It is undeniable that today’s agricultural machines are becoming very sophisticated and full of electronic gadgetry. This tech is exposed to harsh working conditions such as vibration, moisture, dust, smoke and heat, which may all contribute to degradation.

Diodes, transistors, capacitors and inductors are not the daily lingo of the typical mechanic nor using a microscope as it’s a completely different discipline, akin to a dentist and an orthopaedist in the medical world.

What terrifies owners is what happens when some important function doesn’t work when you press a button and the machine is out of warranty. You press it a second time but even harder and still nothing happens.

It is undeniable that this is an area of grave concern for potential buyers who are considering investing in this expensive hi-tech farm equipment, as to who will repair it? Will the once impressive machine have any resale value down the road, once it has higher hours logged. As this happens, repair shops dedicated to farm machinery electronics are starting to thrive in Ireland.

One such business is Sherwood’s Tech repair based in Mullingar, Co Westmeath. Steve Sherwood, who owns the business, claims to be self-taught in electronics as he learned by reading electrical engineering books and conducting his own research and experiments.

Steve does admit to growing up in a family who were passionate about computers and all things electronic. As Steve says: “Myself and my brothers spent our childhood taking apart computers and engines.” This early exposure sparked a passion that led to his career today, and he admits to being very fortunate to turn his passion into a job that continues to challenge and inspire him.

Steve’s parents initially ran a computer repair shop in the 1990s, which helped give him a very solid foundation.

“I started my own business then to create my dream job, as there weren’t many openings for my specific skillset.”

He says his friends found it hard to understand how he could run a tech repair shop without selling physical products; instead, relying only on selling his expertise and time.

When queried on how his business is performing these days, he divulges they are busy all year round, and there is no shortage of work. Steve says that he is not very interested in just pure sales, but it’s the challenge of diagnosing and fault finding that really stimulates him. This is why electronic repairs in farm machinery is his true calling.

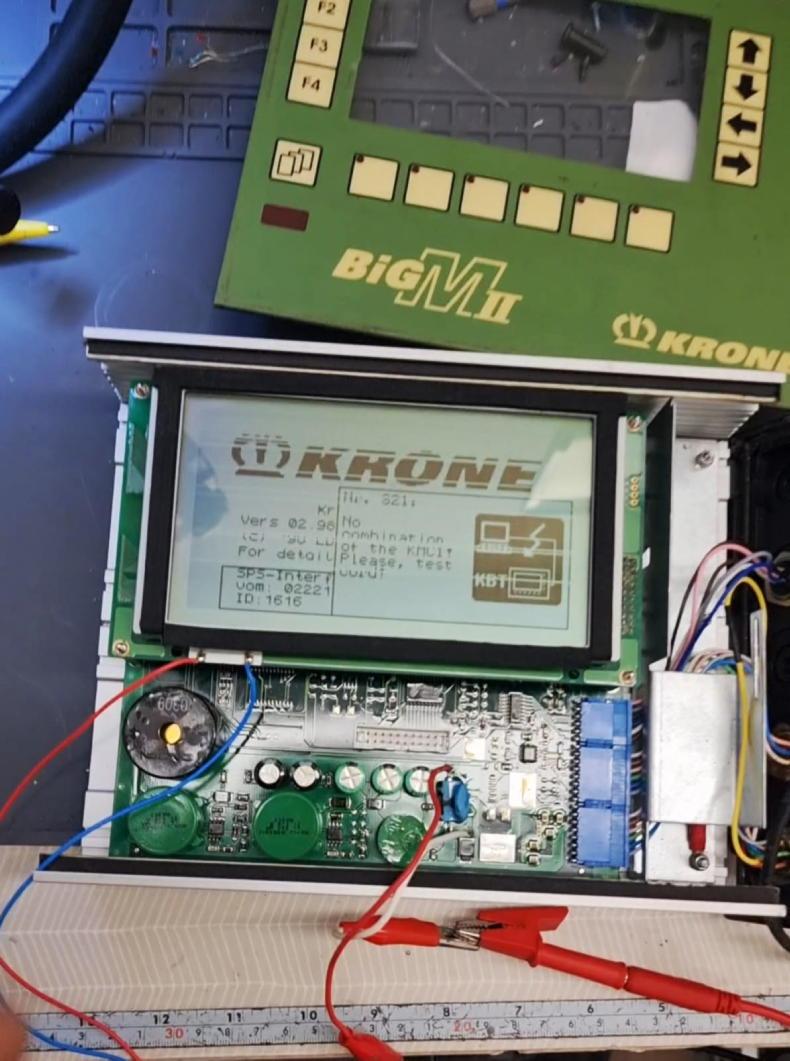

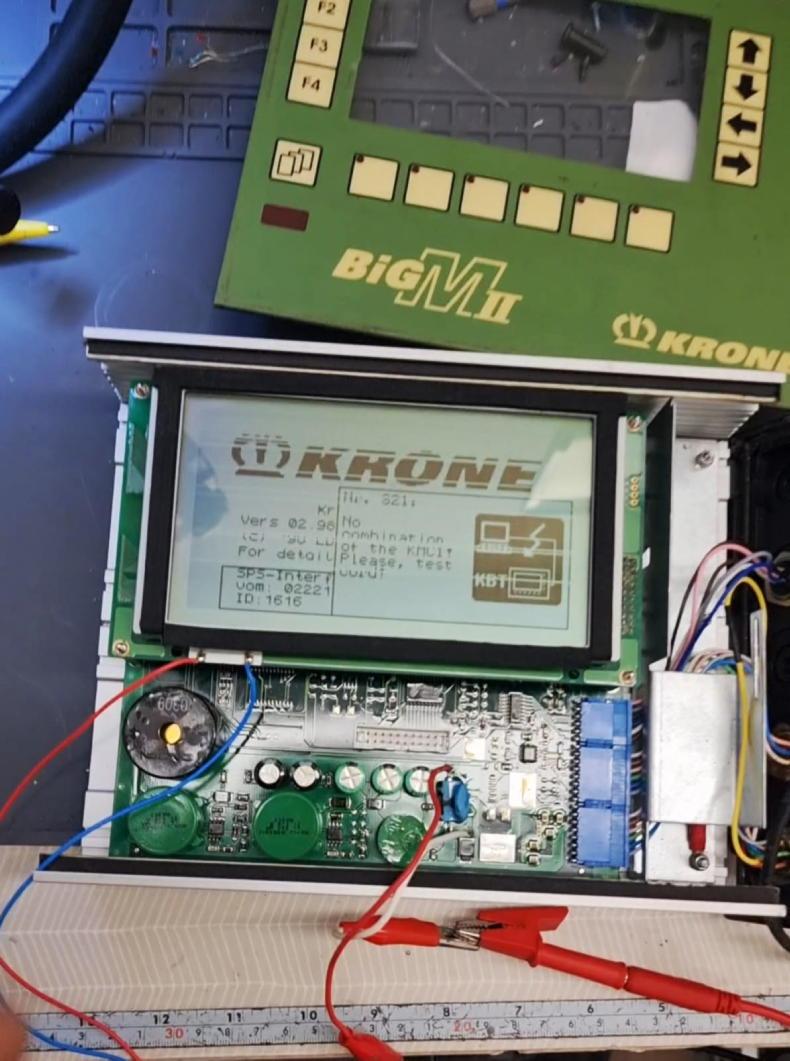

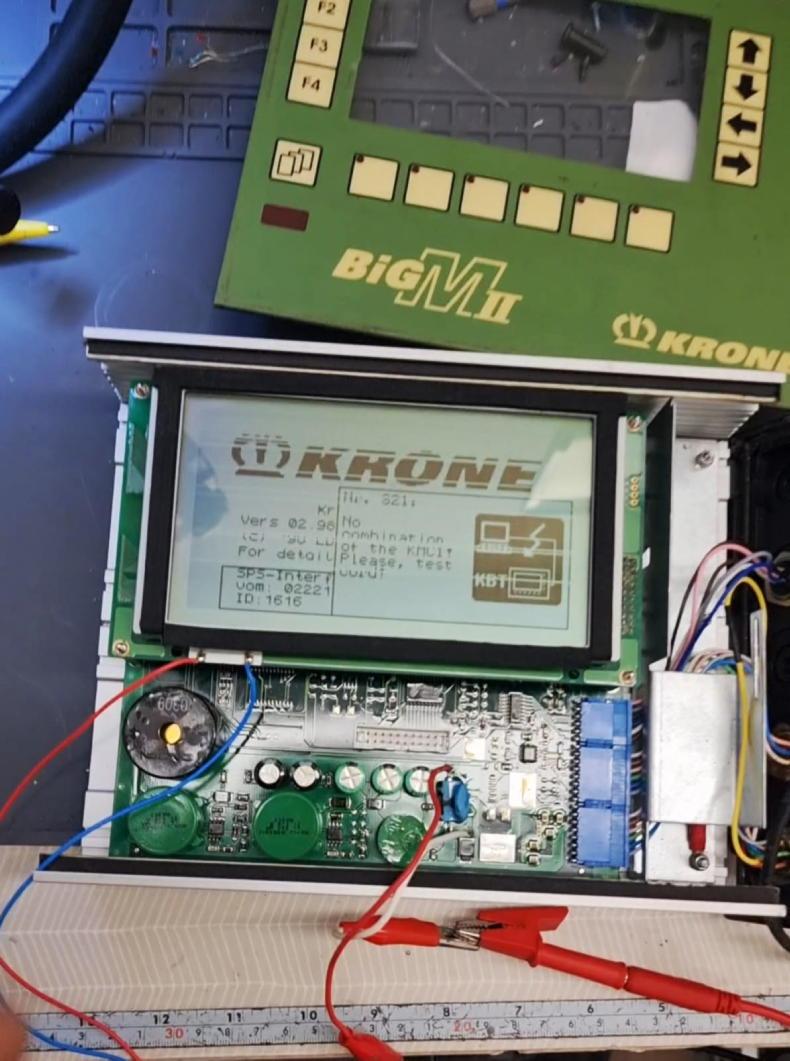

A Krone Big M interface being repaired.

