Today, there are many aspects of farming we take for granted that we did not have all that long ago, the tractor being one of them. I’m sure many of us have family members that still remember a time before such machines. Before this, most farmers operated their farm machinery by horsepower. Donkeys and asses were also used for similar duties for many decades. Some farms had two or three work horses, depending on their size.

Everything from mowing to ploughing as well as carting hay and turf were tasks carried out by these animals. The horse and cart were the mode of transport used to make trips to the local village or town before the arrival of cars.

It wasn’t until the 1940s that tractors started to appear in rural Ireland. Although available for some time, as far back as the 1910s, many farms could simply not afford to own one.

By 1939, it was estimated that there were close to 2,000 tractors in total working on Irish farms. Just to put this number in context, a total of 2,125 new tractors alone were sold in Ireland during 2022.

Over time, the noise of horse-drawn machinery was slowly replaced by the roar of a combustion engine. Farms fortunate enough now had the pulling power of 10, 20 or even 50 horses – this being where the modern term used to measure an engine’s power originates from.

While today’s tractors burn diesel (although slowly changing due to renewable fuel sources), the early tractors ran on petrol and paraffin.

Steam engines were also around, but didn’t fit many typical farm applications or budgets. In most parts of rural Ireland, something small, handy and lightweight was required.

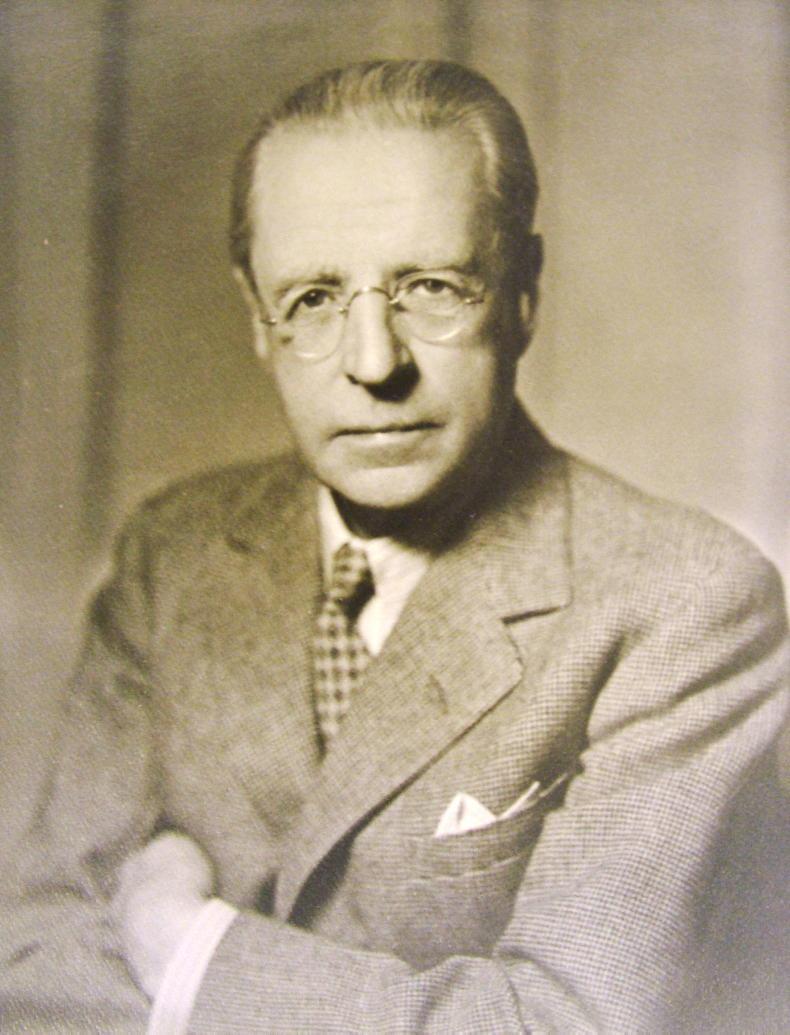

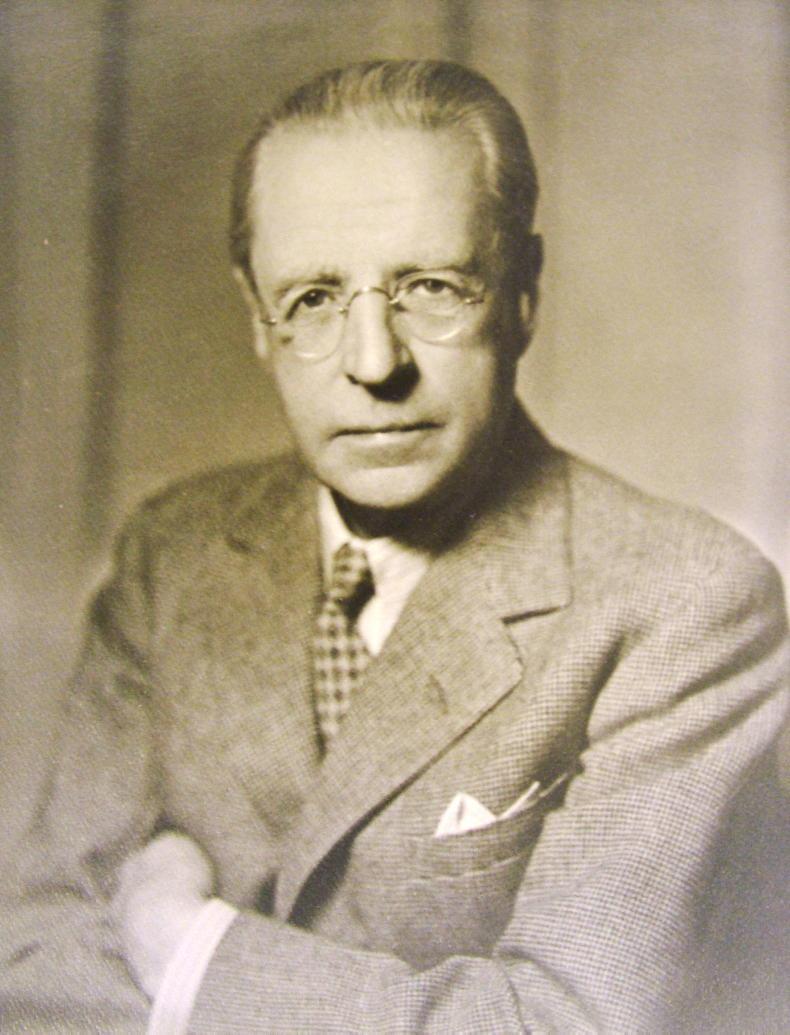

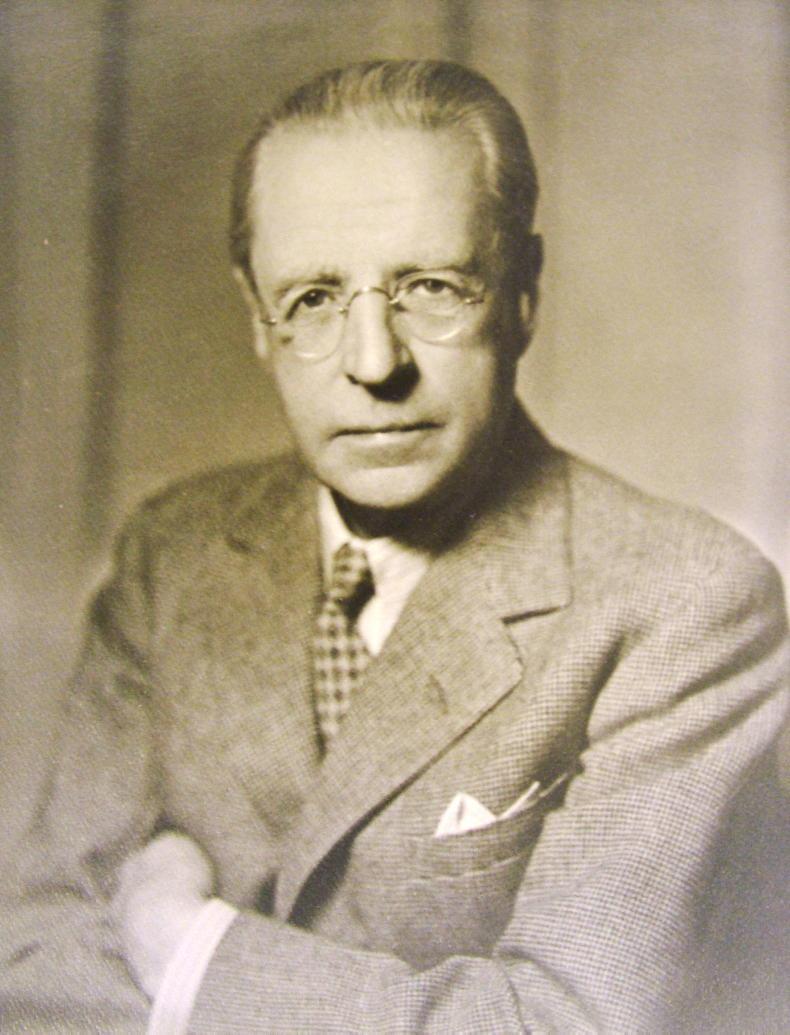

Harry Ferguson

Harry Ferguson was a farmer's son originating from Dromore, Co Down.

One Northern Irish man played a key role in the development of the modern tractor as we know it today. Harry Ferguson, who had been selling some of the country’s first tractors, saw first-hand the difficulties Irish and UK farmers were having. Harry had an agency for the US-built Overtime tractors in Ireland in the 1900s.

Already at this point in his career, the Dromore, Co Down, man and farmer’s son had claimed the title of being the first Irishman to build and fly his own aeroplane.

Having followed the journey of the American Wright brothers’ first flight in 1903 and first British flight in 1908, he and his brother took to designing their own monoplane, which completed the achievement in Hillsborough on 31 December 1909.

Following a disagreement with his brother, Harry ventured into the automotive business in 1911, selling the US-built Maxwell and British-built Star and Vauxhall cars. Shortly after, he then took on the agency for Overtime tractors.

The Overtime tractor was later to become the John Deere Waterloo Boy, John Deere’s first tractor model sold. Harry sold more than 250 Overtime tractors in Ireland.

Three-point linkage

From dealing with customers, Harry Ferguson found that tractors up until the 1920s had been designed too much as a direct replacement for a horse and that the implement coupling system was largely unchanged.

Using his engineering expertise, he devised a linkage system for the rigid mounting of implements called the Ferguson system. Before patenting his design in the late 1920s, he reportedly trialled the Ferguson system integral plough concept on a converted model T Ford (Eros) and Overtime tractor.

Interestingly, Ferguson had not yet designed and built his own tractor. So, he established a company named Ferguson-Sherman Inc to manufacture the Ferguson plough, incorporating his patented hitch system which was mainly intended for use with the famous Fordson F tractor.

Ferguson merged with Massey Harris in 1953 to form the modern day Massey Ferguson tractor brand.

To suit the Fordson F, Ferguson had to develop a new plough with a Duplex hitch. It was this new design that marked a major advancement and clearly displays the features of the current day three-point linkage fitted to almost every tractor.

The hitching system was demonstrated to Henry Ford in 1922. He was impressed and tried to buy out Harry Ferguson, but failed. Then, as expected, having wanted to venture into the tractor manufacturing business, Ferguson’s new hydraulic version of the three-point linkage was first seen on his prototype ‘Ferguson Black’ or the ‘Irish tractor’ as he is believed to have called it.

Ferguson tractors

By May 1936, a production version of the Ferguson Black was introduced, which was to be manufactured under agreement by David Brown at Huddersfield factory in Yorkshire, England. Officially named the Ferguson Model A tractor, a total of 1,356 Model A’s were built under the Ferguson-Brown Company. By 1939, cash flow issues led Ferguson and David Brown to part company after Brown called for changes.

Following this, Ferguson struck an agreement with Henry Ford, who would produce the Ferguson tractor – now called the Ford-Ferguson 9N – fitted with the Ferguson System. The hitching system soon became popular among farmers all across the world.

This tractor was also fitted with a rear PTO that could now be used to power three-point linkage-mounted implements, setting the standard for future tractor developments.

As part of the agreement, it’s understood that the Ferguson tractor was also to be made in the UK at the Ford Ltd factory at Dagenham, Essex, but this did not happen. While US-built 9N tractors were imported into the UK, none were built at Dagenham.

As a consequence of the failure to build tractors at Dagenham, in December 1945, the Standard Motor Company announced that it would produce Ferguson’s tractors under agreement. Production started at Banner Lane in Coventry in England in 1946 and ran until 1956, 10 years after World War II.

The updated and improved 9N was now named the TE20. Annual production for the TE tractors exceeded 73,000 in 1951.

Henry Ford II, grandson of the original Henry Ford, ended the agreement with Ferguson in 1947, so Ferguson set up a factory in Detroit to make the TE20 in America under the new name TO20. Ford continued to produce tractors incorporating Ferguson’s invention.

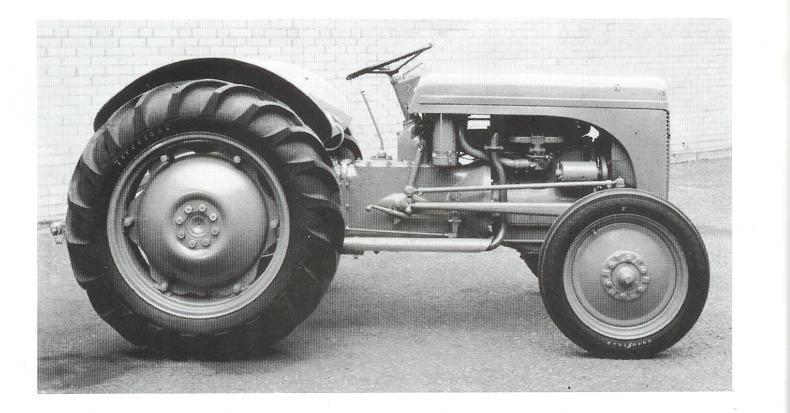

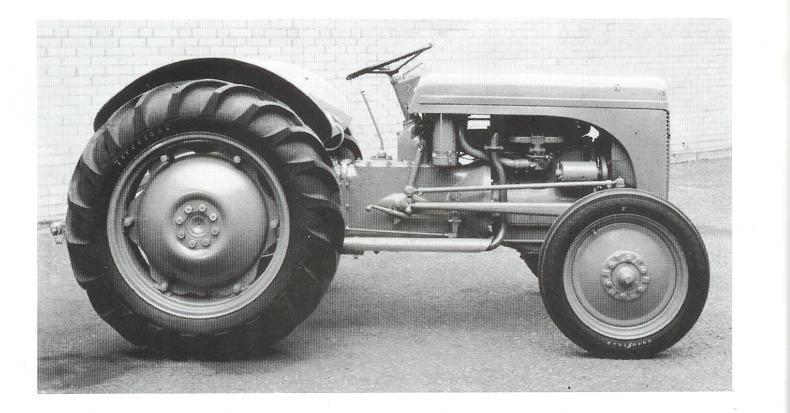

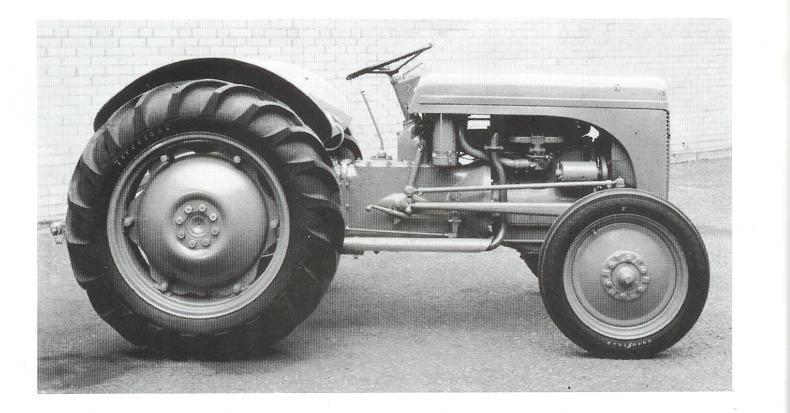

The Ferguson TE20 was built at Banner Lane in Coventry from 1946 until 1956.

By 1952, Ferguson was in fourth place on the US market. He later filed a lawsuit against Ford demanding compensation for infringing patents and the case was settled out of court for $9m. At this point, the case had cost Ferguson about half this figure and ill health.

Ferguson’s patents had run out by 1952, meaning that all other world manufacturers could legally use Ferguson’s invention, which they did. A year later, Ferguson merged with Massey Harris to become Massey Harris Ferguson Co, before being simplified in 1958 to become Massey Ferguson, as we know it today.

Today, there are many aspects of farming we take for granted that we did not have all that long ago, the tractor being one of them. I’m sure many of us have family members that still remember a time before such machines. Before this, most farmers operated their farm machinery by horsepower. Donkeys and asses were also used for similar duties for many decades. Some farms had two or three work horses, depending on their size.

Everything from mowing to ploughing as well as carting hay and turf were tasks carried out by these animals. The horse and cart were the mode of transport used to make trips to the local village or town before the arrival of cars.

It wasn’t until the 1940s that tractors started to appear in rural Ireland. Although available for some time, as far back as the 1910s, many farms could simply not afford to own one.

By 1939, it was estimated that there were close to 2,000 tractors in total working on Irish farms. Just to put this number in context, a total of 2,125 new tractors alone were sold in Ireland during 2022.

Over time, the noise of horse-drawn machinery was slowly replaced by the roar of a combustion engine. Farms fortunate enough now had the pulling power of 10, 20 or even 50 horses – this being where the modern term used to measure an engine’s power originates from.

While today’s tractors burn diesel (although slowly changing due to renewable fuel sources), the early tractors ran on petrol and paraffin.

Steam engines were also around, but didn’t fit many typical farm applications or budgets. In most parts of rural Ireland, something small, handy and lightweight was required.

Harry Ferguson

Harry Ferguson was a farmer's son originating from Dromore, Co Down.

One Northern Irish man played a key role in the development of the modern tractor as we know it today. Harry Ferguson, who had been selling some of the country’s first tractors, saw first-hand the difficulties Irish and UK farmers were having. Harry had an agency for the US-built Overtime tractors in Ireland in the 1900s.

Already at this point in his career, the Dromore, Co Down, man and farmer’s son had claimed the title of being the first Irishman to build and fly his own aeroplane.

Having followed the journey of the American Wright brothers’ first flight in 1903 and first British flight in 1908, he and his brother took to designing their own monoplane, which completed the achievement in Hillsborough on 31 December 1909.

Following a disagreement with his brother, Harry ventured into the automotive business in 1911, selling the US-built Maxwell and British-built Star and Vauxhall cars. Shortly after, he then took on the agency for Overtime tractors.

The Overtime tractor was later to become the John Deere Waterloo Boy, John Deere’s first tractor model sold. Harry sold more than 250 Overtime tractors in Ireland.

Three-point linkage

From dealing with customers, Harry Ferguson found that tractors up until the 1920s had been designed too much as a direct replacement for a horse and that the implement coupling system was largely unchanged.

Using his engineering expertise, he devised a linkage system for the rigid mounting of implements called the Ferguson system. Before patenting his design in the late 1920s, he reportedly trialled the Ferguson system integral plough concept on a converted model T Ford (Eros) and Overtime tractor.

Interestingly, Ferguson had not yet designed and built his own tractor. So, he established a company named Ferguson-Sherman Inc to manufacture the Ferguson plough, incorporating his patented hitch system which was mainly intended for use with the famous Fordson F tractor.

Ferguson merged with Massey Harris in 1953 to form the modern day Massey Ferguson tractor brand.

To suit the Fordson F, Ferguson had to develop a new plough with a Duplex hitch. It was this new design that marked a major advancement and clearly displays the features of the current day three-point linkage fitted to almost every tractor.

The hitching system was demonstrated to Henry Ford in 1922. He was impressed and tried to buy out Harry Ferguson, but failed. Then, as expected, having wanted to venture into the tractor manufacturing business, Ferguson’s new hydraulic version of the three-point linkage was first seen on his prototype ‘Ferguson Black’ or the ‘Irish tractor’ as he is believed to have called it.

Ferguson tractors

By May 1936, a production version of the Ferguson Black was introduced, which was to be manufactured under agreement by David Brown at Huddersfield factory in Yorkshire, England. Officially named the Ferguson Model A tractor, a total of 1,356 Model A’s were built under the Ferguson-Brown Company. By 1939, cash flow issues led Ferguson and David Brown to part company after Brown called for changes.

Following this, Ferguson struck an agreement with Henry Ford, who would produce the Ferguson tractor – now called the Ford-Ferguson 9N – fitted with the Ferguson System. The hitching system soon became popular among farmers all across the world.

This tractor was also fitted with a rear PTO that could now be used to power three-point linkage-mounted implements, setting the standard for future tractor developments.

As part of the agreement, it’s understood that the Ferguson tractor was also to be made in the UK at the Ford Ltd factory at Dagenham, Essex, but this did not happen. While US-built 9N tractors were imported into the UK, none were built at Dagenham.

As a consequence of the failure to build tractors at Dagenham, in December 1945, the Standard Motor Company announced that it would produce Ferguson’s tractors under agreement. Production started at Banner Lane in Coventry in England in 1946 and ran until 1956, 10 years after World War II.

The updated and improved 9N was now named the TE20. Annual production for the TE tractors exceeded 73,000 in 1951.

Henry Ford II, grandson of the original Henry Ford, ended the agreement with Ferguson in 1947, so Ferguson set up a factory in Detroit to make the TE20 in America under the new name TO20. Ford continued to produce tractors incorporating Ferguson’s invention.

The Ferguson TE20 was built at Banner Lane in Coventry from 1946 until 1956.

By 1952, Ferguson was in fourth place on the US market. He later filed a lawsuit against Ford demanding compensation for infringing patents and the case was settled out of court for $9m. At this point, the case had cost Ferguson about half this figure and ill health.

Ferguson’s patents had run out by 1952, meaning that all other world manufacturers could legally use Ferguson’s invention, which they did. A year later, Ferguson merged with Massey Harris to become Massey Harris Ferguson Co, before being simplified in 1958 to become Massey Ferguson, as we know it today.

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: