The Irish Farmers Journal made the trip to the home of Lemken – in Alpen, western Germany,close to the Dutch border – recently.

This site is one of its nine production and assembly sites.

The company also has spare parts warehouses spread across Europe, Asia, North America and Africa.

The Alpen site is home to around 1,200 employees, who focus on building soil cultivation equipment, producing approximately 15,000 machines per year.

The plough is a key product built at the Alpen factory.

A plough was actually the very first product which Lemken secured a patent with.

In conversation with members of the Lemken sales team, they explained that in 2022, the European plough market was approximately 12,500 units.

In 2025, that market has dropped to around 6,500 ploughs, representing a significant shift in trends.

Lemken opened its new Dutch factory at the end of 2023, with the facility specifically designed for the production of mechanical crop care, following Lemken's acquisition of the Dutch company Steketee in 2018.

They explained that labour shortages and legislation are part of the reason driving these changes, which were also a key factor in Lemken developing its first no-till disc drill, the Solitair NT.

Solitair NT no-till disc drill

The Solitair NT no-till disc drill is Lemken’s first direct drill.

The new Solitair NT no-till disc drill marks the introduction of Lemken’s first direct drill. First seen by the public at Agritechnica last month, the drill will initially only be available in a 6m configuration, but further models are expected to come on stream in the near future.

The NT is equipped with two rows of 480mm ProDisc single-disc coulters.

These coulters are capable of placing seed and fertiliser into tilled or untilled ground with up to 340kg of downwards force. Coulter pressure can be adjusted electro-hydraulically or automatically as an option.

The 10-degree undercut and seven-degree to the direction of travel ensure reliable soil penetration in all conditions, while the integrated rubber press wheels control seeding depth (0-10cm). The depth is adjusted without tools via a preloaded lever for each seed coulter.

A series of steel wheels with adjustable angle and pressure settings work to close the seeding furrow. Row spacing is 16.7cm.

There is an option for a 4,400-litre single hopper or a 5,100-litre split hopper, while those who want to further expand the drill’s versatility and sow up to three components can opt for the 500 litre Lemken MultiHub pneumatic seeder for metering of smaller seeds.

Components within the MultiHub can be sent to the ProDisc coulters or applied via splash plates behind the coulters.

An integrated hydraulic tramline mechanism is optionally available which when engaged blocks the required seed tubes and automatically reduces the seeding rate.

The new iQblue Connect solution also introduced at Agritechnica allows numerous IsoBus and non-IsoBus implements, such as the MultiHub to be operated via a single CCI terminal or any IsoBus terminal.

The Onyx subsoiler is available in two versions.

This year, Lemken introduced its Onyx range of subsoilers for deep loosening, marking its first time building such a product.

Available in two rigid versions, the MR/300 and MR/400 offer 3m and 4m working widths.

The frame is fully welded, not assembled, which Lemken claims ensures stability and durability. Under-frame clearance is 90cm to provide ample clearance, even at maximum working depths.

There are two share options with a 42.5cm line spacing. The OM version has a curved leg and the guide plate is designed to move and intensively mix soil to depths ranging between 25cm and 40cm.

The OL is a straight loosening share for working depths ranging from 40cm to 60cm, suited for breaking up compacted soil layers and plough pans.

Both shares can also be equipped with wings to increase loosening and mixing of organic matter.

Hydraulic depth adjustment allows convenient operation from the driver’s seat.

The Onyx is available with two roller options: the DSW 580 double spiked roller and the RSW 600 tube bar roller. A quick-change system allows the rollers to be swapped to suit soil conditions. The Onyx range will be available in limited numbers from 2026.

Diamant 18 with integrated furrow press

The Diamant 18 with integrated furrow press.

With skilled labour shortages continuing to grow across European agriculture, the use of furrow presses in combination with ploughs is regaining popularity.

The resurgence is not only down to the efficiency of completing two jobs in one pass, but on dry soils they are often used to retain moisture in the soil.

Lemken already has a significant plough range, and is further expanding this with its new integrated FlexPack furrow press for the Diamant 18 semi-mounted plough.

According to the manufacturer, this makes the six- to eight-furrow Diamant 18 the only single-wheel semi-mounted plough on the market that can be combined with a directly mounted furrow press as standard. In order to make the Diamant and FlexPack possible in the in-furrow version, Lemken says the design of the transport wheel was changed and the wheel was moved behind the base frame with the introduction of the Diamant 18.

It explains that this new position of the wheel offers a low centre of gravity, reducing torsional loads and ensuring high tipping stability at the headland. The rearmost plough body maintains the set working depth, even in hilly terrain.

In addition to its own weight, the FlexPack furrow press can be hydraulically pressurised, allowing it to be adapted to different soil conditions.

It can also be used together with the OptiStone hydraulic overload protection system on the plough, making it suitable for stony conditions.

To help avoid stones, each pair of rings is suspended individually from spring steel elements. Unlike traditional presses, the Lemken system is permanently mounted, meaning there is no coupling or uncoupling of the furrow press, or to transport it separately.

Lemken has sold several Diamant 18 and FlexPack combinations in Ireland for the 2026 season, with an eight furrow also set for demonstration.

Solitair power harrow combination drill

To start, the Solitair PT combi drill is coming in one working width.

Lemken has introduced its first Solitair PT, a trailed power harrow combination drill. The new seed drill features an integrated Zirkon power harrow, equipped with four tine carriers per metre of working width. The power harrow features hydraulic depth adjustment as standard.

The working depth, rotor speed and forward speed can all be adjusted individually.

This allows the Solitair PT to work either extensively at a shallow depth or deeply, depending on the job at hand.

The levelling bar can also be adjusted hydraulically or mechanically.

The Solitair PT is available in two variants. It comes with a choice of either a single tank with a 4,400-litre capacity, or a double tank with a capacity of 5,100 litres (40:60 split). At the heart of the Solitair PT is the coulter bar with parallelogram-guided double disc coulters, available as OptiDisc M (up to 45kg coulter pressure) or OptiDisc H (up to 70kg coulter pressure).

The coulter pressure can be adjusted mechanically or hydraulically, independently of the seed depth. Buyers can opt for a pre-running trapeze packer roller, which provides better seed-to-soil contact.

Lemken noted that the Solitair PT is designed with a long drawbar, allowing it to turn in tight manoeuvres with big tractors.

Optional tools such as a leading tyre packer, wheel mark eradicator discs or tractor wheel mark eradicators allow for targeted adaptation.

Mounted, folding Solitair MF

The Solitair MF is available in three working widths.

With its new Solitair MF (mounted folding) pneumatic seed drill, Lemken is launching a folding counterpart to the popular Solitair MR (mounted rigid).

The new Solitair MF is available with a working width of four, four and a half and six metres.

The basic version of the Solitair MF comes with two electrically operated metering units, each of which supplies one seed distributor. This design allows width section or half-side control as standard.

With the larger working width of six metres, the seed drill can be extended to up to four width sections. Lemken said the metering units are corrosion-resistant, and thus suitable for use with fertiliser.

The metering wheels can be changed without tools, which allows for quick adaptation to different types of seeds. It can even be changed when the hopper is full, thanks to an integrated shut-off gate.

The dose rate can be set between 0.5 and 500kg/ha from the cab.

The seed hopper of the Solitair MF has a capacity of 2,000 litres.

A double tank with a 60:40 split is available as an option. The Solitair MF can also be combined with the Solitair F front tank (1,900 or 2,400 litres) for users who want more capacity, or to hold additional components.

The tank can be drained via either the 90 mm flap or, for smaller residual quantities, via the metering unit.

At the business end of the drill, it features the OptiDisc coulter bar with parallelogram-guided OptiDisc M double disc coulters.

They offer mechanically adjustable coulter pressure of up to 45kg. The sowing depth can be adjusted centrally from the left-hand side of the machine, independent of the coulter pressure.

There is a choice of row spacings, either 12.5 or 15cm. The coulter bar can be complemented by optional harrow variants, which can be adjusted without tools and optimally adapted to variable operating conditions.

For road transport, the flagship Solitair MF/600 is equipped with an automatic transport support wheel that is controlled automatically when the coulter bar is folded in or out.

Lemkens iQblue machine connect networks several machines, both with and without their own Isobus function, to form a logically coherent unit.

Lemken’s iQblue connect is a cross-manufacturer, IsoBus-based module which is designed to automate agricultural implement functions. It has several functions, such as allowing combinations of a front tank, seed drill, and catch crop or granule spreader to be operated and documented as a single implement. The control of these machines is handled via a single IsoBus terminal, reducing hardware requirements, making the driver’s life easier.

It also enables smart farming features on both new and existing machines.

The system allows the implement, such as a plough or cultivator etc, to control certain tractor functions via the IsoBus standard Tractor-Implement Management (TIM). It controls functions such as forward speed, hydraulic control and lift height.

The aim is to automate repetitive tasks and remove the potential for human error.

The portable module can be retrofitted to a variety of existing machines from different manufacturers, thus, it’s not specific to Lemken kit. Specific sensor kits are available for different implements, such as ploughs and cultivators.

The system is designed to make fieldwork more efficient and precise. For example, when ploughing, GPS-controlled working width adjustment creates straight furrows and manages wedge-shaped fields optimally.

Meanwhile, when cultivating, area-specific working depth adjustment based on pre-loaded field maps, helps optimise fuel consumption and soil health.

The system facilitates seamless and automatic data management by integrating machine data into existing documentation and farm management systems.1

The Irish Farmers Journal made the trip to the home of Lemken – in Alpen, western Germany,close to the Dutch border – recently.

This site is one of its nine production and assembly sites.

The company also has spare parts warehouses spread across Europe, Asia, North America and Africa.

The Alpen site is home to around 1,200 employees, who focus on building soil cultivation equipment, producing approximately 15,000 machines per year.

The plough is a key product built at the Alpen factory.

A plough was actually the very first product which Lemken secured a patent with.

In conversation with members of the Lemken sales team, they explained that in 2022, the European plough market was approximately 12,500 units.

In 2025, that market has dropped to around 6,500 ploughs, representing a significant shift in trends.

Lemken opened its new Dutch factory at the end of 2023, with the facility specifically designed for the production of mechanical crop care, following Lemken's acquisition of the Dutch company Steketee in 2018.

They explained that labour shortages and legislation are part of the reason driving these changes, which were also a key factor in Lemken developing its first no-till disc drill, the Solitair NT.

Solitair NT no-till disc drill

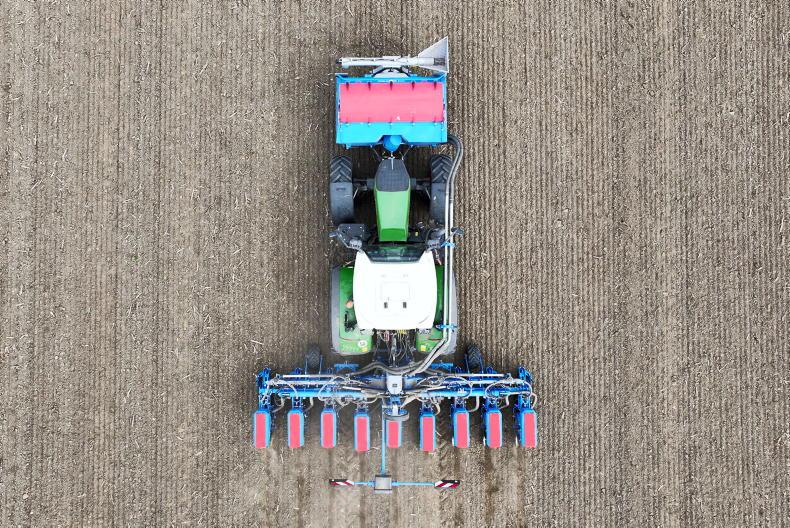

The Solitair NT no-till disc drill is Lemken’s first direct drill.

The new Solitair NT no-till disc drill marks the introduction of Lemken’s first direct drill. First seen by the public at Agritechnica last month, the drill will initially only be available in a 6m configuration, but further models are expected to come on stream in the near future.

The NT is equipped with two rows of 480mm ProDisc single-disc coulters.

These coulters are capable of placing seed and fertiliser into tilled or untilled ground with up to 340kg of downwards force. Coulter pressure can be adjusted electro-hydraulically or automatically as an option.

The 10-degree undercut and seven-degree to the direction of travel ensure reliable soil penetration in all conditions, while the integrated rubber press wheels control seeding depth (0-10cm). The depth is adjusted without tools via a preloaded lever for each seed coulter.

A series of steel wheels with adjustable angle and pressure settings work to close the seeding furrow. Row spacing is 16.7cm.

There is an option for a 4,400-litre single hopper or a 5,100-litre split hopper, while those who want to further expand the drill’s versatility and sow up to three components can opt for the 500 litre Lemken MultiHub pneumatic seeder for metering of smaller seeds.

Components within the MultiHub can be sent to the ProDisc coulters or applied via splash plates behind the coulters.

An integrated hydraulic tramline mechanism is optionally available which when engaged blocks the required seed tubes and automatically reduces the seeding rate.

The new iQblue Connect solution also introduced at Agritechnica allows numerous IsoBus and non-IsoBus implements, such as the MultiHub to be operated via a single CCI terminal or any IsoBus terminal.

The Onyx subsoiler is available in two versions.

This year, Lemken introduced its Onyx range of subsoilers for deep loosening, marking its first time building such a product.

Available in two rigid versions, the MR/300 and MR/400 offer 3m and 4m working widths.

The frame is fully welded, not assembled, which Lemken claims ensures stability and durability. Under-frame clearance is 90cm to provide ample clearance, even at maximum working depths.

There are two share options with a 42.5cm line spacing. The OM version has a curved leg and the guide plate is designed to move and intensively mix soil to depths ranging between 25cm and 40cm.

The OL is a straight loosening share for working depths ranging from 40cm to 60cm, suited for breaking up compacted soil layers and plough pans.

Both shares can also be equipped with wings to increase loosening and mixing of organic matter.

Hydraulic depth adjustment allows convenient operation from the driver’s seat.

The Onyx is available with two roller options: the DSW 580 double spiked roller and the RSW 600 tube bar roller. A quick-change system allows the rollers to be swapped to suit soil conditions. The Onyx range will be available in limited numbers from 2026.

Diamant 18 with integrated furrow press

The Diamant 18 with integrated furrow press.

With skilled labour shortages continuing to grow across European agriculture, the use of furrow presses in combination with ploughs is regaining popularity.

The resurgence is not only down to the efficiency of completing two jobs in one pass, but on dry soils they are often used to retain moisture in the soil.

Lemken already has a significant plough range, and is further expanding this with its new integrated FlexPack furrow press for the Diamant 18 semi-mounted plough.

According to the manufacturer, this makes the six- to eight-furrow Diamant 18 the only single-wheel semi-mounted plough on the market that can be combined with a directly mounted furrow press as standard. In order to make the Diamant and FlexPack possible in the in-furrow version, Lemken says the design of the transport wheel was changed and the wheel was moved behind the base frame with the introduction of the Diamant 18.

It explains that this new position of the wheel offers a low centre of gravity, reducing torsional loads and ensuring high tipping stability at the headland. The rearmost plough body maintains the set working depth, even in hilly terrain.

In addition to its own weight, the FlexPack furrow press can be hydraulically pressurised, allowing it to be adapted to different soil conditions.

It can also be used together with the OptiStone hydraulic overload protection system on the plough, making it suitable for stony conditions.

To help avoid stones, each pair of rings is suspended individually from spring steel elements. Unlike traditional presses, the Lemken system is permanently mounted, meaning there is no coupling or uncoupling of the furrow press, or to transport it separately.

Lemken has sold several Diamant 18 and FlexPack combinations in Ireland for the 2026 season, with an eight furrow also set for demonstration.

Solitair power harrow combination drill

To start, the Solitair PT combi drill is coming in one working width.

Lemken has introduced its first Solitair PT, a trailed power harrow combination drill. The new seed drill features an integrated Zirkon power harrow, equipped with four tine carriers per metre of working width. The power harrow features hydraulic depth adjustment as standard.

The working depth, rotor speed and forward speed can all be adjusted individually.

This allows the Solitair PT to work either extensively at a shallow depth or deeply, depending on the job at hand.

The levelling bar can also be adjusted hydraulically or mechanically.

The Solitair PT is available in two variants. It comes with a choice of either a single tank with a 4,400-litre capacity, or a double tank with a capacity of 5,100 litres (40:60 split). At the heart of the Solitair PT is the coulter bar with parallelogram-guided double disc coulters, available as OptiDisc M (up to 45kg coulter pressure) or OptiDisc H (up to 70kg coulter pressure).

The coulter pressure can be adjusted mechanically or hydraulically, independently of the seed depth. Buyers can opt for a pre-running trapeze packer roller, which provides better seed-to-soil contact.

Lemken noted that the Solitair PT is designed with a long drawbar, allowing it to turn in tight manoeuvres with big tractors.

Optional tools such as a leading tyre packer, wheel mark eradicator discs or tractor wheel mark eradicators allow for targeted adaptation.

Mounted, folding Solitair MF

The Solitair MF is available in three working widths.

With its new Solitair MF (mounted folding) pneumatic seed drill, Lemken is launching a folding counterpart to the popular Solitair MR (mounted rigid).

The new Solitair MF is available with a working width of four, four and a half and six metres.

The basic version of the Solitair MF comes with two electrically operated metering units, each of which supplies one seed distributor. This design allows width section or half-side control as standard.

With the larger working width of six metres, the seed drill can be extended to up to four width sections. Lemken said the metering units are corrosion-resistant, and thus suitable for use with fertiliser.

The metering wheels can be changed without tools, which allows for quick adaptation to different types of seeds. It can even be changed when the hopper is full, thanks to an integrated shut-off gate.

The dose rate can be set between 0.5 and 500kg/ha from the cab.

The seed hopper of the Solitair MF has a capacity of 2,000 litres.

A double tank with a 60:40 split is available as an option. The Solitair MF can also be combined with the Solitair F front tank (1,900 or 2,400 litres) for users who want more capacity, or to hold additional components.

The tank can be drained via either the 90 mm flap or, for smaller residual quantities, via the metering unit.

At the business end of the drill, it features the OptiDisc coulter bar with parallelogram-guided OptiDisc M double disc coulters.

They offer mechanically adjustable coulter pressure of up to 45kg. The sowing depth can be adjusted centrally from the left-hand side of the machine, independent of the coulter pressure.

There is a choice of row spacings, either 12.5 or 15cm. The coulter bar can be complemented by optional harrow variants, which can be adjusted without tools and optimally adapted to variable operating conditions.

For road transport, the flagship Solitair MF/600 is equipped with an automatic transport support wheel that is controlled automatically when the coulter bar is folded in or out.

Lemkens iQblue machine connect networks several machines, both with and without their own Isobus function, to form a logically coherent unit.

Lemken’s iQblue connect is a cross-manufacturer, IsoBus-based module which is designed to automate agricultural implement functions. It has several functions, such as allowing combinations of a front tank, seed drill, and catch crop or granule spreader to be operated and documented as a single implement. The control of these machines is handled via a single IsoBus terminal, reducing hardware requirements, making the driver’s life easier.

It also enables smart farming features on both new and existing machines.

The system allows the implement, such as a plough or cultivator etc, to control certain tractor functions via the IsoBus standard Tractor-Implement Management (TIM). It controls functions such as forward speed, hydraulic control and lift height.

The aim is to automate repetitive tasks and remove the potential for human error.

The portable module can be retrofitted to a variety of existing machines from different manufacturers, thus, it’s not specific to Lemken kit. Specific sensor kits are available for different implements, such as ploughs and cultivators.

The system is designed to make fieldwork more efficient and precise. For example, when ploughing, GPS-controlled working width adjustment creates straight furrows and manages wedge-shaped fields optimally.

Meanwhile, when cultivating, area-specific working depth adjustment based on pre-loaded field maps, helps optimise fuel consumption and soil health.

The system facilitates seamless and automatic data management by integrating machine data into existing documentation and farm management systems.1

SHARING OPTIONS