel without causing excess damage. The system is low-disturbance and non-inversion, and uses seeding blades mounted on tines to cut open the soil, while placing the seed on a terrace before it is then split to either side by a closing tine.

The drill is built on a heavy gauge steel frame to allow for use on high-horsepower tractors to drill direct into heavy clay soils with one pass. The manufacturer notes that the frame has minimal flex so the wider-framed versions will perform best where the field is relatively level.

On David’s particular unit, a 1.2t seed hopper is mounted on the machine, however, a 1.5t front mounted seed tank is also a popular seller for the manufacturer.

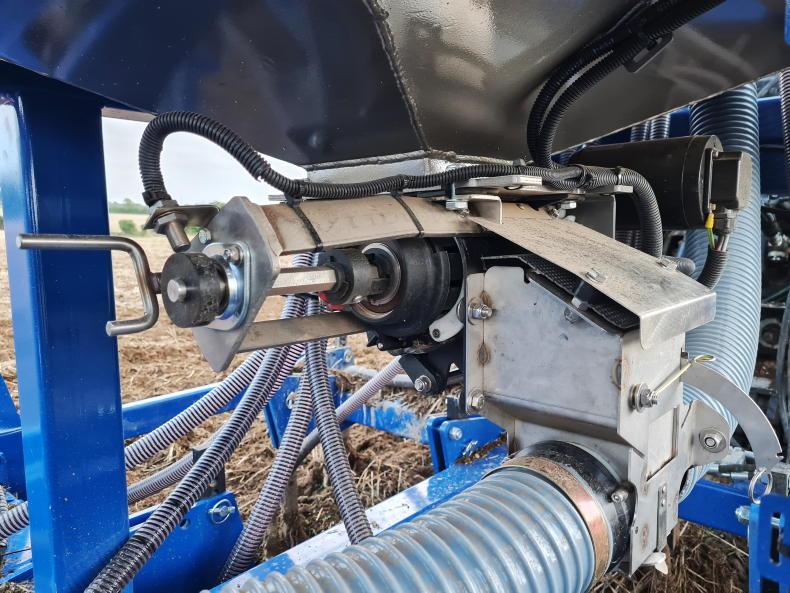

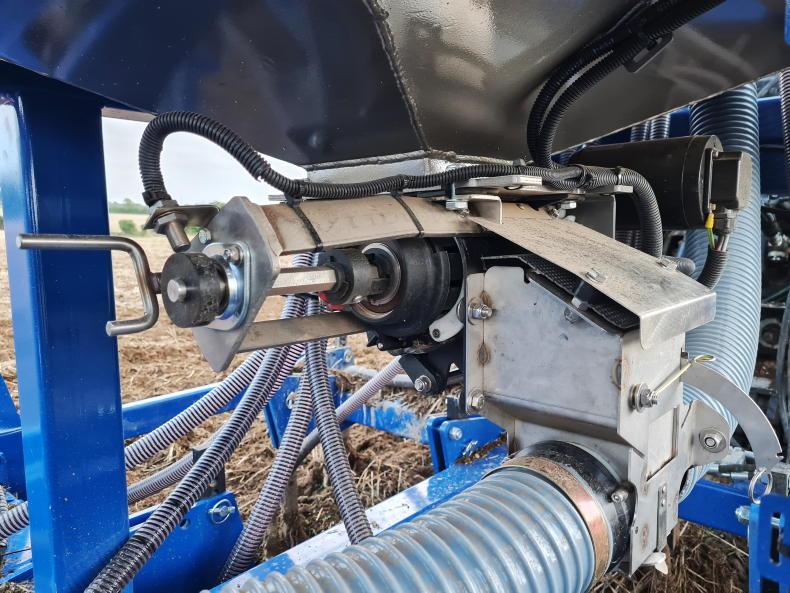

According to Triton, its leading tine is designed to break compaction, aerate the soil and create drainage for the rooting zone in one pass. The manufacturer’s seeding blade concept is designed with a downward-facing front edge for minimal soil disturbance and a lower draft, working down as deep as 7in to break up the soil in the rooting zone directly below every seedling.

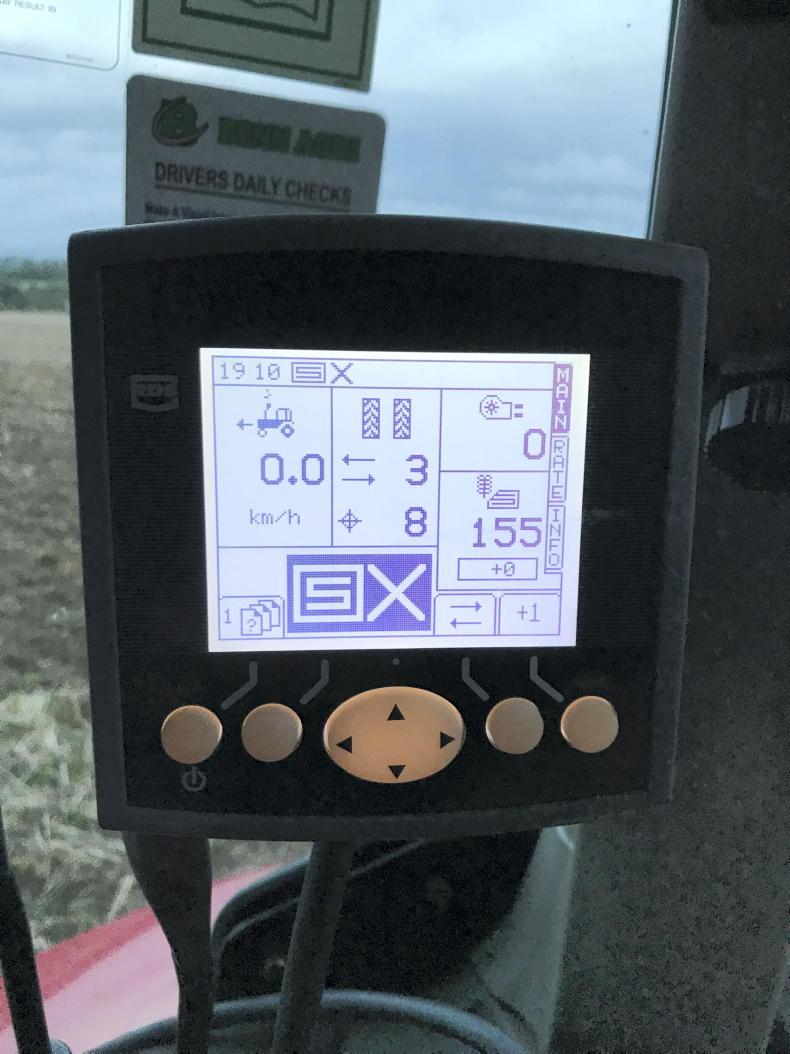

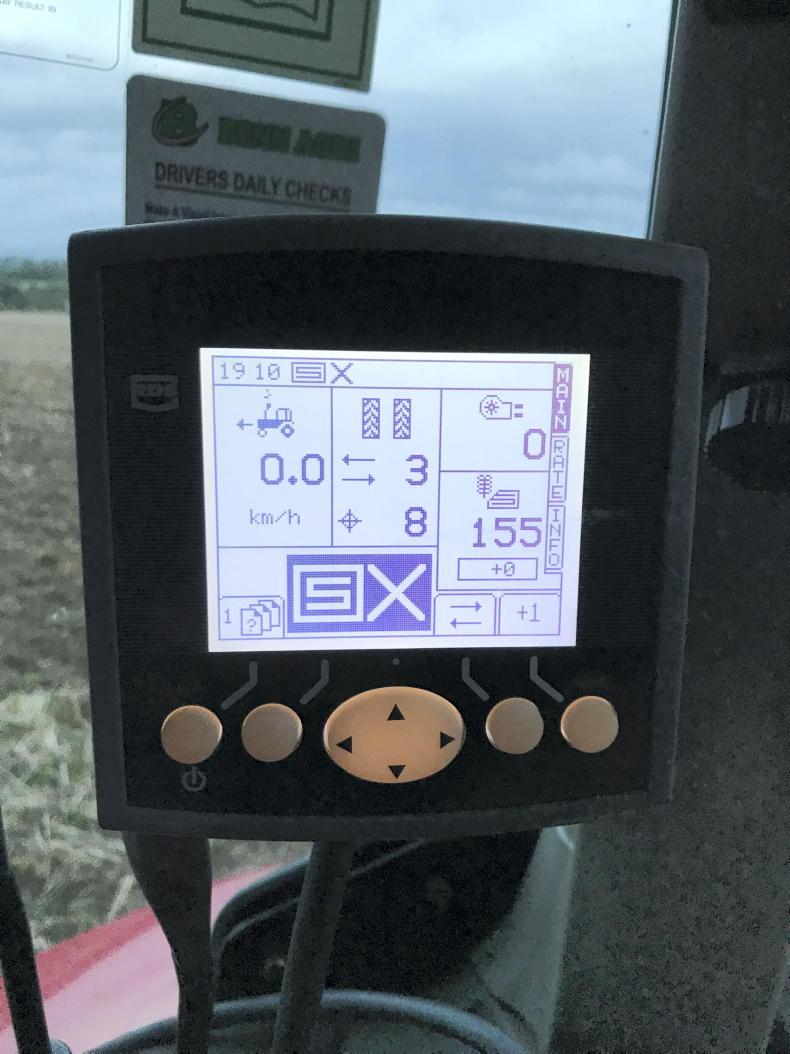

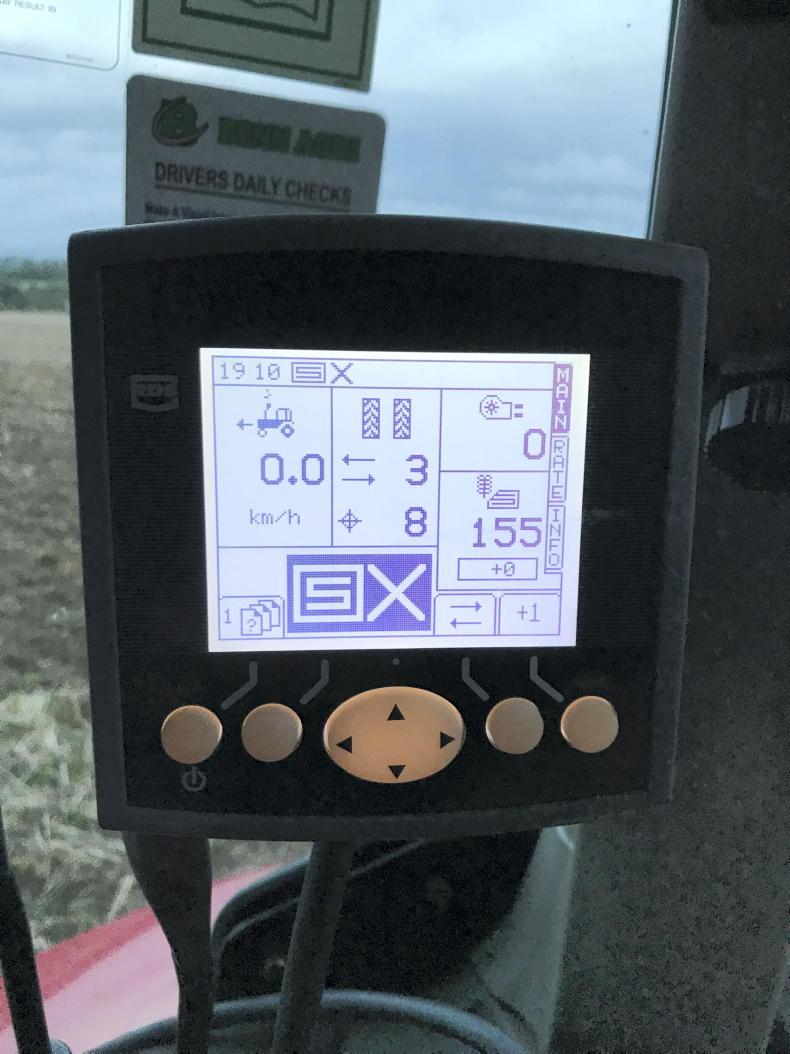

The drill features an RDS electrical control unit.

The blade is manufactured using a hard-wearing boron steel with a tungsten carbide drilling blade. The following coulter aims to place the seed 2in above the drainage channel which is created by the patented tine. The drill features 6in seed-row spacing as standard.

On David’s particular unit, the seed hopper is mounted on the machine, however, a 1.5t front-mounted seed tank is also a popular seller for the manufacturer. With a 1.2t hopper as standard, the drill features the proven Accord metering unit which is hydraulically powered, and married up to an RDS electrical control unit.

Behind the seeding tine, a seedless side press blade, also known as a closing tine, runs between each two rows of seeding tines. This closes the drill slot by pushing the soil between them sideways. The two plus one layout of the legs is where the ‘Triton’ name comes from.

On David’s particular unit, a 1.2t seed hopper is mounted on the machine, however, a 1.5t front mounted seed tank is also a popular seller for the manufacturer.

The drill features a 770mm underframe clearance for trash flow. At the rear of the unit, a lightweight trash rake follows, while the pressure which the transport wheels run at can be adjusted via a manual rachet toplink. The drill is designed to set seed with full soil contact, without using a press or packer roller, while being self-cleaning. The lack of press or roller wheels also allows the drill to work in stickier soils.

The drill features six-inch seed-row spacing as standard.

Triton says the action of the closing tine pressing the seed on to the wall of the seeding terrace, means that regardless of forward speed, there is no need for the soil to fall in around the seed, as it is pressed onto the wall. As a result, the drill can run at up to 20km/h if desired.

The closing tines obviously don’t carry seed, but can be modified to carry placement fertiliser if required. These closing tines run two between four, behind the seeding tines.

The drill features the proven Accord metering unit which is hydraulically powered

Who are Triton?

A relatively new player to the seed drill market, Triton built its first drill in the autumn of 2017, with the unit subsequently being used to drill half of Simon Chaplin’s own farm between November 1 and January 15.

Today, the drills are being manufactured by Covenbrook Engineering in England. Triton currently has over 120 machines working in fields across the UK and Poland. David’s drill was the first of two imported into Ireland, with the other going to a tillage farmer in north Co Dublin. According to the manufacturer, worldwide patents have been granted for various aspects of the Triton seed drill such as the seeding blade design and the closing tine, the latter of which we feel is its best asset. David Weld confirmed to the Irish Farmers Journal that the unit is TAMS approved. He said new drills are built to order, with a 10% deposit required up front and a three-month lead time thereafter.

Drill options

Much of the spec on these drills is pretty standard. Buyers can choose from four working widths and the location of the seed tank. The drills range in width from 3m rigid to 6m folding versions.

Fertiliser can be piped down the slot from a second distributor head, giving a starter effect between the rows and leaving some nutrients on the surface for the spring. This is priced at €566/m. A slug pellet applicator can also be added to blow pellets down the same pipework.

The drill features six-inch seed-row spacing as standard.

The manufacturer says the horsepower requirement is dependent on soil type and the structure of the soil, but 50hp per metre is required for the standard drill setup. When we visited David, a Case Puma 165 with a front-mounted weight block was handling the unit pretty easily after heavy rainfall, in sticky conditions.

Advice for sowing

In terms of advice from the manufacturer on sowing with the unit, it says that crop residues must be finely chopped or baled since pre-discing is not normally carried out, except where there are heavy residues or grass weeds.

If heavy trash residues are present and are not being incorporated, a set of straight trash cutting discs can be fitted as an option.

Where grass weed is low density and crops are to be planted mid-season as opposed to November/December, surface cultivation with discs will help pre-emergent herbicide efficacy.

The following coulter aims to place the seed two inches above the drainage channel which is created by the patented tine.

Model: 3m mounted Triton Drill.

Working width: 3m (4m, 4.8m and 6m folding).

Hopper capacity: 1.2t (or front mounted 1.5t hopper).

Row spacing: 6in.

Weight: 1,900kg

Power requirement: 50hp/m.

Price: Starting at €48,000 plus VAT.

The first two Triton strip till seed drills sold in Ireland broke ground here last week. We travelled to Clane in Co Kildare to catch up with tillage farmer David Weld as he was beginning to sow his winter crops with one of the new machines.

Mainly running a conventional plough system up to now, David sows 400 acres annually and has been carrying out some minimum tillage over the past few years. In doing so, he has tried various machines and systems such as the Duncan disc coulter drill and the Claydon strip till drill, but hadn’t completely settled on any one system prior to this.

However, he feels the Triton is the way forward for his farm, and intends on sowing all his crops with the machine.

According to Triton, its leading tine is designed to break compaction, aerate the soil and create drainage for the rooting zone in one pass.

Why Triton?

While browsing through the internet one night just over a year ago, he came across the Triton seed drills. He was very impressed, and decided to travel to England to see the machine in action for himself. He travelled to Cambridge, where he met Simon Chaplin, a tillage farmer who is also the owner of Triton drills.

Left: after one pass of the drill.

David said: “I was very impressed with the drill and decided to go look at it again in November when he was sowing with it. It was leaving a very nice finish with just one pass.

“Simon farms 4,000 acres of crops and sows all of it from November on using this drill. I returned to England in January and again in March to check out the crops I had seen planted and I was very happy with what I saw.

At the rear of the unit, a lightweight adjustable trash rake follows.

“I then decided to order one for my own farm, and shortly afterwards took on the agency to sell the drills in Ireland. I have demonstrated the machine to approximately 20 farmers so far, and feedback to date has been very good. People are genuinely interested.”

A relatively new player to the seed drill market, Triton built its first drill in the autumn of 2017.

The design

The manufacturer describes the Triton as an all-weather drill, saying it will perform well in any conditions once the tractor can travel without causing excess damage. The system is low-disturbance and non-inversion, and uses seeding blades mounted on tines to cut open the soil, while placing the seed on a terrace before it is then split to either side by a closing tine.

The drill is built on a heavy gauge steel frame to allow for use on high-horsepower tractors to drill direct into heavy clay soils with one pass. The manufacturer notes that the frame has minimal flex so the wider-framed versions will perform best where the field is relatively level.

On David’s particular unit, a 1.2t seed hopper is mounted on the machine, however, a 1.5t front mounted seed tank is also a popular seller for the manufacturer.

According to Triton, its leading tine is designed to break compaction, aerate the soil and create drainage for the rooting zone in one pass. The manufacturer’s seeding blade concept is designed with a downward-facing front edge for minimal soil disturbance and a lower draft, working down as deep as 7in to break up the soil in the rooting zone directly below every seedling.

The drill features an RDS electrical control unit.

The blade is manufactured using a hard-wearing boron steel with a tungsten carbide drilling blade. The following coulter aims to place the seed 2in above the drainage channel which is created by the patented tine. The drill features 6in seed-row spacing as standard.

On David’s particular unit, the seed hopper is mounted on the machine, however, a 1.5t front-mounted seed tank is also a popular seller for the manufacturer. With a 1.2t hopper as standard, the drill features the proven Accord metering unit which is hydraulically powered, and married up to an RDS electrical control unit.

Behind the seeding tine, a seedless side press blade, also known as a closing tine, runs between each two rows of seeding tines. This closes the drill slot by pushing the soil between them sideways. The two plus one layout of the legs is where the ‘Triton’ name comes from.

On David’s particular unit, a 1.2t seed hopper is mounted on the machine, however, a 1.5t front mounted seed tank is also a popular seller for the manufacturer.

The drill features a 770mm underframe clearance for trash flow. At the rear of the unit, a lightweight trash rake follows, while the pressure which the transport wheels run at can be adjusted via a manual rachet toplink. The drill is designed to set seed with full soil contact, without using a press or packer roller, while being self-cleaning. The lack of press or roller wheels also allows the drill to work in stickier soils.

The drill features six-inch seed-row spacing as standard.

Triton says the action of the closing tine pressing the seed on to the wall of the seeding terrace, means that regardless of forward speed, there is no need for the soil to fall in around the seed, as it is pressed onto the wall. As a result, the drill can run at up to 20km/h if desired.

The closing tines obviously don’t carry seed, but can be modified to carry placement fertiliser if required. These closing tines run two between four, behind the seeding tines.

The drill features the proven Accord metering unit which is hydraulically powered

Who are Triton?

A relatively new player to the seed drill market, Triton built its first drill in the autumn of 2017, with the unit subsequently being used to drill half of Simon Chaplin’s own farm between November 1 and January 15.

Today, the drills are being manufactured by Covenbrook Engineering in England. Triton currently has over 120 machines working in fields across the UK and Poland. David’s drill was the first of two imported into Ireland, with the other going to a tillage farmer in north Co Dublin. According to the manufacturer, worldwide patents have been granted for various aspects of the Triton seed drill such as the seeding blade design and the closing tine, the latter of which we feel is its best asset. David Weld confirmed to the Irish Farmers Journal that the unit is TAMS approved. He said new drills are built to order, with a 10% deposit required up front and a three-month lead time thereafter.

Drill options

Much of the spec on these drills is pretty standard. Buyers can choose from four working widths and the location of the seed tank. The drills range in width from 3m rigid to 6m folding versions.

Fertiliser can be piped down the slot from a second distributor head, giving a starter effect between the rows and leaving some nutrients on the surface for the spring. This is priced at €566/m. A slug pellet applicator can also be added to blow pellets down the same pipework.

The drill features six-inch seed-row spacing as standard.

The manufacturer says the horsepower requirement is dependent on soil type and the structure of the soil, but 50hp per metre is required for the standard drill setup. When we visited David, a Case Puma 165 with a front-mounted weight block was handling the unit pretty easily after heavy rainfall, in sticky conditions.

Advice for sowing

In terms of advice from the manufacturer on sowing with the unit, it says that crop residues must be finely chopped or baled since pre-discing is not normally carried out, except where there are heavy residues or grass weeds.

If heavy trash residues are present and are not being incorporated, a set of straight trash cutting discs can be fitted as an option.

Where grass weed is low density and crops are to be planted mid-season as opposed to November/December, surface cultivation with discs will help pre-emergent herbicide efficacy.

The following coulter aims to place the seed two inches above the drainage channel which is created by the patented tine.

Model: 3m mounted Triton Drill.

Working width: 3m (4m, 4.8m and 6m folding).

Hopper capacity: 1.2t (or front mounted 1.5t hopper).

Row spacing: 6in.

Weight: 1,900kg

Power requirement: 50hp/m.

Price: Starting at €48,000 plus VAT.

SHARING OPTIONS