For Tipperary dairy farmer Phonsie Deegan, the purchase of automated heat detection aids in 2022 has made a huge difference to the running of the farm. Milking 460 high yielding cows at Clonmore, near the border with Co Laois, attention to detail and technical performance is high with the herd averaging close to 650kg MS/cow.

The main Cork to Dublin trainline runs alongside the farmyard, giving day-trippers a glimpse into an impressive farmyard with a new 60-bail rotary parlour and high-spec cubicle shed. When the Irish Farmers Journal visited the Deegan farm last week, the cows were still in at night being fed a total mixed ration, while they were out grazing by day.

Land type is mixed and Phonsie says he can remember cutting turf on some of the land the cows are now grazing, but he says it’s a good farm to grow grass. When it came to buying a health and heat detection system, he says he looked at all the options but went with Smaxtec, which is a bolus-based system, because he says he felt the health monitoring is superior on bolus, rather than tag or collar-based systems.

Smaxtec was installed in February 2022, so he is now going into his third breeding season with the system in place.

“It’s working very well for me and I’m very happy with it. I looked at them all at the time, but I felt the true temperature and water-intake reading that the bolus offered would be an advantage with Smaxtec. It alerts you if there is a suspected case of sub-clinical milk fever, ketosis or mastitis.

“It also alerts you when a cow is going to calve, but to be honest I only ever really look at that towards the end of the calving season. There’s so much going on during the peak of calving that we are in the yard anyway, but it comes in handy towards the end of the calving season when maybe we wouldn’t be watching cows as closely,” Phonsie says.

He was using tailpaint for heat detection prior to purchasing Smaxtec.

“The first year I put the system in I was probably a bit sceptical, so I tailpainted everything before we started breeding, but after the first few days I was convinced and never touched the tailpaint since and we use it on the maiden heifers too.”

The Deegans built a new cubicle shed last year, with clear span centre passage.

System

Phonsie opted for what they call a live system, meaning data is flowing between the cows and the processing unit at all times. In order to do this he has five base stations around the farm. One of these is in the farmyard, with the rest dotted around the farm, so every field has full coverage at all times. The external base stations are powered by a small solar array and battery.

According to Smaxtec, each base station will cover a radius of around 300m, but it depends entirely on the line of sight, so high trees or hills will impact the coverage. On good sites they can get up to twice that area covered.

Having the system live was a personal choice by Phonsie. Most farmers installing automated detection aids just have the base station in the yard, so when the cows come in for milking the data from the device is processed and alerts around health or heat are then sent to the operator’s smartphone. Where the system is live, Phonsie has up-to-date information on the herd at all times.

On the Deegan farm, the system is fully integrated with the DeLaval milking parlour. The Delpro system used by DeLaval calls out any health alerts when the cow goes onto the rotary platform for milking. Phonsie says they also have the option of drafting cows with suspected health issues out before milking, meaning they can all be milked last.

When a mastitis alert is issued, Phonsie says they strip the cow and check for signs of mastitis with the CMT test. He says they use some non-antibiotic based remedies and find them pretty successful on young cows.

In terms of fertility, the empty rate last season was 8.5% not in calf after 12 weeks of breeding. Mating start date is 1 May. Phonsie says that one of the big changes has been that the calving rate is a lot more compact over the last few years.

“I was looking back at figures the other day and a few years ago we had 120 cows calved by St Patrick’s Day, whereas this year we had 370 calved. Now there are other changes too, such as the new cubicle shed, so there’s probably less stress on cows than there was. There’s a lot less workload for the people too, as before we used to be watching cows four times per day,” he says.

Phonsie gets the heifers scanned before breeding and based on the scanning data, will inject heifers with prostaglandin to compress a three-week breeding season into two weeks. Heifers are bred to standing heat, based on the data from the boluses. Phonsie opts to keep the heifers in the shed during the breeding season go to grass a few weeks after being served.

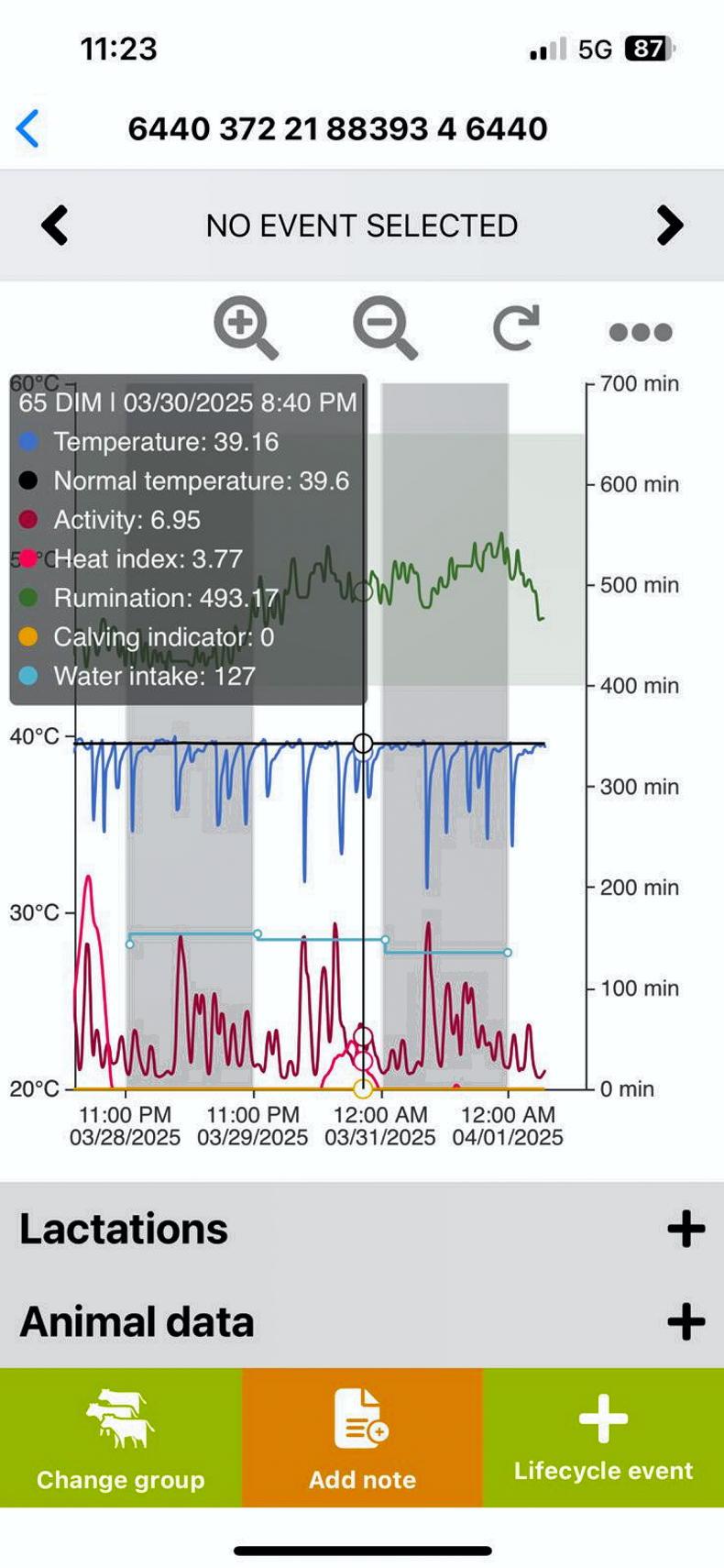

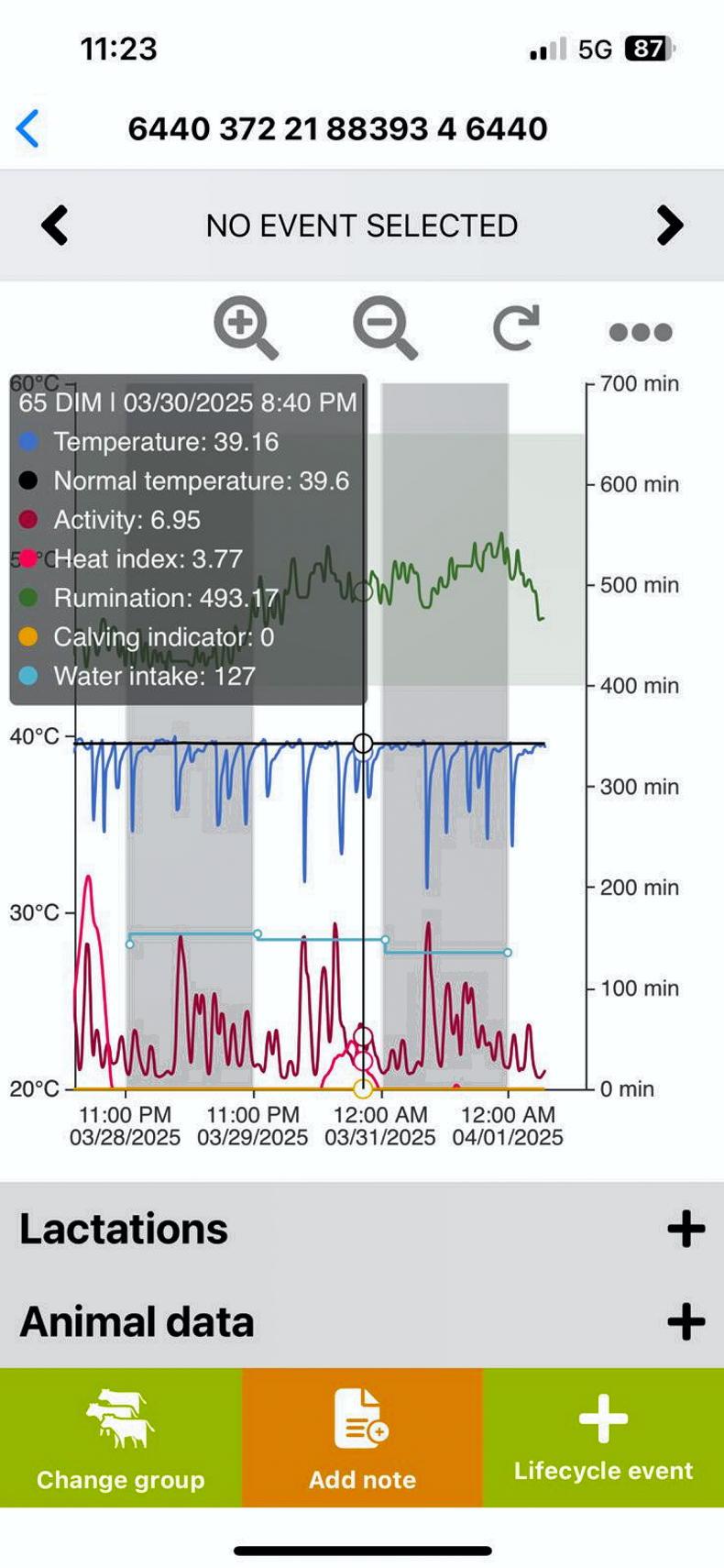

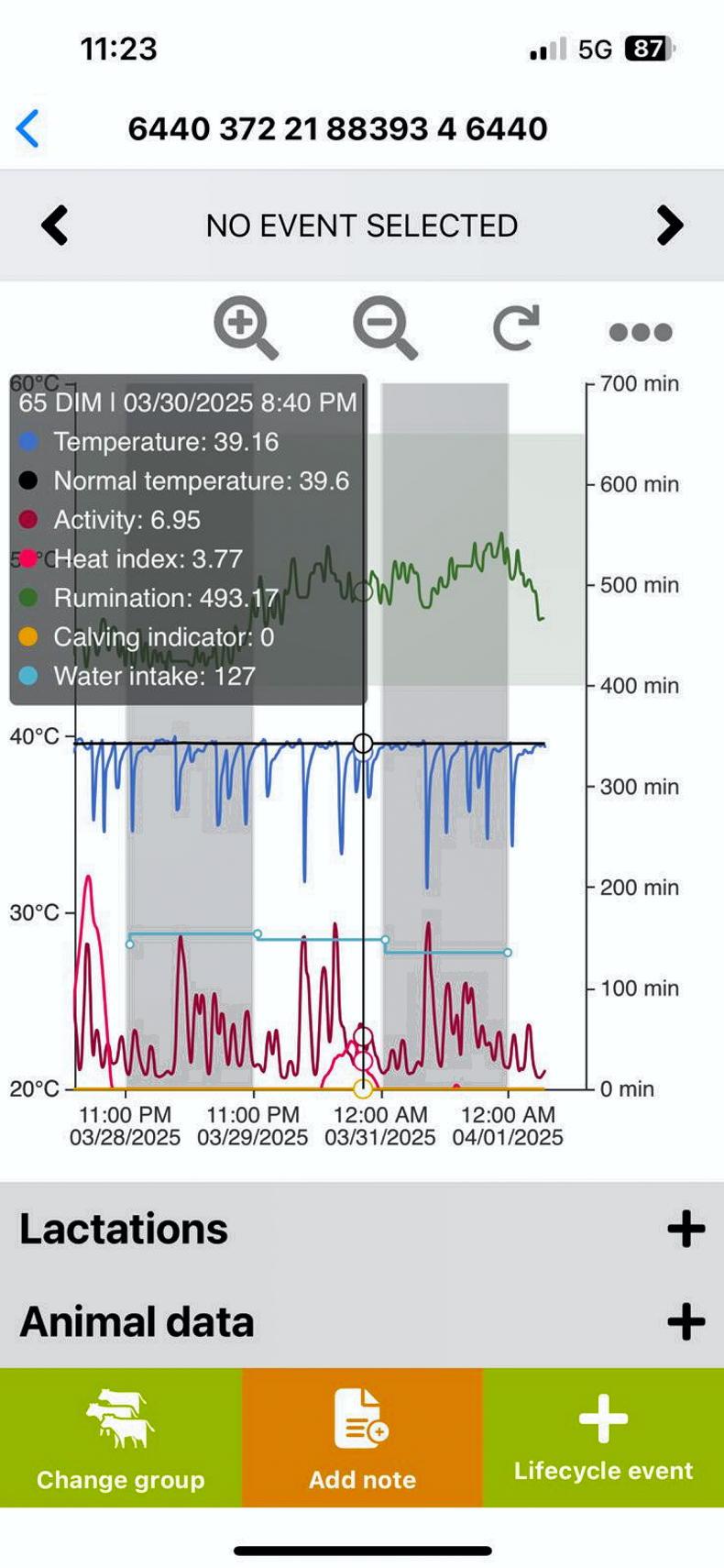

Example screenshots from the Smaxtec programme showing activity.

Example screenshots from the Smaxtec programme showing activity.

Costs

Smaxtec is a subscription-based product. Essentially, the farmer buys the base station and the boluses and then pays a monthly fee for each cow on the system. According to Smaxtec, the main base station costs between €4,000 and €5,500, with each additional base station costing €2,900. Installation and training costs €800. All of these prices are excluding VAT at 23% and are list prices, so are subject to negotiation with the sales reps. A bolus costs €35/cow excluding VAT and while the battery life of the bolus is four to five years, the bolus is guaranteed for the life of the cow. In other words, if the bolus dies before the cow does, it will be replaced for free. Subscription costs are €2.50/cow/month excluding VAT giving an annual subscription cost of €30 per cow, excluding VAT at 23%.

For a farm with say 120 cows and one base station, the capital costs would come to €5,166 including VAT at 23% for the boluses and approximately €6,150 including VAT for the base station. Installation and training would come to €984 including VAT, giving a total upfront cost of €12,300 including VAT, or €103/cow.

According to an update from Revenue issued last year, VAT cannot be reclaimed on heat detection aids by unregistered farmers, so for the vast majority of farmers VAT will need to be paid on the capital and subscription costs.

Annual subscription costs would come to €3,600 plus VAT for the 120 cows, which at 23% VAT comes to €4,428.

At a 20% replacement rate, 24 new boluses would need to be purchased each year to replace the ones in the cows leaving the herd. What some farmers will do is put these into the maiden heifers so they will have heat alerts on these animals. However, if the system is being used then subscription charges will apply. Twenty-four new boluses would cost €1,033 including VAT.

If you were to write off the capital costs over a seven-year period, the annual capital cost would be €1,757 including VAT. When you add the subscription charges and the cost of new boluses to replace the ones in cows leaving the herd, the annual running cost would come to €5,461 including VAT. This gives a total annual cost of €7,218 including VAT for a 120-cow herd, or €60/cow/year.

On the face of it, this works out a good bit more expensive on an annual basis compared to alternative devices such as collars. However, it could be argued that depreciation or replacement costs are factored into the Smaxtec pricing system. In other words, at the end of the seven-year period the battery life of collars would be coming to an end and would need to be replaced, whereas thats not the case with the boluses as they are effectively being replaced each year with new boluses. The system is eligible for TAMS III grant aid.

One of the remote Smaxtec base stations on the Deegan farm.

For Tipperary dairy farmer Phonsie Deegan, the purchase of automated heat detection aids in 2022 has made a huge difference to the running of the farm. Milking 460 high yielding cows at Clonmore, near the border with Co Laois, attention to detail and technical performance is high with the herd averaging close to 650kg MS/cow.

The main Cork to Dublin trainline runs alongside the farmyard, giving day-trippers a glimpse into an impressive farmyard with a new 60-bail rotary parlour and high-spec cubicle shed. When the Irish Farmers Journal visited the Deegan farm last week, the cows were still in at night being fed a total mixed ration, while they were out grazing by day.

Land type is mixed and Phonsie says he can remember cutting turf on some of the land the cows are now grazing, but he says it’s a good farm to grow grass. When it came to buying a health and heat detection system, he says he looked at all the options but went with Smaxtec, which is a bolus-based system, because he says he felt the health monitoring is superior on bolus, rather than tag or collar-based systems.

Smaxtec was installed in February 2022, so he is now going into his third breeding season with the system in place.

“It’s working very well for me and I’m very happy with it. I looked at them all at the time, but I felt the true temperature and water-intake reading that the bolus offered would be an advantage with Smaxtec. It alerts you if there is a suspected case of sub-clinical milk fever, ketosis or mastitis.

“It also alerts you when a cow is going to calve, but to be honest I only ever really look at that towards the end of the calving season. There’s so much going on during the peak of calving that we are in the yard anyway, but it comes in handy towards the end of the calving season when maybe we wouldn’t be watching cows as closely,” Phonsie says.

He was using tailpaint for heat detection prior to purchasing Smaxtec.

“The first year I put the system in I was probably a bit sceptical, so I tailpainted everything before we started breeding, but after the first few days I was convinced and never touched the tailpaint since and we use it on the maiden heifers too.”

The Deegans built a new cubicle shed last year, with clear span centre passage.

System

Phonsie opted for what they call a live system, meaning data is flowing between the cows and the processing unit at all times. In order to do this he has five base stations around the farm. One of these is in the farmyard, with the rest dotted around the farm, so every field has full coverage at all times. The external base stations are powered by a small solar array and battery.

According to Smaxtec, each base station will cover a radius of around 300m, but it depends entirely on the line of sight, so high trees or hills will impact the coverage. On good sites they can get up to twice that area covered.

Having the system live was a personal choice by Phonsie. Most farmers installing automated detection aids just have the base station in the yard, so when the cows come in for milking the data from the device is processed and alerts around health or heat are then sent to the operator’s smartphone. Where the system is live, Phonsie has up-to-date information on the herd at all times.

On the Deegan farm, the system is fully integrated with the DeLaval milking parlour. The Delpro system used by DeLaval calls out any health alerts when the cow goes onto the rotary platform for milking. Phonsie says they also have the option of drafting cows with suspected health issues out before milking, meaning they can all be milked last.

When a mastitis alert is issued, Phonsie says they strip the cow and check for signs of mastitis with the CMT test. He says they use some non-antibiotic based remedies and find them pretty successful on young cows.

In terms of fertility, the empty rate last season was 8.5% not in calf after 12 weeks of breeding. Mating start date is 1 May. Phonsie says that one of the big changes has been that the calving rate is a lot more compact over the last few years.

“I was looking back at figures the other day and a few years ago we had 120 cows calved by St Patrick’s Day, whereas this year we had 370 calved. Now there are other changes too, such as the new cubicle shed, so there’s probably less stress on cows than there was. There’s a lot less workload for the people too, as before we used to be watching cows four times per day,” he says.

Phonsie gets the heifers scanned before breeding and based on the scanning data, will inject heifers with prostaglandin to compress a three-week breeding season into two weeks. Heifers are bred to standing heat, based on the data from the boluses. Phonsie opts to keep the heifers in the shed during the breeding season go to grass a few weeks after being served.

Example screenshots from the Smaxtec programme showing activity.

Example screenshots from the Smaxtec programme showing activity.

Costs

Smaxtec is a subscription-based product. Essentially, the farmer buys the base station and the boluses and then pays a monthly fee for each cow on the system. According to Smaxtec, the main base station costs between €4,000 and €5,500, with each additional base station costing €2,900. Installation and training costs €800. All of these prices are excluding VAT at 23% and are list prices, so are subject to negotiation with the sales reps. A bolus costs €35/cow excluding VAT and while the battery life of the bolus is four to five years, the bolus is guaranteed for the life of the cow. In other words, if the bolus dies before the cow does, it will be replaced for free. Subscription costs are €2.50/cow/month excluding VAT giving an annual subscription cost of €30 per cow, excluding VAT at 23%.

For a farm with say 120 cows and one base station, the capital costs would come to €5,166 including VAT at 23% for the boluses and approximately €6,150 including VAT for the base station. Installation and training would come to €984 including VAT, giving a total upfront cost of €12,300 including VAT, or €103/cow.

According to an update from Revenue issued last year, VAT cannot be reclaimed on heat detection aids by unregistered farmers, so for the vast majority of farmers VAT will need to be paid on the capital and subscription costs.

Annual subscription costs would come to €3,600 plus VAT for the 120 cows, which at 23% VAT comes to €4,428.

At a 20% replacement rate, 24 new boluses would need to be purchased each year to replace the ones in the cows leaving the herd. What some farmers will do is put these into the maiden heifers so they will have heat alerts on these animals. However, if the system is being used then subscription charges will apply. Twenty-four new boluses would cost €1,033 including VAT.

If you were to write off the capital costs over a seven-year period, the annual capital cost would be €1,757 including VAT. When you add the subscription charges and the cost of new boluses to replace the ones in cows leaving the herd, the annual running cost would come to €5,461 including VAT. This gives a total annual cost of €7,218 including VAT for a 120-cow herd, or €60/cow/year.

On the face of it, this works out a good bit more expensive on an annual basis compared to alternative devices such as collars. However, it could be argued that depreciation or replacement costs are factored into the Smaxtec pricing system. In other words, at the end of the seven-year period the battery life of collars would be coming to an end and would need to be replaced, whereas thats not the case with the boluses as they are effectively being replaced each year with new boluses. The system is eligible for TAMS III grant aid.

One of the remote Smaxtec base stations on the Deegan farm.

SHARING OPTIONS