Modern tractor-type fertiliser spreaders are now very high-tech farm implements, with manufacturers making claims of precision accuracy that would impress a neurosurgeon.

Everyone within the farming community knows that fertiliser is too expensive to be wasted, as well as the knock-on environmental implications. Whether it’s getting early applications out in the spring, or the convenience of spreading small quantities, ATV/UTV ground drive spreaders have become increasingly popular.

While these are simple machines that get the job done, we must remember that the latest tractor-mounted and trailed machines feature a whole host of on-board technology to aid precision for a reason.

These days quads and side-by-sides are a more familiar sight due to naturally tougher ground conditions

Proper consideration needs to be given when purchasing a ground-driven spreader, or setting up your current quad spreader to get a good, even spread pattern.

These days quads and side-by-sides are a more familiar sight due to naturally tougher ground conditions, so farmers can achieve early grass. They are seen as an essential tool on some farms for early cow turnout or silage, and help prevent rutting and compaction of tractor spreader combinations.

Hill farmers want them due to the natural terrain they have for grazing, and tillage farmers are using them more for top dressing winter crops. Regardless of method, ground conditions must be considered ahead of spreading.

Variable application rate

Variable application rate (VAR) is a feature within the whole precision agriculture sphere, which is in hot demand, with TAMS funding for the PTO or hydraulic driven tractor-based machines. A different kind of variable application rate with potentially negative consequences, however, can be achieved with ground-driven machines.

This may result in striping, leaching or waste if operators are not in tune with all the variables and correct machine set up.

Maintaining forward speed and the correct bout width is critical for an accurate application.

Fertiliser itself varies greatly in type as well as make up, but also from batch to batch, manufacturer to manufacturer, in characteristics such as weight, density, hardness and particle size. It must be properly examined and tested in order to achieve good distribution, full stop.

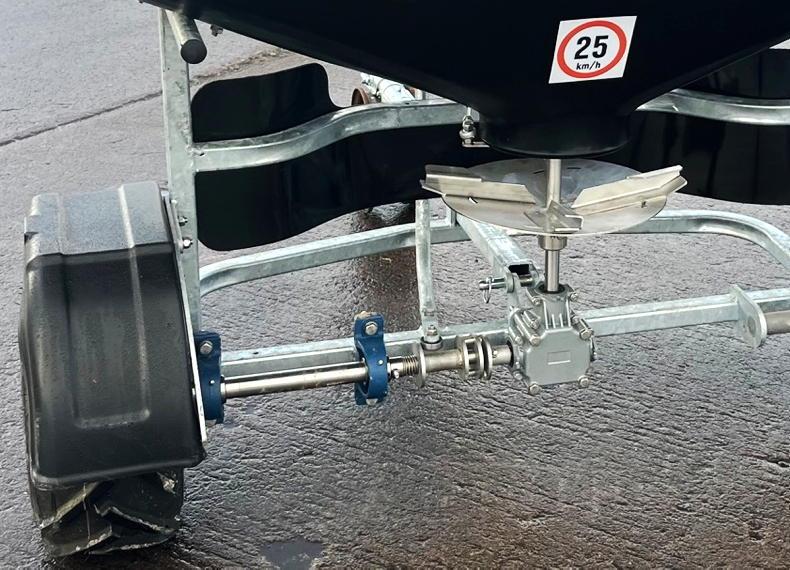

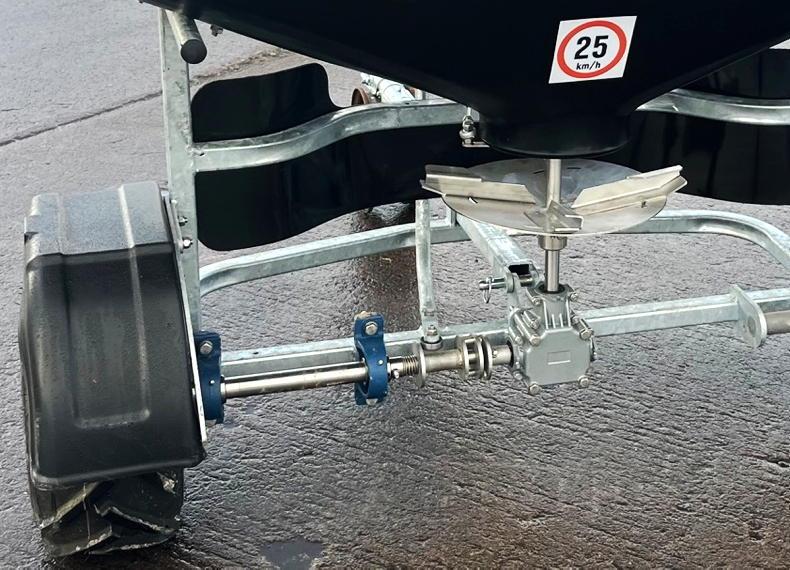

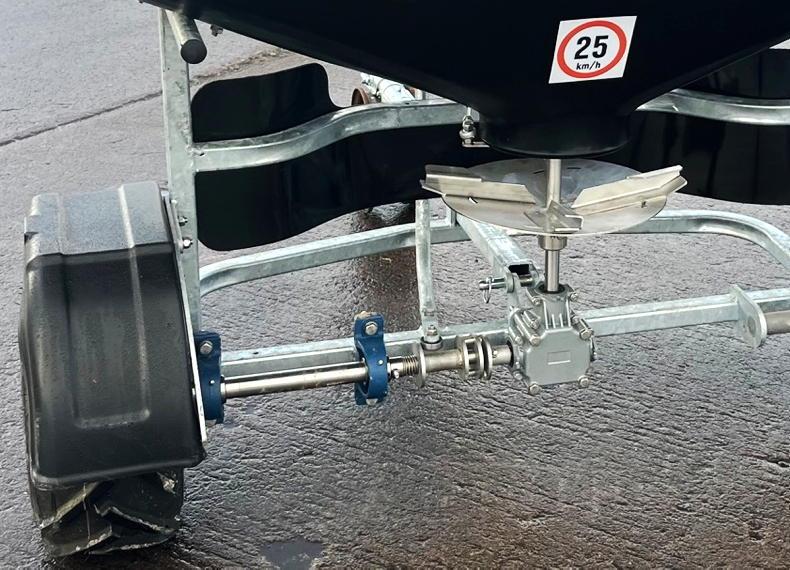

Other major factors that operators may not be attuned to which also affect application rates and bout spreading widths include: forward speed, gearbox ratios, disc size, height, angle, RPMs, tyre size, vane pitch and shutter opening, especially when using ground driven-spreaders.

Spreading fertiliser with a ground-driven spreader is a totally different set-up for accuracy, and non-experienced operators especially need to be diligent when using these machines.

Operators may struggle to get consistent forward speed with quads, due to many factors, such as the thumb throttle set up of a quad. The operator’s thumb can easily get numb after a period of time due to stiffness, and the terrain itself may knock the operator around on uneven ground, resulting in inconsistences or variation in the disc speed.

This alters bout width and hence desired application rate, as the input drive of these machines is different to the fixed drive speed of a PTO-type spreader. Roll, pitch, bounce – this is terminology more familiar to auto mechanics working on car suspensions, but quad spreader operators need to be mindful of the effects this is having on their towed spreader as well.

Quads in Ireland are mainly of the petrol engine variety, and they don’t have the torque back up of a diesel engine like a tractor has.

The humps and hollows across fields or towing uphill and downhill in hilly terrain mean quad bikes can struggle more to get up to the desired forward speed, especially when the spreader is fully loaded, even on bigger cubic capacity ATVs. This also means pulsation of disc speed and changes in working width.

When the spreader is near empty, the ATV will be more responsive, leading to more bouncing of the towed machine and thus further disc height alterations, angles and speeds.

Static calibration

With conventional fertiliser spreaders, good practice after testing the fertiliser itself is to do a static calibration in the yard by following the manufacturer’s instructions and calibration chart (or app on smart phones) and fine tune this further in the field, if needed.

However, this is not possible with a ground-driven spreader. Good practice is to know your machine’s characteristics and find the desired forward speed, and shutter opening for the fertiliser type. Don’t be afraid to contact your dealer or manufacturer.

The trailed spreader with a left hand input drive will speed up the disc if the operator is turning sharply to the right and slow it down turning left so this needs to be compensated by the correct overlap procedure.

Slow speeds mean you may not achieve a correct bout width, high speeds mean you may grind your fertiliser into dust, and you won’t achieve the desired working width either.

This dust, especially if the fertiliser type being applied may be prone to absorbing moisture due to long storage periods, may build up and start to clog up the hopper opening and hence further reduce fertiliser distribution.

The design of the bigger trailed quad machines, which facilitate in excess of 500kg loads, may have a more tapered front headboard to help weight distribution to the quad hitch to benefit traction and field performance, but this may also have a potential undesired side effect.

It’s difficult for operators to see into the spreader hopper during field use due to the seat height of a quad, and operators may get fooled by judging the fertiliser height by a shadow line of the fertiliser coming through the plastic hopper.

Some fertilisers can lodge here towards the front due to this gradient. The back of the spreader can be near empty and application rates reducing, unknown to the operator.

Some farmers use talcum powder to help prevent this issue, but it’s wise to get out and check regularly once you are in tune with your own machine’s characteristics. The bottom line is you need to do in-field tray testing, as it’s the only way of knowing for sure if the spread pattern, bout width, as well as N, P, K element distribution is balanced and the application rate is being achieved

Headland spreading

Headland management is also different with these machines and ideally the spreader should be shut off, as depending on drive shaft location and direction the operator is turning, the speed of the disc may momentarily speed up or slow down, altering both bout width and application in this part of the field.

The trailed spreader with a left hand input drive will speed up the disc if the operator is turning sharply to the right and slow it down turning left. Single-drop opening machines have a different spread pattern to dual-drop (hopper openings) and the coefficient of variation needs to be compensated by the correct overlapping procedure to suit.

For first-time users, it’s advisable to purchase a few 50kg bags and mark out a known area, like an acre/hectare, or known field size and start with manufacturer’s recommended forward speed and narrow shutter openings, then adjust accordingly.

Spreading fields up/down and left/right may take more time, but results in better distribution. Always be diligent on steep slopes and turning suddenly.

Fergal O’Sullivan, is an agricultural engineering lecturer at Munster Technological University.

Think quad safety, especially around the weights being towed.Test fertiliser.Get manufacturer’s recommended forward speed.In-field trays to monitor accuracy.Extended mudflaps on quad, mudguards, hopper cover, prevent splashing.Ease of shut off, ease of drive disc engagement.Variable vane adjustment.Good disc height, disc height also effects spread width.Dual fertiliser drop point, ideally in machine hopper.Spread light, double over up/down and left/right.Travelling too fast mills the granules to dust.

Modern tractor-type fertiliser spreaders are now very high-tech farm implements, with manufacturers making claims of precision accuracy that would impress a neurosurgeon.

Everyone within the farming community knows that fertiliser is too expensive to be wasted, as well as the knock-on environmental implications. Whether it’s getting early applications out in the spring, or the convenience of spreading small quantities, ATV/UTV ground drive spreaders have become increasingly popular.

While these are simple machines that get the job done, we must remember that the latest tractor-mounted and trailed machines feature a whole host of on-board technology to aid precision for a reason.

These days quads and side-by-sides are a more familiar sight due to naturally tougher ground conditions

Proper consideration needs to be given when purchasing a ground-driven spreader, or setting up your current quad spreader to get a good, even spread pattern.

These days quads and side-by-sides are a more familiar sight due to naturally tougher ground conditions, so farmers can achieve early grass. They are seen as an essential tool on some farms for early cow turnout or silage, and help prevent rutting and compaction of tractor spreader combinations.

Hill farmers want them due to the natural terrain they have for grazing, and tillage farmers are using them more for top dressing winter crops. Regardless of method, ground conditions must be considered ahead of spreading.

Variable application rate

Variable application rate (VAR) is a feature within the whole precision agriculture sphere, which is in hot demand, with TAMS funding for the PTO or hydraulic driven tractor-based machines. A different kind of variable application rate with potentially negative consequences, however, can be achieved with ground-driven machines.

This may result in striping, leaching or waste if operators are not in tune with all the variables and correct machine set up.

Maintaining forward speed and the correct bout width is critical for an accurate application.

Fertiliser itself varies greatly in type as well as make up, but also from batch to batch, manufacturer to manufacturer, in characteristics such as weight, density, hardness and particle size. It must be properly examined and tested in order to achieve good distribution, full stop.

Other major factors that operators may not be attuned to which also affect application rates and bout spreading widths include: forward speed, gearbox ratios, disc size, height, angle, RPMs, tyre size, vane pitch and shutter opening, especially when using ground driven-spreaders.

Spreading fertiliser with a ground-driven spreader is a totally different set-up for accuracy, and non-experienced operators especially need to be diligent when using these machines.

Operators may struggle to get consistent forward speed with quads, due to many factors, such as the thumb throttle set up of a quad. The operator’s thumb can easily get numb after a period of time due to stiffness, and the terrain itself may knock the operator around on uneven ground, resulting in inconsistences or variation in the disc speed.

This alters bout width and hence desired application rate, as the input drive of these machines is different to the fixed drive speed of a PTO-type spreader. Roll, pitch, bounce – this is terminology more familiar to auto mechanics working on car suspensions, but quad spreader operators need to be mindful of the effects this is having on their towed spreader as well.

Quads in Ireland are mainly of the petrol engine variety, and they don’t have the torque back up of a diesel engine like a tractor has.

The humps and hollows across fields or towing uphill and downhill in hilly terrain mean quad bikes can struggle more to get up to the desired forward speed, especially when the spreader is fully loaded, even on bigger cubic capacity ATVs. This also means pulsation of disc speed and changes in working width.

When the spreader is near empty, the ATV will be more responsive, leading to more bouncing of the towed machine and thus further disc height alterations, angles and speeds.

Static calibration

With conventional fertiliser spreaders, good practice after testing the fertiliser itself is to do a static calibration in the yard by following the manufacturer’s instructions and calibration chart (or app on smart phones) and fine tune this further in the field, if needed.

However, this is not possible with a ground-driven spreader. Good practice is to know your machine’s characteristics and find the desired forward speed, and shutter opening for the fertiliser type. Don’t be afraid to contact your dealer or manufacturer.

The trailed spreader with a left hand input drive will speed up the disc if the operator is turning sharply to the right and slow it down turning left so this needs to be compensated by the correct overlap procedure.

Slow speeds mean you may not achieve a correct bout width, high speeds mean you may grind your fertiliser into dust, and you won’t achieve the desired working width either.

This dust, especially if the fertiliser type being applied may be prone to absorbing moisture due to long storage periods, may build up and start to clog up the hopper opening and hence further reduce fertiliser distribution.

The design of the bigger trailed quad machines, which facilitate in excess of 500kg loads, may have a more tapered front headboard to help weight distribution to the quad hitch to benefit traction and field performance, but this may also have a potential undesired side effect.

It’s difficult for operators to see into the spreader hopper during field use due to the seat height of a quad, and operators may get fooled by judging the fertiliser height by a shadow line of the fertiliser coming through the plastic hopper.

Some fertilisers can lodge here towards the front due to this gradient. The back of the spreader can be near empty and application rates reducing, unknown to the operator.

Some farmers use talcum powder to help prevent this issue, but it’s wise to get out and check regularly once you are in tune with your own machine’s characteristics. The bottom line is you need to do in-field tray testing, as it’s the only way of knowing for sure if the spread pattern, bout width, as well as N, P, K element distribution is balanced and the application rate is being achieved

Headland spreading

Headland management is also different with these machines and ideally the spreader should be shut off, as depending on drive shaft location and direction the operator is turning, the speed of the disc may momentarily speed up or slow down, altering both bout width and application in this part of the field.

The trailed spreader with a left hand input drive will speed up the disc if the operator is turning sharply to the right and slow it down turning left. Single-drop opening machines have a different spread pattern to dual-drop (hopper openings) and the coefficient of variation needs to be compensated by the correct overlapping procedure to suit.

For first-time users, it’s advisable to purchase a few 50kg bags and mark out a known area, like an acre/hectare, or known field size and start with manufacturer’s recommended forward speed and narrow shutter openings, then adjust accordingly.

Spreading fields up/down and left/right may take more time, but results in better distribution. Always be diligent on steep slopes and turning suddenly.

Fergal O’Sullivan, is an agricultural engineering lecturer at Munster Technological University.

Think quad safety, especially around the weights being towed.Test fertiliser.Get manufacturer’s recommended forward speed.In-field trays to monitor accuracy.Extended mudflaps on quad, mudguards, hopper cover, prevent splashing.Ease of shut off, ease of drive disc engagement.Variable vane adjustment.Good disc height, disc height also effects spread width.Dual fertiliser drop point, ideally in machine hopper.Spread light, double over up/down and left/right.Travelling too fast mills the granules to dust.

SHARING OPTIONS