AutoTill is a new automatic setting and function monitoring system for cultivators. It allows a cultivator to set itself automatically in accordance with pre-defined parameters such as working position, working depth, roller speed as well as detecting share loss, weakness and clogging. Data recorded by the cultivator is compared with tractor data, and will adapt operating speed when blockages are detected etc. It utilises tilt sensors on the frame, depth control cylinders on the roller, pressure sensors integrated in the tine element to monitor blockages, speed sensors on the roller and inductive sensors that monitor the presence and strength of the shares. At an entry level, AutoTill can monitor the functionality of the machine in combination with a standard tractor, using IsoBus, and warns the driver of any problems with the cultivator. Going one step further, the system can communicate through IsoBus with the tractor and independently react to the problems from the error messages received from the sensors, reducing the driver’s workload.

AutoTill is also ready to operate autonomously with a robot. The cultivator can communicate with the robot through IsoBus, and can monitor the functionality of the cultivator and react independently to any irregularities. The cultivator informs the robot how to resolve any potential problems. Amazone says this feature will reap rewards on long working days at high working speeds particularly with wide working widths, where dust often impairs vision. It says the fact problems can be resolved autonomously, whilst making it possible to use autonomous tractors and mounted machinery in 24-hour shifts in a highly-efficient manner.

Distance measuring system for setting the working depth via the rear roller.

Various different sensors help with monitoring the function of the machine

1. Information of the tractor unit

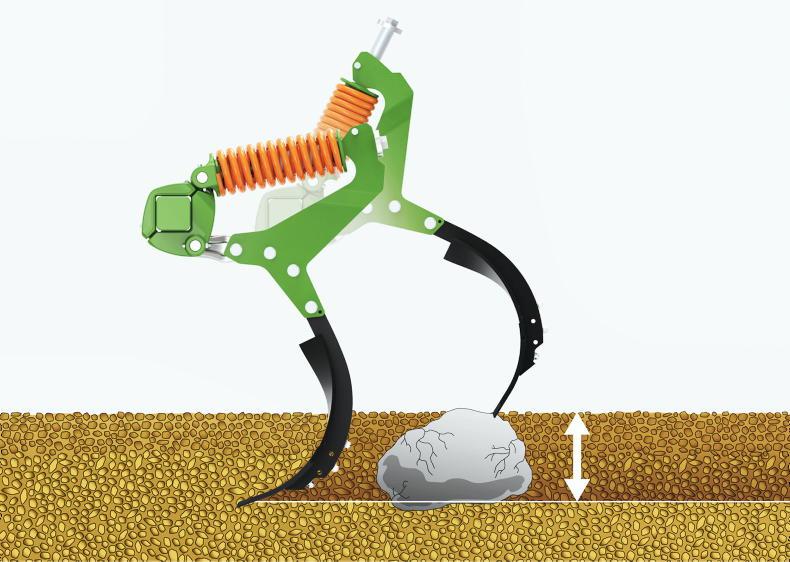

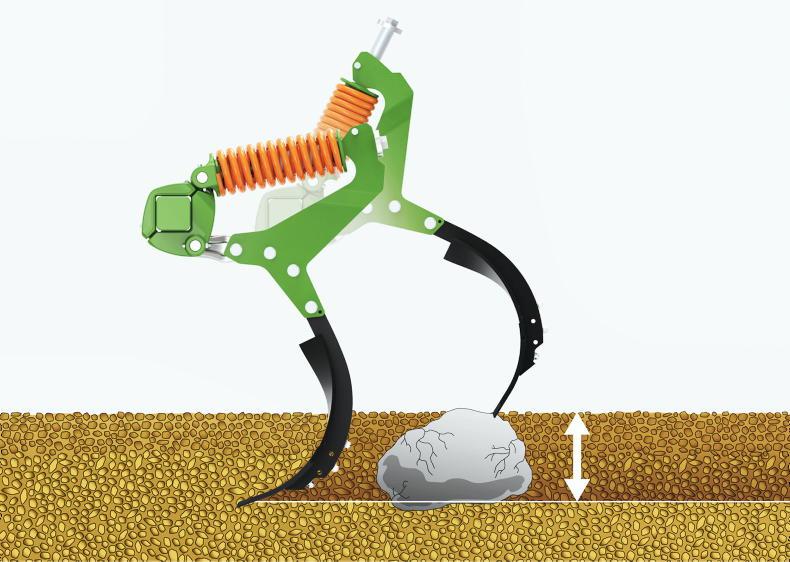

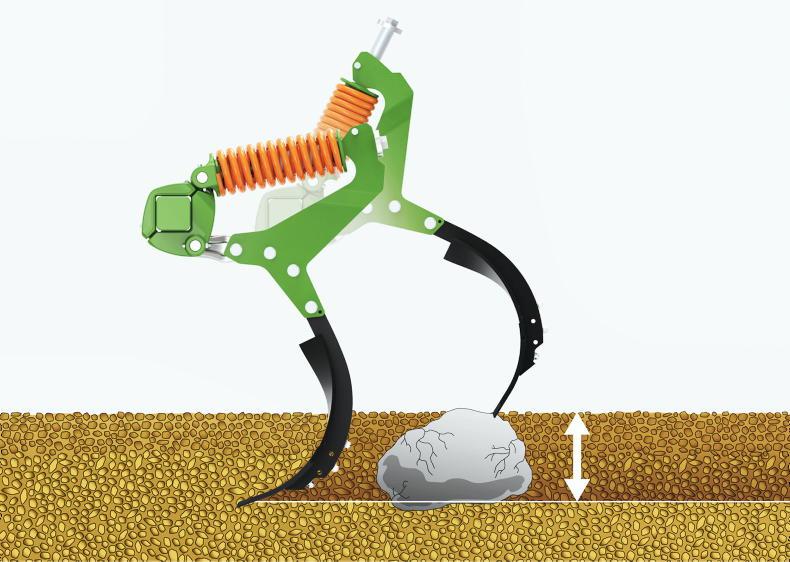

2. Activity of the overload safety device

3. Setting the working depth

4. Preventing blockages

5. Detection share loss

6. Monitoring the roller speed

Blockage detection integrated in the tine element.

Monitoring the overload safety device for mapping the soil conditions.

Inductive sensor for monitoring the shares.

AutoTill is a new automatic setting and function monitoring system for cultivators. It allows a cultivator to set itself automatically in accordance with pre-defined parameters such as working position, working depth, roller speed as well as detecting share loss, weakness and clogging. Data recorded by the cultivator is compared with tractor data, and will adapt operating speed when blockages are detected etc. It utilises tilt sensors on the frame, depth control cylinders on the roller, pressure sensors integrated in the tine element to monitor blockages, speed sensors on the roller and inductive sensors that monitor the presence and strength of the shares. At an entry level, AutoTill can monitor the functionality of the machine in combination with a standard tractor, using IsoBus, and warns the driver of any problems with the cultivator. Going one step further, the system can communicate through IsoBus with the tractor and independently react to the problems from the error messages received from the sensors, reducing the driver’s workload.

AutoTill is also ready to operate autonomously with a robot. The cultivator can communicate with the robot through IsoBus, and can monitor the functionality of the cultivator and react independently to any irregularities. The cultivator informs the robot how to resolve any potential problems. Amazone says this feature will reap rewards on long working days at high working speeds particularly with wide working widths, where dust often impairs vision. It says the fact problems can be resolved autonomously, whilst making it possible to use autonomous tractors and mounted machinery in 24-hour shifts in a highly-efficient manner.

Distance measuring system for setting the working depth via the rear roller.

Various different sensors help with monitoring the function of the machine

1. Information of the tractor unit

2. Activity of the overload safety device

3. Setting the working depth

4. Preventing blockages

5. Detection share loss

6. Monitoring the roller speed

Blockage detection integrated in the tine element.

Monitoring the overload safety device for mapping the soil conditions.

Inductive sensor for monitoring the shares.

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: