The finishing touches are being applied to Iain Minto’s new beef shed which was constructed just outside of Biggar, South Lanarkshire in Scotland.

“This shed was put up to make my life easier for the next 20 years,” according to Iain. “I’m not going mad expanding; it just makes management much easier.”

The new straw-bedded beef shed has been designed with the handling unit at its core in a bid to make management of livestock as easy as possible.

The 900ac farm is home to 130 spring-calving suckler cows and 850 ewes split between Blackface, Mules, Texel and Blue Leicester, with pedigree flocks of the latter two breeds kept.

The shed

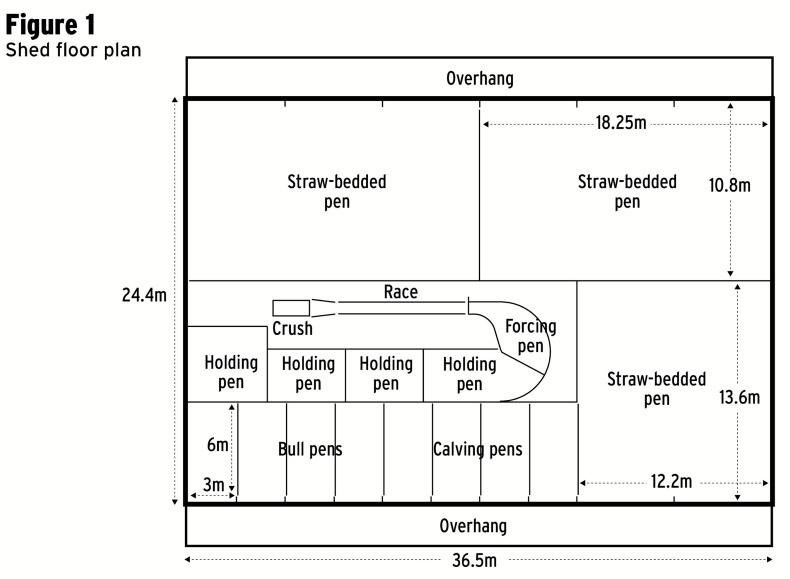

The shed is six bays long, measuring 36.5m by 24.4m wide, excluding the overhangs which are 2.4m either side of the shed. Bays are 6m wide as opposed to the conventional 4.8m.

Internally, the shed is divided between three large straw pens, eight individual calving pens/bull pens and an impressive handling unit. A steel portal frame structure was chosen for the shed.

Cattle are fed at either side of the outside of the shed, with no central feed passage present.

“I had thought about putting a central feed passage in the shed but I think it is a waste of space and the shed cost enough so I want to make use of the space I have,” said Iain.

The decision to go with a straw-bedded shed as opposed to slats was made because of the high costs involved with putting in tanks under such a large unit. The shed is bright and airy for cattle. Good airflow is important for Iain as it will help to keep disease pressure off calves and weanlings in particular.

One side of the shed is open, while the other side, along the individual calving pens is closed down to the feed barrier with spaced boarding to prevent draughts getting at calves. Spaced boarding is also used at both gable ends of the shed which stands at 8.1m at its highest, dropping to approximately 4m at the eaves.

Pens

There are two larger dry pens along one side of the shed. Each of these measures 18.25m by 10.8m. There are 36 individual feed spaces in each of these pens, but in reality capacity is much smaller.

“I would keep about 18 cows with calves in each of these pens, bedding every second day. You could probably get away with having 30 or more weanlings in a pen either but the shed was mainly designed to make managing suckler cows and calves easier.

A smaller dry pen to the rear of the handling pen which has access to the individual pens will predominantly be used to house cows as they come close to calving, with the option to move them to the individual pens if necessary.

Housing plans

There are eight individual pens in total. The plan is to use four of these to house stock bulls while the other four will be used for calving pens. Each of these pens is approximately 6m wide by 3m long. These pens are set up so that everything can be locked into the back or front section of the pen to allow Iain to safely clean the pens.

Handling unit

The central handling unit is key to the entire design of the shed.

“I wanted the shed to allow me to deal with problems as quickly as possible,” Iain said. There are four large holding pens leading up to a circular forcing pen which is lined with stockboard. Cattle will move from the forcing pen up a race and into a crush box. Guillotine gates are in place at either end of the race. These are a much safer option than swinging gates when handling cattle.

“I think the forcing pen is a great system. I can push cattle up the race without standing in the same pen as them. I don’t think anyone should install a new handling system unless they put in a forcing pen,” said Iain.

Cost

The total cost of the shed was approximately £150,000 (€171,000) excluding the VAT, with the handling unit costing approximately £25,000 (€28,500) of this. The large dry pens have a hardcore floor which did save substantially on concrete costs.

Smith Contracts Scotland Ltd completed the entire project, including all electrical and plumbing work for the shed.

“I think it has been finished to a really high standard. It’s really the little things that make the shed. Having insulation around all the pipes going into drinkers and acid resistant coating at the feeding areas where the silage goes are just little touches that will make life easier down the road,” Iain concluded.

SHARING OPTIONS