Early April will see an increase in field activity across Northern Ireland as a growing number of farmers look to close off silage ground for the first cut.

Wet conditions over the second half of March have left ground conditions extremely poor for travelling with machinery, particularly slurry equipment.

As such, there will be farmers operating a three-cut system that may be behind schedule for getting first cut closed off.

Although fertiliser price is falling, it is still expensive compared to previous years with the exception of 2022.

In addition, a lot of nitrogen was forward-bought last autumn at prices of £650 to £900 depending on the product.

Where this fertiliser will be used for first cut, it is important to get the best growth response possible from silage swards. Outlined are 10 tips to closing off silage ground for first cut.

1 When should silage ground be closed up?

Closing date should tie in with target harvesting date. Where first cut will get 100 units/acre of nitrogen (N) between slurry and chemical fertiliser, the sward will use on average 2 units/day of N.

As such, silage will be safe to harvest around 50 days from fertiliser being applied when swards are closed off.

Therefore, if fields are closed off by the week starting Monday 10 April, silage will be ready for cutting around 5 June.

It is possible to pull the cutting date forward by a few days if harvesting conditions are dry and grass can be wilted for 24 to 48 hours.

2 How much fertiliser is needed for first-cut silage?

Grass growth will surge to peak levels during May, so it is important there is adequate nitrogen applied to bulk out swards and drive forage protein.

For a two-cut system on ryegrass swards with soils at Index 2 for phosphate (P) and potash (K), aim to apply 100 units/acre of nitrogen to drive yields along with 30 units of P and 60 units of K.

On older silage swards with less ryegrass, there is little point applying more than 80 units/acre of nitrogen between slurry and chemical fertiliser as the growth response will not be cost effective.

If the aim is to harvest silage by mid-May in a multi-cut system, and ground has yet to be closed off, then go with a dressing of 60 to 70 units/acre of nitrogen for first cut.

3 Slurry

Slurry will be used on most farms as a key fertiliser on silage ground. But do not over-value the nutrients contained in such forms of organic manure.

Slurry produced by animals on a high-concentrate diet will have a high N, P and K content. Slurry produced by cows on a silage-only diet will have a low nutrient content, particularly if the fertiliser used to grow such forage was an N-only product. Therefore, on suckler to weanling farms where it is mainly dry cows carried over winter, slurry is unlikely to provide to provide adequate P and K. As such, compound NPK products should be used to produce first-cut silage.

However, it should be noted that under the current Nutrients Action Programme, chemical P can only be applied where there is a crop need determined by a soil analysis.

4 Avoid liming silage ground

If there were plans to lime silage ground this spring, but wet conditions during March meant this was not possible, put these plans on hold until late summer or autumn.

Do not lime silage swards at this stage of the year. Lime can interfere with some fertilisers and there is a risk of bringing traces of the product back into the clamp which will hinder lactic acid production and fermentation.

5 Fertiliser rates

In a two-cut system on index 2 soils, spreading 3,000 gallons/acre of cattle slurry produced by dairy cows, pigs or finishing cattle will provide enough P and K for first cut.

It will also apply around 25 to 30 units/acre of nitrogen, so top up to the recommended 100 units with three bags/acre of CAN or 1.5 bags/acre of protected urea.

On soils with lower P and K levels, slurry and straight nitrogen will not provide adequate nutrient for first cut.

Therefore, a compound like 24-6-12 will be required to top up the nutrients required.

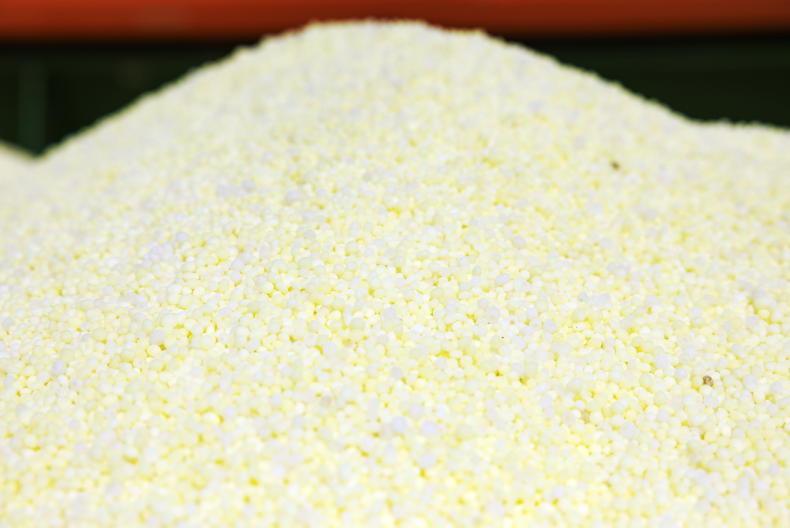

6 Don’t forget about sulphur

Sulphur is often forgotten when applying silage fertiliser, mainly because many products that contain the element are £10 to £20/t more expensive.

Yet without sulphur, grass will not yield anywhere close to its potential. If applying 100 units of nitrogen, spread at least 25 units/acre of sulphur.

7 Don’t spread slurry and chemical nitrogen on the same day

When closing off silage ground, do not apply slurry and chemical nitrogen to silage swards on the same day. Leave a gap of one week between applications to avoid enzyme reactions that cause nitrogen loss.

8 Split chemical fertiliser over two allocations

Where ground conditions are difficult and grass growth is struggling, applying 100 units/acre of N in one go may not be the best thing to do. Until grass growth increases, N uptake will be low, meaning there is an increased risk of fertiliser being lost to the atmosphere or leached from soils. Therefore, splitting fertiliser over two dressings may make better use of the nitrogen being applied, although it does double the workload.

9 Early spraying of grassland weeds

Grass covers are likely to be low on silage swards in early April. Weeds like docks and thistles are also likely to be at an immature stage. Spraying weeds now will help get a more efficient kill before these plants mature and produce seeds.

10 Rolling surface-damaged swards

If silage swards have been damaged from grazing early this spring or in late autumn of last year, use a light roller to level out ground. Poached ground can hold surface water and there is a higher risk of soil contaminating grass when mowing, raking and ensiling. Damaged ground also increases the number of stones in the sward which can do serious damage to machinery at harvesting time.

Read more

MartBids Database: light cattle up as grass buyers move out

Merchants can choose manual or automated method of inputting fertiliser records

Early April will see an increase in field activity across Northern Ireland as a growing number of farmers look to close off silage ground for the first cut.

Wet conditions over the second half of March have left ground conditions extremely poor for travelling with machinery, particularly slurry equipment.

As such, there will be farmers operating a three-cut system that may be behind schedule for getting first cut closed off.

Although fertiliser price is falling, it is still expensive compared to previous years with the exception of 2022.

In addition, a lot of nitrogen was forward-bought last autumn at prices of £650 to £900 depending on the product.

Where this fertiliser will be used for first cut, it is important to get the best growth response possible from silage swards. Outlined are 10 tips to closing off silage ground for first cut.

1 When should silage ground be closed up?

Closing date should tie in with target harvesting date. Where first cut will get 100 units/acre of nitrogen (N) between slurry and chemical fertiliser, the sward will use on average 2 units/day of N.

As such, silage will be safe to harvest around 50 days from fertiliser being applied when swards are closed off.

Therefore, if fields are closed off by the week starting Monday 10 April, silage will be ready for cutting around 5 June.

It is possible to pull the cutting date forward by a few days if harvesting conditions are dry and grass can be wilted for 24 to 48 hours.

2 How much fertiliser is needed for first-cut silage?

Grass growth will surge to peak levels during May, so it is important there is adequate nitrogen applied to bulk out swards and drive forage protein.

For a two-cut system on ryegrass swards with soils at Index 2 for phosphate (P) and potash (K), aim to apply 100 units/acre of nitrogen to drive yields along with 30 units of P and 60 units of K.

On older silage swards with less ryegrass, there is little point applying more than 80 units/acre of nitrogen between slurry and chemical fertiliser as the growth response will not be cost effective.

If the aim is to harvest silage by mid-May in a multi-cut system, and ground has yet to be closed off, then go with a dressing of 60 to 70 units/acre of nitrogen for first cut.

3 Slurry

Slurry will be used on most farms as a key fertiliser on silage ground. But do not over-value the nutrients contained in such forms of organic manure.

Slurry produced by animals on a high-concentrate diet will have a high N, P and K content. Slurry produced by cows on a silage-only diet will have a low nutrient content, particularly if the fertiliser used to grow such forage was an N-only product. Therefore, on suckler to weanling farms where it is mainly dry cows carried over winter, slurry is unlikely to provide to provide adequate P and K. As such, compound NPK products should be used to produce first-cut silage.

However, it should be noted that under the current Nutrients Action Programme, chemical P can only be applied where there is a crop need determined by a soil analysis.

4 Avoid liming silage ground

If there were plans to lime silage ground this spring, but wet conditions during March meant this was not possible, put these plans on hold until late summer or autumn.

Do not lime silage swards at this stage of the year. Lime can interfere with some fertilisers and there is a risk of bringing traces of the product back into the clamp which will hinder lactic acid production and fermentation.

5 Fertiliser rates

In a two-cut system on index 2 soils, spreading 3,000 gallons/acre of cattle slurry produced by dairy cows, pigs or finishing cattle will provide enough P and K for first cut.

It will also apply around 25 to 30 units/acre of nitrogen, so top up to the recommended 100 units with three bags/acre of CAN or 1.5 bags/acre of protected urea.

On soils with lower P and K levels, slurry and straight nitrogen will not provide adequate nutrient for first cut.

Therefore, a compound like 24-6-12 will be required to top up the nutrients required.

6 Don’t forget about sulphur

Sulphur is often forgotten when applying silage fertiliser, mainly because many products that contain the element are £10 to £20/t more expensive.

Yet without sulphur, grass will not yield anywhere close to its potential. If applying 100 units of nitrogen, spread at least 25 units/acre of sulphur.

7 Don’t spread slurry and chemical nitrogen on the same day

When closing off silage ground, do not apply slurry and chemical nitrogen to silage swards on the same day. Leave a gap of one week between applications to avoid enzyme reactions that cause nitrogen loss.

8 Split chemical fertiliser over two allocations

Where ground conditions are difficult and grass growth is struggling, applying 100 units/acre of N in one go may not be the best thing to do. Until grass growth increases, N uptake will be low, meaning there is an increased risk of fertiliser being lost to the atmosphere or leached from soils. Therefore, splitting fertiliser over two dressings may make better use of the nitrogen being applied, although it does double the workload.

9 Early spraying of grassland weeds

Grass covers are likely to be low on silage swards in early April. Weeds like docks and thistles are also likely to be at an immature stage. Spraying weeds now will help get a more efficient kill before these plants mature and produce seeds.

10 Rolling surface-damaged swards

If silage swards have been damaged from grazing early this spring or in late autumn of last year, use a light roller to level out ground. Poached ground can hold surface water and there is a higher risk of soil contaminating grass when mowing, raking and ensiling. Damaged ground also increases the number of stones in the sward which can do serious damage to machinery at harvesting time.

Read more

MartBids Database: light cattle up as grass buyers move out

Merchants can choose manual or automated method of inputting fertiliser records

SHARING OPTIONS