Yield mapping is a term becoming more prevalent in Irish agriculture, particularly within the tillage sector, and one that we believe is here to stay. The process of yield mapping is as simple as the term sounds – it’s collecting and recording geo-referenced yield-related data in a given field. This data is then used to produce a yield map to visually show yield distribution within a field using colour. By analysing and using this data, results-based decisions can then be made regarding seeding rates, nutrient application, etc. This allows farmers to potentially investigate low-yielding areas, make improvements, as well as potentially save and make better usage of costly inputs.

While becoming more common in Ireland, yield mapping is not new technology and something that has been done in North America, Canada parts of Europe and the UK for some time now. Measuring crop yield is essentially a starting point for any modern, precision-farming system. Once yield maps have been created, variable rate seed, fertiliser and pesticide applications are all possible using the latest of technology. Although, the majority of combine harvester manufacturers can supply yield monitoring technology from factories, it is often an option left unticked on many modern machines. Now there is a cost-effective way of measuring this invaluable yield data at a fraction of the price of upgrading the combine. Making things more attractive, yield monitors are eligible for grant aid under the current TAMS III Tillage Capital Investment Scheme (TCIS).

FarmTRX

FarmTRX is a Canadian company that specialises in retrofit yield monitor solutions. Precision farming Solutions Company and Irish Trimble distributor, Vantage Ireland is now the Irish distributor for the FarmTRX yield monitor. Having spent some time working with combines in Australia, Vantage Ireland’s Andrew Shorten had noticed that a lot of combines in the region where he had worked were all fitted with the Canadian solution. Upon moving home and taking up a role with Vantage, Andrew and the team felt such a solution would be of interest to Irish tillage farmers. Last year, Vantage successfully trialled a number of units ahead of becoming official Irish sales partners this year. To date, Vantage has seven units fitted to machines across the country.

“We feel that yield data and yield maps are going to become more and more important in the future. Whether it’s recording yield for carbon credits in the future, or to simply maximise land and input performance, it is something that will undoubtedly become more popular. It’s an inexpensive solution that has the potential to bring savings. The beauty of the FarmTRX system is that it will work on any machine with a clean grain elevator,” Andrew explained.

We caught up with Andrew to walk through the fitment of the FarmTRX Plus+ yield monitor to a 2012 Claas Lexion 650 combine. Andrew pointed out that the fitment process is a fairly straightforward procedure, taking in the region of two to three hours on most machines and something the majority of farmers could do themselves.

FarmTRX offer two solutions, Base and Plus+. According to Andrew, the main difference is the accuracy of the GPS antenna. The Plus+ model can achieve an accuracy down to 20cm in RTK mode, which is said to be 10 times more accurate than the Base model antenna.

What’s in the box?

The system comes practically plug-and-play. Inside the box there is the two-part elevator sensor (sender and receiver), control unit, wiring harnesses and the GPS antenna, which determines field positioning for geo-referencing. A drill bit for cutting the two holes in the clean grain elevator is also included. The in-cab tablet display is optionally available to view live harvest data. While it’s not essential, it is an option most customers tend to fit.

Fitment process

The first port of call is to mount the sensors – which first involves drilling a hole straight through the side of the clean grain elevator and centrally between the internal paddles. Andrew outlined that the closer the hole is to the top of the elevator, the better for accuracy purposes.

“By the time grain gets to the top of the elevator, any grains that were going to fall off would have at this stage. It’s also important that the paddles are in good condition and that the chain is kept tensioned,” Andrew said.

Since there is a sender and a receiver sensor, it’s important that both are directly facing each other. The sensors are already fitted with a bracket, which quickly attaches to the elevator without the need for any tools or fixings.

The next step is to mount the controller in the cab and run the wiring harness from it down to the sensors. The controller will need a 12V power source, which can be taken from a socket within the cab. Andrew recommends carefully considering the route of the harness and to avoid any areas where the harness may be exposed to direct engine heat or moving parts. Cable ties will be needed to securely fasten the harness along the way. The magnetic GPS antenna then needs to be positioned on the cab roof and its cable run back to the controller in the cab.

Where used, the tablet display screen is mounted on a simple Ram mount and connects wirelessly over Bluetooth to the controller.

Setup and calibration

Once installed, a customer account needs to be created, which gives them one year’s free access to the FarmTRX portal. After the first year, farmers harvesting up to 500ac will pay a €250/year subscription while farmers up to 2,000ac will pay €500/year. Once set up, all field boundaries are inputted or imported. Upon completion, the relevant yield data will be shown within these boundaries.

On screen, the operator selects the crop type and header width and from here can view all the associated live harvest information. This includes threshing time, yield, forward speed, area covered and moisture (if retrofitted). To calibrate the system, the yield monitor reading can be edited and changed out for the weighbridge reading via the portal. The yield maps are then updated accordingly.

Connectivity

Through the optional cloud sync feature, all harvest data can be uploaded to the FarmTRX portal once an internet connection has been established. From here, yield maps are created for post-harvest analysis and sharing with third party platforms.

Data can also be transferred manually using a USB/SD card. The controller itself has the capacity to store up to five years of harvest data.

The FarmTRX platform is now fully integrated with John Deere Operations Centre and Trimble Ag Software for the seamless transfer of yield map data, which can then be used for further analysis, variable rate applications, such as drilling, fertiliser spreading, etc.

Costs

As outlined above, FarmTRX offers a base and a Plus+ package. According to Andrew, the Base kit is priced at €3,100 plus VAT and the Plus+ is priced at €3,500 plus VAT. Both prices include installation, setup and a tablet display and Ram mounting bracket. For the sake of the small price difference, most customers will opt for the Plus+ and add-ons available, for the increased accuracy.

FarmTRX also offers a retrofit moisture sensor which can be added to the kit. It is fitted in a similar manner to the clean grain elevator and costs an additional €1,150 plus VAT.

Andrew confirmed that the FarmTRX yield monitor system does fall under TAMS III TCIS, meaning that all farmers are eligible for 40% grant, while female and young farmers are eligible for 60% grant aid.

Case study: Thomas Greene, Co Kildare

Farming in Castledermot, Co Kildare, Thomas Greene grows a mix of winter and spring cereals, as well as peas and oilseed rape, all of which are established by direct drilling. Last year, the farm’s 2001 Claas Medion combine was upgraded to a used Claas Lexion 650.

Keen to find an easier way to make informed decisions in order to maximise farm inputs and land performance, while keeping expenditure to a minimum, Thomas felt that variable rate applications were the next step. In order to do this, a combine yield monitor was the starting point and necessity to gather yield data.

“I first considered yield monitoring a number of years back. Prior to Vantage Ireland I had come across the FarmTRX system, but there was no Irish agent and Claas’ own system was working out too costly to retrofit.”

“When Vantage took on the agency I had the yield monitor and moisture meter fitted. So far it has been great. Everything about it has been straightforward, it’s a neat easy to use package. If I upgrade the combine in years to come, I can transfer the system across in minutes.”

“I use Farmplan as a third party platform to view and analyse the data collected and help make cropping decisions and nutrient plans. So far, I have used the data for variable rate fertiliser applications and to target areas for soil sampling. The intention in due course is to get to the point of variable rate seeding,” Thomas explained.

The sensor fitted to the clean grain elevator.

The control unit mounted inside the cab.

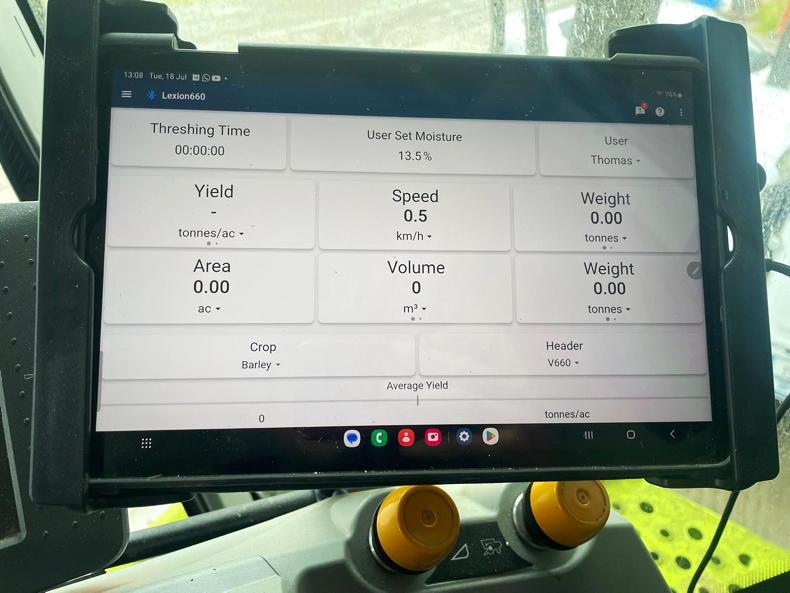

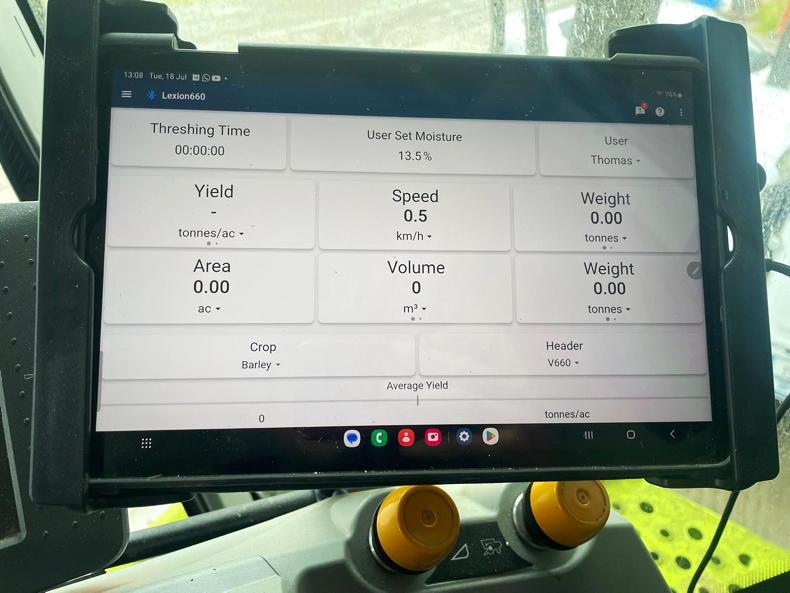

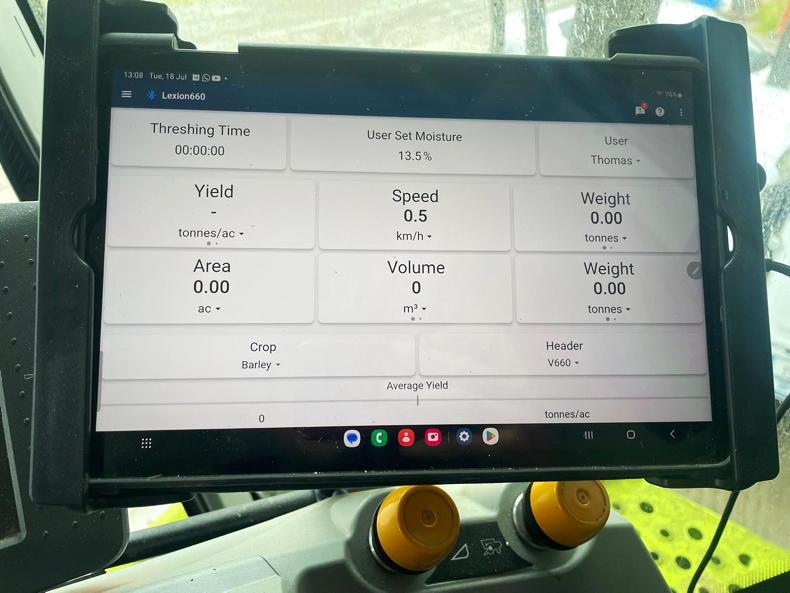

The optional tablet display wirelessly shows live yield information.

Through the optional cloud sync feature, all harvest data can be uploaded to the FarmTRX portal once an internet connection has been established.

Connect FarmTRX yield data working on the Trimble Ag platform.

The installation process can take as little as one hour.

The FarmTRX platform is fully integrated with John Deere Operations Centre and Trimble Ag Software.

The yield map displayed on the FarmTRX portal.

All yield data is synced to the portal where it can be corrected or converted into a visual report.

Yield mapping is a term becoming more prevalent in Irish agriculture, particularly within the tillage sector, and one that we believe is here to stay. The process of yield mapping is as simple as the term sounds – it’s collecting and recording geo-referenced yield-related data in a given field. This data is then used to produce a yield map to visually show yield distribution within a field using colour. By analysing and using this data, results-based decisions can then be made regarding seeding rates, nutrient application, etc. This allows farmers to potentially investigate low-yielding areas, make improvements, as well as potentially save and make better usage of costly inputs.

While becoming more common in Ireland, yield mapping is not new technology and something that has been done in North America, Canada parts of Europe and the UK for some time now. Measuring crop yield is essentially a starting point for any modern, precision-farming system. Once yield maps have been created, variable rate seed, fertiliser and pesticide applications are all possible using the latest of technology. Although, the majority of combine harvester manufacturers can supply yield monitoring technology from factories, it is often an option left unticked on many modern machines. Now there is a cost-effective way of measuring this invaluable yield data at a fraction of the price of upgrading the combine. Making things more attractive, yield monitors are eligible for grant aid under the current TAMS III Tillage Capital Investment Scheme (TCIS).

FarmTRX

FarmTRX is a Canadian company that specialises in retrofit yield monitor solutions. Precision farming Solutions Company and Irish Trimble distributor, Vantage Ireland is now the Irish distributor for the FarmTRX yield monitor. Having spent some time working with combines in Australia, Vantage Ireland’s Andrew Shorten had noticed that a lot of combines in the region where he had worked were all fitted with the Canadian solution. Upon moving home and taking up a role with Vantage, Andrew and the team felt such a solution would be of interest to Irish tillage farmers. Last year, Vantage successfully trialled a number of units ahead of becoming official Irish sales partners this year. To date, Vantage has seven units fitted to machines across the country.

“We feel that yield data and yield maps are going to become more and more important in the future. Whether it’s recording yield for carbon credits in the future, or to simply maximise land and input performance, it is something that will undoubtedly become more popular. It’s an inexpensive solution that has the potential to bring savings. The beauty of the FarmTRX system is that it will work on any machine with a clean grain elevator,” Andrew explained.

We caught up with Andrew to walk through the fitment of the FarmTRX Plus+ yield monitor to a 2012 Claas Lexion 650 combine. Andrew pointed out that the fitment process is a fairly straightforward procedure, taking in the region of two to three hours on most machines and something the majority of farmers could do themselves.

FarmTRX offer two solutions, Base and Plus+. According to Andrew, the main difference is the accuracy of the GPS antenna. The Plus+ model can achieve an accuracy down to 20cm in RTK mode, which is said to be 10 times more accurate than the Base model antenna.

What’s in the box?

The system comes practically plug-and-play. Inside the box there is the two-part elevator sensor (sender and receiver), control unit, wiring harnesses and the GPS antenna, which determines field positioning for geo-referencing. A drill bit for cutting the two holes in the clean grain elevator is also included. The in-cab tablet display is optionally available to view live harvest data. While it’s not essential, it is an option most customers tend to fit.

Fitment process

The first port of call is to mount the sensors – which first involves drilling a hole straight through the side of the clean grain elevator and centrally between the internal paddles. Andrew outlined that the closer the hole is to the top of the elevator, the better for accuracy purposes.

“By the time grain gets to the top of the elevator, any grains that were going to fall off would have at this stage. It’s also important that the paddles are in good condition and that the chain is kept tensioned,” Andrew said.

Since there is a sender and a receiver sensor, it’s important that both are directly facing each other. The sensors are already fitted with a bracket, which quickly attaches to the elevator without the need for any tools or fixings.

The next step is to mount the controller in the cab and run the wiring harness from it down to the sensors. The controller will need a 12V power source, which can be taken from a socket within the cab. Andrew recommends carefully considering the route of the harness and to avoid any areas where the harness may be exposed to direct engine heat or moving parts. Cable ties will be needed to securely fasten the harness along the way. The magnetic GPS antenna then needs to be positioned on the cab roof and its cable run back to the controller in the cab.

Where used, the tablet display screen is mounted on a simple Ram mount and connects wirelessly over Bluetooth to the controller.

Setup and calibration

Once installed, a customer account needs to be created, which gives them one year’s free access to the FarmTRX portal. After the first year, farmers harvesting up to 500ac will pay a €250/year subscription while farmers up to 2,000ac will pay €500/year. Once set up, all field boundaries are inputted or imported. Upon completion, the relevant yield data will be shown within these boundaries.

On screen, the operator selects the crop type and header width and from here can view all the associated live harvest information. This includes threshing time, yield, forward speed, area covered and moisture (if retrofitted). To calibrate the system, the yield monitor reading can be edited and changed out for the weighbridge reading via the portal. The yield maps are then updated accordingly.

Connectivity

Through the optional cloud sync feature, all harvest data can be uploaded to the FarmTRX portal once an internet connection has been established. From here, yield maps are created for post-harvest analysis and sharing with third party platforms.

Data can also be transferred manually using a USB/SD card. The controller itself has the capacity to store up to five years of harvest data.

The FarmTRX platform is now fully integrated with John Deere Operations Centre and Trimble Ag Software for the seamless transfer of yield map data, which can then be used for further analysis, variable rate applications, such as drilling, fertiliser spreading, etc.

Costs

As outlined above, FarmTRX offers a base and a Plus+ package. According to Andrew, the Base kit is priced at €3,100 plus VAT and the Plus+ is priced at €3,500 plus VAT. Both prices include installation, setup and a tablet display and Ram mounting bracket. For the sake of the small price difference, most customers will opt for the Plus+ and add-ons available, for the increased accuracy.

FarmTRX also offers a retrofit moisture sensor which can be added to the kit. It is fitted in a similar manner to the clean grain elevator and costs an additional €1,150 plus VAT.

Andrew confirmed that the FarmTRX yield monitor system does fall under TAMS III TCIS, meaning that all farmers are eligible for 40% grant, while female and young farmers are eligible for 60% grant aid.

Case study: Thomas Greene, Co Kildare

Farming in Castledermot, Co Kildare, Thomas Greene grows a mix of winter and spring cereals, as well as peas and oilseed rape, all of which are established by direct drilling. Last year, the farm’s 2001 Claas Medion combine was upgraded to a used Claas Lexion 650.

Keen to find an easier way to make informed decisions in order to maximise farm inputs and land performance, while keeping expenditure to a minimum, Thomas felt that variable rate applications were the next step. In order to do this, a combine yield monitor was the starting point and necessity to gather yield data.

“I first considered yield monitoring a number of years back. Prior to Vantage Ireland I had come across the FarmTRX system, but there was no Irish agent and Claas’ own system was working out too costly to retrofit.”

“When Vantage took on the agency I had the yield monitor and moisture meter fitted. So far it has been great. Everything about it has been straightforward, it’s a neat easy to use package. If I upgrade the combine in years to come, I can transfer the system across in minutes.”

“I use Farmplan as a third party platform to view and analyse the data collected and help make cropping decisions and nutrient plans. So far, I have used the data for variable rate fertiliser applications and to target areas for soil sampling. The intention in due course is to get to the point of variable rate seeding,” Thomas explained.

The sensor fitted to the clean grain elevator.

The control unit mounted inside the cab.

The optional tablet display wirelessly shows live yield information.

Through the optional cloud sync feature, all harvest data can be uploaded to the FarmTRX portal once an internet connection has been established.

Connect FarmTRX yield data working on the Trimble Ag platform.

The installation process can take as little as one hour.

The FarmTRX platform is fully integrated with John Deere Operations Centre and Trimble Ag Software.

The yield map displayed on the FarmTRX portal.

All yield data is synced to the portal where it can be corrected or converted into a visual report.

SHARING OPTIONS