On 20 May 2018, legislation was introduced requiring fast tractors to undergo a roadworthiness test, similar to an NCT.

These tractors are now required to display a certificate of roadworthiness (CRW). This detachable disc must be displayed on the vehicle’s windscreen.

What is a “fast tractor”?

According to the Road Safety Authority (RSA), a fast tractor is defined as a wheeled tractor in category T, with a maximum design speed exceeding 40 km/h.

The requirement of a fast tractor to be tested is based on its use. Any fast tractor which is used for a non-exempted activity (that is non-agricultural work) requires a CRW.

Such examples of tractors required to be tested include: those involved in local authority work, the construction industry, the quarrying industry, the manufacturing industry, the mining industry or road construction/roadworks.

The RSA also noted that a fast tractor will not have to be tested if it is being used for the purposes of agricultural, horticultural, forestry, farming or fishery activity solely within the State and mainly on the land where such activity takes place, including agricultural roads, forestry roads or agricultural fields.

The test

The tractor test mirrors the test currently carried out on heavy commercial vehicles (HCVs), but it has been modified where necessary to suit tractors.

Since the legislation came into place, a total of 70 tractors have been tested at independent test centres.

Tractors that are eligible should be tested after they have reached their fourth birthday and every second year after that

The first test took place on 4 June 2018. The fail rate of these tractors on their first test was 54%, while 11% failed dangerously, meaning 65% of initial tests were failed.

This means that only 35% passed the initial test. Ninety-two per cent of tractors later passed the retest.

Tractors that are eligible should be tested after they have reached their fourth birthday and every second year after that.

Once a tractor has passed the test, a CVRT certificate will be issued to the owner.

By the rule of the law, if a tractor is deemed to have failed dangerously, the tractor cannot be driven out of the test centre. Typically, each tractor test takes around one hour for one person to carry out the test.

Tractor identification

Before a test commences, the tester must check and verify the identification of the tractor. This involves starting with the registration plate, ensuring that it matches the tractor in question. The tractor can be failed if it’s not fitted with two road legal registration plates.

“Fancy”, faded, dirty or insecure registration plates can all cause test failure.

The chassis number and manufacturer’s plate are checked to ensure they are correct and match the tractor in question.

The presence and condition of a speed disc is then inspected. If the speed disc is absent, the wrong size, not displayed in km/h or other various issues it will result in a fail.

The test is broken up in eight sections as follows.

The tractor’s brakes are tested using a portable decelormeter. The tractor is lined up in front of an 80-100m sealed-off straight strip of tarmac.

The decelormeter is positioned against the windscreen of the tractor, and set up for the test.

The tractor is then driven at up to a minimum speed of 20km/h on a level surface, before the brakes are applied at full force at which point all four wheels should be locked.

The tractors braking efficiency is tested using a Brake Safe Turnkey portable decelormeter.

The decelormeter will then print a receipt of the test, where it provides a number of results including time to stop, speed at braking, stopping distance and pulls in either direction.

However, the main reason the decelormeter is used is to determine the brake efficiency of the tractor.

A pressure gauge is used to check the hydraulic pressure of the trailer brake connection. The tractor must hit the manufacturer’s specification which is typically around 140 bar pressure.

The cutoff reading is 50%, anything below this is a fail.

The decelormeter will also give a reading on how much the tractor is pulling to one side. This figure has to be over 30% for the tractor to fail the test. The tractor we tested had a 57.7% brake efficiency and was pulling to the left by 7.5%.

Handbrake

The handbrake is tested by means of a slope test. The tractor is placed on a 9° slope.

The process is as follows: put the tractor into neutral, release clutch, release brakes and apply the handbrake. If the tractor holds with no movement down the slope, it’s a pass.

If the tractor creeps slightly it’s a fail, while if there is no functioning handbrake in the tractor it will be noted as a dangerous fail.

A pressure gauge is used to check the hydraulic pressure of the trailer brake connection.

The tractor must hit the manufacturer’s specification which is typically around 140 bar pressure.

The air pressure is also tested and must display a minimum of 5.5 bar and a maximum of 8.5 bar.

Steering linkage condition was the main reason for failure across all tractors tested by RSA centres.

To access the steering gear condition, the tractor is driven over a pit and positioned on the wheel play detector plates (shaker plates) with the brakes applied.

When assessing the rack and pinion, steering box and the orbital box, reasons for failure include stiffness of bushings, a worn or damaged sector shaft/splines, continuous oil leaks, or any welded steering component other than by the manufacturer.

Next up, the steering gear casing attachment is assessed.

When assessing the steering linkage, namely the idler assembly, track rod ends/steering arm, some tractor models are jacked up slightly clear of the floor to examine properly.

If the casing is not properly attached, or there are dangerously loose steering attachments, missing mounting bolts or damaged/worn steering gear, the tractor will fail.

When assessing the steering linkage, namely the idler assembly, track rod ends/steering arm, some tractor models are jacked up slightly clear of the floor to examine properly. Using the shaker plates, the steering mechanisms from the point it is secured to the chassis, to the point where the steering arms are secured to their fixings are examined.

Joints, drop arms, track rods and other components are checked for wear.

The New Holland T7.200 tractor that we tested had 10mm movement in the CV joint after 5,700 hours, meaning it would have failed the test.

When it comes to visibility, the RSA has a zero tolerance policy against anything obstructing a driver’s line of sight.

Tractors with missing or damaged mirrors or glassware will automatically fail the test.

Likewise, stickers or objects across the windscreen that are within a driver’s field of view will result in a fail. Any damage to the windscreen, 175mm either side of the centre point, must be contained within a 10mm diameter circle.

Washer and wipers

Similarly, a tractor with either the windscreen washer (if fitted) or the windscreen wipers not functioning will cause the tractor to fail the test.

This includes wiper blades not cleaning the windscreen effectively or wipers not working at a normal speed.

4 Lights, reflectors and electrics

The headlamp aim tester (HAT) is used to test the alignment of the dipped beam.

This is the same tester that’s used in NCT test centres around the country.

The HAT is set up in front of the tractor using lasers, before it takes readings of the gradient percentage of both the left and right dipped beam.

The type of headlamp fitted to the tractor will fall into two categories, either a European-type headlamp (vast majority) or a British-American-type headlamp.

Depending on whether the centre of the bulbs for the headlamp are greater than or less than 850mm, each type of headlamp will have different requirements for both vertical and horizontal lines.

In addition to the headlamps, each tractor must be fitted with two front position lights, one on each side showing white light and two rear position lights showing red light to the back.

To pass the test, tractors must also have two rear functioning brake lights, indicators and hazard warning lights.

Repairs to light lens (repair tape, etc) will be assessed on their merits, such as security, colour, light output and durability.

Any lights not working, incorrectly positioned, not fitted symmetrically or with badly cracked lens will result in a fail.

The presence and operation of all switches will be assessed during the test.

All tractors should be fitted with at least one beacon/flashing amber light which needs to be visible from all around.

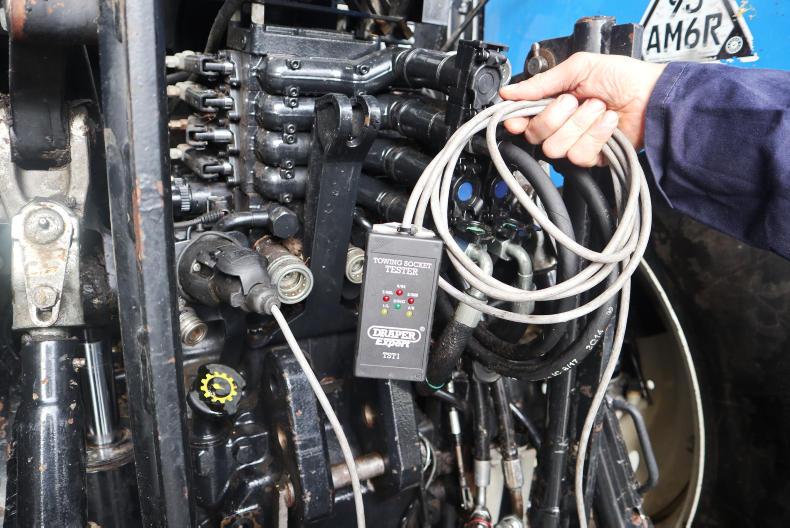

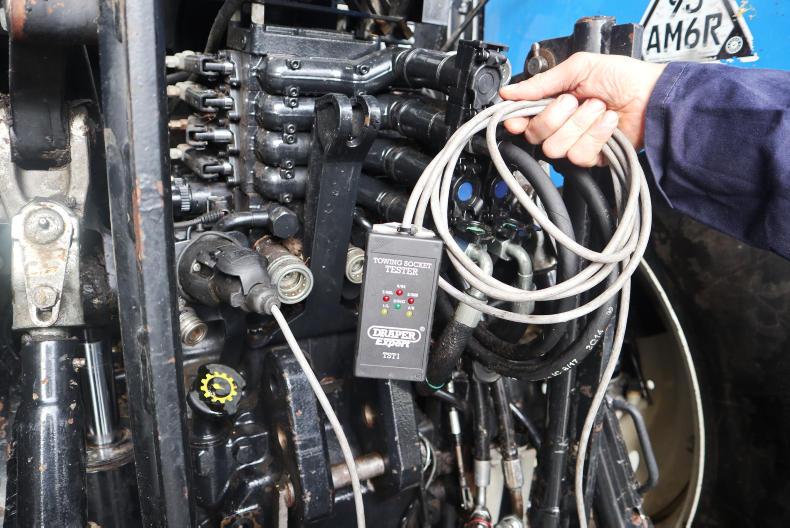

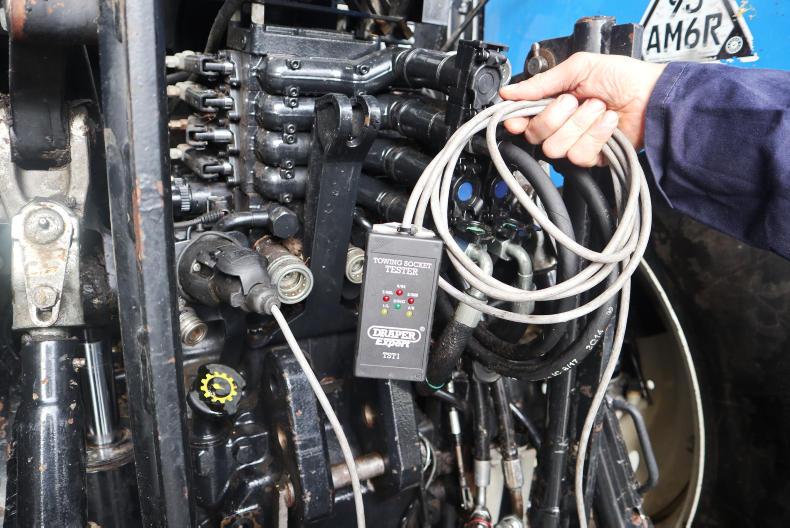

The electrical output from the seven pin plug (or 13 pin electrical socket if fitted) is assessed using a towing socket tester.

It is essential that tractors are fitted with a rear registration plate light. If this light is insecurely mounted it will result in a fail.

All tractors are also required to be fitted with two rear red deflectors, one on each side of the centre line of the tractor. If missing, this will result in a fail.

The electrical output from the seven-pin plug (or 13-pin electrical socket if fitted) is assessed using a towing socket tester.

This checks each indicator, the hazards, brake lights and the rear position lights. If the battery is insecurely mounted or if there are any leakages of hazardous substances, it will result in a fail.

5 Axles, tyres and suspension

The tractor is positioned on the wheel play detector plates with the brakes applied. The axle beams are inspected along with the condition of the mounting bushings and joints. If any modifications have been made, a modifications report must be presented by the tractor owner.

When jacked up, the wheel bearings and road wheel hubs are examined. The wheel bearings are checked for excessive play and any roughness or damage

Any issues relating to the axle, such as fractures or insecure fixings, will result in a fail.

Next up, the tester jacks up the tractor to inspect the area between the axle and the stub axle/kingpin for wear. A damaged stub axle, an excessively worn swivel pin or any insecure components will also result in a fail.

When jacked up, the wheel bearings and road wheel hubs are examined. The wheel bearings are checked for excessive play and any roughness or damage.

The road wheel hub is inspected for any wear or damage, along with the presence and condition of wheel studs. The rim is inspected for any cracks, defective weld, or any distortion which would result in a fail.

Tyres

Representatives from the RSA explained that in their experience, tyre fails have related to the condition (cuts, bulges, cracks, etc) of a tyre rather than the tread depth.

A tyre that has a cut greater than 25mm in length or 10% of section width, will be failed. In addition, any inappropriate tyre repairs, such as supergluing black plastic into cracks, will result in a failure. The minimum tread depth required to pass a test is 1.6mm around the entire circumference of the tyre.

However, the specification of a tyre also plays a huge factor. A tractor needs to be fitted with tyres that match its maximum speed rating.

Each tyre needs to have a load index rating for not less than 50% of the design axle weight. Both tyres on each axle need to have the same structure and nominal size.

RSA representatives noted that they have failed one particular JCB Fastrac tractor that was rated at 60km/h but was fitted with tyres rated to travel at just 40km/h.

Suspension

While on the shaker plates, the springs, stabiliser and torsion bar are inspected. Loose, damaged or missing springs will result in a fail. Shock absorbers (where fitted) must be correctly connected and in good condition. Worn, damaged or loose shock absorbers will fail.

The condition of the wishbones and their inner bearings, ball joints, rubber gaiters, swivel joints, retaining devices, track control arms, radius rods and their mounting bushes/washers, leading arms and swinging arms are checked for damage or distortion.

The condition of the chassis and body structure around the suspension mounting points is carefully looked at for signs of corrosion. Any modifications made to the suspension strictly require another modifications report.

For testing an air suspension, the tester will be looking for leaks, checking the condition of supply lines, the condition of the levelling valves linkages, attachment of the suspension bellows and to the frame/axle. Damaged or modified components will lead to a failure.

6 Chassis, cab and bodywork

The general condition of the chassis frame, cross members and the underbody will be inspected for cracks in high-stress areas and for corrosion.

Any deformation, fractures, welds, corrosion or modifications will lead to a fail.

The condition of the exhaust and silencers will be assessed. So too will the positioning of the exhaust, ensuring no fumes enter the cab.

An insecurely mounted exhaust and a damaged or leaking exhaust system will result in a fail.

If fitted with a hook type coupling, using a clearance tool the distance between the keeper plate and the tip of the hook must not exceed 15mm.

The lift arms and hitch will be inspected for repairs or modifications. All lift arm components such as stabilisers, quick release latches and the levelling assembly must be checked for wear.

A test is carried out to ensure the lift arm can retain the ball, ensuring the lever and retaining clamp are functional.

Hitch

The condition of the hitch is inspected, ensuring it is free from damage or distortion. If fitted with a hook-type coupling, using a clearance tool the distance between the keeper plate and the tip of the hook must not exceed 15mm. The maximum wear limit will depend on the original profile of the hook. For example, a 45mm hook must not be worn below the 39mm diameter to pass the test. No building up of a hook with weld will be permitted.

When over a pit, the areas surrounding the transmission and drive train will be thoroughly inspected.

This includes checking the clutch linkage, clutch operation, drive shafts, universal joints, CV joints, condition of PTO covers and oil leaks.

Loose or missing nuts/bolts, excessive wear at joints, damaged bearing housings, a missing PTO U-guard, or loose/worn engine/gearbox mountings, will also result in a fail.

When it comes to the cab area, advanced rusting of the pillars, floor or mounting areas will result in a fail.

The cab should be securely mounted to the body, while all doors and catches should be intact and fully functional.

Both the driver and passenger seats should be securely mounted. All driver controls necessary for the safe operation of the tractor need to be functioning correctly.

The steps must be securely attached to the tractor and not be damaged.

The distance between the ground and the first step must be no more than 600mm, unless stated elsewhere in the manufacturer’s recommendations.

7 Safety restraints, horn, speedometer

If any load-bearing piece of the vehicle structure or panelling, within 30cm of the seat belt anchorage point, is cracked, corroded or weakened, the tractor will fail the test.

The seatbelt and buckle must be in working order.

A horn must be fitted and working correctly. Likewise, the speedometer must be visible from the driver’s seat, be illuminated and working correctly.

The reading on the hour meter/odometer must be recorded at the time of the test.

Initially, the tester will visually check that the emission control system is present, connected and not bypassed.

Each tractor will undergo an opacity test, otherwise known as an emissions test. This test is based on the colour of the smoke.

Each tractor must undergo an opacity test, otherwise known as an emissions test.

The amount of light that travels through the smoke is measured using three sensors. This test is based on a K-value with a cut-off at 3m-1.

The tractor that we tested on the day had a value of 0.13m-1. To date, only one tractor has failed the emissions test.

Tractors also must pass a noise test. However, as the limit is 99 decibels, only tractors that come across as being notably noisy are tested using a sound meter. According to the RSA, no tractor has failed the test on noise as of yet.

Similar to other vehicle tests, if the initial test is failed the retest must be carried out within 21 days.

On 20 May 2018, legislation was introduced requiring fast tractors to undergo a roadworthiness test, similar to an NCT.

These tractors are now required to display a certificate of roadworthiness (CRW). This detachable disc must be displayed on the vehicle’s windscreen.

What is a “fast tractor”?

According to the Road Safety Authority (RSA), a fast tractor is defined as a wheeled tractor in category T, with a maximum design speed exceeding 40 km/h.

The requirement of a fast tractor to be tested is based on its use. Any fast tractor which is used for a non-exempted activity (that is non-agricultural work) requires a CRW.

Such examples of tractors required to be tested include: those involved in local authority work, the construction industry, the quarrying industry, the manufacturing industry, the mining industry or road construction/roadworks.

The RSA also noted that a fast tractor will not have to be tested if it is being used for the purposes of agricultural, horticultural, forestry, farming or fishery activity solely within the State and mainly on the land where such activity takes place, including agricultural roads, forestry roads or agricultural fields.

The test

The tractor test mirrors the test currently carried out on heavy commercial vehicles (HCVs), but it has been modified where necessary to suit tractors.

Since the legislation came into place, a total of 70 tractors have been tested at independent test centres.

Tractors that are eligible should be tested after they have reached their fourth birthday and every second year after that

The first test took place on 4 June 2018. The fail rate of these tractors on their first test was 54%, while 11% failed dangerously, meaning 65% of initial tests were failed.

This means that only 35% passed the initial test. Ninety-two per cent of tractors later passed the retest.

Tractors that are eligible should be tested after they have reached their fourth birthday and every second year after that.

Once a tractor has passed the test, a CVRT certificate will be issued to the owner.

By the rule of the law, if a tractor is deemed to have failed dangerously, the tractor cannot be driven out of the test centre. Typically, each tractor test takes around one hour for one person to carry out the test.

Tractor identification

Before a test commences, the tester must check and verify the identification of the tractor. This involves starting with the registration plate, ensuring that it matches the tractor in question. The tractor can be failed if it’s not fitted with two road legal registration plates.

“Fancy”, faded, dirty or insecure registration plates can all cause test failure.

The chassis number and manufacturer’s plate are checked to ensure they are correct and match the tractor in question.

The presence and condition of a speed disc is then inspected. If the speed disc is absent, the wrong size, not displayed in km/h or other various issues it will result in a fail.

The test is broken up in eight sections as follows.

The tractor’s brakes are tested using a portable decelormeter. The tractor is lined up in front of an 80-100m sealed-off straight strip of tarmac.

The decelormeter is positioned against the windscreen of the tractor, and set up for the test.

The tractor is then driven at up to a minimum speed of 20km/h on a level surface, before the brakes are applied at full force at which point all four wheels should be locked.

The tractors braking efficiency is tested using a Brake Safe Turnkey portable decelormeter.

The decelormeter will then print a receipt of the test, where it provides a number of results including time to stop, speed at braking, stopping distance and pulls in either direction.

However, the main reason the decelormeter is used is to determine the brake efficiency of the tractor.

A pressure gauge is used to check the hydraulic pressure of the trailer brake connection. The tractor must hit the manufacturer’s specification which is typically around 140 bar pressure.

The cutoff reading is 50%, anything below this is a fail.

The decelormeter will also give a reading on how much the tractor is pulling to one side. This figure has to be over 30% for the tractor to fail the test. The tractor we tested had a 57.7% brake efficiency and was pulling to the left by 7.5%.

Handbrake

The handbrake is tested by means of a slope test. The tractor is placed on a 9° slope.

The process is as follows: put the tractor into neutral, release clutch, release brakes and apply the handbrake. If the tractor holds with no movement down the slope, it’s a pass.

If the tractor creeps slightly it’s a fail, while if there is no functioning handbrake in the tractor it will be noted as a dangerous fail.

A pressure gauge is used to check the hydraulic pressure of the trailer brake connection.

The tractor must hit the manufacturer’s specification which is typically around 140 bar pressure.

The air pressure is also tested and must display a minimum of 5.5 bar and a maximum of 8.5 bar.

Steering linkage condition was the main reason for failure across all tractors tested by RSA centres.

To access the steering gear condition, the tractor is driven over a pit and positioned on the wheel play detector plates (shaker plates) with the brakes applied.

When assessing the rack and pinion, steering box and the orbital box, reasons for failure include stiffness of bushings, a worn or damaged sector shaft/splines, continuous oil leaks, or any welded steering component other than by the manufacturer.

Next up, the steering gear casing attachment is assessed.

When assessing the steering linkage, namely the idler assembly, track rod ends/steering arm, some tractor models are jacked up slightly clear of the floor to examine properly.

If the casing is not properly attached, or there are dangerously loose steering attachments, missing mounting bolts or damaged/worn steering gear, the tractor will fail.

When assessing the steering linkage, namely the idler assembly, track rod ends/steering arm, some tractor models are jacked up slightly clear of the floor to examine properly. Using the shaker plates, the steering mechanisms from the point it is secured to the chassis, to the point where the steering arms are secured to their fixings are examined.

Joints, drop arms, track rods and other components are checked for wear.

The New Holland T7.200 tractor that we tested had 10mm movement in the CV joint after 5,700 hours, meaning it would have failed the test.

When it comes to visibility, the RSA has a zero tolerance policy against anything obstructing a driver’s line of sight.

Tractors with missing or damaged mirrors or glassware will automatically fail the test.

Likewise, stickers or objects across the windscreen that are within a driver’s field of view will result in a fail. Any damage to the windscreen, 175mm either side of the centre point, must be contained within a 10mm diameter circle.

Washer and wipers

Similarly, a tractor with either the windscreen washer (if fitted) or the windscreen wipers not functioning will cause the tractor to fail the test.

This includes wiper blades not cleaning the windscreen effectively or wipers not working at a normal speed.

4 Lights, reflectors and electrics

The headlamp aim tester (HAT) is used to test the alignment of the dipped beam.

This is the same tester that’s used in NCT test centres around the country.

The HAT is set up in front of the tractor using lasers, before it takes readings of the gradient percentage of both the left and right dipped beam.

The type of headlamp fitted to the tractor will fall into two categories, either a European-type headlamp (vast majority) or a British-American-type headlamp.

Depending on whether the centre of the bulbs for the headlamp are greater than or less than 850mm, each type of headlamp will have different requirements for both vertical and horizontal lines.

In addition to the headlamps, each tractor must be fitted with two front position lights, one on each side showing white light and two rear position lights showing red light to the back.

To pass the test, tractors must also have two rear functioning brake lights, indicators and hazard warning lights.

Repairs to light lens (repair tape, etc) will be assessed on their merits, such as security, colour, light output and durability.

Any lights not working, incorrectly positioned, not fitted symmetrically or with badly cracked lens will result in a fail.

The presence and operation of all switches will be assessed during the test.

All tractors should be fitted with at least one beacon/flashing amber light which needs to be visible from all around.

The electrical output from the seven pin plug (or 13 pin electrical socket if fitted) is assessed using a towing socket tester.

It is essential that tractors are fitted with a rear registration plate light. If this light is insecurely mounted it will result in a fail.

All tractors are also required to be fitted with two rear red deflectors, one on each side of the centre line of the tractor. If missing, this will result in a fail.

The electrical output from the seven-pin plug (or 13-pin electrical socket if fitted) is assessed using a towing socket tester.

This checks each indicator, the hazards, brake lights and the rear position lights. If the battery is insecurely mounted or if there are any leakages of hazardous substances, it will result in a fail.

5 Axles, tyres and suspension

The tractor is positioned on the wheel play detector plates with the brakes applied. The axle beams are inspected along with the condition of the mounting bushings and joints. If any modifications have been made, a modifications report must be presented by the tractor owner.

When jacked up, the wheel bearings and road wheel hubs are examined. The wheel bearings are checked for excessive play and any roughness or damage

Any issues relating to the axle, such as fractures or insecure fixings, will result in a fail.

Next up, the tester jacks up the tractor to inspect the area between the axle and the stub axle/kingpin for wear. A damaged stub axle, an excessively worn swivel pin or any insecure components will also result in a fail.

When jacked up, the wheel bearings and road wheel hubs are examined. The wheel bearings are checked for excessive play and any roughness or damage.

The road wheel hub is inspected for any wear or damage, along with the presence and condition of wheel studs. The rim is inspected for any cracks, defective weld, or any distortion which would result in a fail.

Tyres

Representatives from the RSA explained that in their experience, tyre fails have related to the condition (cuts, bulges, cracks, etc) of a tyre rather than the tread depth.

A tyre that has a cut greater than 25mm in length or 10% of section width, will be failed. In addition, any inappropriate tyre repairs, such as supergluing black plastic into cracks, will result in a failure. The minimum tread depth required to pass a test is 1.6mm around the entire circumference of the tyre.

However, the specification of a tyre also plays a huge factor. A tractor needs to be fitted with tyres that match its maximum speed rating.

Each tyre needs to have a load index rating for not less than 50% of the design axle weight. Both tyres on each axle need to have the same structure and nominal size.

RSA representatives noted that they have failed one particular JCB Fastrac tractor that was rated at 60km/h but was fitted with tyres rated to travel at just 40km/h.

Suspension

While on the shaker plates, the springs, stabiliser and torsion bar are inspected. Loose, damaged or missing springs will result in a fail. Shock absorbers (where fitted) must be correctly connected and in good condition. Worn, damaged or loose shock absorbers will fail.

The condition of the wishbones and their inner bearings, ball joints, rubber gaiters, swivel joints, retaining devices, track control arms, radius rods and their mounting bushes/washers, leading arms and swinging arms are checked for damage or distortion.

The condition of the chassis and body structure around the suspension mounting points is carefully looked at for signs of corrosion. Any modifications made to the suspension strictly require another modifications report.

For testing an air suspension, the tester will be looking for leaks, checking the condition of supply lines, the condition of the levelling valves linkages, attachment of the suspension bellows and to the frame/axle. Damaged or modified components will lead to a failure.

6 Chassis, cab and bodywork

The general condition of the chassis frame, cross members and the underbody will be inspected for cracks in high-stress areas and for corrosion.

Any deformation, fractures, welds, corrosion or modifications will lead to a fail.

The condition of the exhaust and silencers will be assessed. So too will the positioning of the exhaust, ensuring no fumes enter the cab.

An insecurely mounted exhaust and a damaged or leaking exhaust system will result in a fail.

If fitted with a hook type coupling, using a clearance tool the distance between the keeper plate and the tip of the hook must not exceed 15mm.

The lift arms and hitch will be inspected for repairs or modifications. All lift arm components such as stabilisers, quick release latches and the levelling assembly must be checked for wear.

A test is carried out to ensure the lift arm can retain the ball, ensuring the lever and retaining clamp are functional.

Hitch

The condition of the hitch is inspected, ensuring it is free from damage or distortion. If fitted with a hook-type coupling, using a clearance tool the distance between the keeper plate and the tip of the hook must not exceed 15mm. The maximum wear limit will depend on the original profile of the hook. For example, a 45mm hook must not be worn below the 39mm diameter to pass the test. No building up of a hook with weld will be permitted.

When over a pit, the areas surrounding the transmission and drive train will be thoroughly inspected.

This includes checking the clutch linkage, clutch operation, drive shafts, universal joints, CV joints, condition of PTO covers and oil leaks.

Loose or missing nuts/bolts, excessive wear at joints, damaged bearing housings, a missing PTO U-guard, or loose/worn engine/gearbox mountings, will also result in a fail.

When it comes to the cab area, advanced rusting of the pillars, floor or mounting areas will result in a fail.

The cab should be securely mounted to the body, while all doors and catches should be intact and fully functional.

Both the driver and passenger seats should be securely mounted. All driver controls necessary for the safe operation of the tractor need to be functioning correctly.

The steps must be securely attached to the tractor and not be damaged.

The distance between the ground and the first step must be no more than 600mm, unless stated elsewhere in the manufacturer’s recommendations.

7 Safety restraints, horn, speedometer

If any load-bearing piece of the vehicle structure or panelling, within 30cm of the seat belt anchorage point, is cracked, corroded or weakened, the tractor will fail the test.

The seatbelt and buckle must be in working order.

A horn must be fitted and working correctly. Likewise, the speedometer must be visible from the driver’s seat, be illuminated and working correctly.

The reading on the hour meter/odometer must be recorded at the time of the test.

Initially, the tester will visually check that the emission control system is present, connected and not bypassed.

Each tractor will undergo an opacity test, otherwise known as an emissions test. This test is based on the colour of the smoke.

Each tractor must undergo an opacity test, otherwise known as an emissions test.

The amount of light that travels through the smoke is measured using three sensors. This test is based on a K-value with a cut-off at 3m-1.

The tractor that we tested on the day had a value of 0.13m-1. To date, only one tractor has failed the emissions test.

Tractors also must pass a noise test. However, as the limit is 99 decibels, only tractors that come across as being notably noisy are tested using a sound meter. According to the RSA, no tractor has failed the test on noise as of yet.

Similar to other vehicle tests, if the initial test is failed the retest must be carried out within 21 days.

SHARING OPTIONS