Farming on the outskirts of Tullamore, Co Offaly, PJ McGrath and his brother operate a tillage enterprise. On average, 290 acres of beet is grown annually as part of the farm’s crop rotation. Once grown and harvested, the beet is sold to livestock farmers locally and across the country.

Carrying out all associated work themselves, the McGraths decided in 2018 to upgrade the Accord 12-row planter they used for drilling fodder beet to a newer, more versatile machine.

The new drill has the added flexibility of being well suited to planting maize as well as beet, with the addition of being able to place fertiliser alongside seed during the planting process.

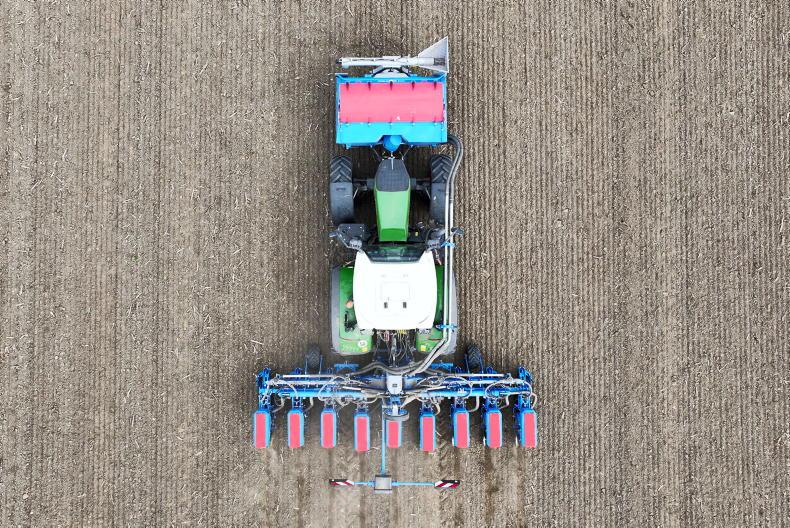

The fact that the farm practises minimum tillage (min-till) was also a factor in the decision to upgrade the machine. They felt the model of Accord drill they had wasn’t ideally suited to a min-till setup. So, the brothers opted to invest in an Amazone ED 602 Contour precision drill.

PJ noted that a larger tractor was needed for drilling with the new machine given the addition of the front hopper, which weighs 640kg and can carry up to 1,100 litres of fertiliser.

This, plus the overall heavy build quality of the ED 602, leaves it requiring a large-framed tractor.

The planter itself weighs 2,112kg empty and PJ said its 6m mounted working width leaves it requiring a large tractor for stability. The McGraths now drill with a 280hp Claas Axion 870, which they say is more than capable of the task.

McGraths plant 290 acres of fodder beet on the farm annually.

What is a precision planter?

A precision planter is typically used for sowing maize and beet or any similar crops that require large amounts of row spacing compared with the likes of wheat and barley.

They are generally air seeders that are designed to be very accurate, with seed singling systems for precise planting of each individual seed. These types of planter are usually notable for their individual seed boxes for each and every sowing unit.

The Amazone ED drill offers both Classic and Contour sowing units. The Classic sowing unit is a simpler configuration primarily designed just for sowing into ploughed ground.

The Contour unit is configured for drilling in zero-till and min-till situations, as well as ploughed soils. Along with its added abilities, the Contour unit has a better ability to adapt to more uneven ground.

Eight to 10 acres per hour can be planted witht he ED 602 Contour drill.

Fertiliser delivery

For each of the 12 sowing units on PJ’s drill, there is a disc coulter placing fertiliser in the seedbed just ahead of the beet seed.

Each of these coulters are fitted with tension springs with a tripping force of 160kg to protect the coulter from stone damage.

The front tank can be set up to carry and distribute either seed or fertiliser by just swapping out the mechanically driven metering cassettes.

This leaves the front tank flexible for use in combination with another drill setup.

However, the McGraths only use the front hopper for applying fertiliser. Fertiliser is pneumatically delivered to each coulter, with each distributor head positioned high for good distribution at low air pressure.

Fertiliser application rate can be pre-selected from outside on the hopper, with application rates ranging from 50kg/ha to 550kg/ha.

Planting

Using the control box inside the cab, PJ can shut off individual sowing units for marking out tramlines, etc.

The 12-row ED planter works at row spacings of 50cm. Each of the 12 seed boxes is fitted with level sensors to warn the operator when their 70l storage capacity is nearing empty.

Each seeder is driven mechanically via a central chain wheel transmission offering 54 steps. Depending on the crop being planted, different singling discs are used, as well as altering their rotational speed to achieve the desired seed spacings ranging from 3.1cm to 86.9cm.

Rollers

Once fertiliser has been placed in the seed bed, a press roller consolidates the track left after the large Boron disc. The blower fan forces seeds to be placed in the holes of each singling disc.

As the disc rotates to its lowest point, each seed then falls 140mm into the trench made with the sowing coulter disc and so lands in between the furrow former. After seeds have been placed, the seed press rollers close the trench and a larger press roller follows.

Given the fact PJ operates a min-till setup, the 360mm V-press rollers follow lastly, providing optimum seed contact with the soil.

Each Contour sowing unit is hinged in such a way that it can adapt itself to rough or uneven terrain.

Typically, PJ can plant anywhere from eight to 10 acres an hour, depending on the conditions, travelling at a speed of 7km/h.

Having owned the 12-row Amazone ED 602 Contour drill for a number of seasons, the McGraths are happy with how it has performed, as yet another planting season has just been completed. Little maintenance has been required, apart from replacing typical wearing metal parts here and there on the drill, PJ outlined. The drill’s control box is straightforward, showing all the necessary information.

“Upgrading to this planter provided us with more flexibility that if we want to plant maize all that we need to do is change the singling discs and make a few other small adjustments and away we go. Crop seems to emerge well after planting. So far, it’s doing all we ask of it.”

The spec

Model: ED 602 Contour.

Number of rows: 12.

Fertiliser hopper capacity: 1,100l.

Fertiliser hopper weight (empty):640kg.

Planter weight empty: 2,112kg.

Singling drive: Mechanical.

Fertiliser metering: Mechanical.

Blower fan drive: PTO.

Seed spacing: 3.1cm to 86.9cm depending on singling disc used.

Farming on the outskirts of Tullamore, Co Offaly, PJ McGrath and his brother operate a tillage enterprise. On average, 290 acres of beet is grown annually as part of the farm’s crop rotation. Once grown and harvested, the beet is sold to livestock farmers locally and across the country.

Carrying out all associated work themselves, the McGraths decided in 2018 to upgrade the Accord 12-row planter they used for drilling fodder beet to a newer, more versatile machine.

The new drill has the added flexibility of being well suited to planting maize as well as beet, with the addition of being able to place fertiliser alongside seed during the planting process.

The fact that the farm practises minimum tillage (min-till) was also a factor in the decision to upgrade the machine. They felt the model of Accord drill they had wasn’t ideally suited to a min-till setup. So, the brothers opted to invest in an Amazone ED 602 Contour precision drill.

PJ noted that a larger tractor was needed for drilling with the new machine given the addition of the front hopper, which weighs 640kg and can carry up to 1,100 litres of fertiliser.

This, plus the overall heavy build quality of the ED 602, leaves it requiring a large-framed tractor.

The planter itself weighs 2,112kg empty and PJ said its 6m mounted working width leaves it requiring a large tractor for stability. The McGraths now drill with a 280hp Claas Axion 870, which they say is more than capable of the task.

McGraths plant 290 acres of fodder beet on the farm annually.

What is a precision planter?

A precision planter is typically used for sowing maize and beet or any similar crops that require large amounts of row spacing compared with the likes of wheat and barley.

They are generally air seeders that are designed to be very accurate, with seed singling systems for precise planting of each individual seed. These types of planter are usually notable for their individual seed boxes for each and every sowing unit.

The Amazone ED drill offers both Classic and Contour sowing units. The Classic sowing unit is a simpler configuration primarily designed just for sowing into ploughed ground.

The Contour unit is configured for drilling in zero-till and min-till situations, as well as ploughed soils. Along with its added abilities, the Contour unit has a better ability to adapt to more uneven ground.

Eight to 10 acres per hour can be planted witht he ED 602 Contour drill.

Fertiliser delivery

For each of the 12 sowing units on PJ’s drill, there is a disc coulter placing fertiliser in the seedbed just ahead of the beet seed.

Each of these coulters are fitted with tension springs with a tripping force of 160kg to protect the coulter from stone damage.

The front tank can be set up to carry and distribute either seed or fertiliser by just swapping out the mechanically driven metering cassettes.

This leaves the front tank flexible for use in combination with another drill setup.

However, the McGraths only use the front hopper for applying fertiliser. Fertiliser is pneumatically delivered to each coulter, with each distributor head positioned high for good distribution at low air pressure.

Fertiliser application rate can be pre-selected from outside on the hopper, with application rates ranging from 50kg/ha to 550kg/ha.

Planting

Using the control box inside the cab, PJ can shut off individual sowing units for marking out tramlines, etc.

The 12-row ED planter works at row spacings of 50cm. Each of the 12 seed boxes is fitted with level sensors to warn the operator when their 70l storage capacity is nearing empty.

Each seeder is driven mechanically via a central chain wheel transmission offering 54 steps. Depending on the crop being planted, different singling discs are used, as well as altering their rotational speed to achieve the desired seed spacings ranging from 3.1cm to 86.9cm.

Rollers

Once fertiliser has been placed in the seed bed, a press roller consolidates the track left after the large Boron disc. The blower fan forces seeds to be placed in the holes of each singling disc.

As the disc rotates to its lowest point, each seed then falls 140mm into the trench made with the sowing coulter disc and so lands in between the furrow former. After seeds have been placed, the seed press rollers close the trench and a larger press roller follows.

Given the fact PJ operates a min-till setup, the 360mm V-press rollers follow lastly, providing optimum seed contact with the soil.

Each Contour sowing unit is hinged in such a way that it can adapt itself to rough or uneven terrain.

Typically, PJ can plant anywhere from eight to 10 acres an hour, depending on the conditions, travelling at a speed of 7km/h.

Having owned the 12-row Amazone ED 602 Contour drill for a number of seasons, the McGraths are happy with how it has performed, as yet another planting season has just been completed. Little maintenance has been required, apart from replacing typical wearing metal parts here and there on the drill, PJ outlined. The drill’s control box is straightforward, showing all the necessary information.

“Upgrading to this planter provided us with more flexibility that if we want to plant maize all that we need to do is change the singling discs and make a few other small adjustments and away we go. Crop seems to emerge well after planting. So far, it’s doing all we ask of it.”

The spec

Model: ED 602 Contour.

Number of rows: 12.

Fertiliser hopper capacity: 1,100l.

Fertiliser hopper weight (empty):640kg.

Planter weight empty: 2,112kg.

Singling drive: Mechanical.

Fertiliser metering: Mechanical.

Blower fan drive: PTO.

Seed spacing: 3.1cm to 86.9cm depending on singling disc used.

SHARING OPTIONS