Most common electronic issues

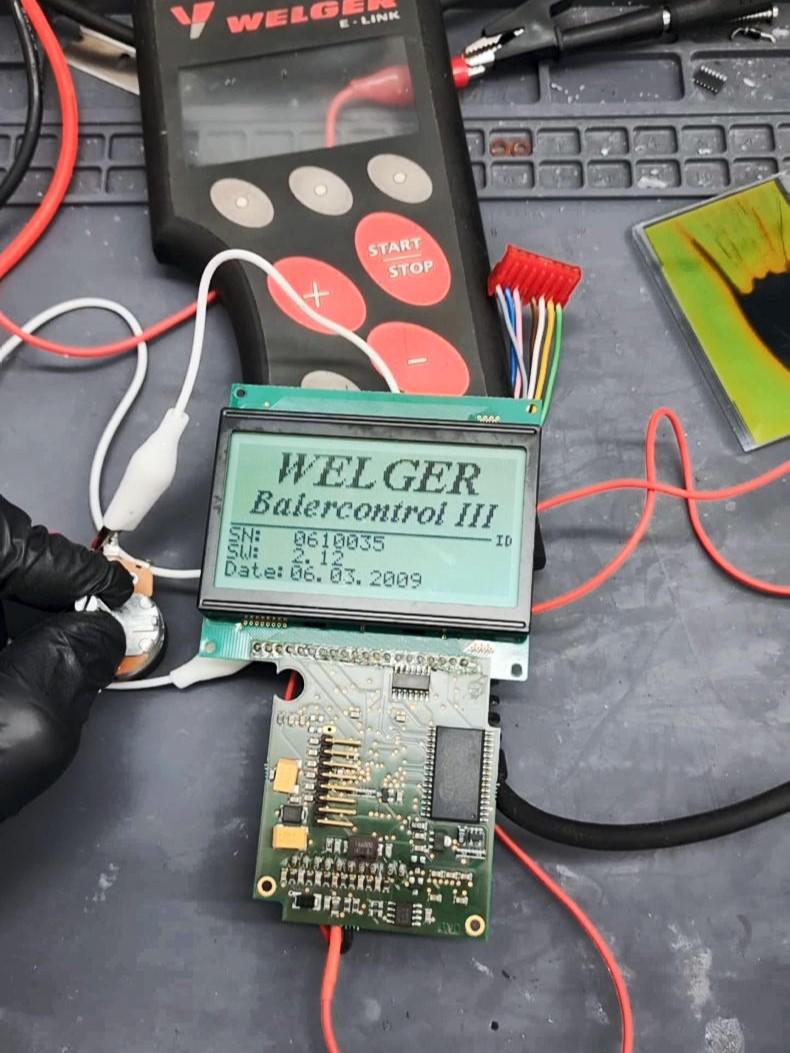

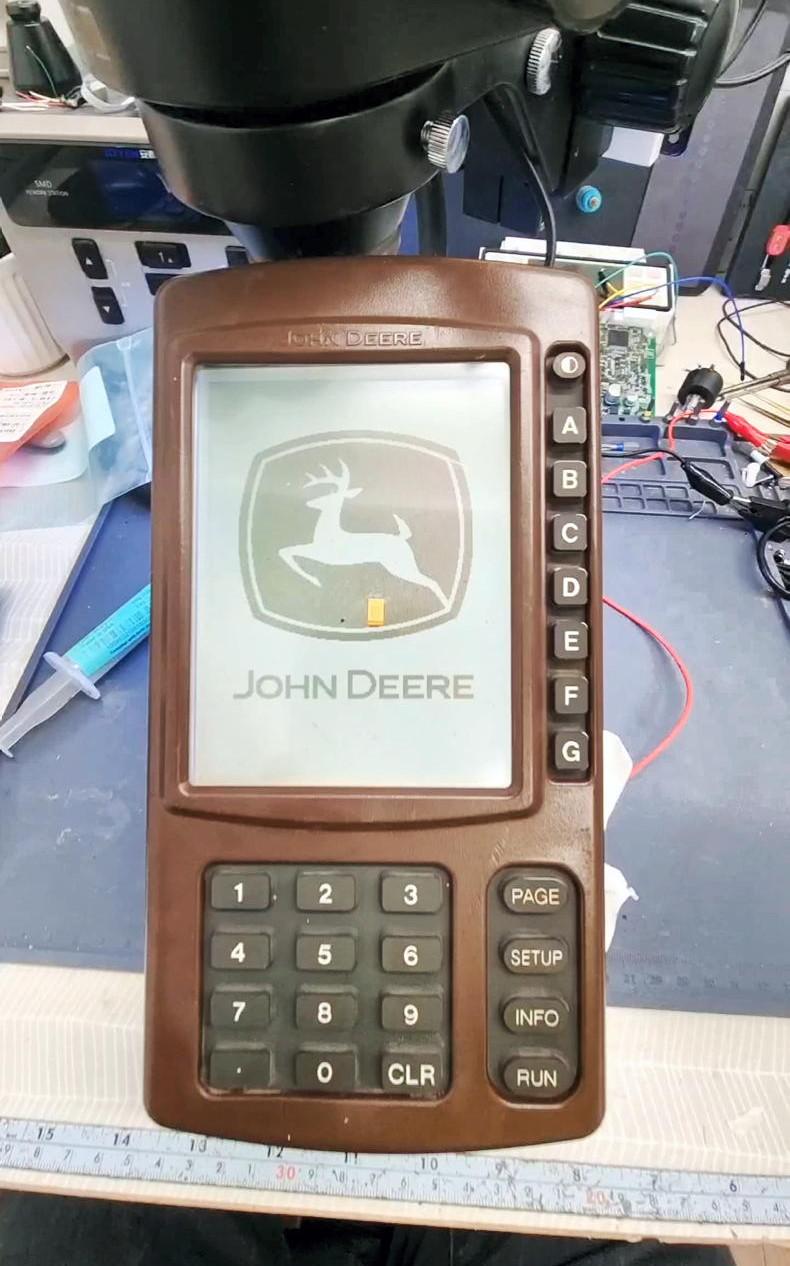

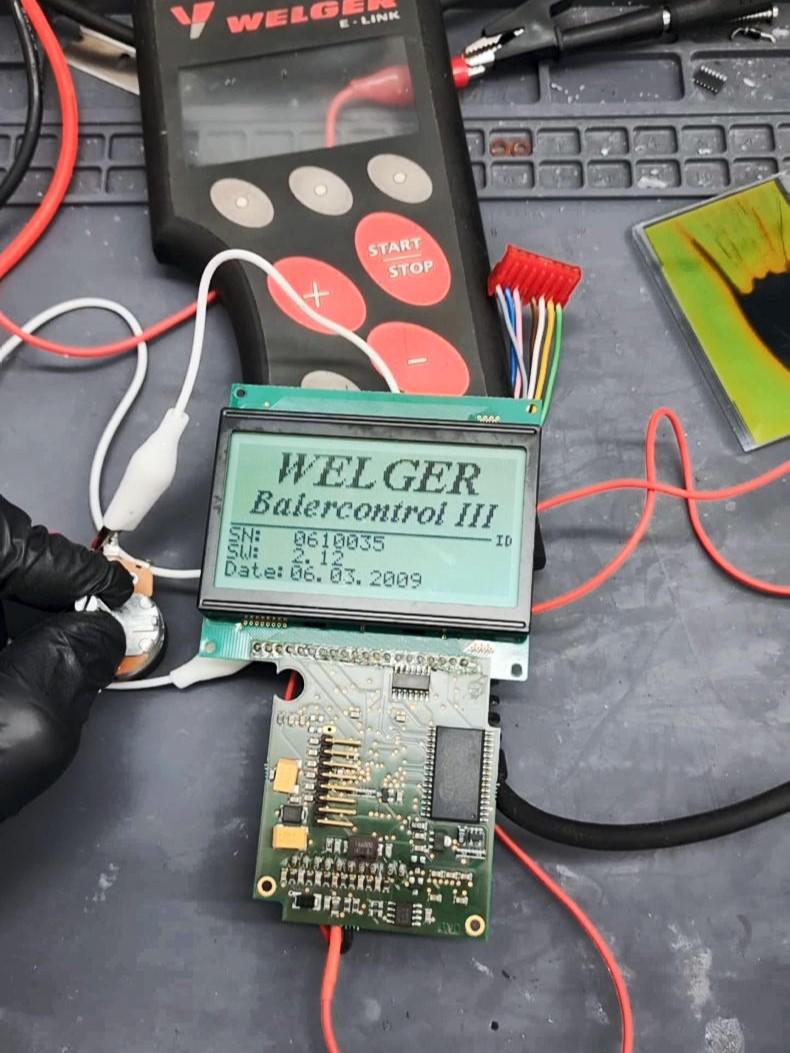

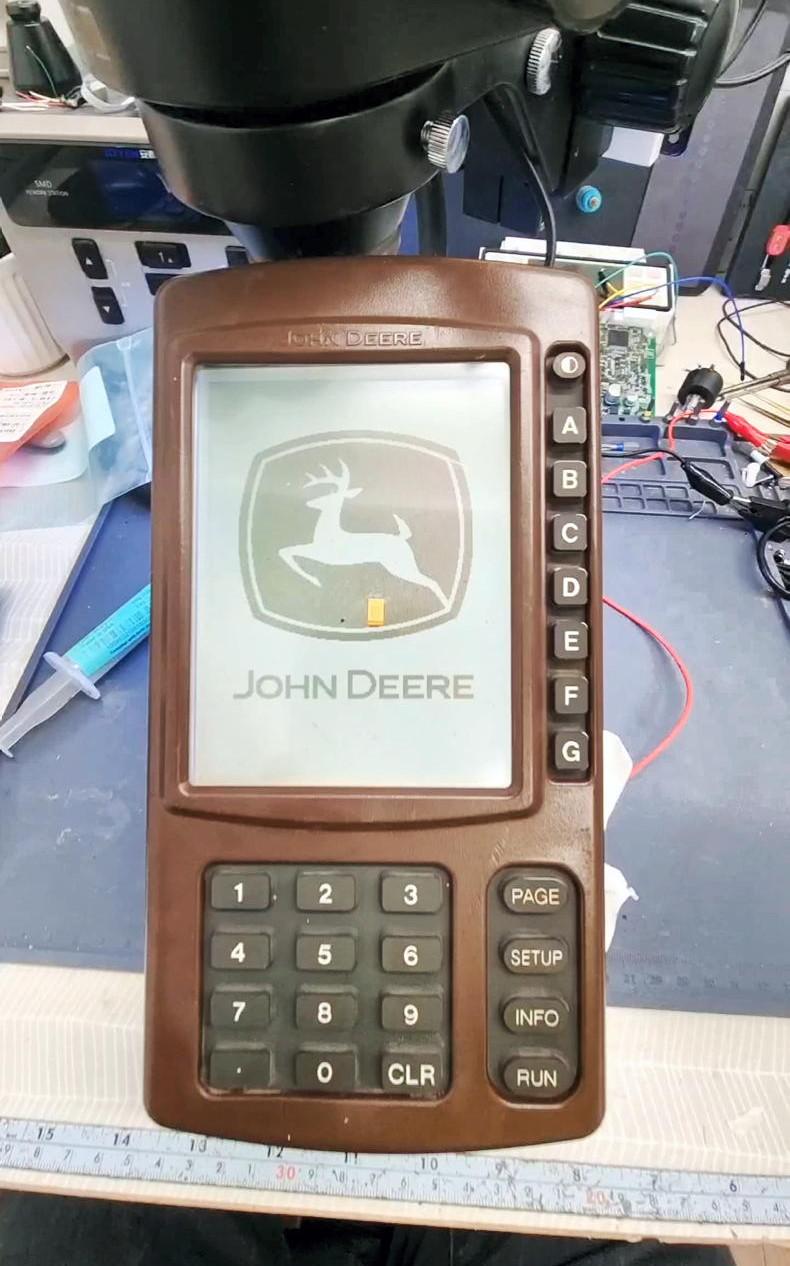

According to Steve, the most common problems he encounters include dead dashboards and joysticks with missing functions or other electronics with moisture/liquid damage. This occurs across many brands such as Fendt, Massey Ferguson, CNH, John Deere, Hyundai, and JCB, to name but a few.

A typical day for him involves staring into a microscope and reading microchip datasheets. “It’s like working on a complex puzzle, but after years of experience, I have a pretty high success rate, even though you don’t always get it right on the first try.”

You have to have great patience and perseverance for this type of work he acknowledges. Steve has developed custom procedures for every device that lands on his bench, using a variety of specialised electronic tools.

He also keeps detailed notes on each device to improve efficiency and accuracy when a similar issue arises.

There are no schematics or manuals available for any of the devices he works on, so he reverse-engineers the circuits himself, starting from the power rails and moving up to how the chips communicate with one another.

“I’ve designed specific bench testing methods to simulate conditions without needing the full wiring harness or loading the circuit. This allows me to test the devices in isolation and be confident in the repair job.”

When queried about the various machinery manufacturers and helping with more and better-quality information to help all dealers and repair shops, he is very clear in saying they could do a lot better.

“Yes, manufacturers could provide much more transparency, offer better access to repair manuals and parts, and not restrict repairs to only authorised centres.” This would greatly benefit farmers and contractors.

This leads to the controversial topic in the US currently around the “right to repair”. Steve highlights how it is a major issue, though many people still haven’t heard about it.

“It revolves around manufacturers restricting repairs by withholding specific parts, electronic components, repair manuals, software, diagnostic tools and schematics.

“They often use tactics like adding passwords on parts, making it necessary for the manufacturer to be involved in every repair or, simply put, just profit.”

Manufacturers claim they are protecting the equipment from interference.

Sourcing parts is often challenging as they often don’t have a part number, as they are a tiny component within a bigger, more elaborate part such as on an LCD screen.

He highlights some components even have their part numbers scratched off, and since there are no available schematics, finding a replacement for a damaged component can be very difficult, according to him.

Steve says he has built up a network of specialist suppliers over the years and from his own experience and personal contacts, he has various avenues to try to locate specific bits and pieces.

This, along with the knowledge he gained over the years, is what he mainly relies on to dig himself out of tricky repair jobs.

Steve claims to be self-taught in electronics as he learned by reading electrical engineering books and conducting his own research and experiments by himself.

Pricing electronic repairs and

improvementsSteve acknowledges that pricing work is tricky.

“I aim to create solutions that are a fair deal for both my customers and the business. I charge roughly €100 per hour, with adjustments based on complexity, part availability, risk and the time it takes to complete the repair.”

When queried about what is causing the issues in agricultural machinery electronics, he notes that there is a variety of reasons but, in his own opinion, “issues often stem from poor circuit design, low-quality components, moisture, dust, or operational stresses like vibration. For instance, the Fendt Vario 10in screen backlight circuit uses an outdated high-voltage design prone to failure. I modify it to a more reliable low-voltage LED backlight, which outlasts the original”.

Maintenance and advice for farmers/contractors In relation to maintenance and what owners could do to help preserve their own equipment, he says.

“Firstly, they should regularly check battery voltage, use good-quality isolator switches, install silica gel sachets to absorb excess moisture in cabs or for winter storage where practical, and inspect and clean connectors along with cleaning out the cab interior.”

These simple steps help to prevent a lot of electronic issues across all machinery brands. Currently, Steve is not repairing engine control units (ECUs), but he is working in the background on an engine simulator so that in 2025 he hopes to be set up to repair them properly.

The simulator will allow him to test the functionality of the controllers in-house as it’s very difficult to be sure of a guaranteed repair without the host tractor in situ, along with the wiring harness, the software and network of other controllers, to be fully confident that all issues are completely rectified before posting it back out to the customer. Watch this space, he says.

Earlier teaching in schools

Steve is very passionate about his business and electronics but makes a very good point about education, in general. Everything today is “smart” he says from phones, to watches, internet banking and the software to run all these apps across every sector and industry.

He is adamant this isn’t going to go away but, if anything, only increase not only in agriculture but in life in general.

“Yes, basic electronics should definitely be introduced earlier in secondary school. It’s becoming an integral part of everyday life now, and early exposure could help students develop skills that are highly valuable in the modern world.”

Steve says every day really is a school day for him and he is continuously learning from various sources, including books, online forums, and experimenting on his own.

“Upskilling is an ongoing process for everyone, as electronics evolve rapidly.”

Power of social media and inspiring the next generationSteve has been publishing videos of his work for the last two years across different platforms on the web and today has great engagement from all over Ireland, as well as overseas.

According to Steve, “I showcase what types of repairs are possible now with microscopic tools and explain exactly what is going on under the hood of these electronics and try my best to break these complex structures down to layman’s terms.

“I share all of this information because I really want to inspire the next generation to get involved and get curious about electronics. I don’t own these ideas as they are an accumulation of many great ideas from great men and women over the last century.”

For those mechanics and handy men interested in electronics, he recommends starting with DIY projects and learning the basics.

“It’s important to cultivate curiosity and not be afraid to experiment or make mistakes, as these are key to learning. I still make many mistakes today and the day I stop making them is the day I stop learning.”

He also highlights that understanding CAN bus systems (the machines internal computer network) is crucial for modern vehicles and recommends that mechanics familiarise themselves more with how CAN bus networks communicate and how to use diagnostic tools and to isolate faults.

Oscilloscopes are a tool that are a necessity nowadays to capture signals and should be invested in by garages, he feels.

The best way to contact Steve is through his website or just simply Google “Sherwood tech repairs”.

Potential customers needing repair work done can conveniently use the postal service to send their components to his premises.

According to Steve, postal reliability has significantly improved in recent years.

However, delicate electronic parts should be carefully packaged up properly with plenty of padding to protect the components from getting damaged in transit.

He says that, to date, he has had no goods damaged in shipment out from his workshop, but he takes great care with labelling and packaging when reposting.

Confidence

Services like those provided by Sherwood’s tech repair help instil confidence in dealers and potential customers by demonstrating that even after a decade or so of field use, equipment can retain its value as electronics may now be expertly refurbished and thus deliver continued value in the agricultural sector.

Electronic repairs are possible.Fendt Vario 10in screen backlight circuit improvements.Reverse engineers the circuits.Vibration, moisture, dust, smoke and heat all contribute.Right to repair – no information.Diodes, transistors, capacitors are a different discipline.Good maintenance helps prolong machine electronics.

Steve has built up a network of specialist suppliers over the years and from his own experience and personal contacts he has various avenues to try locating specific bits and pieces.

It is undeniable that today’s agricultural machines are becoming very sophisticated and full of electronic gadgetry. This tech is exposed to harsh working conditions such as vibration, moisture, dust, smoke and heat, which may all contribute to degradation.

Diodes, transistors, capacitors and inductors are not the daily lingo of the typical mechanic nor using a microscope as it’s a completely different discipline, akin to a dentist and an orthopaedist in the medical world.

What terrifies owners is what happens when some important function doesn’t work when you press a button and the machine is out of warranty. You press it a second time but even harder and still nothing happens.

It is undeniable that this is an area of grave concern for potential buyers who are considering investing in this expensive hi-tech farm equipment, as to who will repair it? Will the once impressive machine have any resale value down the road, once it has higher hours logged. As this happens, repair shops dedicated to farm machinery electronics are starting to thrive in Ireland.

One such business is Sherwood’s Tech repair based in Mullingar, Co Westmeath. Steve Sherwood, who owns the business, claims to be self-taught in electronics as he learned by reading electrical engineering books and conducting his own research and experiments.

Steve does admit to growing up in a family who were passionate about computers and all things electronic. As Steve says: “Myself and my brothers spent our childhood taking apart computers and engines.” This early exposure sparked a passion that led to his career today, and he admits to being very fortunate to turn his passion into a job that continues to challenge and inspire him.

Steve’s parents initially ran a computer repair shop in the 1990s, which helped give him a very solid foundation.

“I started my own business then to create my dream job, as there weren’t many openings for my specific skillset.”

He says his friends found it hard to understand how he could run a tech repair shop without selling physical products; instead, relying only on selling his expertise and time.

When queried on how his business is performing these days, he divulges they are busy all year round, and there is no shortage of work. Steve says that he is not very interested in just pure sales, but it’s the challenge of diagnosing and fault finding that really stimulates him. This is why electronic repairs in farm machinery is his true calling.

A Krone Big M interface being repaired.

Most common electronic issues

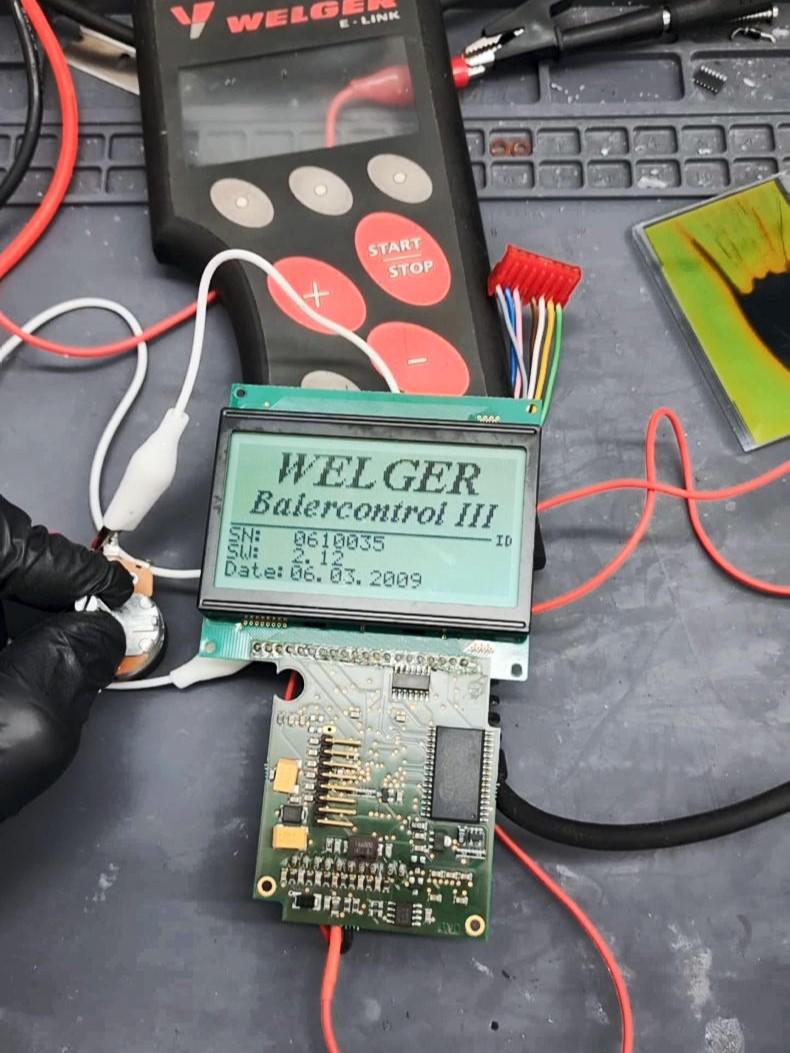

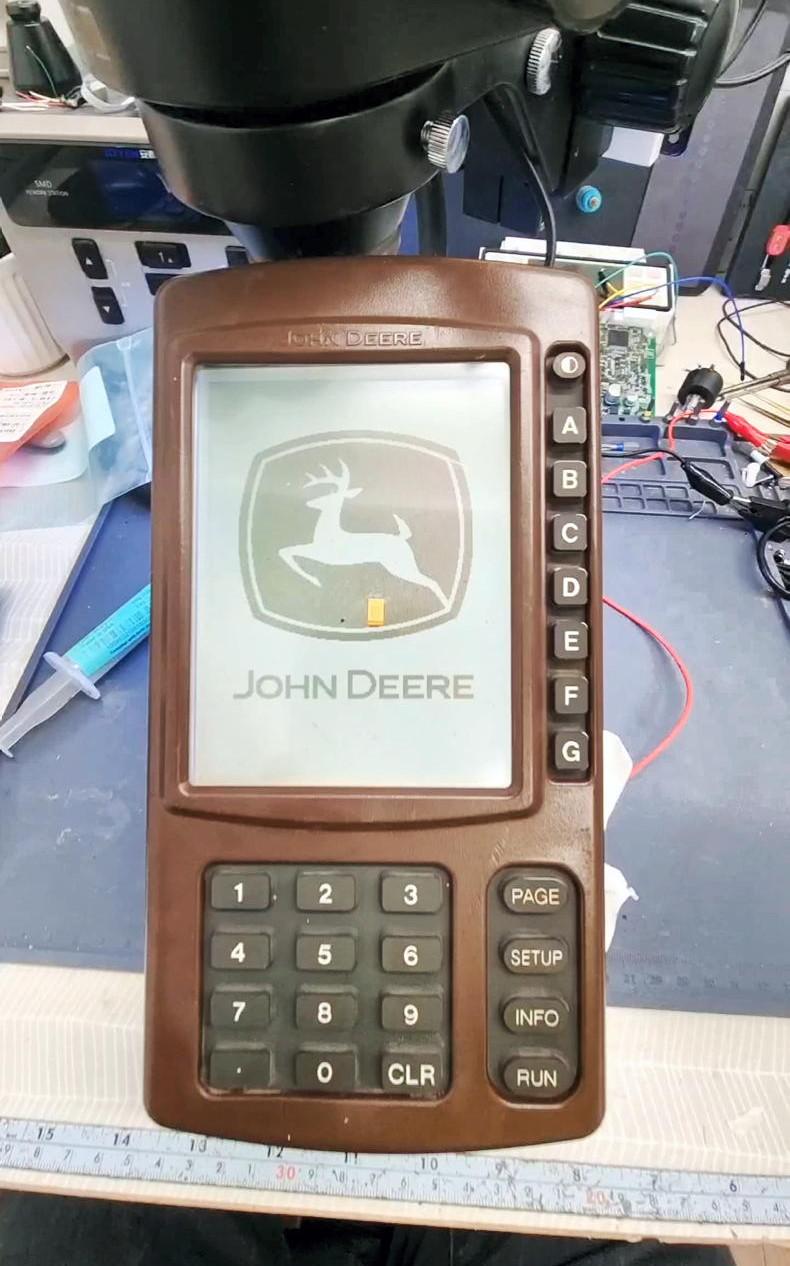

According to Steve, the most common problems he encounters include dead dashboards and joysticks with missing functions or other electronics with moisture/liquid damage. This occurs across many brands such as Fendt, Massey Ferguson, CNH, John Deere, Hyundai, and JCB, to name but a few.

A typical day for him involves staring into a microscope and reading microchip datasheets. “It’s like working on a complex puzzle, but after years of experience, I have a pretty high success rate, even though you don’t always get it right on the first try.”

You have to have great patience and perseverance for this type of work he acknowledges. Steve has developed custom procedures for every device that lands on his bench, using a variety of specialised electronic tools.

He also keeps detailed notes on each device to improve efficiency and accuracy when a similar issue arises.

There are no schematics or manuals available for any of the devices he works on, so he reverse-engineers the circuits himself, starting from the power rails and moving up to how the chips communicate with one another.

“I’ve designed specific bench testing methods to simulate conditions without needing the full wiring harness or loading the circuit. This allows me to test the devices in isolation and be confident in the repair job.”

When queried about the various machinery manufacturers and helping with more and better-quality information to help all dealers and repair shops, he is very clear in saying they could do a lot better.

“Yes, manufacturers could provide much more transparency, offer better access to repair manuals and parts, and not restrict repairs to only authorised centres.” This would greatly benefit farmers and contractors.

This leads to the controversial topic in the US currently around the “right to repair”. Steve highlights how it is a major issue, though many people still haven’t heard about it.

“It revolves around manufacturers restricting repairs by withholding specific parts, electronic components, repair manuals, software, diagnostic tools and schematics.

“They often use tactics like adding passwords on parts, making it necessary for the manufacturer to be involved in every repair or, simply put, just profit.”

Manufacturers claim they are protecting the equipment from interference.

Sourcing parts is often challenging as they often don’t have a part number, as they are a tiny component within a bigger, more elaborate part such as on an LCD screen.

He highlights some components even have their part numbers scratched off, and since there are no available schematics, finding a replacement for a damaged component can be very difficult, according to him.

Steve says he has built up a network of specialist suppliers over the years and from his own experience and personal contacts, he has various avenues to try to locate specific bits and pieces.

This, along with the knowledge he gained over the years, is what he mainly relies on to dig himself out of tricky repair jobs.

Steve claims to be self-taught in electronics as he learned by reading electrical engineering books and conducting his own research and experiments by himself.

Pricing electronic repairs and

improvementsSteve acknowledges that pricing work is tricky.

“I aim to create solutions that are a fair deal for both my customers and the business. I charge roughly €100 per hour, with adjustments based on complexity, part availability, risk and the time it takes to complete the repair.”

When queried about what is causing the issues in agricultural machinery electronics, he notes that there is a variety of reasons but, in his own opinion, “issues often stem from poor circuit design, low-quality components, moisture, dust, or operational stresses like vibration. For instance, the Fendt Vario 10in screen backlight circuit uses an outdated high-voltage design prone to failure. I modify it to a more reliable low-voltage LED backlight, which outlasts the original”.

Maintenance and advice for farmers/contractors

In relation to maintenance and what owners could do to help preserve their own equipment, he says.

“Firstly, they should regularly check battery voltage, use good-quality isolator switches, install silica gel sachets to absorb excess moisture in cabs or for winter storage where practical, and inspect and clean connectors along with cleaning out the cab interior.”

These simple steps help to prevent a lot of electronic issues across all machinery brands. Currently, Steve is not repairing engine control units (ECUs), but he is working in the background on an engine simulator so that in 2025 he hopes to be set up to repair them properly.

The simulator will allow him to test the functionality of the controllers in-house as it’s very difficult to be sure of a guaranteed repair without the host tractor in situ, along with the wiring harness, the software and network of other controllers, to be fully confident that all issues are completely rectified before posting it back out to the customer. Watch this space, he says.

Earlier teaching in schools

Steve is very passionate about his business and electronics but makes a very good point about education, in general. Everything today is “smart” he says from phones, to watches, internet banking and the software to run all these apps across every sector and industry.

He is adamant this isn’t going to go away but, if anything, only increase not only in agriculture but in life in general.

“Yes, basic electronics should definitely be introduced earlier in secondary school. It’s becoming an integral part of everyday life now, and early exposure could help students develop skills that are highly valuable in the modern world.”

Steve says every day really is a school day for him and he is continuously learning from various sources, including books, online forums, and experimenting on his own.

“Upskilling is an ongoing process for everyone, as electronics evolve rapidly.”

Power of social media and inspiring the next generationSteve has been publishing videos of his work for the last two years across different platforms on the web and today has great engagement from all over Ireland, as well as overseas.

According to Steve, “I showcase what types of repairs are possible now with microscopic tools and explain exactly what is going on under the hood of these electronics and try my best to break these complex structures down to layman’s terms.

“I share all of this information because I really want to inspire the next generation to get involved and get curious about electronics. I don’t own these ideas as they are an accumulation of many great ideas from great men and women over the last century.”

For those mechanics and handy men interested in electronics, he recommends starting with DIY projects and learning the basics.

“It’s important to cultivate curiosity and not be afraid to experiment or make mistakes, as these are key to learning. I still make many mistakes today and the day I stop making them is the day I stop learning.”

He also highlights that understanding CAN bus systems (the machines internal computer network) is crucial for modern vehicles and recommends that mechanics familiarise themselves more with how CAN bus networks communicate and how to use diagnostic tools and to isolate faults.

Oscilloscopes are a tool that are a necessity nowadays to capture signals and should be invested in by garages, he feels.

The best way to contact Steve is through his website or just simply Google “Sherwood tech repairs”.

Potential customers needing repair work done can conveniently use the postal service to send their components to his premises.

According to Steve, postal reliability has significantly improved in recent years.

However, delicate electronic parts should be carefully packaged up properly with plenty of padding to protect the components from getting damaged in transit.

He says that, to date, he has had no goods damaged in shipment out from his workshop, but he takes great care with labelling and packaging when reposting.

Confidence

Services like those provided by Sherwood’s tech repair help instil confidence in dealers and potential customers by demonstrating that even after a decade or so of field use, equipment can retain its value as electronics may now be expertly refurbished and thus deliver continued value in the agricultural sector.

Electronic repairs are possible.Fendt Vario 10in screen backlight circuit improvements.Reverse engineers the circuits.Vibration, moisture, dust, smoke and heat all contribute.Right to repair – no information.Diodes, transistors, capacitors are a different discipline.Good maintenance helps prolong machine electronics.

Steve has built up a network of specialist suppliers over the years and from his own experience and personal contacts he has various avenues to try locating specific bits and pieces.

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: