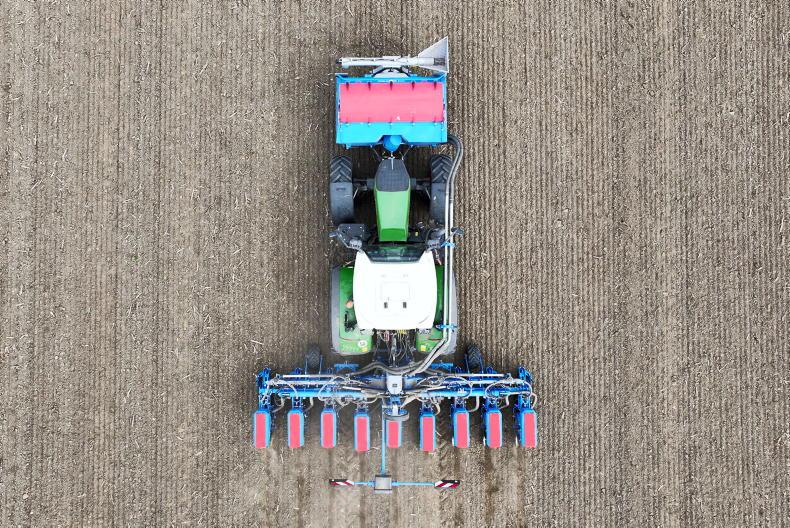

Lemken has launched its new Faya MF, a classic precision seed drill that offers a single-row seeding solution to complement the firms Azurit range with Delta Row seeding.

The Faya MF is available now as a pre-series machine, with series production scheduled to begin in 2027. The drill will be available in eight, nine or 12-row versions.

At the heart of the precision drill is a modular frame design with a working width of six metres and a two-section folding mechanism. Depending on the specific crop and the farm’s production methods, this allows a variety of row and spacing combinations to be implemented, ranging from a narrow 45cm to a maximum of 80cm. Lemken notes that the system also allows for quick conversion between 12 x 50cm and 8 x 75cm.

It says this increases the machine’s capacity and makes it economically attractive for a wide range of crops, from beet to maize.

High-speed precision

For seed singling, Lemken uses an overpressure system housed in die-cast aluminum.

It says that overpressure pushes the seeds towards the singling discs, while a scraper prevents seeds from doubling up. The implement offers three options for controlling the scraper: mechanical control per row, electrical control via the control terminal, and automatic control with grain sensor integration.

Lemken says forward speeds of up to 16km/h are possible. The singling discs can be fitted without tools.

Double disc

The manufacturer explains that the offset double disc coulter has a small opening angle, a geometry that was originally developed for direct seeding.

It says this reduces soil movement and compaction of the furrow walls, decreases the required tractive power and offers precise depth control.

Lateral depth control wheels, which can optionally be fitted with scrapers, to stabilise the system even further.

The seeding coulter can be subjected to a coulter pressure of up to 350kg and can be controlled mechanically, hydraulically or automatically.

The Faya MF also features 70-litre row hoppers for seeds, the option of under-root fertilisation via a combination unit, and the Lemken iQblue seed IsoBus control system, including automatic width section control and an automatic tramline mechanism.

SHARING OPTIONS