Despite the rise in sales of dedicated materials handlers into the sector, the humble tractor and loader remains the prime materials handler on many Irish farms. Regardless of brand, the installation of a front-mounted loader on a tractor provides farmers with a cost-effective materials handling option.

While the capabilities of the tractor and loader have increased substantially over the years, so have the demands on this dynamic combination. In particular, chopped silage bales and large shear grabs place enormous loads on the tractor’s front axle.

The Irish Farmers Journal carried out an exercise in Teagasc Oak Park, Co Carlow, to establish exactly what these loads may be. Our test tractor was a 2010 Case IH Maxxum 100, equipped with a Case IH LRZ100 loader with fork (a Case IH-branded Stoll loader with parallel linkage).

At 100hp, the Case IH Maxxum 100 is still typical of many loader tractors around the country. A four-cylinder engine and front axle tucked right up to the engine keeps its wheelbase short. This short wheelbase and compact design make it manoeuvrable around tight farmyards.

While the capabilities of the tractor and loader have increased substantially over the years, so have the demands on this dynamic combination

Our ‘load’ was a 4x4 chopped and wrapped silage bale. Ideal for our test (but not for silage quality), these bales were made in wet conditions and were very, very heavy. For the rear of the tractor, we used an 850kg three-point linkage weight.

With permission from the kind folks at Teagasc Oak Park, we used the facility’s weighbridge for all the weighing in this exercise. The weighbridge had been calibrated not long before we carried out our exercise.

We looked at many different scenarios, examining what effect carrying a load on the front loader had on both the front and rear axles of the tractor. We did this with and without ballast on the tractor’s three-point linkage, and at different loader heights.

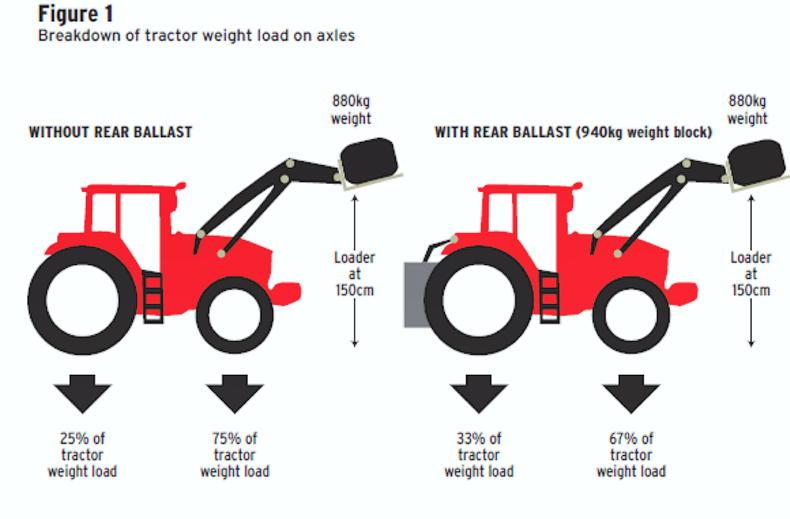

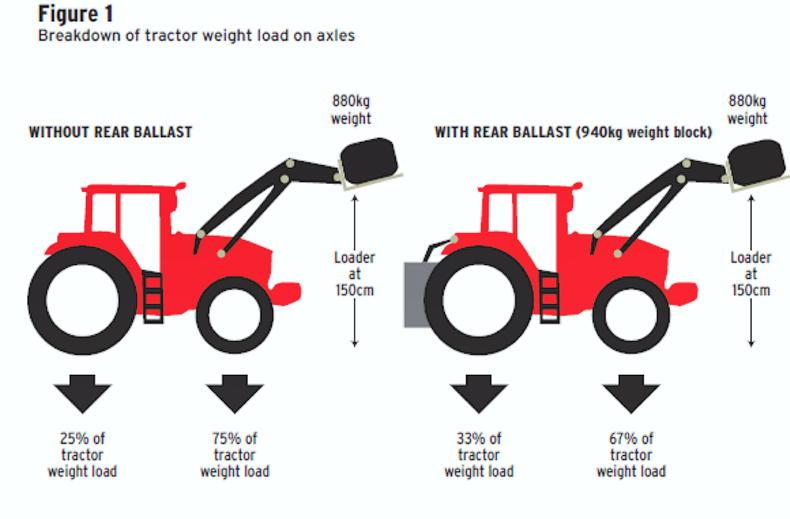

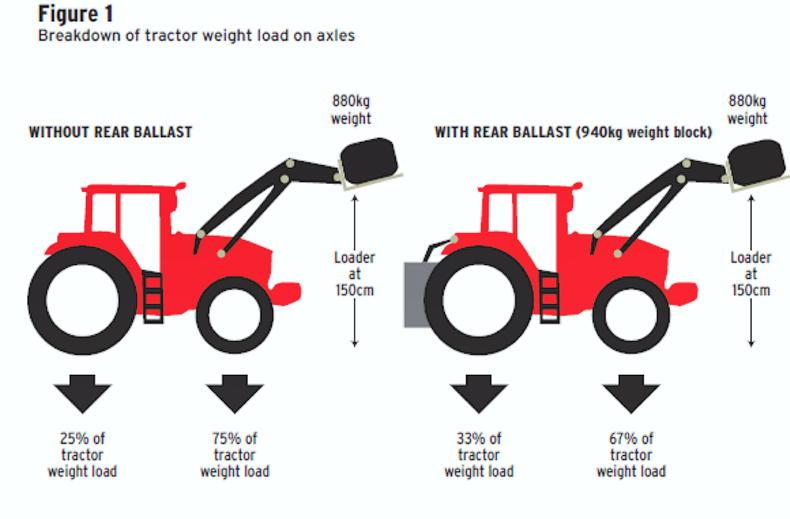

One of the biggest criteria of the exercise was to establish what effect adding rear ballast to the tractor’s rear three-point linkage would have. That is not just adding stability, but also investigating the see-saw effect by adding weight behind the rear axle.

Like a see-saw, this should create a lift in front of the tractor by pivoting over the tractor’s rear axle. So not just adding stability, but also reducing the loading on the front axle.

The weigh-in

To begin with, we weighed everything individually before starting our axle loading exercise.

Tractor weight with loader only – 6,080kg.Tractor weight with loader removed – 5,480kg.Loader weight (with fork) – 600kg.Bale weight – 880kg.Three-point linkage weight, weight with frame, drawbar storage, etc – 940kg.Axle loading

We measured axle loading at three benchmark loader heights – 300mm, 1,500mm and 3,050mm respectively – travelling with the bale, unloading the bale off a trailer and loading a bale into a diet feeder.

Due to the weight of the silage bale, we expected the results to be quite significant. That said, we were still extremely surprised by the results, in particular with the front axle load recorded with silage bale and no ballast.

Incredibly, in this, the most extreme scenario, the front axle loading was just 240kg less that the entire weight of the tractor (minus the loader) – see below. That is a huge figure of 5,240kg or 5.24t on the front axle. We accept that this was not a normal load, but nonetheless, it is a scenario that could be mirrored elsewhere if silage baling conditions were similar.

The addition of a rear weight on the tractor linkage did offset the front axle loading, but not by an awful lot. Adding the three-point linkage, 940kg rear weight reduced the front axle loading to 4,680kg.

That is a reduction of 560kg on the front axle. This was not as much as expected and highlighted the importance of adding a substantial rear weight for loader operations.

Case IH Maxxum 100 with LRZ100 front loader and rear ballast weight. Weighing front axles with bale at 1,500mm.

Adding a ballast in the form of rear wheel weights or filling the wheels with water just adds to the overall weight of the tractor.

Yes, ballasting may improve stability, but because the weight is not mounted behind the rear axles, ballasting the rear wheels provides no lift off the front axle.

In our exercise, we also found that loader position has a much larger weight-bearing effect on the front axle than we considered. As the loader is raised, it creates an arc or part of a circle.

Measuring from the centre of the front axle to the centre of the silage bale, we recorded weights at each of our three working heights.

At our first measurement height of 300mm, the distance from the centre of the front axle to centre of the bale was 2,800mm. At 1,500mm loading height, this increased to 3,300mm. At max height of the loader this reduced considerably to 2,250mm.

Front axle weight measurements for each of these heights with the rear three-point linkage weight attached were 4,620kg, 4,680kg and 4,240kg respectively. So, with the loader in its most unstable position – at max height – there is a little bit of comfort in the fact that the load on the front axle is reduced to a minimum.

The capabilities of the front tyres and front axles also need serious consideration when working with heavy loads. According to the CaseIH Maxxum 100’s operator’s manual, its maximum front axle loading is just 3,600kg. This is considerably lower than the figure of 5,240kg we recorded on test.

Front-end loader demands on a tractors front axle.

The manufacturer does make an allowance for what it describes as “restricted operation”. In the manual, it states that for intermittent operation, the front axle loading may be increased, provided that the ground speed does not exceed 8km/h (5mph).

The manufacturer’s figures for maximum axle loading under restricted operation jumps substantially upwards from 3,600kg to 6,200kg. Key requirements to remember for this level of axle loading are that it is only done intermittently and the tractor is operated below 8km/h.

Max loading figure

The maximum axle loading figure above is considerable. The capabilities of the tractor’s front tyres also need to be considered, especially when purchasing new tyres.

On the front of this CaseIH Maxxum 100 are Firestone 420/70R24 tyres. Below is the load pressure table for these tyres. From the table, it is clear that the tyres’ maximum load specification is well below CaseIH’s restricted operation figure of 6,200kg. Inflated to 1.6 bar and travelling up to 10km/h, each tyre’s maximum loading capability is quoted at 2,470kg.

Combined front axle tyre capacity is a maximum of 4,940kg. That is 60kg shy of 5t and 1,260kg less than CaseIH’s maximum axle loading for restricted usage.

More importantly, it is also 300kg less than the maximum load we had on the front axle during our test. With no rear ballast, we were 300kg above the tyres’ maximum loading. Again, this highlights the importance of carrying rear ballast on the tractor’s three-point linkage.

Points for considerations and maintenance

Before purchasing a tractor or loader, or replacing front tyres, there are many things to consider.

What is the tractor and loading going to handle? Silage bales or shear grab and their potential weights will all need to be considered before purchasing a tractor and/or a loader. Check the load rating of the tractor’s front axle. Damage caused by overloading could invalidate warranty and leave a hefty bill. Check the load rating of tyres for application, especially if purchasing new tyres. Be kind to your tractor’s front axle. Using a loader places enormous pressure on the axle least suitable to take it – the front one. Grease the front axle at least weekly if doing significant loading. Check the condition of the tractor’s tyres regularly. A blowout with a load on the loader could be catastrophic. Regularly check that tyre pressures are correct and even. Check wheel nut and rim nuts regularly for tightness. Importantly, where possible, use a three-point linkage ballast weight to reduce a loader’s impact on the front axle. It also makes the tractor more stable and ultimately safer. (Note: water ballasting or adding rear wheel weights will make the tractor and loader combination safer, but will not reduce the loading on the front axle. Ballasting the rear wheels acts on the rear axle, adding weight at that point and not behind the rear axle. So, there will be no see-saw effect to provide lift and reduce the loading on the front axle.

Despite the rise in sales of dedicated materials handlers into the sector, the humble tractor and loader remains the prime materials handler on many Irish farms. Regardless of brand, the installation of a front-mounted loader on a tractor provides farmers with a cost-effective materials handling option.

While the capabilities of the tractor and loader have increased substantially over the years, so have the demands on this dynamic combination. In particular, chopped silage bales and large shear grabs place enormous loads on the tractor’s front axle.

The Irish Farmers Journal carried out an exercise in Teagasc Oak Park, Co Carlow, to establish exactly what these loads may be. Our test tractor was a 2010 Case IH Maxxum 100, equipped with a Case IH LRZ100 loader with fork (a Case IH-branded Stoll loader with parallel linkage).

At 100hp, the Case IH Maxxum 100 is still typical of many loader tractors around the country. A four-cylinder engine and front axle tucked right up to the engine keeps its wheelbase short. This short wheelbase and compact design make it manoeuvrable around tight farmyards.

While the capabilities of the tractor and loader have increased substantially over the years, so have the demands on this dynamic combination

Our ‘load’ was a 4x4 chopped and wrapped silage bale. Ideal for our test (but not for silage quality), these bales were made in wet conditions and were very, very heavy. For the rear of the tractor, we used an 850kg three-point linkage weight.

With permission from the kind folks at Teagasc Oak Park, we used the facility’s weighbridge for all the weighing in this exercise. The weighbridge had been calibrated not long before we carried out our exercise.

We looked at many different scenarios, examining what effect carrying a load on the front loader had on both the front and rear axles of the tractor. We did this with and without ballast on the tractor’s three-point linkage, and at different loader heights.

One of the biggest criteria of the exercise was to establish what effect adding rear ballast to the tractor’s rear three-point linkage would have. That is not just adding stability, but also investigating the see-saw effect by adding weight behind the rear axle.

Like a see-saw, this should create a lift in front of the tractor by pivoting over the tractor’s rear axle. So not just adding stability, but also reducing the loading on the front axle.

The weigh-in

To begin with, we weighed everything individually before starting our axle loading exercise.

Tractor weight with loader only – 6,080kg.Tractor weight with loader removed – 5,480kg.Loader weight (with fork) – 600kg.Bale weight – 880kg.Three-point linkage weight, weight with frame, drawbar storage, etc – 940kg.Axle loading

We measured axle loading at three benchmark loader heights – 300mm, 1,500mm and 3,050mm respectively – travelling with the bale, unloading the bale off a trailer and loading a bale into a diet feeder.

Due to the weight of the silage bale, we expected the results to be quite significant. That said, we were still extremely surprised by the results, in particular with the front axle load recorded with silage bale and no ballast.

Incredibly, in this, the most extreme scenario, the front axle loading was just 240kg less that the entire weight of the tractor (minus the loader) – see below. That is a huge figure of 5,240kg or 5.24t on the front axle. We accept that this was not a normal load, but nonetheless, it is a scenario that could be mirrored elsewhere if silage baling conditions were similar.

The addition of a rear weight on the tractor linkage did offset the front axle loading, but not by an awful lot. Adding the three-point linkage, 940kg rear weight reduced the front axle loading to 4,680kg.

That is a reduction of 560kg on the front axle. This was not as much as expected and highlighted the importance of adding a substantial rear weight for loader operations.

Case IH Maxxum 100 with LRZ100 front loader and rear ballast weight. Weighing front axles with bale at 1,500mm.

Adding a ballast in the form of rear wheel weights or filling the wheels with water just adds to the overall weight of the tractor.

Yes, ballasting may improve stability, but because the weight is not mounted behind the rear axles, ballasting the rear wheels provides no lift off the front axle.

In our exercise, we also found that loader position has a much larger weight-bearing effect on the front axle than we considered. As the loader is raised, it creates an arc or part of a circle.

Measuring from the centre of the front axle to the centre of the silage bale, we recorded weights at each of our three working heights.

At our first measurement height of 300mm, the distance from the centre of the front axle to centre of the bale was 2,800mm. At 1,500mm loading height, this increased to 3,300mm. At max height of the loader this reduced considerably to 2,250mm.

Front axle weight measurements for each of these heights with the rear three-point linkage weight attached were 4,620kg, 4,680kg and 4,240kg respectively. So, with the loader in its most unstable position – at max height – there is a little bit of comfort in the fact that the load on the front axle is reduced to a minimum.

The capabilities of the front tyres and front axles also need serious consideration when working with heavy loads. According to the CaseIH Maxxum 100’s operator’s manual, its maximum front axle loading is just 3,600kg. This is considerably lower than the figure of 5,240kg we recorded on test.

Front-end loader demands on a tractors front axle.

The manufacturer does make an allowance for what it describes as “restricted operation”. In the manual, it states that for intermittent operation, the front axle loading may be increased, provided that the ground speed does not exceed 8km/h (5mph).

The manufacturer’s figures for maximum axle loading under restricted operation jumps substantially upwards from 3,600kg to 6,200kg. Key requirements to remember for this level of axle loading are that it is only done intermittently and the tractor is operated below 8km/h.

Max loading figure

The maximum axle loading figure above is considerable. The capabilities of the tractor’s front tyres also need to be considered, especially when purchasing new tyres.

On the front of this CaseIH Maxxum 100 are Firestone 420/70R24 tyres. Below is the load pressure table for these tyres. From the table, it is clear that the tyres’ maximum load specification is well below CaseIH’s restricted operation figure of 6,200kg. Inflated to 1.6 bar and travelling up to 10km/h, each tyre’s maximum loading capability is quoted at 2,470kg.

Combined front axle tyre capacity is a maximum of 4,940kg. That is 60kg shy of 5t and 1,260kg less than CaseIH’s maximum axle loading for restricted usage.

More importantly, it is also 300kg less than the maximum load we had on the front axle during our test. With no rear ballast, we were 300kg above the tyres’ maximum loading. Again, this highlights the importance of carrying rear ballast on the tractor’s three-point linkage.

Points for considerations and maintenance

Before purchasing a tractor or loader, or replacing front tyres, there are many things to consider.

What is the tractor and loading going to handle? Silage bales or shear grab and their potential weights will all need to be considered before purchasing a tractor and/or a loader. Check the load rating of the tractor’s front axle. Damage caused by overloading could invalidate warranty and leave a hefty bill. Check the load rating of tyres for application, especially if purchasing new tyres. Be kind to your tractor’s front axle. Using a loader places enormous pressure on the axle least suitable to take it – the front one. Grease the front axle at least weekly if doing significant loading. Check the condition of the tractor’s tyres regularly. A blowout with a load on the loader could be catastrophic. Regularly check that tyre pressures are correct and even. Check wheel nut and rim nuts regularly for tightness. Importantly, where possible, use a three-point linkage ballast weight to reduce a loader’s impact on the front axle. It also makes the tractor more stable and ultimately safer. (Note: water ballasting or adding rear wheel weights will make the tractor and loader combination safer, but will not reduce the loading on the front axle. Ballasting the rear wheels acts on the rear axle, adding weight at that point and not behind the rear axle. So, there will be no see-saw effect to provide lift and reduce the loading on the front axle.

SHARING OPTIONS