Tackling farm safety and machinery theft

Farm safety has become a critical issue on farms over the past number of years and University College Dublin (UCD) is developing a way to combat this.

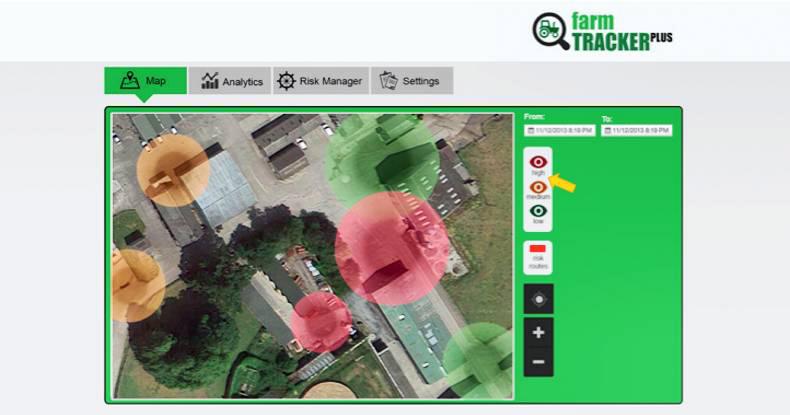

They are in the prototype stage of developing FarmTracker, which consists of a tractor cab unit and supporting units on all trailers and equipment, which would allow the farmer to keep track of all machinery, improving safety on the farm while also aiding in the elimination of machinery theft.

All persons entering the farm must then wear a SmartBand. This would allow people entering the farm to be tracked, which would be especially useful for children and the elderly, who are particularly at risk around the farmyard.

The idea is to have a zoned area on the farm, for example it could be an area around a slatted shed during agitating, and if the wristband wearer enters this area it will send a text message to an assigned number to alert them of the potential danger.

With heavy machinery constantly moving around the farm, it would ensure that children are monitored at all times to keep them out of danger.

High-risk areas can be identified and routes mapped to avoid risk zones.

A large team is responsible for developing this technology including CW Applied Technology and DELL Gateway, via their Internet of Things (IoT) facility in Limerick. The gateway will enable the creation of a network of sensor systems around a farmyard for safety and security. ActionPoint and Eir are also involved in the project.

Magnetic spraying

Irish weather will always mean difficulties when deciding when to spray crops, with strong winds often a reason to postpone spraying. UCD has been trialling a novel approach to reduce drift when spraying by combining magnets and sprayers.

Spray drift is the most common cause of off-target chemical movement. It can injure or damage plants, animals and the environment in the form of droplets, particles or vapour.

MagGrow is a patented magnetic spraying technology system for the horticulture and arable sectors of the agricultural industry.

Trials carried out by UCD have shown that the magnetic spraying technology system reduces drift by over 80% and enables better coverage and capacity with the same spraying equipment.

It can enable spraying to take place on days that would be deemed too windy for conventional sprayers, allowing greater flexibility for farmers when it comes to managing their crop.

The system is based upon the premise of fitting magnetic inserts to a sprayer, which imparts a magnetic charge into the sprayed liquid. All living things have a magnetic field and so the magnetically charged liquid is attracted to its target.

The drift control that is provided by the system means that plants can be sprayed using fine droplets, thus delivering enhanced coverage.

The technology can be easily fitted to new or existing spray equipment, including crop sprayers, greenhouse gantry sprayers, aerial sprayers, air blast sprayers and centre-pivot irrigation systems, which can make it a viable option for many farmers.

Trials are being carried out in Ireland on drift studies, plant performance studies and yield implications by UCD and MagGrow. The company was awarded a certificate of merit for environmental innovation at LAMMA 2016, the UK’s flagship agricultural trade show.

Field compaction

Soil compaction is one of the major problems facing modern agriculture. Overuse of heavy machinery, intensive cropping, short crop rotations, intensive grazing and inappropriate soil management are all leading to compaction of our soil.

Soil compaction increases soil strength (bulk density) and decreases soil physical fertility through decreasing storage and supply of water and nutrients. This leads to additional fertiliser requirement by the crop, which in turn increases production cost, which all lead to decreased profitability for farmers.

Wet soils are more vulnerable to compaction. However, soil type is also a key factor.

A penetrometer is an instrument used for determining the consistency or hardness of a substance by measuring the depth and rate of penetration.

However, it is a slow and laborious method of determining compaction with many samples having to be taken.

When a penetrometer was used to measure soil penetration resistance, it was found that the ability of plant roots to penetrate soil is restricted as soil strength increases.

Recent advances in non-destructive sensors have enabled the use of field spectrophotometers to measure the moisture content of the soil.

This is combined with a subsoiler point on the linkage of a tractor to measure the resistance of the soil with the use of strain gauges.

This can allow a field to be mapped in a couple of hours and give you an accurate picture of the compaction of your field.

UCD has been carrying this out on stubble after harvesting to give the most accurate information on compaction in the field, as compaction would have occurred from seeding, spraying, fertiliser application and harvesting of the crop, with bale collection also perhaps occurring.

The use of this technology would allow a farmer to map a field to assess exactly where deep cultivation would be required, or if it would be required at all.

This will allow a field to be optimised for production based on soil properties, and hence a field can be more easily mapped for subsequent treatment or management.

It could lead to substantial financial and time savings for farmers, as it would allow them to see exactly which parts of the field may require deeper cultivation.

Spectral cameras on drones

Another developing technology is the use of spectral cameras on drones. These are cameras that would be able to detect not just visible light, but all wavelengths of light, such as infrared and UV light.

Drones are flown at 50m to collect spectral fingerprints of crops or grasses to predict disease or nutrient stress in plants. This will allow crop management decisions to be developed faster, as the spectral imaging will potentially identify stress before the eye can detect it.

It would be possible to show leaves that are stressed. However, the current ongoing work is to differentiate between stresses caused by wind chill or by moisture and those caused by disease.

This technology has the potential to identify diseases before they are visible to the naked eye, which could allow farmers to use a preventative spray rather than a curative spray.

Less chemicals would be used, which is beneficial for both crops and human health.

Read more

Full Agri Technology Focus Supplement

Tackling farm safety and machinery theft

Farm safety has become a critical issue on farms over the past number of years and University College Dublin (UCD) is developing a way to combat this.

They are in the prototype stage of developing FarmTracker, which consists of a tractor cab unit and supporting units on all trailers and equipment, which would allow the farmer to keep track of all machinery, improving safety on the farm while also aiding in the elimination of machinery theft.

All persons entering the farm must then wear a SmartBand. This would allow people entering the farm to be tracked, which would be especially useful for children and the elderly, who are particularly at risk around the farmyard.

The idea is to have a zoned area on the farm, for example it could be an area around a slatted shed during agitating, and if the wristband wearer enters this area it will send a text message to an assigned number to alert them of the potential danger.

With heavy machinery constantly moving around the farm, it would ensure that children are monitored at all times to keep them out of danger.

High-risk areas can be identified and routes mapped to avoid risk zones.

A large team is responsible for developing this technology including CW Applied Technology and DELL Gateway, via their Internet of Things (IoT) facility in Limerick. The gateway will enable the creation of a network of sensor systems around a farmyard for safety and security. ActionPoint and Eir are also involved in the project.

Magnetic spraying

Irish weather will always mean difficulties when deciding when to spray crops, with strong winds often a reason to postpone spraying. UCD has been trialling a novel approach to reduce drift when spraying by combining magnets and sprayers.

Spray drift is the most common cause of off-target chemical movement. It can injure or damage plants, animals and the environment in the form of droplets, particles or vapour.

MagGrow is a patented magnetic spraying technology system for the horticulture and arable sectors of the agricultural industry.

Trials carried out by UCD have shown that the magnetic spraying technology system reduces drift by over 80% and enables better coverage and capacity with the same spraying equipment.

It can enable spraying to take place on days that would be deemed too windy for conventional sprayers, allowing greater flexibility for farmers when it comes to managing their crop.

The system is based upon the premise of fitting magnetic inserts to a sprayer, which imparts a magnetic charge into the sprayed liquid. All living things have a magnetic field and so the magnetically charged liquid is attracted to its target.

The drift control that is provided by the system means that plants can be sprayed using fine droplets, thus delivering enhanced coverage.

The technology can be easily fitted to new or existing spray equipment, including crop sprayers, greenhouse gantry sprayers, aerial sprayers, air blast sprayers and centre-pivot irrigation systems, which can make it a viable option for many farmers.

Trials are being carried out in Ireland on drift studies, plant performance studies and yield implications by UCD and MagGrow. The company was awarded a certificate of merit for environmental innovation at LAMMA 2016, the UK’s flagship agricultural trade show.

Field compaction

Soil compaction is one of the major problems facing modern agriculture. Overuse of heavy machinery, intensive cropping, short crop rotations, intensive grazing and inappropriate soil management are all leading to compaction of our soil.

Soil compaction increases soil strength (bulk density) and decreases soil physical fertility through decreasing storage and supply of water and nutrients. This leads to additional fertiliser requirement by the crop, which in turn increases production cost, which all lead to decreased profitability for farmers.

Wet soils are more vulnerable to compaction. However, soil type is also a key factor.

A penetrometer is an instrument used for determining the consistency or hardness of a substance by measuring the depth and rate of penetration.

However, it is a slow and laborious method of determining compaction with many samples having to be taken.

When a penetrometer was used to measure soil penetration resistance, it was found that the ability of plant roots to penetrate soil is restricted as soil strength increases.

Recent advances in non-destructive sensors have enabled the use of field spectrophotometers to measure the moisture content of the soil.

This is combined with a subsoiler point on the linkage of a tractor to measure the resistance of the soil with the use of strain gauges.

This can allow a field to be mapped in a couple of hours and give you an accurate picture of the compaction of your field.

UCD has been carrying this out on stubble after harvesting to give the most accurate information on compaction in the field, as compaction would have occurred from seeding, spraying, fertiliser application and harvesting of the crop, with bale collection also perhaps occurring.

The use of this technology would allow a farmer to map a field to assess exactly where deep cultivation would be required, or if it would be required at all.

This will allow a field to be optimised for production based on soil properties, and hence a field can be more easily mapped for subsequent treatment or management.

It could lead to substantial financial and time savings for farmers, as it would allow them to see exactly which parts of the field may require deeper cultivation.

Spectral cameras on drones

Another developing technology is the use of spectral cameras on drones. These are cameras that would be able to detect not just visible light, but all wavelengths of light, such as infrared and UV light.

Drones are flown at 50m to collect spectral fingerprints of crops or grasses to predict disease or nutrient stress in plants. This will allow crop management decisions to be developed faster, as the spectral imaging will potentially identify stress before the eye can detect it.

It would be possible to show leaves that are stressed. However, the current ongoing work is to differentiate between stresses caused by wind chill or by moisture and those caused by disease.

This technology has the potential to identify diseases before they are visible to the naked eye, which could allow farmers to use a preventative spray rather than a curative spray.

Less chemicals would be used, which is beneficial for both crops and human health.

Read more

Full Agri Technology Focus Supplement

SHARING OPTIONS