The Irish Farm Buildings Organisation (IFBA) saw its annual conference and tour take place between 17-19 October this year, the first time in three years that the association was able to convene due to COVID-19 restrictions. The town of Birr, Co Offaly, acted as the conference location, with the farm tours taking place in the surrounding hinterland that is synonymous with a strong agriculturally-based economy.

Gurteen college

The association was lucky to view the high-quality facilities that have been developed in Gurteen College. Students are actively involved in the farm from a practical sense, with many of the farm buildings adapted with this in mind.

A galebreaker was used on the side with a prevailing wind, with an overhang in place as additional shelter.

“Our milking pit is wide for a single milker, but there were eight people down there milking this morning, and there’ll be seven this evening,” explained Jon Parry, principal of Gurteen College, who led the group on a tour of the farm facilities.

Parlour and drafting

Major redevelopments were completed in 2018 to the college’s dairy facilities, one of which was the college milking parlour. A DeLaval 30-unit parlour was built in 2018, with capacity to extend to 36 units.

An Alfco backing gate, complete with a hydraulic scraper, is fitted in the collection yard.

“From the end of May through to the beginning of September (when students are on holidays), there are two people on duty, but one of those people is moving fences and herding cattle, so it needs to be a single person operation,” stated Parry. Automatic cluster removers (ACR) and auto wash are fitted.

The crossover points are a full bay (4.8m) wide, with a water trough bolted to the cubicle end.

EID tags are inserted into all the cows, with each cow being recognised as it enters the parlour. Feed to yield is in place, but generally cows are batch fed. When the parlour was first being planned, the college was still in a liquid milk contract. The EID tags are then used for the three-way drafting unit, also supplied by DeLaval, with lame cows to the left, cows for AI to the right and all others straight on. The unit also encompasses a dedicated roofed handling unit to the side of the parlour.

Wide passageways, head-to-head cubicles with plastic railing and mattresses all add to cow comfort.

Other features of note in the parlour are the high grip surface constructed using a mesh roller, air gates at the front and rear and a mat for milkers on the pit floor. Milkers are able to remain in the pit, with the Alfco hydraulic slurry scraper/backing gate funnelling cows in to the parlour.

The collecting yard at the rear of the parlour has a capacity of 250 cows – the entire herd. Some adjustments were made to allow all cows to be held post-milking, as the majority of the milking platform is at the opposite side of a regional road.

The Easifix Jupiter F mattress is made of a 45mm PU latex foam for optimum cow comfort.

A 20,000l direct expansion bulk tank with a heat recovery system was installed alongside the parlour, with the college receiving a storage bonus for three-day collections.

Overall, the project cost around €600,000 for the green field site. In total, €230,000 was spent on the DeLaval equipment, with the remainder of the funds being spent on the building works and associated materials.

Cubicle accommodation

Around the same time, Gurteen invested heavily in its dairy cow accommodation, with a 12-bay cubicle shed. Again, attention to detail – with optimum cow comfort in mind – was given to the construction of the shed.

One of the most notable features of the shed is the use of Easifix products, namely the Dream cow cubicle, the Jupiter F cow mattress and the Evolve flexible feed rail.

Auto drafting, feed to yield and ACRs are some of the additional extras on the parlour.

The Dream cow cubicle is designed to reduce injuries associated with cubicles and allow greater space and flexibility for cows lying down and getting up from the cubicle.

The Jupiter F mattress has a 45mm layer of PU latex foam to create a cushioned top surface in an effort to provide maximum cow comfort.

The back of the mat has a sloped, non-abrasive profile, which allows dung to be easily pushed into the passageway. A seamless interlock is fitted, along with a built-in brisket board for correct positioning of the cows in the cubicle. The Evolve flexible feed rail is designed to extend the cows reach and encourage higher feed intake.

At 30 units, Parry said one person could milk by themselves, but they had to be fit.

The shed throughout is designed with cow welfare to the fore. Cross-over points are a full bay (4.8m) in width, with water troughs in situ at cubicle end walls.

