Urea is less dense than other fertiliser types. This can limit bout widths and will require spreaders to be set/adjusted to spread the product evenly. If you use a contractor, you must ensure that the spreader is set properly.

Machine setting

There are two elements with machine setting:

Rate setting or calibration – while this is vital, it does not impact on how evenly it is spread. Evenness setting – the spread pattern of most spreaders can be adjusted to suit the fertiliser type and bout width. The use of GPS-controlled systems normally has no impact on the evenness of spread in the main field area.

Best practice for spreaders and urea

1. Use a spreader that is capable of spreading urea at the desired bout width, and which is supported by a good database of setting information for a range of fertilisers, from the manufacturer. All of the major spreader manufacturers have Hall test information that is essential for urea.

2. Make sure all of the spreading components (vanes, etc) are in good condition.

3. Purchase urea with good physical quality: larger particle sizes (90% in the 2-4mm+ category), good particle strength (ideally > 5kg crush force for a good spread pattern, but always > 3kg).

4. Avoid urea blends (eg N and K together) unless there are independent test results that show satisfactory spread patterns with your machine model.

5. Use the spreader manufacturer’s resources to get the correct setting for your machine by checking their database (app or online) for an exact or nearest match of the fertiliser type.

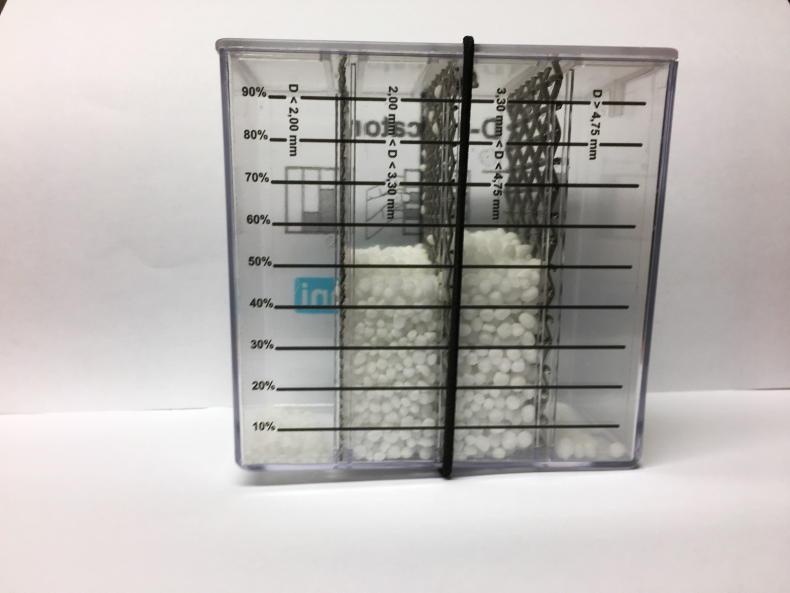

Preferably use a sieve box, strength and density test equipment to

characterise the fertiliser.

6. Carefully set the spreader according to the manufacturer’s guidance, based on bout width and fertiliser characteristics.

7. What is adjusted varies for different models. It may be disc type, vane type and position, fertiliser drop point, disc speed, hopper angle, etc.

8. Check the spread pattern, if possible, using purpose-developed trays or mats.

9. Note that ‘rules of thumb’ like ‘the last granules reaching the next tramline’ are not universal across machines, fertilisers or bout widths.

You must follow the guidelines for your machine, with your fertiliser, at the chosen bout width.

10. You may need to reduce your bout width and, generally, if you have a choice on grassland, it is often easier to spread urea evenly at narrower bout widths, particularly if it’s windy.

Good granule strength will ensure even fertiliser application across the bout width.

In short

For even spreading you need:

A spreader capable of spreading urea.Good-quality fertiliser.The correct bout width.The correct spreader adjustments.

Urea is less dense than other fertiliser types. This can limit bout widths and will require spreaders to be set/adjusted to spread the product evenly. If you use a contractor, you must ensure that the spreader is set properly.

Machine setting

There are two elements with machine setting:

Rate setting or calibration – while this is vital, it does not impact on how evenly it is spread. Evenness setting – the spread pattern of most spreaders can be adjusted to suit the fertiliser type and bout width. The use of GPS-controlled systems normally has no impact on the evenness of spread in the main field area.

Best practice for spreaders and urea

1. Use a spreader that is capable of spreading urea at the desired bout width, and which is supported by a good database of setting information for a range of fertilisers, from the manufacturer. All of the major spreader manufacturers have Hall test information that is essential for urea.

2. Make sure all of the spreading components (vanes, etc) are in good condition.

3. Purchase urea with good physical quality: larger particle sizes (90% in the 2-4mm+ category), good particle strength (ideally > 5kg crush force for a good spread pattern, but always > 3kg).

4. Avoid urea blends (eg N and K together) unless there are independent test results that show satisfactory spread patterns with your machine model.

5. Use the spreader manufacturer’s resources to get the correct setting for your machine by checking their database (app or online) for an exact or nearest match of the fertiliser type.

Preferably use a sieve box, strength and density test equipment to

characterise the fertiliser.

6. Carefully set the spreader according to the manufacturer’s guidance, based on bout width and fertiliser characteristics.

7. What is adjusted varies for different models. It may be disc type, vane type and position, fertiliser drop point, disc speed, hopper angle, etc.

8. Check the spread pattern, if possible, using purpose-developed trays or mats.

9. Note that ‘rules of thumb’ like ‘the last granules reaching the next tramline’ are not universal across machines, fertilisers or bout widths.

You must follow the guidelines for your machine, with your fertiliser, at the chosen bout width.

10. You may need to reduce your bout width and, generally, if you have a choice on grassland, it is often easier to spread urea evenly at narrower bout widths, particularly if it’s windy.

Good granule strength will ensure even fertiliser application across the bout width.

In short

For even spreading you need:

A spreader capable of spreading urea.Good-quality fertiliser.The correct bout width.The correct spreader adjustments.

SHARING OPTIONS