A dairy infrastructure handbook was launched by Teagasc at the Moorepark open day held last week. Roadway construction was one key area of focus both in the handbook and on the day and here we will look at some of the key points outlined.

There has been considerable investment in grazing infrastructure on dairy farms over the past number of years but in many cases more is needed. Increasing grassland production and utilisation relies heavily on having a robust grazing infrastructure and roadways play a key part in this.

When it comes to roadways, there can be a significant variation within the one farm, according to Teagasc. Roadways closer to the farmyard tend to be better developed and maintained while those servicing the outer extremities can be underdeveloped. In many cases, the core road network has been in place for many years and is designed for much lower stock numbers than currently exist.

While herds may have expanded from 100 to 200 cows over the past 10 years, has the roadway expanded at the same time?

Table one outlines the recommended roadway width based on the size of the herd.

When it comes to fencing along roadways, it is advised to keep it 0.5m back from the edge of the roadway to allow the cows to utilise the full width of the roadway while preventing them from walking on the grass margin.

Roadway options

There were four different roadway designs on show on the day, two 4m wide options and two 2m wide options.

The roadway network required on the farm will be dictated to a large extent by the soil type, with a more intensive roadway network required for heavy soils. The land area devoted to farm roadways ranges from 1% to 2% of the grazing area.

When it comes to roadway design, it is vital to avoid sharp turns at corners and junctions. Farmers should also try to avoid restrictions and distractions to cow flow and movement. It is vital to take a step back and observe cow movement both on the way to the collecting yard and back to the paddock. Identify areas where bottlenecks may occur and make a plan to alleviate them.

When it comes to roadways on steep inclines, water run-off has to be managed. Tapering the roadway to get water off the track as quickly as possible is the best option. Another option is to use ramps or channels to divert water at intervals, otherwise flowing water will create tracks and wash away the expensive surface layer.

More farmers are installing 2m wide spur roadways on their farm to service individual paddocks or perhaps to allow larger paddocks to be split. These come into play at the shoulders of the year in particular and provide access to paddocks that would otherwise be difficult to graze.

Water troughs should be located away from gaps on to the roadway. This will not only help prevent damage around gates, but will also reduce bottlenecks.

It is good to have an open mind when it comes to the existing roadway network and if it does not efficiently service the existing paddocks then it could be an option to move certain sections.

The handbook also goes into detail on the construction of farm roadways. Ideally it is recommended to remove a thin layer of topsoil before placing the roadway material. Be careful not to remove too much topsoil as the depth of the roadway will have to be increased to bring the surface of the roadway above the field level. The finished roadway must be above the level of the field to allow water to drain away. The foundation layer is made up of granular fill material with a usual depth of 200-300mm. The biggest stones should be no bigger than about one-third of the thickness of this layer. The intended slope of the roadway should be formed in the foundation layer, this means that the surface layer will have the same slope.

Generally 75mm or 100mm down material is used. This is a graded mixture of different-sized stones from 75mm or 100mm down to dust. Another option for farmers is to use crushed rubble.

It is important to compact the material with a vibrating roller before the surface layer is spread. Compaction interlocks the material and gives a stronger roadway. It will also help prevent stones from mixing with the surface layer.

The handbook then recommends completing the roadway with a 50-75mm layer of fine material on the surface. The layer needs to be laid evenly and be well compacted. If the road is sloping to one side, then a slope of 1:20/1:25 is recommended while if it is sloped to either side a slope of 1:15 is advised.

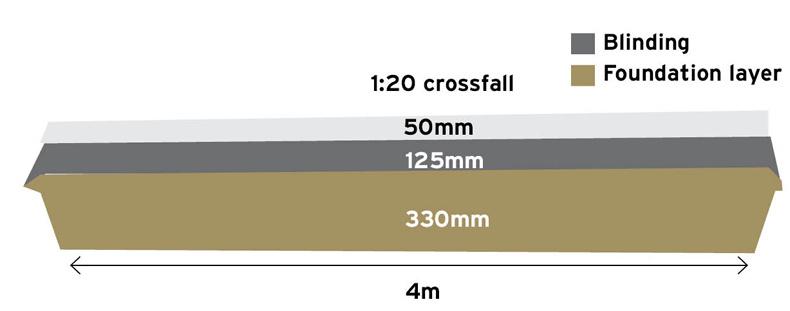

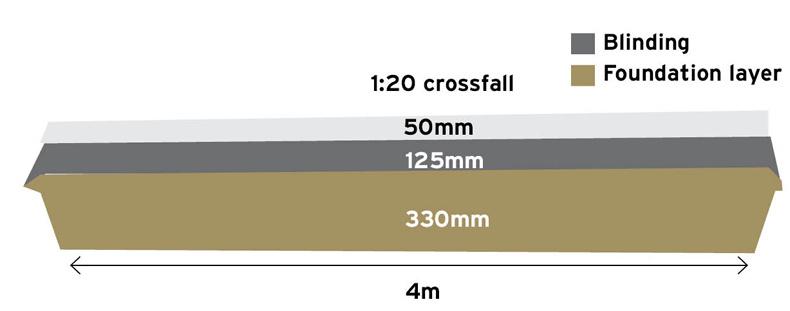

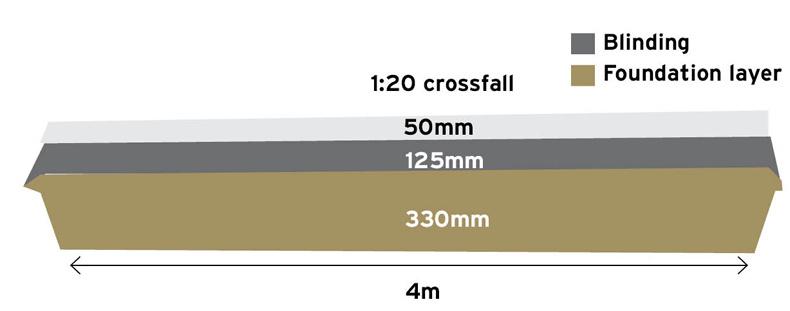

This is designed to be one of the main roadways in the farm. It is 4m wide with 300mm of topsoil removed.

Roadway one.

We can see from the images that there are three distinct layers. A 350mm layer of 4in down trunking material is laid, with 1t of material doing a 4m wide by 1m long stretch.

A 125mm blinding layer is added on top of this, with a 50mm layer of surface dust used to finish the roadway. Total installation cost is €31.90/m for a 4m wide roadway.

Another option is to just have a 200mm blinding layer above the larger stone. Installation cost for this type of a roadway is €2.40/m according to Teagasc.

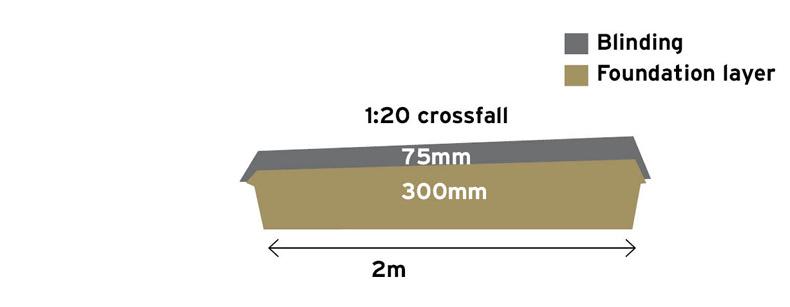

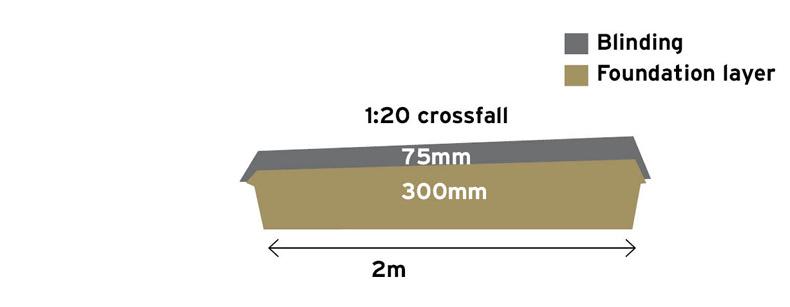

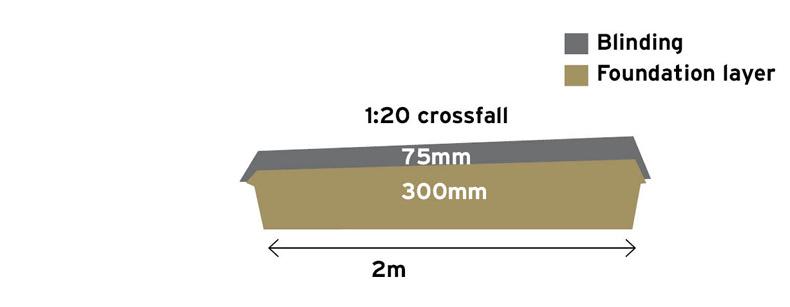

This 2m wide roadway would generally be used as a spur roadway to provide access to a small number of paddocks that throughout the year would receive considerably less foot traffic that the main farm roadways.

Roadway two.

They may also be suitable for robotic grazing systems.

Roadway two.

A 200mm layer of topsoil is first removed, with a 300mm layer of 4in down trunking material then laid and compacted. A 75mm blinding layer is then installed and compacted. This roadway works out at €11.90/m.

Another option explored was to install this roadway without excavating any topsoil. This reduced costs to €10.35/m as there was only a 250mm layer of 4in down trunking material.

A cheaper option again to provide access to one paddock for example could be to install a 150mm layer of material on the surface of the ground. This is then blinded with a fine surface layer. This type of cow track could be installed for as little as €8/m. The width is generally between 1.8m and 2.5m.

All roadways on the day had a cross fall of 1:20.

Costs and repairing roadways

The material will make up over 80% of the overall cost so it is important not to dig down too much when removing topsoil or this can greatly add to the overall cost. In general, roadways will cost between €4/square metre and €7.50/ square metre. The VAT is refundable on new roadways but it is not refundable on repairs.

Roadways on the farm will generally need some attention every year. This is particularly the case for the 50-100m most-used section of the roadway adjoining the farmyard. This area can get very dirty, worn and low. This can lead to increased SCC levels, udder washing, raised TBC and sediment levels due to cows being dirtier. It can also increase lameness issues considerably. Generally 40mm to 50mm down granular fill is used to raise the level of existing roadways where they have become low. They should be brought above the level of the roadway and finished with a blinding layer.

Getting water off roadways will extend the life of the surface and will also reduce the cost of maintenance, with potholes less likely to develop. A crossfall of 1:20 should be enough to divert water to the sides. The introduction of legislation requiring the prevention of direct runoff of water from farm roadways to open drains and watercourses by 01 January 2021 must be considered when constructing any roadway.

While some farmers will opt to install concrete portions on their roadways, the presence of them on farms has shown to increase the incidence of lameness due to a higher risk of loose gravel or pebbles lying on the roadway surface. If concrete is used, it must be cleaned regularly.

Roadways in poor condition will also negatively impact on cow-flow and cause cows to slow down. If they are forced to move on from behind cows can become bunched and they lift their heads and shorten their stride. In this instance they cannot see where they are putting their front feet.

A dairy infrastructure handbook was launched by Teagasc at the Moorepark open day held last week. Roadway construction was one key area of focus both in the handbook and on the day and here we will look at some of the key points outlined.

There has been considerable investment in grazing infrastructure on dairy farms over the past number of years but in many cases more is needed. Increasing grassland production and utilisation relies heavily on having a robust grazing infrastructure and roadways play a key part in this.

When it comes to roadways, there can be a significant variation within the one farm, according to Teagasc. Roadways closer to the farmyard tend to be better developed and maintained while those servicing the outer extremities can be underdeveloped. In many cases, the core road network has been in place for many years and is designed for much lower stock numbers than currently exist.

While herds may have expanded from 100 to 200 cows over the past 10 years, has the roadway expanded at the same time?

Table one outlines the recommended roadway width based on the size of the herd.

When it comes to fencing along roadways, it is advised to keep it 0.5m back from the edge of the roadway to allow the cows to utilise the full width of the roadway while preventing them from walking on the grass margin.

Roadway options

There were four different roadway designs on show on the day, two 4m wide options and two 2m wide options.

The roadway network required on the farm will be dictated to a large extent by the soil type, with a more intensive roadway network required for heavy soils. The land area devoted to farm roadways ranges from 1% to 2% of the grazing area.

When it comes to roadway design, it is vital to avoid sharp turns at corners and junctions. Farmers should also try to avoid restrictions and distractions to cow flow and movement. It is vital to take a step back and observe cow movement both on the way to the collecting yard and back to the paddock. Identify areas where bottlenecks may occur and make a plan to alleviate them.

When it comes to roadways on steep inclines, water run-off has to be managed. Tapering the roadway to get water off the track as quickly as possible is the best option. Another option is to use ramps or channels to divert water at intervals, otherwise flowing water will create tracks and wash away the expensive surface layer.

More farmers are installing 2m wide spur roadways on their farm to service individual paddocks or perhaps to allow larger paddocks to be split. These come into play at the shoulders of the year in particular and provide access to paddocks that would otherwise be difficult to graze.

Water troughs should be located away from gaps on to the roadway. This will not only help prevent damage around gates, but will also reduce bottlenecks.

It is good to have an open mind when it comes to the existing roadway network and if it does not efficiently service the existing paddocks then it could be an option to move certain sections.

The handbook also goes into detail on the construction of farm roadways. Ideally it is recommended to remove a thin layer of topsoil before placing the roadway material. Be careful not to remove too much topsoil as the depth of the roadway will have to be increased to bring the surface of the roadway above the field level. The finished roadway must be above the level of the field to allow water to drain away. The foundation layer is made up of granular fill material with a usual depth of 200-300mm. The biggest stones should be no bigger than about one-third of the thickness of this layer. The intended slope of the roadway should be formed in the foundation layer, this means that the surface layer will have the same slope.

Generally 75mm or 100mm down material is used. This is a graded mixture of different-sized stones from 75mm or 100mm down to dust. Another option for farmers is to use crushed rubble.

It is important to compact the material with a vibrating roller before the surface layer is spread. Compaction interlocks the material and gives a stronger roadway. It will also help prevent stones from mixing with the surface layer.

The handbook then recommends completing the roadway with a 50-75mm layer of fine material on the surface. The layer needs to be laid evenly and be well compacted. If the road is sloping to one side, then a slope of 1:20/1:25 is recommended while if it is sloped to either side a slope of 1:15 is advised.

This is designed to be one of the main roadways in the farm. It is 4m wide with 300mm of topsoil removed.

Roadway one.

We can see from the images that there are three distinct layers. A 350mm layer of 4in down trunking material is laid, with 1t of material doing a 4m wide by 1m long stretch.

A 125mm blinding layer is added on top of this, with a 50mm layer of surface dust used to finish the roadway. Total installation cost is €31.90/m for a 4m wide roadway.

Another option is to just have a 200mm blinding layer above the larger stone. Installation cost for this type of a roadway is €2.40/m according to Teagasc.

This 2m wide roadway would generally be used as a spur roadway to provide access to a small number of paddocks that throughout the year would receive considerably less foot traffic that the main farm roadways.

Roadway two.

They may also be suitable for robotic grazing systems.

Roadway two.

A 200mm layer of topsoil is first removed, with a 300mm layer of 4in down trunking material then laid and compacted. A 75mm blinding layer is then installed and compacted. This roadway works out at €11.90/m.

Another option explored was to install this roadway without excavating any topsoil. This reduced costs to €10.35/m as there was only a 250mm layer of 4in down trunking material.

A cheaper option again to provide access to one paddock for example could be to install a 150mm layer of material on the surface of the ground. This is then blinded with a fine surface layer. This type of cow track could be installed for as little as €8/m. The width is generally between 1.8m and 2.5m.

All roadways on the day had a cross fall of 1:20.

Costs and repairing roadways

The material will make up over 80% of the overall cost so it is important not to dig down too much when removing topsoil or this can greatly add to the overall cost. In general, roadways will cost between €4/square metre and €7.50/ square metre. The VAT is refundable on new roadways but it is not refundable on repairs.

Roadways on the farm will generally need some attention every year. This is particularly the case for the 50-100m most-used section of the roadway adjoining the farmyard. This area can get very dirty, worn and low. This can lead to increased SCC levels, udder washing, raised TBC and sediment levels due to cows being dirtier. It can also increase lameness issues considerably. Generally 40mm to 50mm down granular fill is used to raise the level of existing roadways where they have become low. They should be brought above the level of the roadway and finished with a blinding layer.

Getting water off roadways will extend the life of the surface and will also reduce the cost of maintenance, with potholes less likely to develop. A crossfall of 1:20 should be enough to divert water to the sides. The introduction of legislation requiring the prevention of direct runoff of water from farm roadways to open drains and watercourses by 01 January 2021 must be considered when constructing any roadway.

While some farmers will opt to install concrete portions on their roadways, the presence of them on farms has shown to increase the incidence of lameness due to a higher risk of loose gravel or pebbles lying on the roadway surface. If concrete is used, it must be cleaned regularly.

Roadways in poor condition will also negatively impact on cow-flow and cause cows to slow down. If they are forced to move on from behind cows can become bunched and they lift their heads and shorten their stride. In this instance they cannot see where they are putting their front feet.

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: