Guillaume Bucket operates a dairy, tillage and pig fattening unit located in La Gélinais, 48km from Nantes in western France.

The farm is owned by Guillaume and a shareholder, with a 50-50 partnership split.

In the past, his parents were stakeholders in the company as well, but Guillaume bought them out so they could retire. He now owns 60% of the land and rents the rest from his parents.

In this part of France, most dairy herds are made up of purebred Holsteins due to the low land and the productivity of high milk yields.

Overall dairy production in France is in decline but it is only a modest drop as productivity has increased. In 2024, the price of milk is stable at 43c/l and last year was a good year for dairy farmers, according to Guillaume.

Production

The farm is milking 155 purebred Holsteins with a yield of 10,000 litres per cow, resulting in the production of 1.5m litres of milk each year.

Farmers are not paid on the volume of milk and, like in Ireland, they are paid on the quality of solids, protein levels and somatic cell count.

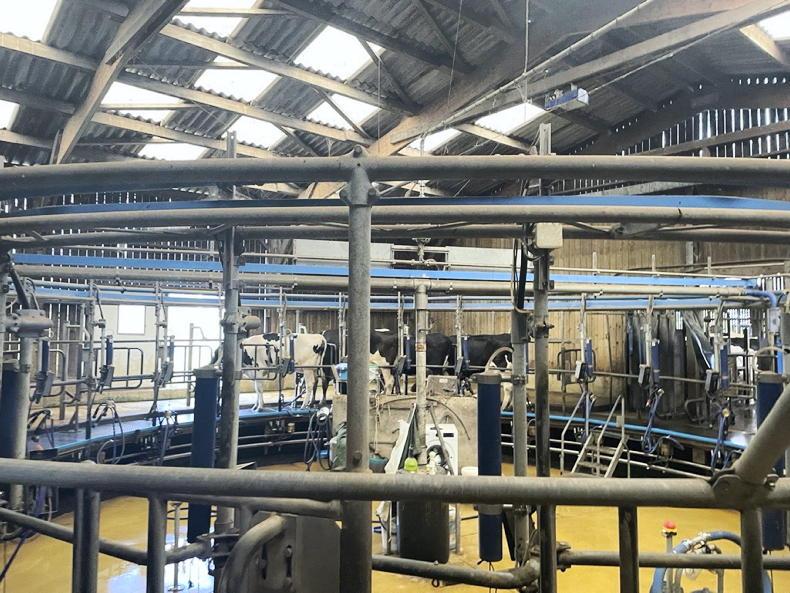

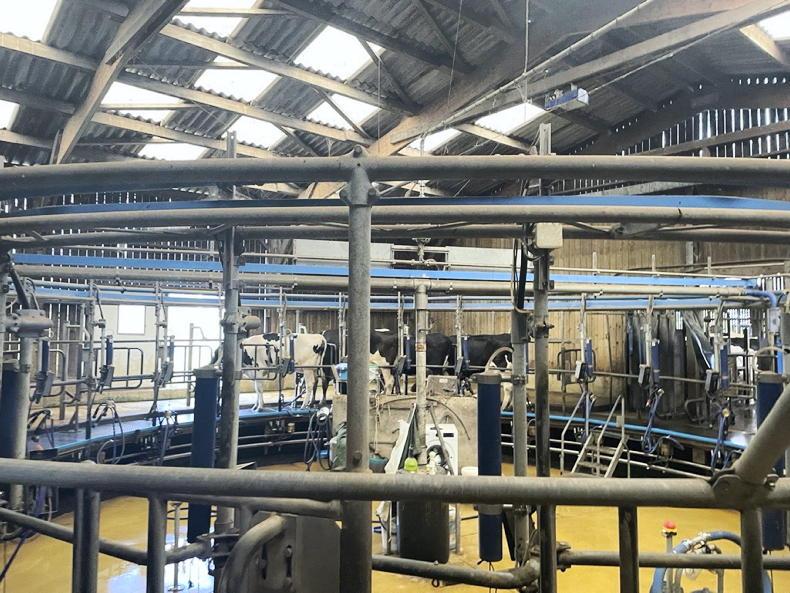

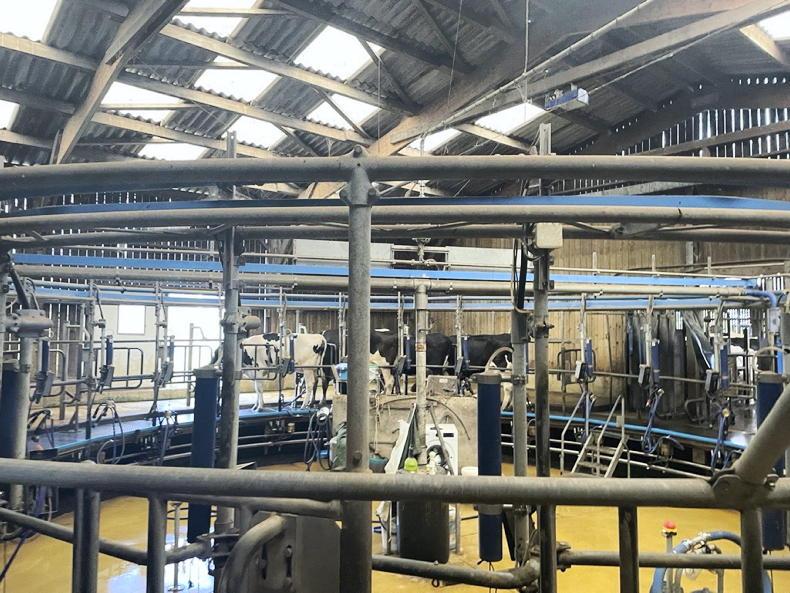

The milking parlour is a rotary with 26 units.

Cows lined up for milking.

Guillaume decided on this system as there is more flexibility with milking times.

Land usage

There are 145ha of crops on the farm, split into 50ha of grassland, 55ha of corn and the remaining 40ha are allocated to wheat. Everything that is grown is used as feed for the livestock.

In France, they normally use white clover due to the synergy with ryegrass and they grow it in the same field.

France’s agriculture sector is experiencing price inflation and higher input costs across the board.

This has had a direct impact at farm level and affected the cost of production for Guillaume over the last number of years.

Before COVID-19, the cost of production per litre of milk was €355/tonne of milk.

This year's calves grazing.

Now the current cost of production is €436/t.

Last year, farmers received a price of 48c/l and it was the best year for farmers in this region for 15 years.

Calves

This enterprise is calving all year round. The bull calves are sold when they are 10 days old and are fattened elsewhere. The end use of bull Holstein calves in France is beef.

The 26-unit rotary milking parlour.

Calves are currently being sold for an average of €100, which is high at the moment as there is a shortage of bull calves in the region.

Extra payments

The farm is also in receipt of sustainability payments because the cows are grazing outside. These include a €5/t of milk bonus, along with an extra €2/t bonus for having a lower carbon footprint.

This was given after the farm was evaluated and received a rate of 0.83kg of carbon produced for one litre of milk.

Guillaume is receiving a total of €14,000 roughly from sustainability payments.

The new shed has automatic sides that can be easily moved to improve ventilation.

There is a specific tool developed and used in France to measure the carbon footprint of farms. To get the sustainability payment, cows must be grazing outdoors for 150 days and must remain outside for a minimum of six hours per day.

The French Department of Agriculture checks farmers’ grazing plans and rotations to ensure they are out for the allocated time.

Guillaume doesn’t use any protected urea or artificial fertiliser. He only spreads pig or cow manure. The farm is limited to 170kg of organic nitrogen per hectare.

To create a better work-life balance and improve efficiency, they have modified the herd housing unit, installed a rotary parlour and replaced the mixer with a feeding robot.

“Our objective was to free up time by working only one weekend out of two and to have three weeks of vacation per year,” says Guillaume.

As a result, in 2009, they constructed a new building on the farm to group the cows and heifers as they were previously kept on two different sites.

The 'feed kitchen' for the automatic Lely vector.

The heifers are in a straw area and the cows are in straw stalls on a single corridor to facilitate scraping.

With the herd expanding, the farm turned to automation in 2014, when Guillaume became the 13th farmer in France to invest in the automatic Lely vector feeder.

The automatic Lely vector feeder in action.

At the time, he was trying to decide on hiring another worker but instead, he invested in the automatic feeder.

The area in which the feed is stored, selected, picked up and loaded into the robot for mixing is called the feed kitchen.

It takes him four hours a week to fill. This area is marked off and closed in for health and safety purposes to ensure no one gets hurt when it is being refilled.

All in, the building and feed area cost him €210,000 of an investment. Now, he doesn’t have to go out and feed the cows at the weekend as the machine does it for him.

The outside of the milking parlour and housing unit.

Pigs

Along with the dairy herd, the farm enterprise also has a pig unit. They keep a mixture of breeds. Very young piglets come in for weaning between 6kg and 25kg.

The pigs are finished to a carcase weight of 94 to 95kg.

They have a mortality rate of 6% with 2,200 pigs going through the unit every year. They receive a pig price of €2/kg.

The pig production on the farm balances the uncertainty of milk market prices.

The outside of the pig fattening sheds.

“The pigs [are for] profitability and the cows are more of a hobby. You work for cows and earn money with pigs. It is not as simple as this but the efficiency of the pig business is very good,” Guillaume said.

The Sodiaal co-operative is one of the largest co-ops in the region to serve the farmers’ and consumers’ interests.

Guillaume has been on the board of the Sodiaal co-op for the last seven years. He supplies his milk to the co-op.

The group has 16,055 dairy farmers collecting 4.3bn litres of milk.

The inside of the new shed.

Since October they haven’t gone one week without two or three days of rain.

As a result, the climate and weather have been the biggest challenge facing farmers.

The main impact of this has been the delay in sowing crops. Along with this, only 5% of the cows’ diet on Guillaume’s farm has been grass this year.

Another issue they are facing in France is generational renewal. As a result, when some farmers in the area retire, they put solar farms on their land instead of farming it.

Purebred Holsteins are a popular dairy breed in the west of France due to the low land in the region and their high milk yields.The current milk price French dairy farmers are receiving is 43c/l.Calves are currently being sold for an average of €100.A sustainability payment of €7/l of milk is available. Read more

Agri Careers: redundancies - know your rights

Finishing up to 800 pedigree Limousins cattle in western France

Guillaume Bucket operates a dairy, tillage and pig fattening unit located in La Gélinais, 48km from Nantes in western France.

The farm is owned by Guillaume and a shareholder, with a 50-50 partnership split.

In the past, his parents were stakeholders in the company as well, but Guillaume bought them out so they could retire. He now owns 60% of the land and rents the rest from his parents.

In this part of France, most dairy herds are made up of purebred Holsteins due to the low land and the productivity of high milk yields.

Overall dairy production in France is in decline but it is only a modest drop as productivity has increased. In 2024, the price of milk is stable at 43c/l and last year was a good year for dairy farmers, according to Guillaume.

Production

The farm is milking 155 purebred Holsteins with a yield of 10,000 litres per cow, resulting in the production of 1.5m litres of milk each year.

Farmers are not paid on the volume of milk and, like in Ireland, they are paid on the quality of solids, protein levels and somatic cell count.

The milking parlour is a rotary with 26 units.

Cows lined up for milking.

Guillaume decided on this system as there is more flexibility with milking times.

Land usage

There are 145ha of crops on the farm, split into 50ha of grassland, 55ha of corn and the remaining 40ha are allocated to wheat. Everything that is grown is used as feed for the livestock.

In France, they normally use white clover due to the synergy with ryegrass and they grow it in the same field.

France’s agriculture sector is experiencing price inflation and higher input costs across the board.

This has had a direct impact at farm level and affected the cost of production for Guillaume over the last number of years.

Before COVID-19, the cost of production per litre of milk was €355/tonne of milk.

This year's calves grazing.

Now the current cost of production is €436/t.

Last year, farmers received a price of 48c/l and it was the best year for farmers in this region for 15 years.

Calves

This enterprise is calving all year round. The bull calves are sold when they are 10 days old and are fattened elsewhere. The end use of bull Holstein calves in France is beef.

The 26-unit rotary milking parlour.

Calves are currently being sold for an average of €100, which is high at the moment as there is a shortage of bull calves in the region.

Extra payments

The farm is also in receipt of sustainability payments because the cows are grazing outside. These include a €5/t of milk bonus, along with an extra €2/t bonus for having a lower carbon footprint.

This was given after the farm was evaluated and received a rate of 0.83kg of carbon produced for one litre of milk.

Guillaume is receiving a total of €14,000 roughly from sustainability payments.

The new shed has automatic sides that can be easily moved to improve ventilation.

There is a specific tool developed and used in France to measure the carbon footprint of farms. To get the sustainability payment, cows must be grazing outdoors for 150 days and must remain outside for a minimum of six hours per day.

The French Department of Agriculture checks farmers’ grazing plans and rotations to ensure they are out for the allocated time.

Guillaume doesn’t use any protected urea or artificial fertiliser. He only spreads pig or cow manure. The farm is limited to 170kg of organic nitrogen per hectare.

To create a better work-life balance and improve efficiency, they have modified the herd housing unit, installed a rotary parlour and replaced the mixer with a feeding robot.

“Our objective was to free up time by working only one weekend out of two and to have three weeks of vacation per year,” says Guillaume.

As a result, in 2009, they constructed a new building on the farm to group the cows and heifers as they were previously kept on two different sites.

The 'feed kitchen' for the automatic Lely vector.

The heifers are in a straw area and the cows are in straw stalls on a single corridor to facilitate scraping.

With the herd expanding, the farm turned to automation in 2014, when Guillaume became the 13th farmer in France to invest in the automatic Lely vector feeder.

The automatic Lely vector feeder in action.

At the time, he was trying to decide on hiring another worker but instead, he invested in the automatic feeder.

The area in which the feed is stored, selected, picked up and loaded into the robot for mixing is called the feed kitchen.

It takes him four hours a week to fill. This area is marked off and closed in for health and safety purposes to ensure no one gets hurt when it is being refilled.

All in, the building and feed area cost him €210,000 of an investment. Now, he doesn’t have to go out and feed the cows at the weekend as the machine does it for him.

The outside of the milking parlour and housing unit.

Pigs

Along with the dairy herd, the farm enterprise also has a pig unit. They keep a mixture of breeds. Very young piglets come in for weaning between 6kg and 25kg.

The pigs are finished to a carcase weight of 94 to 95kg.

They have a mortality rate of 6% with 2,200 pigs going through the unit every year. They receive a pig price of €2/kg.

The pig production on the farm balances the uncertainty of milk market prices.

The outside of the pig fattening sheds.

“The pigs [are for] profitability and the cows are more of a hobby. You work for cows and earn money with pigs. It is not as simple as this but the efficiency of the pig business is very good,” Guillaume said.

The Sodiaal co-operative is one of the largest co-ops in the region to serve the farmers’ and consumers’ interests.

Guillaume has been on the board of the Sodiaal co-op for the last seven years. He supplies his milk to the co-op.

The group has 16,055 dairy farmers collecting 4.3bn litres of milk.

The inside of the new shed.

Since October they haven’t gone one week without two or three days of rain.

As a result, the climate and weather have been the biggest challenge facing farmers.

The main impact of this has been the delay in sowing crops. Along with this, only 5% of the cows’ diet on Guillaume’s farm has been grass this year.

Another issue they are facing in France is generational renewal. As a result, when some farmers in the area retire, they put solar farms on their land instead of farming it.

Purebred Holsteins are a popular dairy breed in the west of France due to the low land in the region and their high milk yields.The current milk price French dairy farmers are receiving is 43c/l.Calves are currently being sold for an average of €100.A sustainability payment of €7/l of milk is available. Read more

Agri Careers: redundancies - know your rights

Finishing up to 800 pedigree Limousins cattle in western France

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: