Kevin McCluskey is a new entrant to dairy farming, based near Carrickmacross in Co Monaghan. He has just sent the first milk to the co-op in the last fortnight.

Up to last year he was suckler farming, but decided to make the switch to dairy farming, where he hopes to get a better return for his work.

Last March, Kevin bought 60 Friesian maiden heifers and of those just two did not go in calf.

He bought another 16 in-calf heifers last back end, which means 74 heifers are due to calve this spring. To milk the cows Kevin decided to install a robotic milking machine.

Kevin was also enticed by the lifestyle benefits a robot could offer, cutting out the time he would have to spend milking cows

He said he had three reasons for going down the robotic milking route. For one, the site where the shed and robot milker are situated is very central in the farm, which suits both robotic milking and grazing systems.

Kevin was also enticed by the lifestyle benefits a robot could offer, cutting out the time he would have to spend milking cows.

Lastly, he liked the information available on each cow’s production and health available with the robot.

Before making the decision, he visited other farms with robots to ensure it was the right move for him.

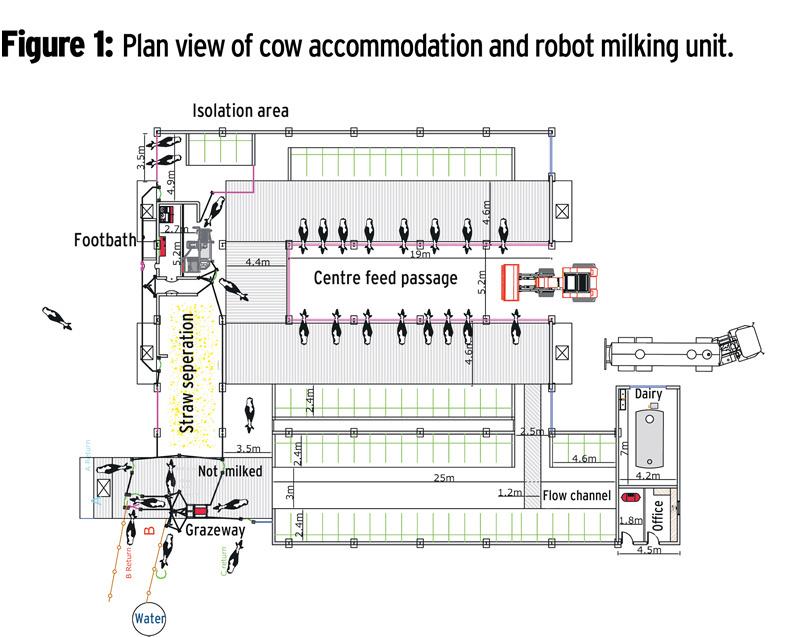

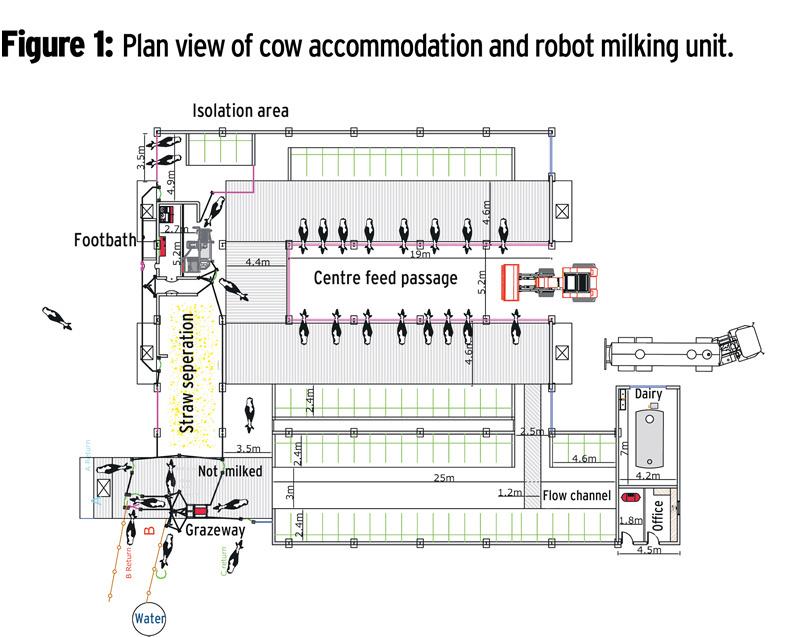

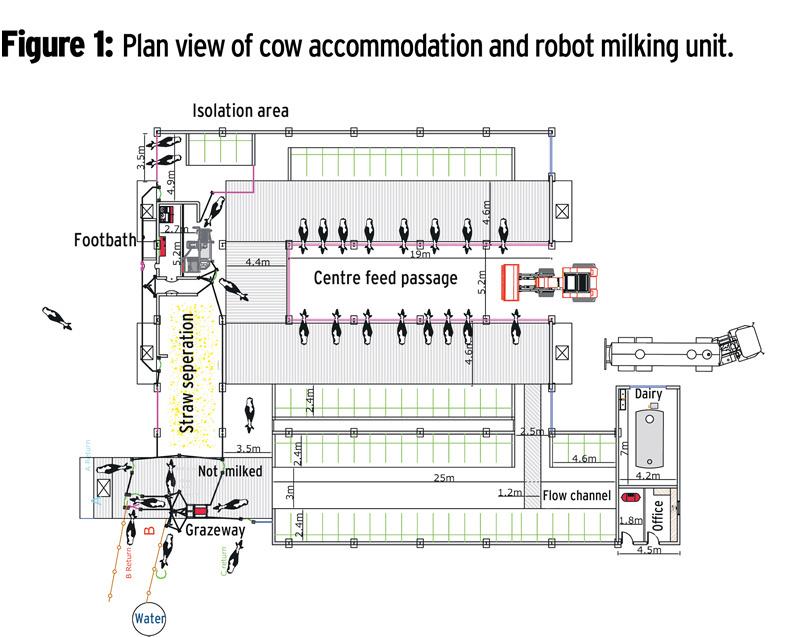

Picture one and figure one

Kevin was fortunate that he could do the conversion on a phased basis. He had already built a new six-bay suckler shed with calf creeps, which was rearranged for the new dairy development.

The shed had an unusual H-shaped tank. Pat Boylan did the concrete work for the original slatted shed and PJ Kelly did the steelwork.

To convert this shed, Kevin added cubicles to the area where the calf creeps were located and put in additional cubicles on one side. He ended up with 76 cubicles in total.

He used a walk-behind petrol scraper to clean the cow passages, and said that in the future he will look at alternative ways of automatically cleaning these passages. Another slatted tank was added underneath the grazeway gate. This will be a high cow traffic area, so it is great to be able to collect the slurry created here.

He purchased the robot from Lely Center Mullingar and they completed the design and project conversion

Barry Doogan built the tank and concrete flow channel in the topless cubicle area. Kevin had girders erected beside the topless cubicle area, just in case he plans on roofing it in the future. He installed the cubicle beds and Teemore Engineering cubicles in the shed himself. He purchased the robot from Lely Center Mullingar and they completed the design and project conversion.

According to the Lely design team, when planning a new greenfield shed or converting existing sheds, they look at trying to provide two separation areas for cows, where possible – one to cubicles and one to straw. When cows are in these areas, they are still able to cycle around the machine. It can be useful for recently calved cows and shy heifers, as they have priority access.

Picture two and three

When I spoke to Kevin, he had 27 heifers calved. He explained the calving routine he has been following: “When a heifer calves, I put her behind the calving gate. I then put a corresponder collar on her, which is used by the robot and the drafter gate to identify her movements.”

Picture two.

He then milks the heifer with a portable bucket plant and the colostrum is given to the calf. Any hair around the udder is clipped, because hair can interfere with the robotic milking sensors. The freshly calved heifer’s collar and tag number are inputted into the system computer.

I supervise the first milking to make sure everything is going to plan and the robot is doing its job

“The robot then knows that her milk needs to be withheld from the tank for four to five days and will wash itself after milking these transition cows,” said Kevin. If the heifer calves at night, Kevin will wait until the following morning to train her with the robot. “I supervise the first milking to make sure everything is going to plan and the robot is doing its job,” said Kevin.

Picture three.

On average, heifers are trained to use the robot after four to five days. “Some will learn quicker and some will take a little longer,” he explained. According to Kevin, even if a heifer is kicking, the robot will persist until she is milked. “We had one heifer that didn’t take to the machine and was getting excited, so I just decided to sell her to keep everything simple,” Kevin said.

He says it is a lot of work to train them but manageable

As he is a new entrant dairy farmer, he has to train every animal on to the robot. Next year, he believes the workload will be far less, because only a handful of heifers will need to be trained. The majority will know the drill at that stage, because it will be the second year in the system. He says it is a lot of work to train them but manageable.

Picture four

Outside, the grazeway gate is positioned on top of a slatted tank. This is an automatic drafting gate.

Picture four.

When cows leave the parlour, they walk through this grazeway gate. An ABC paddock system is used on the farm. This means the farm is divided into three grazing areas, which are available to the cow at different times of the day.

Every time the cows move from one allocation to the other, they must move through the grazeway gate. Cows have access to the robot at all times.

If they are not due to be milked they are drafted to the designated paddock

If they try to exit through the grazeway but are due to be milked, they will be turned back into the shed. If they are not due to be milked they are drafted to the designated paddock. Because the weather was so wet when I spoke to Kevin, he couldn’t start grazing. However, once the opportunity permits, cows will be out.

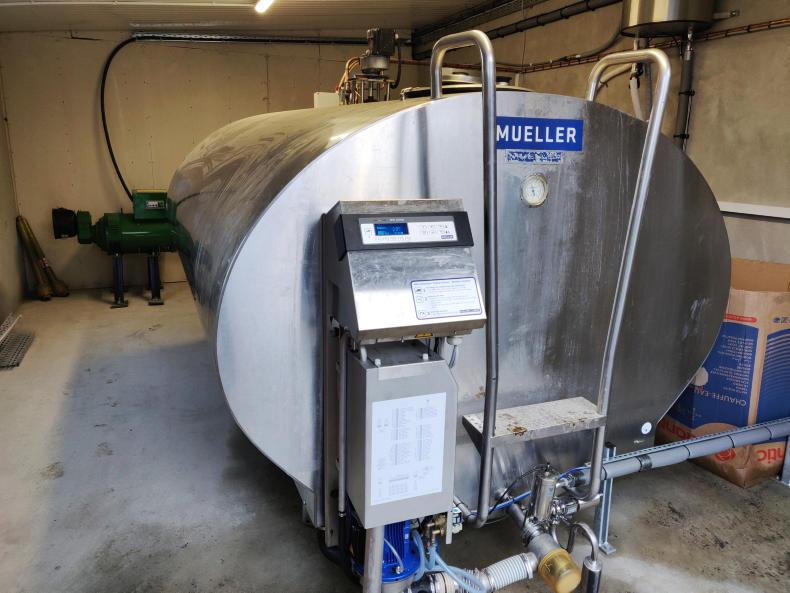

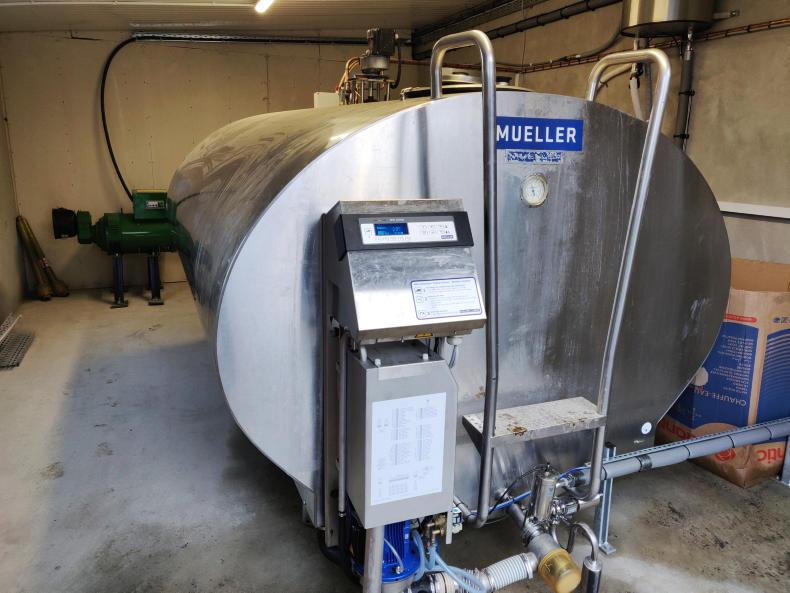

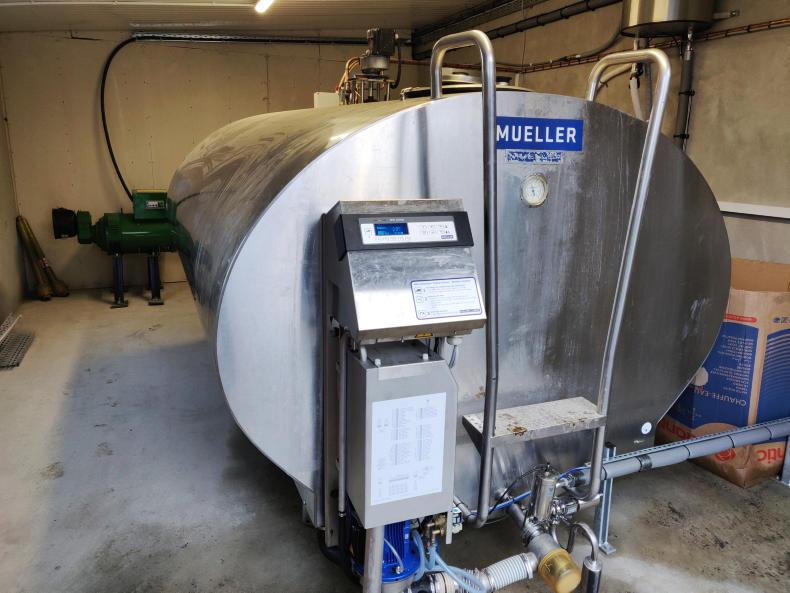

Picture five

To complete the new dairy setup, Kevin was able to re-use his McAree 10t silo. He got an auger fitted to it to transfer the feed to the robot.

Picture five.

A new Mueller 6,000l bulk tank was also installed and fitted in the dairy, as well as a compressor, tube cooler and office.

The dairy is approximately 30m away from the robot, but this is not an issue.

The location of the milk tank means that it is easy access for the milk lorry and does not affect on the rest of the yard.

According to Lely Mullingar, there are different options for housing the robot and bulk tank, depending on the site and the farmer’s preference.

Cost

Kevin was fortunate that he had a lot of the concrete and steel infrastructure already in place.

This helped to keep down the financial outlay during the conversion work last year. The two major investments made were the Lely Astronaut A5 robot and the Mueller tank.

Kevin McCluskey.

The robot cost €150,000, excluding VAT and the bulk tank cost €13,000 excluding VAT.

It is still early days, but so far so good for this new entrant, who is happy with the move

He also installed 1,400m of roadways and some concrete 150 gallon water troughs, as well as the cubicles and tank.

It is still early days, but so far so good for this new entrant, who is happy with the move. A second robot would cost less, at between €90,000 to €100,000.

This is because it can use the first robot’s central unit and compressor, and there is no need for a second grazeway gate. Each robot can comfortably milk 70 cows, Lely says.

Kevin McCluskey is a new entrant to dairy farming, based near Carrickmacross in Co Monaghan. He has just sent the first milk to the co-op in the last fortnight.

Up to last year he was suckler farming, but decided to make the switch to dairy farming, where he hopes to get a better return for his work.

Last March, Kevin bought 60 Friesian maiden heifers and of those just two did not go in calf.

He bought another 16 in-calf heifers last back end, which means 74 heifers are due to calve this spring. To milk the cows Kevin decided to install a robotic milking machine.

Kevin was also enticed by the lifestyle benefits a robot could offer, cutting out the time he would have to spend milking cows

He said he had three reasons for going down the robotic milking route. For one, the site where the shed and robot milker are situated is very central in the farm, which suits both robotic milking and grazing systems.

Kevin was also enticed by the lifestyle benefits a robot could offer, cutting out the time he would have to spend milking cows.

Lastly, he liked the information available on each cow’s production and health available with the robot.

Before making the decision, he visited other farms with robots to ensure it was the right move for him.

Picture one and figure one

Kevin was fortunate that he could do the conversion on a phased basis. He had already built a new six-bay suckler shed with calf creeps, which was rearranged for the new dairy development.

The shed had an unusual H-shaped tank. Pat Boylan did the concrete work for the original slatted shed and PJ Kelly did the steelwork.

To convert this shed, Kevin added cubicles to the area where the calf creeps were located and put in additional cubicles on one side. He ended up with 76 cubicles in total.

He used a walk-behind petrol scraper to clean the cow passages, and said that in the future he will look at alternative ways of automatically cleaning these passages. Another slatted tank was added underneath the grazeway gate. This will be a high cow traffic area, so it is great to be able to collect the slurry created here.

He purchased the robot from Lely Center Mullingar and they completed the design and project conversion

Barry Doogan built the tank and concrete flow channel in the topless cubicle area. Kevin had girders erected beside the topless cubicle area, just in case he plans on roofing it in the future. He installed the cubicle beds and Teemore Engineering cubicles in the shed himself. He purchased the robot from Lely Center Mullingar and they completed the design and project conversion.

According to the Lely design team, when planning a new greenfield shed or converting existing sheds, they look at trying to provide two separation areas for cows, where possible – one to cubicles and one to straw. When cows are in these areas, they are still able to cycle around the machine. It can be useful for recently calved cows and shy heifers, as they have priority access.

Picture two and three

When I spoke to Kevin, he had 27 heifers calved. He explained the calving routine he has been following: “When a heifer calves, I put her behind the calving gate. I then put a corresponder collar on her, which is used by the robot and the drafter gate to identify her movements.”

Picture two.

He then milks the heifer with a portable bucket plant and the colostrum is given to the calf. Any hair around the udder is clipped, because hair can interfere with the robotic milking sensors. The freshly calved heifer’s collar and tag number are inputted into the system computer.

I supervise the first milking to make sure everything is going to plan and the robot is doing its job

“The robot then knows that her milk needs to be withheld from the tank for four to five days and will wash itself after milking these transition cows,” said Kevin. If the heifer calves at night, Kevin will wait until the following morning to train her with the robot. “I supervise the first milking to make sure everything is going to plan and the robot is doing its job,” said Kevin.

Picture three.

On average, heifers are trained to use the robot after four to five days. “Some will learn quicker and some will take a little longer,” he explained. According to Kevin, even if a heifer is kicking, the robot will persist until she is milked. “We had one heifer that didn’t take to the machine and was getting excited, so I just decided to sell her to keep everything simple,” Kevin said.

He says it is a lot of work to train them but manageable

As he is a new entrant dairy farmer, he has to train every animal on to the robot. Next year, he believes the workload will be far less, because only a handful of heifers will need to be trained. The majority will know the drill at that stage, because it will be the second year in the system. He says it is a lot of work to train them but manageable.

Picture four

Outside, the grazeway gate is positioned on top of a slatted tank. This is an automatic drafting gate.

Picture four.

When cows leave the parlour, they walk through this grazeway gate. An ABC paddock system is used on the farm. This means the farm is divided into three grazing areas, which are available to the cow at different times of the day.

Every time the cows move from one allocation to the other, they must move through the grazeway gate. Cows have access to the robot at all times.

If they are not due to be milked they are drafted to the designated paddock

If they try to exit through the grazeway but are due to be milked, they will be turned back into the shed. If they are not due to be milked they are drafted to the designated paddock. Because the weather was so wet when I spoke to Kevin, he couldn’t start grazing. However, once the opportunity permits, cows will be out.

Picture five

To complete the new dairy setup, Kevin was able to re-use his McAree 10t silo. He got an auger fitted to it to transfer the feed to the robot.

Picture five.

A new Mueller 6,000l bulk tank was also installed and fitted in the dairy, as well as a compressor, tube cooler and office.

The dairy is approximately 30m away from the robot, but this is not an issue.

The location of the milk tank means that it is easy access for the milk lorry and does not affect on the rest of the yard.

According to Lely Mullingar, there are different options for housing the robot and bulk tank, depending on the site and the farmer’s preference.

Cost

Kevin was fortunate that he had a lot of the concrete and steel infrastructure already in place.

This helped to keep down the financial outlay during the conversion work last year. The two major investments made were the Lely Astronaut A5 robot and the Mueller tank.

Kevin McCluskey.

The robot cost €150,000, excluding VAT and the bulk tank cost €13,000 excluding VAT.

It is still early days, but so far so good for this new entrant, who is happy with the move

He also installed 1,400m of roadways and some concrete 150 gallon water troughs, as well as the cubicles and tank.

It is still early days, but so far so good for this new entrant, who is happy with the move. A second robot would cost less, at between €90,000 to €100,000.

This is because it can use the first robot’s central unit and compressor, and there is no need for a second grazeway gate. Each robot can comfortably milk 70 cows, Lely says.

SHARING OPTIONS