Up to now, herbicide use has been the solution to weed problems, but for a multitude of reasons, this is changing and the focus is now on development of integrated control measures where herbicide use is minimised.

This approach will continue as herbicide resistance increases, new herbicide introductions fall, and a desire for less pesticide use grows among the general population.

While some crops can be managed to reduce weed development and growth, through crop choice, time of sowing, seeding rate, row spacing and other management strategies; in most cases significant weed development will still occur and weed destruction will still be required.

There are three categories of post emergence weed destruction that can be used as part of integrated weed control strategies:

Mechanical weed control (including stale seedbed)Novel physical approaches: thermal, water or electrical weed control strategiesTargeted application of herbicidesMechanical weed control and targeted application of herbicides were featured strongly at Agritechnica 2023.

Mechanical weed control

The majority of cultivation equipment manufacturers displaying at Agritechnica have acquired expertise and developed machines either in-house or through the acquisition of smaller companies that were specialising in this area.

There are a range of

technologies in this area varying in sophistication. These include:

Simple fixed position tine weeders that rely on spring pressure and timing of the treatment to damage the weeds, but leave the sown crop or plants unscathed.Newer rotary weed hoes that use two rows of spider wheel type elements with even ground pressure to damage weeds more than the plants, eg, Kverneland Helios.Inter-row cultivator for field crops, which are now almost universally fitted with camera sensor technology and a side-shift frame to allow them centre the hoeing elements between the row plants. While these were traditionally used in row crops like beet or vegetables, at Agritechnica, some models were shown with a row accuracy and tool set-up capable of hoeing between standard 125mm cereal seed rows.

While inter-row weeders were traditionally used in row crops, manufacturers are now offering machines capable of working in 125mm cereal seed rows.

Inter-row and inter-plant weeders using more complex sensor and tool control systems, working at lower forward speeds in rows with individually spaced plants. These are more suited to high value horticultural crops and are capable of weeding between plants as well as between rows.Autonomous weeders using arrays of weed identification and position sensors along with mechatronic weeding tools, which work slowly and carefully around the plants, normally in horticultural plants, but potentially in any row-crop situation. There are a number of these on the market with the companies Naio and Farmdroid being well established.Many of these technologies were shown at the 2023 Crops and Cover Crops Open day at Oak Park in June.

While mechanical weeders will have a role to play, their complexity and operational cost increases rapidly as more effective weeding is required and the need for continuous shallow soil working can also be quite hard on the soil.

Challenge

Perhaps most challenging of all though, in a wetter climate like ours, is whether the weeds will quickly recover, as mechanical weeders may be more effective in dry climates.

Getting the timing right in our conditions, to knock out the weeds, prevent soil damage and avoid weed regrowth, could be challenging.

But we have used basic versions of these systems before, mainly as steerage hoes; no doubt we can do it again if conditions demand it.

Spot spraying of weeds

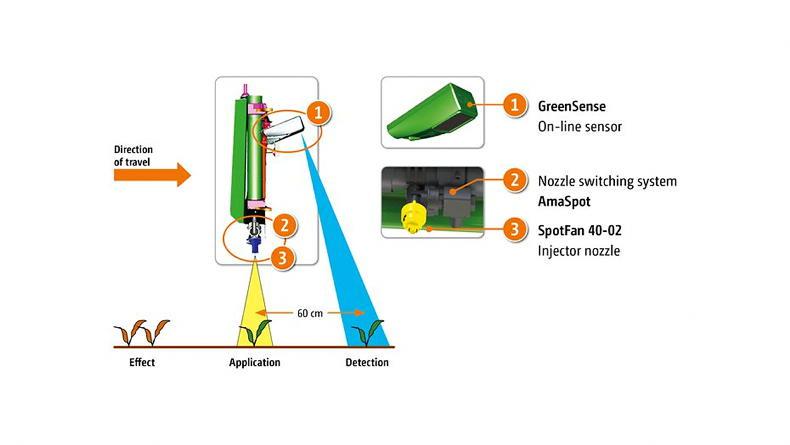

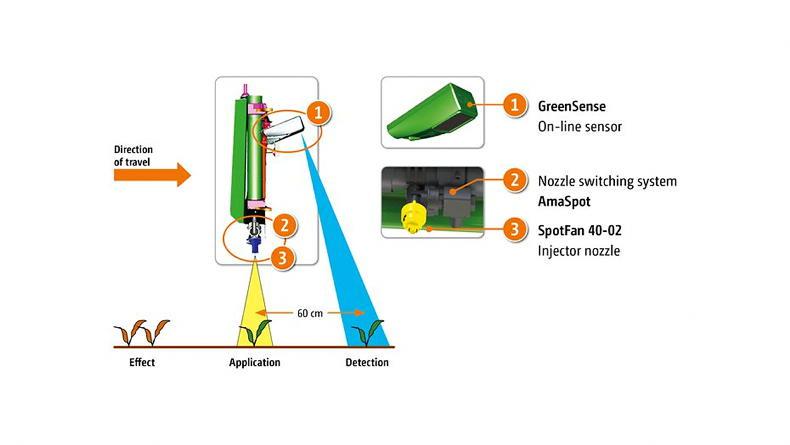

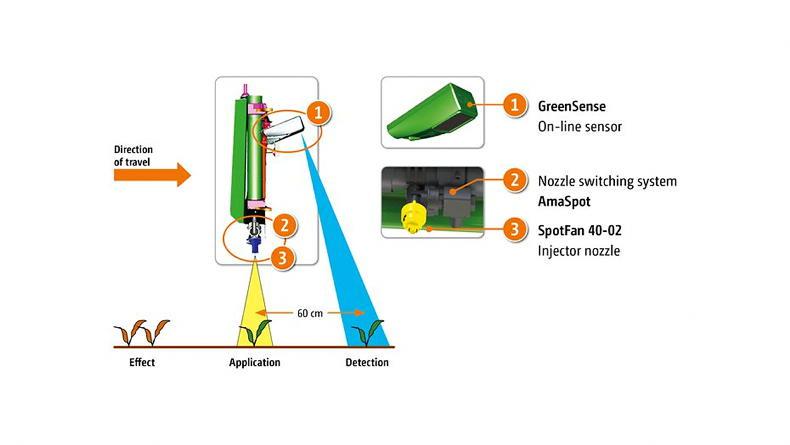

The second weeding technology, where there were significant developments on display at Agritechnica, is spot-spraying, where weeds are only sprayed where they are identified.

Nozzle placement on these high precision systems is 3.5 cm to 4cm compared to 50cm on a standard sprayer in order to target areas as small as 4cm x 4cm (16cm2).

The concept of identifying and spraying weeds has been around for at least 30 years, but bringing it to reality has been a slow process; but progress is being made.

Bayer exhibited a 6m development model of their high-precision green-on-green sprayer which had a 4cm x 4cm spot spraying target resolution.

All of these systems use similar weed sensing approaches using one or more camera type sensors; either RGB (visible spectrum) or multispec sensors (additional non-visible wavelengths) to help identify the weeds or weedy areas.

But there is a huge difference in the capabilities and precision with which different versions of this technology operate.

Currently the technology can largely be divided into three categories:

Green-on-Brown spot spraying technologyGreen-on-Green standard precision for selective herbicides usedGreen-on-Green high precision where individual weeds are targeted allowing non-selective herbicides to be used.

The 'green on brown' system simply identifies green growth in a fallow or stubble background.

To improve weed detection, the sprayer uses a hooded boom and camera system, with powerful LED lighting, ensuring that the captured images/crop reflectance is not impacted by poor or variable natural light.

The Bilberry system uses RGB cameras to send images to the controller, which identifies weeds through the use of AI in real-time before making decision to spot spray the targeted area.

Up to now, herbicide use has been the solution to weed problems, but for a multitude of reasons, this is changing and the focus is now on development of integrated control measures where herbicide use is minimised.

This approach will continue as herbicide resistance increases, new herbicide introductions fall, and a desire for less pesticide use grows among the general population.

While some crops can be managed to reduce weed development and growth, through crop choice, time of sowing, seeding rate, row spacing and other management strategies; in most cases significant weed development will still occur and weed destruction will still be required.

There are three categories of post emergence weed destruction that can be used as part of integrated weed control strategies:

Mechanical weed control (including stale seedbed)Novel physical approaches: thermal, water or electrical weed control strategiesTargeted application of herbicidesMechanical weed control and targeted application of herbicides were featured strongly at Agritechnica 2023.

Mechanical weed control

The majority of cultivation equipment manufacturers displaying at Agritechnica have acquired expertise and developed machines either in-house or through the acquisition of smaller companies that were specialising in this area.

There are a range of

technologies in this area varying in sophistication. These include:

Simple fixed position tine weeders that rely on spring pressure and timing of the treatment to damage the weeds, but leave the sown crop or plants unscathed.Newer rotary weed hoes that use two rows of spider wheel type elements with even ground pressure to damage weeds more than the plants, eg, Kverneland Helios.Inter-row cultivator for field crops, which are now almost universally fitted with camera sensor technology and a side-shift frame to allow them centre the hoeing elements between the row plants. While these were traditionally used in row crops like beet or vegetables, at Agritechnica, some models were shown with a row accuracy and tool set-up capable of hoeing between standard 125mm cereal seed rows.

While inter-row weeders were traditionally used in row crops, manufacturers are now offering machines capable of working in 125mm cereal seed rows.

Inter-row and inter-plant weeders using more complex sensor and tool control systems, working at lower forward speeds in rows with individually spaced plants. These are more suited to high value horticultural crops and are capable of weeding between plants as well as between rows.Autonomous weeders using arrays of weed identification and position sensors along with mechatronic weeding tools, which work slowly and carefully around the plants, normally in horticultural plants, but potentially in any row-crop situation. There are a number of these on the market with the companies Naio and Farmdroid being well established.Many of these technologies were shown at the 2023 Crops and Cover Crops Open day at Oak Park in June.

While mechanical weeders will have a role to play, their complexity and operational cost increases rapidly as more effective weeding is required and the need for continuous shallow soil working can also be quite hard on the soil.

Challenge

Perhaps most challenging of all though, in a wetter climate like ours, is whether the weeds will quickly recover, as mechanical weeders may be more effective in dry climates.

Getting the timing right in our conditions, to knock out the weeds, prevent soil damage and avoid weed regrowth, could be challenging.

But we have used basic versions of these systems before, mainly as steerage hoes; no doubt we can do it again if conditions demand it.

Spot spraying of weeds

The second weeding technology, where there were significant developments on display at Agritechnica, is spot-spraying, where weeds are only sprayed where they are identified.

Nozzle placement on these high precision systems is 3.5 cm to 4cm compared to 50cm on a standard sprayer in order to target areas as small as 4cm x 4cm (16cm2).

The concept of identifying and spraying weeds has been around for at least 30 years, but bringing it to reality has been a slow process; but progress is being made.

Bayer exhibited a 6m development model of their high-precision green-on-green sprayer which had a 4cm x 4cm spot spraying target resolution.

All of these systems use similar weed sensing approaches using one or more camera type sensors; either RGB (visible spectrum) or multispec sensors (additional non-visible wavelengths) to help identify the weeds or weedy areas.

But there is a huge difference in the capabilities and precision with which different versions of this technology operate.

Currently the technology can largely be divided into three categories:

Green-on-Brown spot spraying technologyGreen-on-Green standard precision for selective herbicides usedGreen-on-Green high precision where individual weeds are targeted allowing non-selective herbicides to be used.

The 'green on brown' system simply identifies green growth in a fallow or stubble background.

To improve weed detection, the sprayer uses a hooded boom and camera system, with powerful LED lighting, ensuring that the captured images/crop reflectance is not impacted by poor or variable natural light.

The Bilberry system uses RGB cameras to send images to the controller, which identifies weeds through the use of AI in real-time before making decision to spot spray the targeted area.

SHARING OPTIONS