While travelling though the Mid Canterbury region in the South Island of New Zealand, I caught up with Andrew Quigley from Quigley Contracting, one of New Zealand’s largest contractors. The day I visited Andrew, a member of staff was getting married, so I was lucky enough to see all of Quigley’s kit in the two adjoining yards. Quigley’s fleet would be comparable to the stock carried by some of Ireland’s largest machinery dealerships.

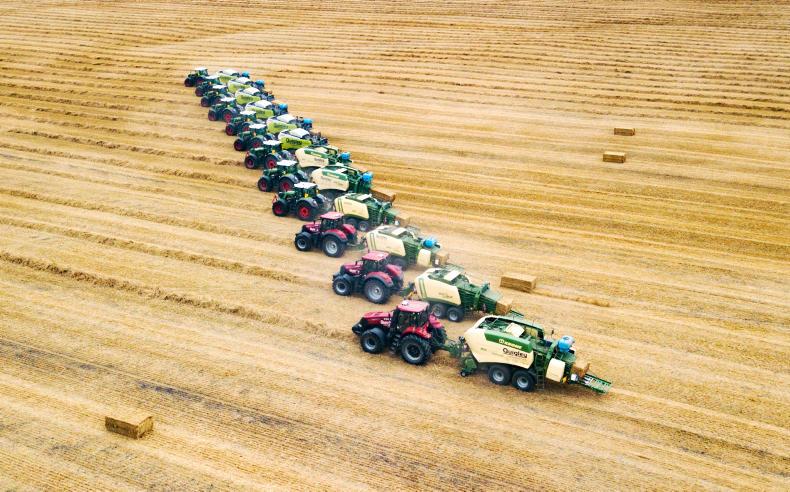

The fleet is made up of over 50 tractors across a number of brands including Fendt, Case IH, Massey Ferguson, Claas and John Deere tractors.

After spending a few seasons working for contractors in New Zealand and the UK, Andrew set up Quigley Contracting in April 2003.

“I worked hard getting the business off the ground. The first year, I leased tractors and started out with a 3×3 square baler. In year two, I quickly learned that not all clients want just one sized bale so I grew the business to four balers.

“In year three, I saw an opening in the area for a forager. There was a huge demand and very weak competition. I ended up buying a second forager soon after. For the first four to five years, I put every cent I made back into building up the fleet”.

When I visited Andrew in December, he had in excess of 80 people employed in the contracting business.

Day-to-day business

The scale and business structure in Quigleys is like nothing you would ever see in any other contracting business in Ireland. The firm has its area split into four sections, and has four regional managers that look after the customers within each area.

Under the regional managers are four operations managers. Two are baling managers, one is a forager/combining manager and the other is a cultivation manager. Each of these operations managers has what’s called a 2IC (second in charge) who they work closely with to organise the day-to-day running of the business.

“The biggest problem we encounter nowadays is machine operators on their phones. It’s not just a problem with us, but a common issue amongst many contractors", explained Andrew

“We have over 400 clients across a 50km radius. We probably could run the business with fewer people but we’re trying to avoid burnout. Anyone can buy equipment, but you need good people in a business. This is the most sustainable business model we could come up with. This way the operations managers get every second weekend off. We’ve often had Irish guys in these roles,” explained Andrew.

Quigleys run four Claas foragers and three Strautmann tri-axle 52m3 forage wagons

When a farmer rings looking for silage cut, for example, they send an email with maps of what land needs to be cut, the job details and any special requirements. It’s then booked into the central job management system.

This waiting list can be up to a week for baling and up to two weeks for a forager. Running in excess of 50 tractors means that the staff need to be organised. Generally, each driver has a designated tractor. Inside each tractor is an iPad. This iPad contains the work scheduled for each driver that day, including the location and full details. Each tractor has a tracker and a speed monitor. This means the admin team can see where every machine in the fleet is at any time.

Once a job is completed, the operations managers check the hours and details and an invoice is compiled. The invoice is passed on to the admin team who then email it out to the customer. An invoice issued on the first of each month has payment due by the 20th of the same month. Andrew noted that 90% of customers now pay with bank transfer.

Machinery

Andrew runs a fleet of over 50 tractors. These fall into three categories: 150hp, 250-280hp and 330-350hp. Today, the fleet is made up of Fendt, Case IH, Massey Ferguson, Claas and John Deere tractors.

Andrew noted that he runs four Claas foragers. This is down to backup, resale and reliability reasoning. He runs three Strautmann tri-axle 52m3 forage wagons and a fleet of JCB wheel loaders. Baling is the biggest part of the business. Andrew runs a total of 17 balers, 14 of which are square balers and the remaining three are round balers. They are Claas, Krone, McHale, Massey Ferguson and Goweil machines.

He added: “To justify these balers they need to do a minimum of 10,000 bales each per year. The busier balers in our fleet will do up to 40,000 bales per year.”

For cultivation, the firm runs Vaderstad, Allen, Horsch and Samco drills/planters. Andrew had a great word to say about Irish machinery, explaining that he has some Irish-built machines. Some of these brands include Smyth, Combi Lift, Keenan and McHale.

Staff

When I visited Andrew in December, he had in excess of 80 people employed in the contracting business, around 40 full-time and 40 seasonal staff.

“We have employed loads of Irish staff over the years, and continue to do so. We are always looking out for enthusiastic and hard-working people to join our team,” he said.

For a small fee, Quigleys provide accommodation for overseas employees, a cooked breakfast and a packed lunch. If staff are working late, a dinner will be brought out to them in the field.

“Health and safety is a big concern. We know better than anyone the long hours that are required to get through large volumes of work. However, to keep our staff safe, we introduced a system that all staff need a minimum of an eight-hour stand-down between shifts,” noted Andrew.

Challenges/opportunities

“The biggest problem we encounter nowadays is machine operators on their phones. It’s not just a problem with us, but a common issue among many contractors. As a result, costly damage is being done to machinery – stuff that could and should be easily avoided. It’s an issue that I’m not sure how we’re going to address; perhaps we will have to block social media. The cost of new kit is going through the roof- and depreciation is increasing.”

“Our focus at the minute isn’t to grow the business any more, but to concentrate on what we’re good at. We want to become better at what we do and become as efficient as we can.”

Quigley feeds

Quigley Feeds was set up by Andrew in February 2019 to take in hay/straw/feed harvested by the contracting business, press and rewrap it, before shipping it to the North Island where feed isn’t as plentiful. In addition, this feed is now going overseas.

The press was specially imported from America. By putting hay and straw through the press, it can increase container capacity from 11t to 13t of feed right up to 27t. It compresses 7ft bales to half, making them much more efficient to transport.

“In recent years there was a surplus of feed in our area. I wanted to create a demand and so Quigley Feeds was born. We hope to continue to develop this business alongside the contracting,” Andrew said.

While travelling though the Mid Canterbury region in the South Island of New Zealand, I caught up with Andrew Quigley from Quigley Contracting, one of New Zealand’s largest contractors. The day I visited Andrew, a member of staff was getting married, so I was lucky enough to see all of Quigley’s kit in the two adjoining yards. Quigley’s fleet would be comparable to the stock carried by some of Ireland’s largest machinery dealerships.

The fleet is made up of over 50 tractors across a number of brands including Fendt, Case IH, Massey Ferguson, Claas and John Deere tractors.

After spending a few seasons working for contractors in New Zealand and the UK, Andrew set up Quigley Contracting in April 2003.

“I worked hard getting the business off the ground. The first year, I leased tractors and started out with a 3×3 square baler. In year two, I quickly learned that not all clients want just one sized bale so I grew the business to four balers.

“In year three, I saw an opening in the area for a forager. There was a huge demand and very weak competition. I ended up buying a second forager soon after. For the first four to five years, I put every cent I made back into building up the fleet”.

When I visited Andrew in December, he had in excess of 80 people employed in the contracting business.

Day-to-day business

The scale and business structure in Quigleys is like nothing you would ever see in any other contracting business in Ireland. The firm has its area split into four sections, and has four regional managers that look after the customers within each area.

Under the regional managers are four operations managers. Two are baling managers, one is a forager/combining manager and the other is a cultivation manager. Each of these operations managers has what’s called a 2IC (second in charge) who they work closely with to organise the day-to-day running of the business.

“The biggest problem we encounter nowadays is machine operators on their phones. It’s not just a problem with us, but a common issue amongst many contractors", explained Andrew

“We have over 400 clients across a 50km radius. We probably could run the business with fewer people but we’re trying to avoid burnout. Anyone can buy equipment, but you need good people in a business. This is the most sustainable business model we could come up with. This way the operations managers get every second weekend off. We’ve often had Irish guys in these roles,” explained Andrew.

Quigleys run four Claas foragers and three Strautmann tri-axle 52m3 forage wagons

When a farmer rings looking for silage cut, for example, they send an email with maps of what land needs to be cut, the job details and any special requirements. It’s then booked into the central job management system.

This waiting list can be up to a week for baling and up to two weeks for a forager. Running in excess of 50 tractors means that the staff need to be organised. Generally, each driver has a designated tractor. Inside each tractor is an iPad. This iPad contains the work scheduled for each driver that day, including the location and full details. Each tractor has a tracker and a speed monitor. This means the admin team can see where every machine in the fleet is at any time.

Once a job is completed, the operations managers check the hours and details and an invoice is compiled. The invoice is passed on to the admin team who then email it out to the customer. An invoice issued on the first of each month has payment due by the 20th of the same month. Andrew noted that 90% of customers now pay with bank transfer.

Machinery

Andrew runs a fleet of over 50 tractors. These fall into three categories: 150hp, 250-280hp and 330-350hp. Today, the fleet is made up of Fendt, Case IH, Massey Ferguson, Claas and John Deere tractors.

Andrew noted that he runs four Claas foragers. This is down to backup, resale and reliability reasoning. He runs three Strautmann tri-axle 52m3 forage wagons and a fleet of JCB wheel loaders. Baling is the biggest part of the business. Andrew runs a total of 17 balers, 14 of which are square balers and the remaining three are round balers. They are Claas, Krone, McHale, Massey Ferguson and Goweil machines.

He added: “To justify these balers they need to do a minimum of 10,000 bales each per year. The busier balers in our fleet will do up to 40,000 bales per year.”

For cultivation, the firm runs Vaderstad, Allen, Horsch and Samco drills/planters. Andrew had a great word to say about Irish machinery, explaining that he has some Irish-built machines. Some of these brands include Smyth, Combi Lift, Keenan and McHale.

Staff

When I visited Andrew in December, he had in excess of 80 people employed in the contracting business, around 40 full-time and 40 seasonal staff.

“We have employed loads of Irish staff over the years, and continue to do so. We are always looking out for enthusiastic and hard-working people to join our team,” he said.

For a small fee, Quigleys provide accommodation for overseas employees, a cooked breakfast and a packed lunch. If staff are working late, a dinner will be brought out to them in the field.

“Health and safety is a big concern. We know better than anyone the long hours that are required to get through large volumes of work. However, to keep our staff safe, we introduced a system that all staff need a minimum of an eight-hour stand-down between shifts,” noted Andrew.

Challenges/opportunities

“The biggest problem we encounter nowadays is machine operators on their phones. It’s not just a problem with us, but a common issue among many contractors. As a result, costly damage is being done to machinery – stuff that could and should be easily avoided. It’s an issue that I’m not sure how we’re going to address; perhaps we will have to block social media. The cost of new kit is going through the roof- and depreciation is increasing.”

“Our focus at the minute isn’t to grow the business any more, but to concentrate on what we’re good at. We want to become better at what we do and become as efficient as we can.”

Quigley feeds

Quigley Feeds was set up by Andrew in February 2019 to take in hay/straw/feed harvested by the contracting business, press and rewrap it, before shipping it to the North Island where feed isn’t as plentiful. In addition, this feed is now going overseas.

The press was specially imported from America. By putting hay and straw through the press, it can increase container capacity from 11t to 13t of feed right up to 27t. It compresses 7ft bales to half, making them much more efficient to transport.

“In recent years there was a surplus of feed in our area. I wanted to create a demand and so Quigley Feeds was born. We hope to continue to develop this business alongside the contracting,” Andrew said.

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: