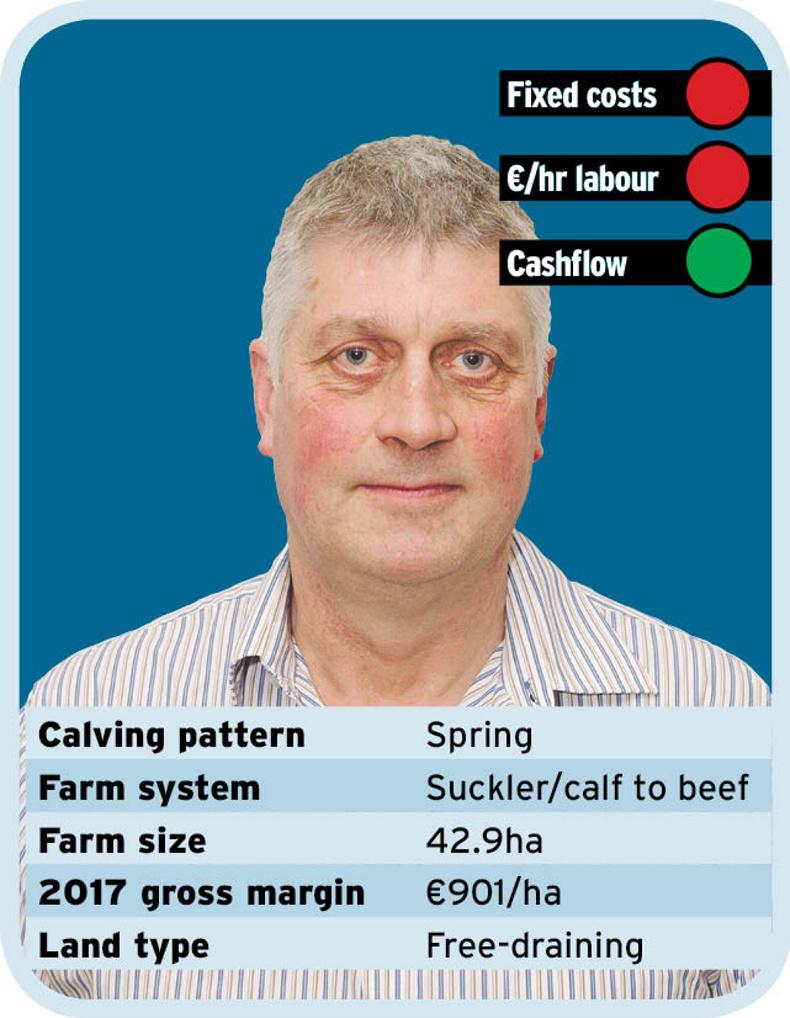

Ciarán Lenehan visited Carlow BETTER farmer Tom Bolger, who has embraced technology to improve bottom line and reduce labour.

Tom Bolger calves 50 suckler cows alongside a calf-rearing enterprise on 43ha near Borris in Carlow.

An ever-shrinking sheep flock runs alongside the herd, which calves in spring. Change has been afoot in the last couple of years – Tom has moved from a store-selling enterprise, towards finishing his own animals.

Given the weight for age he was achieving consistently, it was a no-brainer. In 2017, his homebred steers killed out at an average of 411kg carcase, grading U=, 3+ at two years-of-age.

Tom farms in conjunction with his son Ian and the pair share an ingenuity when it comes to farm tasks and safety. Whether it’s an investment in technology that can make their life easier, or the construction of equipment themselves, there are examples of innovation and clever adaptations dotted all over the farm. With some farm safety measures chronicled in an article last year, this time around we went in search of labour-reducing equipment on the Bolger’s farm.

Dehorning crate

“Dehorning is a breeze with this thing. We built it all from scratch,” Tom told me.

The crate is on wheels and has dedicated handles for movement. Calves walk in from the back, are caught in an adjustable headlock and are then restrained by movable side walls which pivot from the calf’s head.

A chain can be slipped under the calf to prevent him going down. The head is caught pointing downwards in a circular nose ring and held in place by a bar which is adjustable and locks down on the back of the head.

One of the most impressive aspects of the crate is that the calf exits through the front – there is less stress on both the calf and operator.

MooCall Heat

“I was spending hours watching heifers every week last year and still getting it hard to pick them up,” Tom told me.

“I vasectomised a dairy Hereford bull this year, bought the device, tagged the cows and put the (MooCall) collar on him – now he’s on the job the whole time,” Tom said.

He was particularly satisfied with the device’s simplicity – aim the phone’s camera at one of the MooCall RFID tags, scan it, enter the animal’s ear tag number, press “OK” and tag her.

Update text

“I get a text when there’s an animal on heat. The only thing I have to change is the time I get my daily update text – it’s set at 5.30am for some reason,” Tom joked.

“What I’m particularly impressed with is how accurate it’s been – the heifers I’ve served so far have had lovely clear mucous coming out of them and were opened up lovely inside for serving,” Tom said.

Loader-mounted sprayer

“This is simply a quad sprayer that we made a bracket for – there’s one for the lawnmower too. I can work the nozzle from the cab and it keeps me out of the spray drift. I’m spraying along electric fences at the minute with Grazeon Pro for nettles and docks.

The boom is adjustable. I can go at 6-7km/h so you get a lot of paddocks covered in an evening.

Automatic calf feeder

“We wanted to drive on the calf-rearing enterprise here. Before, we were using a six-teat trough hanging across a gate and rearing small numbers. Expanding with the same system would mean lots of smaller pens – a nightmare for cleaning out and bedding as well as a significant investment required in infrastructure like gates, troughs, feeders, racks, etc. Bigger numbers would also need some sort of a milk trolley that would mix the milk and then distribute to the troughs,” Tom told me.

When he and Ian did the sums, the change would require €3,000-4,000 worth of investment. At the time, a secondhand Volac Calf Mom automatic calf feeding system with two stations was available for €5,000 and they opted to purchase.

“It’s the biggest labour-saver on the whole farm and we’re thrilled with it. It has reared 56 calves this year. It feeds every calf six litres daily in three equal feeds and will introduce calves to and wean calves off feed gradually (weaned over two weeks) based on your inputted targets. At the moment, we’re rearing calves on around 28kg of milk powder in total,” Tom pointed out.

The system automatically undergoes a vigorous washout procedure twice daily and alerts the Bolgers when individual calves have not visited the machine or consumption is below target.

“I can clean out the pens with the loader every ten days. If we had smaller pens it would be a job for the spring (pitchfork),” Tom concluded.

SHARING OPTIONS