Uneven spreading is not uncommon. Crop or grass yield is impacted long before any visual striping is seen. In the lifetime of a fertiliser spreader working on a 100ha tillage farm, poor spreading could cause a crop loss of €40,000. To avoid these losses, three critical factors must be considered:

The correct choice of machine for the fertiliser being used at the chosen bout width.The use of fertiliser with good physical quality characteristics.Correct setting of the machine for fertiliser and bout width and proper maintenance.The challenge

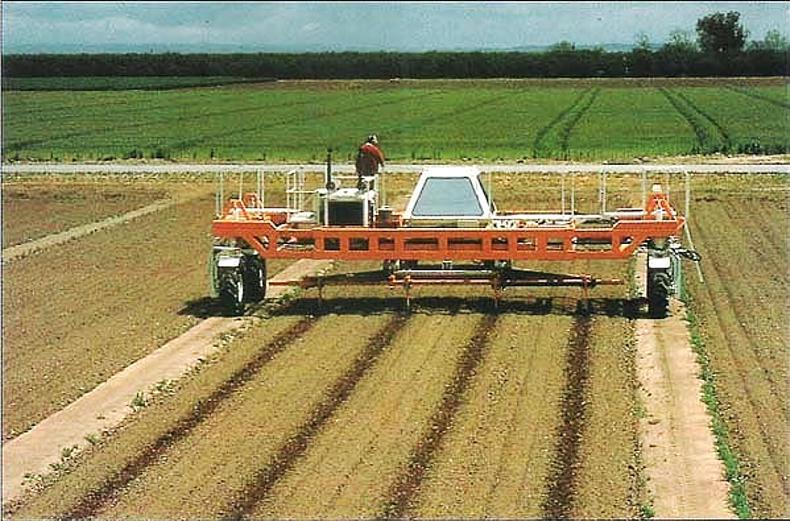

Todays’ spreaders have a huge challenge, with farmers using bout widths from 6m to 36m. Broadcast spreaders rely on forming an overlapped pattern (Figure 1) to give an even spread.

Some 12m spreaders will spread fertiliser 24m, with fertiliser visible in the next tramline. This is challenging in perfect conditions, but in the field with bumpy ground and wind, it’s much more difficult.

Machine design

Not all fertiliser spreaders are equal. While many will judge a fertiliser spreader on how robust it is or the quality of its paint, the most important characteristic is how evenly it spreads fertiliser.

Machine design has a huge impact on how evenly the fertiliser is spread. The only way to assess a particular model is to have a spread test report where evenness of application is measured.

While the major fertiliser spreader manufacturers have their own test facilities capable of giving very accurate test results, they only put the best results in their brochure.

Results from independent test halls are of far more value, but these tests are increasingly rare. You should look for an independent test result and always favour a manufacturer who provides one.

What to look for in a test result

The evenness of spread is frequently summarised by a single figure; the coefficient of variation (CV) – the lower the CV percentage the better the spread pattern. A CV value of less than 15% would be acceptable in the field, but figures of 5% to 10% should be demanded from a test hall where perfect conditions prevail.

But the CV does not tell the full story. The shape of the basic spread pattern determines how likely good spreading will be achieved in the field. A triangular shape, like that in Figure 1, tells us that the spread will be a little less sensitive to wind or fertiliser variation than the more shouldered pattern of Figure 2.

The spreader producing a pattern like Figure 2 would need to be very carefully set to suit the fertiliser characteristics and spreading conditions. Better spreaders should have both a low CV and a good basic spread pattern – and these should be verified by an independent test.

Fertiliser quality

The physical characteristics of the fertiliser will affect how evenly it spreads and the settings required. The key factors are:

Density of the fertiliser – low-density fertiliser such as urea (80% normal density) is more difficult to throw. Size of the granules – generally larger particles will throw further. Particle size distributions with the majority of particles (80%) in the 2mm to 4mm range will usually allow a good spread to be achieved, but larger diameters (3mm to 4.5mm) will probably make it easier achieve wider spread widths. The component parts of blends should have similar size distributions.Shape of the granule – rounded particles will roll off the disc more predictably than irregular granules.Strength of granule – strong particles will resist break-up on the disc.When purchasing fertiliser, always take physical quality into account when making choices.

Urea

Urea will be more widely used across all farm types in the future. Its lower density presents a greater spreading challenge and it usually will not spread as wide as denser material. Look for a urea product with larger particle sizes by asking the supplier for the size distribution figures.

Even with a good-size distribution, it is vital that the correct spreader setting is used and that the limitations of the spreader with urea are observed (maximum bout width, etc).

Wind will affect urea more than ordinary fertiliser, so spread in calm conditions if possible. Blends of urea and conventional-density fertiliser need to be considered very carefully.

Proper size-matching of particles (larger urea with smaller dense fertiliser particles) can help even spreading, but the onus is on the fertiliser supplier to show that this can be achieved.

Machine setting

Spreaders need to be correctly set/adjusted for specific fertilisers spreading at specific bout widths. Some spreader models require very careful setting. The components that are adjustable vary between manufacturer and model but include one or more of the following:

Disc type.Pto/disc speed.Vane type and position/angle on disc.Position of fertiliser drop point.Disc height over crop/soil.Spreader/disc angle.The setting is determined by fertiliser type (density, particle size distribution, shape, strength) and bout width. Setting information is usually available in detailed setting charts provided by the manufacturer, but increasingly is more easily accessible on the internet or as a smart phone app.

While some manufacturers provide setting information for specific fertiliser brands, increasingly a simple sieve test and visual type test are used to identify fertiliser type and consequently the settings required. It’s vital to follow the setting procedure.

Rate setting

Getting the correct rate of fertiliser out (kg/ha or bags/acre) is also important and while manufacturers’ setting guides are a starting point, some level of field calibration is usually needed.

Some makers have very useful setting aids and of course on-board weighing systems make it very easy. Whatever system is used, it is important to establish the correct rate setting before field-scale errors are made.

Field use

Correct attachment to the tractor to make sure it’s level from right to left and at the correct angle front/back and height over the crop is essential, as is a working rev counter.

Driving at accurate bout widths is essential; tramlines facilitate this in cereals and GPS guidance systems can help when there are no tramlines. However, there is no shame in measuring and marking the bouts! Wear on the spreader components: fertiliser outlet, disc, vanes or spouts must be monitored.

Headland

To avoid uneven spreading on the headland and the loss of fertiliser into headlands/drains, most spreaders have a headland setting mechanism which adjusts the spread pattern.

Matching the in-field runs with the headland runs requires the spreader to be turned on and off at exactly the correct times as the tractor approaches and leaves the headland – on high tech spreaders, this can be automatically controlled by GPS, but careful manual operation is possible once the distances are known.

Read more

Ten steps to get set up for the spreading season

Special focus: fertilisers

Uneven spreading is not uncommon. Crop or grass yield is impacted long before any visual striping is seen. In the lifetime of a fertiliser spreader working on a 100ha tillage farm, poor spreading could cause a crop loss of €40,000. To avoid these losses, three critical factors must be considered:

The correct choice of machine for the fertiliser being used at the chosen bout width.The use of fertiliser with good physical quality characteristics.Correct setting of the machine for fertiliser and bout width and proper maintenance.The challenge

Todays’ spreaders have a huge challenge, with farmers using bout widths from 6m to 36m. Broadcast spreaders rely on forming an overlapped pattern (Figure 1) to give an even spread.

Some 12m spreaders will spread fertiliser 24m, with fertiliser visible in the next tramline. This is challenging in perfect conditions, but in the field with bumpy ground and wind, it’s much more difficult.

Machine design

Not all fertiliser spreaders are equal. While many will judge a fertiliser spreader on how robust it is or the quality of its paint, the most important characteristic is how evenly it spreads fertiliser.

Machine design has a huge impact on how evenly the fertiliser is spread. The only way to assess a particular model is to have a spread test report where evenness of application is measured.

While the major fertiliser spreader manufacturers have their own test facilities capable of giving very accurate test results, they only put the best results in their brochure.

Results from independent test halls are of far more value, but these tests are increasingly rare. You should look for an independent test result and always favour a manufacturer who provides one.

What to look for in a test result

The evenness of spread is frequently summarised by a single figure; the coefficient of variation (CV) – the lower the CV percentage the better the spread pattern. A CV value of less than 15% would be acceptable in the field, but figures of 5% to 10% should be demanded from a test hall where perfect conditions prevail.

But the CV does not tell the full story. The shape of the basic spread pattern determines how likely good spreading will be achieved in the field. A triangular shape, like that in Figure 1, tells us that the spread will be a little less sensitive to wind or fertiliser variation than the more shouldered pattern of Figure 2.

The spreader producing a pattern like Figure 2 would need to be very carefully set to suit the fertiliser characteristics and spreading conditions. Better spreaders should have both a low CV and a good basic spread pattern – and these should be verified by an independent test.

Fertiliser quality

The physical characteristics of the fertiliser will affect how evenly it spreads and the settings required. The key factors are:

Density of the fertiliser – low-density fertiliser such as urea (80% normal density) is more difficult to throw. Size of the granules – generally larger particles will throw further. Particle size distributions with the majority of particles (80%) in the 2mm to 4mm range will usually allow a good spread to be achieved, but larger diameters (3mm to 4.5mm) will probably make it easier achieve wider spread widths. The component parts of blends should have similar size distributions.Shape of the granule – rounded particles will roll off the disc more predictably than irregular granules.Strength of granule – strong particles will resist break-up on the disc.When purchasing fertiliser, always take physical quality into account when making choices.

Urea

Urea will be more widely used across all farm types in the future. Its lower density presents a greater spreading challenge and it usually will not spread as wide as denser material. Look for a urea product with larger particle sizes by asking the supplier for the size distribution figures.

Even with a good-size distribution, it is vital that the correct spreader setting is used and that the limitations of the spreader with urea are observed (maximum bout width, etc).

Wind will affect urea more than ordinary fertiliser, so spread in calm conditions if possible. Blends of urea and conventional-density fertiliser need to be considered very carefully.

Proper size-matching of particles (larger urea with smaller dense fertiliser particles) can help even spreading, but the onus is on the fertiliser supplier to show that this can be achieved.

Machine setting

Spreaders need to be correctly set/adjusted for specific fertilisers spreading at specific bout widths. Some spreader models require very careful setting. The components that are adjustable vary between manufacturer and model but include one or more of the following:

Disc type.Pto/disc speed.Vane type and position/angle on disc.Position of fertiliser drop point.Disc height over crop/soil.Spreader/disc angle.The setting is determined by fertiliser type (density, particle size distribution, shape, strength) and bout width. Setting information is usually available in detailed setting charts provided by the manufacturer, but increasingly is more easily accessible on the internet or as a smart phone app.

While some manufacturers provide setting information for specific fertiliser brands, increasingly a simple sieve test and visual type test are used to identify fertiliser type and consequently the settings required. It’s vital to follow the setting procedure.

Rate setting

Getting the correct rate of fertiliser out (kg/ha or bags/acre) is also important and while manufacturers’ setting guides are a starting point, some level of field calibration is usually needed.

Some makers have very useful setting aids and of course on-board weighing systems make it very easy. Whatever system is used, it is important to establish the correct rate setting before field-scale errors are made.

Field use

Correct attachment to the tractor to make sure it’s level from right to left and at the correct angle front/back and height over the crop is essential, as is a working rev counter.

Driving at accurate bout widths is essential; tramlines facilitate this in cereals and GPS guidance systems can help when there are no tramlines. However, there is no shame in measuring and marking the bouts! Wear on the spreader components: fertiliser outlet, disc, vanes or spouts must be monitored.

Headland

To avoid uneven spreading on the headland and the loss of fertiliser into headlands/drains, most spreaders have a headland setting mechanism which adjusts the spread pattern.

Matching the in-field runs with the headland runs requires the spreader to be turned on and off at exactly the correct times as the tractor approaches and leaves the headland – on high tech spreaders, this can be automatically controlled by GPS, but careful manual operation is possible once the distances are known.

Read more

Ten steps to get set up for the spreading season

Special focus: fertilisers

SHARING OPTIONS