The feed passages are wider than a typical cubicle shed at 4.75m and are serviced by an Alfco rope scraper, scraping down into a collection tank from which slurry is pumped to additional storage on-farm.

There is full feeding on each side of the shed, totalling 24 bays of feeding capacity, adequate for 190 cows to feed at the one time. Currently, there are 118 cubicles in the shed, with two rows of head-to-head cubicles, although loose calving accommodation could be converted to hold an additional 32 cubicles, which Parry said was currently underutilised.

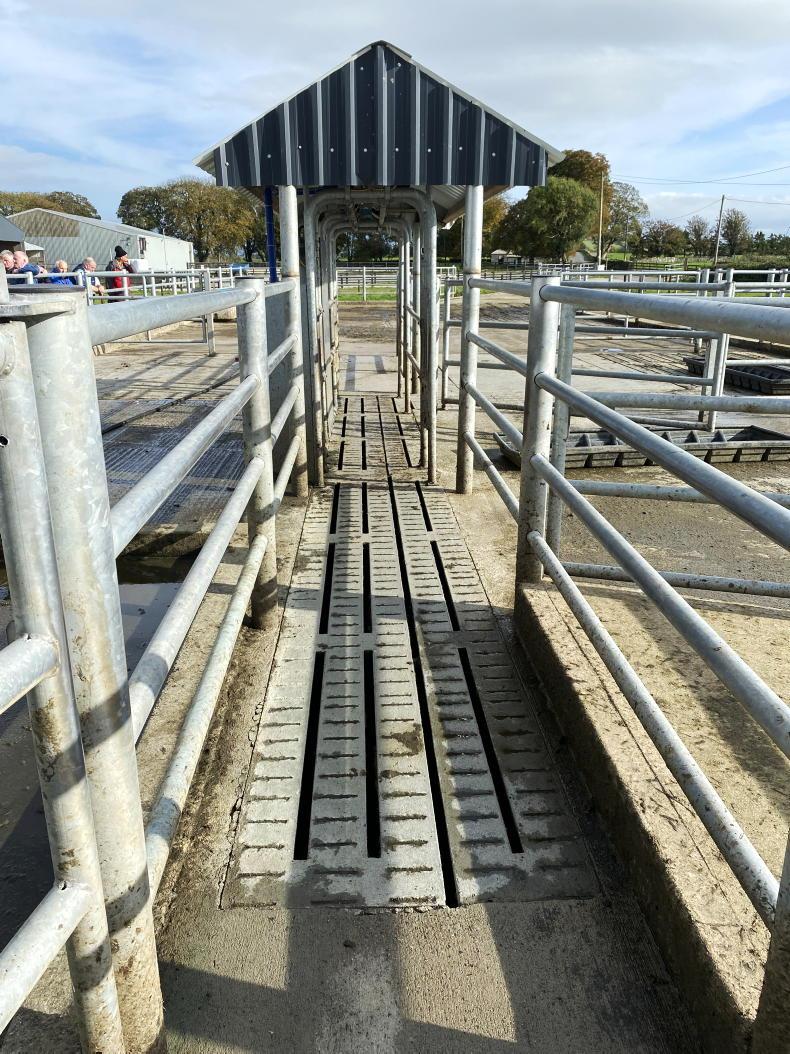

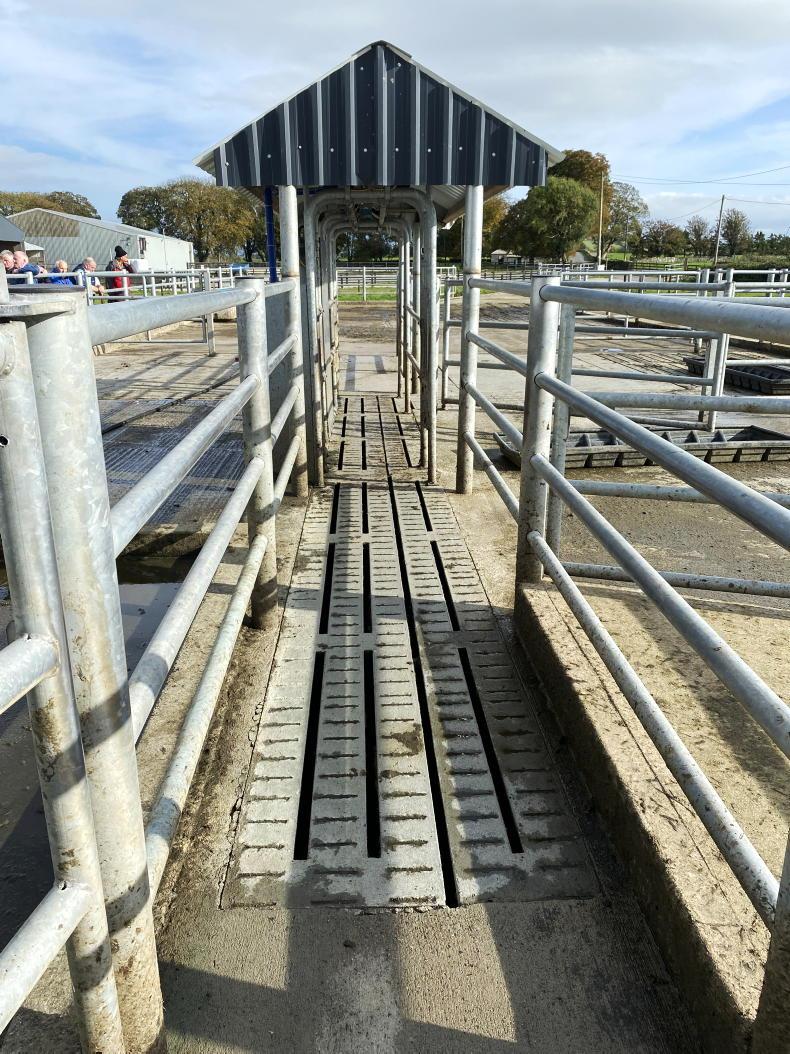

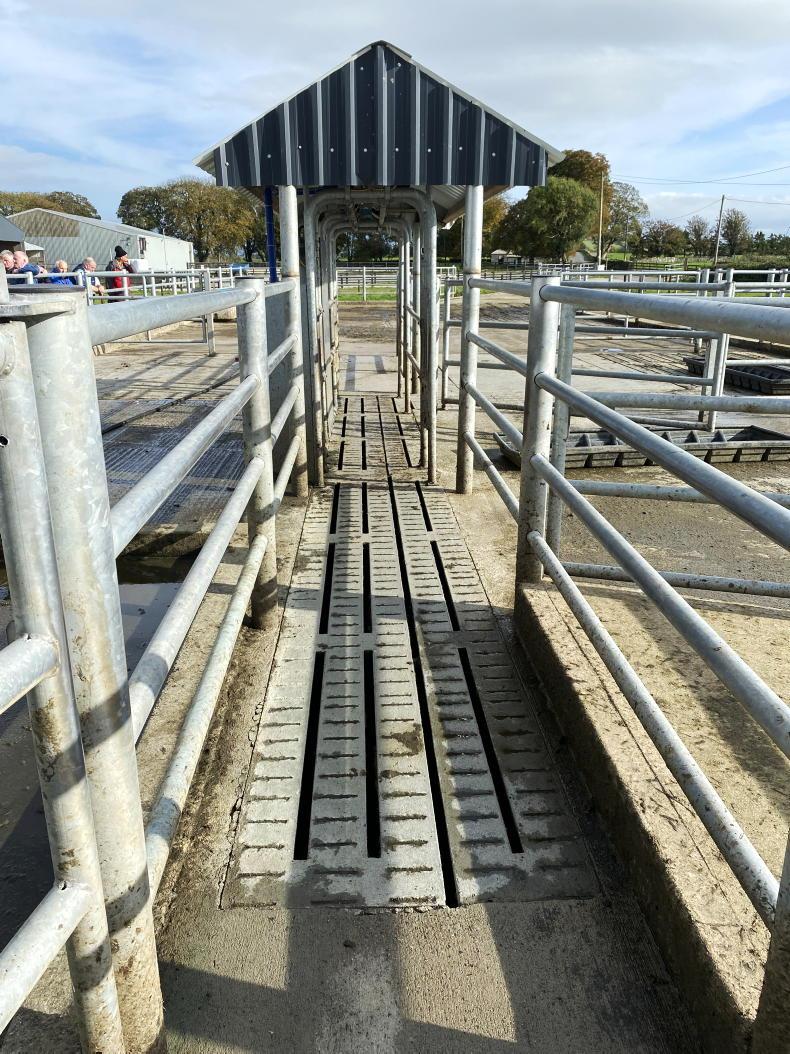

The DeLaval auto drafter drafts three ways and was recently roofed due to sunlight affecting the machine reading cow numbers.

The cubicles are approximately 150m away from the parlour, with cows having to walk on a gravel roadway between the two, which Parry said would likely be changed to a concrete roadway in the near future. Leaving a distance in between the two will allow for extentsion of the cubicle shed should the need arise.

A roof handling area for routine tasks is to the left of the milking parlour. Cows can be auto-drafted to here.

The cost of the project was €299,963 or €2,542/cow. Slurry storage is only used as a nurse tank for additional on-farm storage. While the cost per cow seems significant, cow comfort was the critical factor in designing the accommodation, again due to the herd being in a liquid milk contract at the time.

The delegation from the IFBA voiced that many of the features future-proofed the building from a welfare and cow comfort point of view and should be what more farmers aim for when designing accommodation.

The collecting yard is capable of holding the herd of 250 cows all at once.

In brief

Like many colleges, Gurteen’s facilities are at the higher end of the scale. While the costs of the project seem significant, it is showing students, and the farmer discussion groups that attend, the best possible practice when it comes to comfort. Many of the features in the cubicle shed would be more commonplace in winter milk or year-round systems, but they nonetheless improve animal welfare and should ensure less injuries and greater longevity in the herd.

The Irish Farm Buildings Organisation (IFBA) saw its annual conference and tour take place between 17-19 October this year, the first time in three years that the association was able to convene due to COVID-19 restrictions. The town of Birr, Co Offaly, acted as the conference location, with the farm tours taking place in the surrounding hinterland that is synonymous with a strong agriculturally-based economy.

Gurteen college

The association was lucky to view the high-quality facilities that have been developed in Gurteen College. Students are actively involved in the farm from a practical sense, with many of the farm buildings adapted with this in mind.

A galebreaker was used on the side with a prevailing wind, with an overhang in place as additional shelter.

“Our milking pit is wide for a single milker, but there were eight people down there milking this morning, and there’ll be seven this evening,” explained Jon Parry, principal of Gurteen College, who led the group on a tour of the farm facilities.

Parlour and drafting

Major redevelopments were completed in 2018 to the college’s dairy facilities, one of which was the college milking parlour. A DeLaval 30-unit parlour was built in 2018, with capacity to extend to 36 units.

An Alfco backing gate, complete with a hydraulic scraper, is fitted in the collection yard.

“From the end of May through to the beginning of September (when students are on holidays), there are two people on duty, but one of those people is moving fences and herding cattle, so it needs to be a single person operation,” stated Parry. Automatic cluster removers (ACR) and auto wash are fitted.

The crossover points are a full bay (4.8m) wide, with a water trough bolted to the cubicle end.

EID tags are inserted into all the cows, with each cow being recognised as it enters the parlour. Feed to yield is in place, but generally cows are batch fed. When the parlour was first being planned, the college was still in a liquid milk contract. The EID tags are then used for the three-way drafting unit, also supplied by DeLaval, with lame cows to the left, cows for AI to the right and all others straight on. The unit also encompasses a dedicated roofed handling unit to the side of the parlour.

Wide passageways, head-to-head cubicles with plastic railing and mattresses all add to cow comfort.

Other features of note in the parlour are the high grip surface constructed using a mesh roller, air gates at the front and rear and a mat for milkers on the pit floor. Milkers are able to remain in the pit, with the Alfco hydraulic slurry scraper/backing gate funnelling cows in to the parlour.

The collecting yard at the rear of the parlour has a capacity of 250 cows – the entire herd. Some adjustments were made to allow all cows to be held post-milking, as the majority of the milking platform is at the opposite side of a regional road.

The Easifix Jupiter F mattress is made of a 45mm PU latex foam for optimum cow comfort.

A 20,000l direct expansion bulk tank with a heat recovery system was installed alongside the parlour, with the college receiving a storage bonus for three-day collections.

Overall, the project cost around €600,000 for the green field site. In total, €230,000 was spent on the DeLaval equipment, with the remainder of the funds being spent on the building works and associated materials.

Cubicle accommodation

Around the same time, Gurteen invested heavily in its dairy cow accommodation, with a 12-bay cubicle shed. Again, attention to detail – with optimum cow comfort in mind – was given to the construction of the shed.

One of the most notable features of the shed is the use of Easifix products, namely the Dream cow cubicle, the Jupiter F cow mattress and the Evolve flexible feed rail.

Auto drafting, feed to yield and ACRs are some of the additional extras on the parlour.

The Dream cow cubicle is designed to reduce injuries associated with cubicles and allow greater space and flexibility for cows lying down and getting up from the cubicle.

The Jupiter F mattress has a 45mm layer of PU latex foam to create a cushioned top surface in an effort to provide maximum cow comfort.

The back of the mat has a sloped, non-abrasive profile, which allows dung to be easily pushed into the passageway. A seamless interlock is fitted, along with a built-in brisket board for correct positioning of the cows in the cubicle. The Evolve flexible feed rail is designed to extend the cows reach and encourage higher feed intake.

At 30 units, Parry said one person could milk by themselves, but they had to be fit.

The shed throughout is designed with cow welfare to the fore. Cross-over points are a full bay (4.8m) in width, with water troughs in situ at cubicle end walls.

The feed passages are wider than a typical cubicle shed at 4.75m and are serviced by an Alfco rope scraper, scraping down into a collection tank from which slurry is pumped to additional storage on-farm.

There is full feeding on each side of the shed, totalling 24 bays of feeding capacity, adequate for 190 cows to feed at the one time. Currently, there are 118 cubicles in the shed, with two rows of head-to-head cubicles, although loose calving accommodation could be converted to hold an additional 32 cubicles, which Parry said was currently underutilised.

The DeLaval auto drafter drafts three ways and was recently roofed due to sunlight affecting the machine reading cow numbers.

The cubicles are approximately 150m away from the parlour, with cows having to walk on a gravel roadway between the two, which Parry said would likely be changed to a concrete roadway in the near future. Leaving a distance in between the two will allow for extentsion of the cubicle shed should the need arise.

A roof handling area for routine tasks is to the left of the milking parlour. Cows can be auto-drafted to here.

The cost of the project was €299,963 or €2,542/cow. Slurry storage is only used as a nurse tank for additional on-farm storage. While the cost per cow seems significant, cow comfort was the critical factor in designing the accommodation, again due to the herd being in a liquid milk contract at the time.

The delegation from the IFBA voiced that many of the features future-proofed the building from a welfare and cow comfort point of view and should be what more farmers aim for when designing accommodation.

The collecting yard is capable of holding the herd of 250 cows all at once.

In brief

Like many colleges, Gurteen’s facilities are at the higher end of the scale. While the costs of the project seem significant, it is showing students, and the farmer discussion groups that attend, the best possible practice when it comes to comfort. Many of the features in the cubicle shed would be more commonplace in winter milk or year-round systems, but they nonetheless improve animal welfare and should ensure less injuries and greater longevity in the herd.

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: