When news broke in early 2023 that the hugely popular dribble bar had been omitted from the list of eligible items under the TAMS III Low Emissions Slurry Spreading (LESS) scheme in favour of the more complex trailing shoe and shallow injection attachments, manufacturers and farmers alike were left equally as discontent.

For a period, it looked like all grant eligible farmers including those in more challenging regions less suited to LESS given the topography of the land, would only be grant aided to fit heavier, more complex trailing shoe systems.

These being areas where 100hp tractors and 1,300-1,800 gallon tankers are the norm, often working on hilly or marginal land – better suited to the dribble bar.

Farmers who were sceptical about the viability of LESS on their farm were soon put at ease with the arrival of the flexible trailing shoe alternative.

A hybrid solution

Cavan slurry equipment manufacturer Mastek promptly devloped a solution to overcome what many believed were limitations of the conventional trailing shoe.

Nestled in the midlands amid some of the areas most effected by the change, Mastek knew too well the extent of the challenges faced by farmers including the limitations of the traditional trailing shoe.

Soon after, Mastek publically presented what it called the FlexiShoe, essentially a hybrid between a rigid trailing shoe and dribble bar. It combined all the features of a dribble bar but with the addition of a steel coulter and rubber boot to split the grass canopy and deposit the slurry onto the surface.

The main difference compared to a trailing shoe is the absence of the steel spring and additional steelwork needed to provide downward force on the coulters.

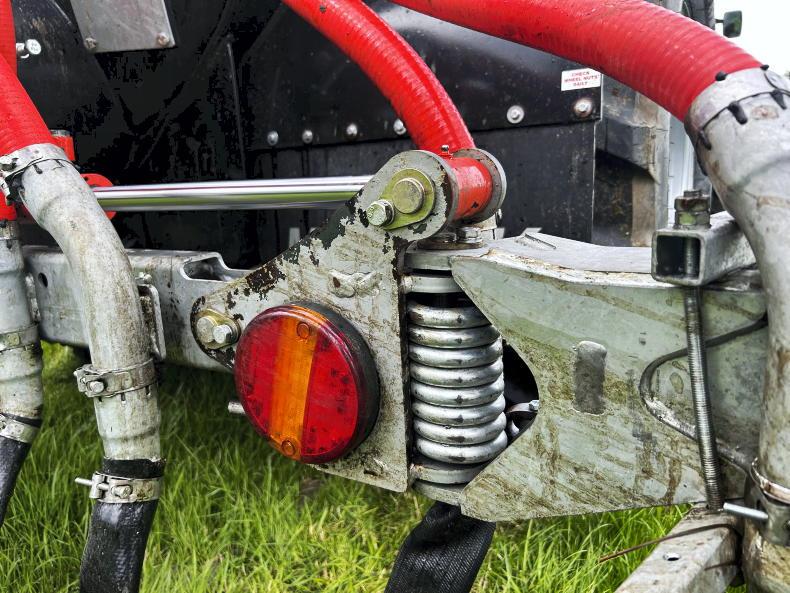

(1) Both booms are protected with a sprung break back system.

After Mastek debuted its FlexiShoe, which met the criteria outlined by the Department of Agriculture deeming it grant eligible, other manufacturers came forward with their own spin on the hybrid style LESS applicator. To date, Mastek has in the region of 130 units sold and working.

Earlier in the season, Mastek provided us with the opportunity to try out its 7.6m FlexiShoe fitted to a Mastek 1,600 gallon tanker, a well matched duo.

FlexiShoe range

The Mastek standard FlexiShoe range currently includes five models, 7.6m, 8m, 8m (double fold), 9.2m (double fold), 10.2m (double fold) and 12.5m (double fold).

Meanwhile, a heavier duty 10m and 12m model are offered and are available for slurry tanker mounting or umbilical use.

The 7.6m model is available chassis or rear door mounted, the latter in its lightest form weighing 480kg, which is marginally more than a dribble bar of the equivalent working width. Transport height is 3.5m and transport width is 2.7m. Optional equipment includes three point linkage mounting, and a flow meter.

Its design is very similar to Mastek’s Professional Universal Dribble Bar (PUDB) of which units are working in their thousands across the globe. Albeit there are some slight tweaks.

As with the entire Mastek range, all design and fabrication takes place in house in Cootehill, Co Cavan.

Build

Both outer wings and the central piece are formed from a rectangular box section in order to keep weight to a minimum and strength as high as possible.

The very outer ends on each side are further hollowed, again to minimise weight. All steel components are galvanised as standard. A total of 28 brackets evenly spaced at 27cm hold on to the individual outlet hoses.

Unlike most trailing shoes, the FlexiShoe features a mechanical hinged break back protection system. Mastek’s design incorporates an 18mm coil spring which returns back to its working position once tripped.

It can be seen from the design that Mastek has focused on maximising strength within this particular area and around all hinge points through the use of additional steel plating and gussets. All pivots are pinned and bushed with easy to access grease points which we like to see.

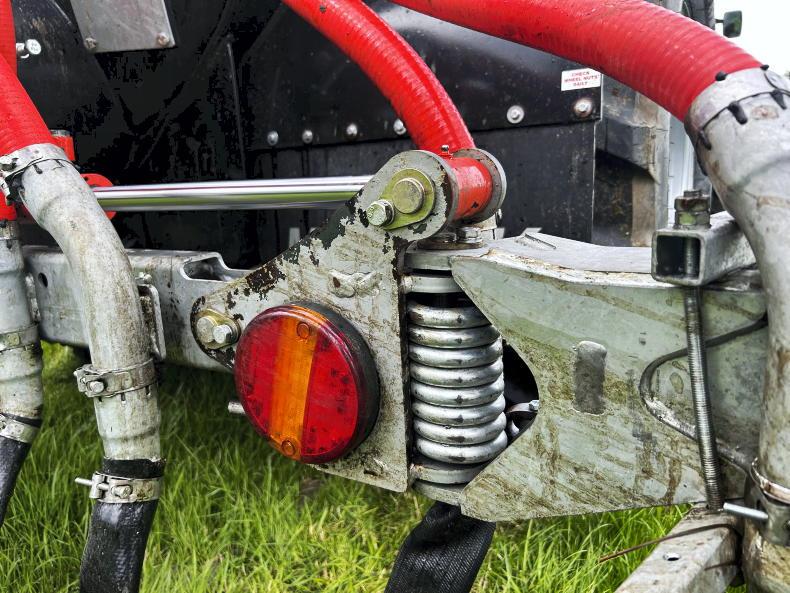

(2) The SuperCut 2 macerator is a key selling point on all Mastek LESS aplicators.

Folding of the outer booms is done using two hydraulic cylinders, positioned along the main frame and out of harm’s way. Both rams are protected with check valves to prevent the booms dropping out of transport positon in an event oil pressure is lost.

Being the smaller 7.6m model, our test unit was mounted via the slurry tanker’s rear door, the lighter and more cost effective option for tankers not fitted with brackets. Door and chassis mounting is an option across all models, aside from the heavier duty 10m and 12m machines.

As expected, we had no issues with the rear door mount, especially given the fact it was on a modern tanker that was designed to bear such weight.

The only minor downside was the distance between the FlexiShoe and the rear of the tanker. Could it have been designed to sit a little bit closer to the rear of the tanker? On the flip side, it leaves access to the macerator easy from all angles.

SuperCut 2 Gen 2 macerator

At the heart of all Mastek’s LESS applicators is its patented SuperCut Gen 2 macerator. Features of which include easy access, 2.5m of serrated cutting surface area, double sided internal screens with various hole size options to increase or decrease slurry flow. The macerator is powered using a high torque hydraulic motor, which Mastek states has a hydraulic flow requirement of 35l/min.

As with its PUDB range, Mastek uses 45mm diameter distribution hoses to deliver slurry from the macerator to each of the 28 outlets. The hoses are clamped into the booms using hose clamps.

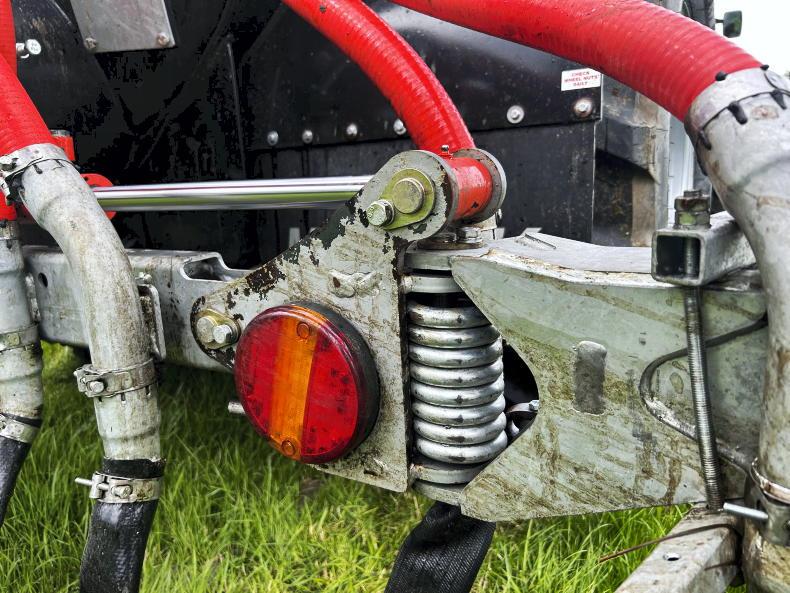

(3) The diverter valve allows the operator to switch between sending oil to the macerator or the booms.

The outlet side is where things differ from the PUDB. Instead of a straight drop, the brackets have a lower sweeping bend on the outlet side to allow the 50mm polyurethane (PU) hose to trail without restricting slurry flow.

Each hose is fitted with a rubber boot and coulter assembly, identical to what is found on a conventional trailing shoe. The boot and coulter provide enough weight to seperate the grass canopy.

Transport

Once raised into transport position, the PU hoses on the outer booms hang down on themselves and prevent any slurry residue from dripping out. Meanwhile, the central eight outlets are held rigid using a length of tubular box steel.

Chains at either end connected to the outer booms simultaneously raise and lower the central boots and coulters in and out of working/transport position.

Again, once folded the design sees the hoses kink to prevent any slurry residue from leaking out. As standard, all applicators come with the option of fitting two rear fill points.

Both are angled for better access. As standard an upper and lower set of LED tailights are integrated into the design.

In the field

Controls are straightforward. Two double acting spools and a 12v power supply is all that is required to work the raising/lowering of the booms, macerator and gate valve.

A solenoid operated diverter valve switches between the booms and the macerator, while the second service is dedicated to the opening/closing of the gate valve.

The reasoning for having the macerator and booms on the one spool is to prevent the macerator running dry during transport. The simple valve block and solenoid is mounted on the outer side of the central bar below the tanker barrel. Again, access is easy for the purpose of maintenance.

(4) A simple switch operated solenoid valve allows two hydraulic services to be used via the one double acting spool.

Like the dribble bar, the glory of the FlexiShoe is if the tractor happens to roll back or the operator reverses without raising the applicator, then no damage can be done. Instead, the PU hoses kink and the shoes lie over.

Having lost traction on a hilly surface causing the tractor to roll back slightly, we wondered what the outcome would have been if it was a trailing shoe? Would the downwards force on the coulters have resulted in bent springs?

After spreading on a mix of terrain, we found that in hollows and on certain slopes where the boom doesn’t run exactly parallel to the surface, the trailing PU go from a state of tension to compression and need all their rigidity to remain open.

Given that the macerator and boom are worked off the same spool (for good reason), it’s not as straightforward as pulling the spool and raising the boom on the fly.

In the event that the splashplate needs to be used, it can be done by swapping one quick release hose from the macerator inlet gate valve to the splashplate gate valve.

The 7.6m unit folds to 3.5m high and 2.7m wide.

During our time spent with the Mastek 1,600 gallon tanker and 7.6m FlexiShoe, we had it coupled with a New Holland TM 130 which most would consider a good match. The tanker pulled exceptionally well in all scenarios, empty and full.

Although correct slurry consistency is key with all LESS systems, it is especially the case with the Flexi-Shoe given the additional bend and narrower outlet on the rubber boot. Macerator performance and access couldn’t be faulted. The stone trap which opens in a similar manner was also easily accessed.

The FlexiShoe does what it is designed to do and is the best solution for those in areas not really suited towards conventional trailing shoes but yet still wanting to avail of TAMS grant aid. However, in ideal conditions and as expected, a fully-fledged trailing shoe would have the edge in terms of providing a more precise placement of slurry.

Personally, we would opt for an 8m double folding or 9.2m unit on tankers over 1,800 gallon in order to avoid speeds of 10km/h when applying rates as low as 1,500 gallons/ac. Another benefit of the double fold is the lower transport height, reducing the risk of damage.

Model: FlexiShoe. Working width: 7.6m.Transport width: 2.7m.Transport height: 3.5m. Mounting method: Rear door. No of outlets: 28.Weight: 480kg. Price: €18,000-€32,000 Inc VAT. (depending on working width)

Like all Mastek's dribble bars and trailing shoes, they are well designed and well built.

Two rear fill points can be fitted.

An easy access stone trap is built in as standard.

Across the 7.6m workign width there are 28 outlets.

In hollows, the layflat hose can kink and close if the boom is lowered to tis limit.

The FlexiShoe is effective at splitting the grass canopy.

The 7.6m FlexiShoe has 28 outlets.

When news broke in early 2023 that the hugely popular dribble bar had been omitted from the list of eligible items under the TAMS III Low Emissions Slurry Spreading (LESS) scheme in favour of the more complex trailing shoe and shallow injection attachments, manufacturers and farmers alike were left equally as discontent.

For a period, it looked like all grant eligible farmers including those in more challenging regions less suited to LESS given the topography of the land, would only be grant aided to fit heavier, more complex trailing shoe systems.

These being areas where 100hp tractors and 1,300-1,800 gallon tankers are the norm, often working on hilly or marginal land – better suited to the dribble bar.

Farmers who were sceptical about the viability of LESS on their farm were soon put at ease with the arrival of the flexible trailing shoe alternative.

A hybrid solution

Cavan slurry equipment manufacturer Mastek promptly devloped a solution to overcome what many believed were limitations of the conventional trailing shoe.

Nestled in the midlands amid some of the areas most effected by the change, Mastek knew too well the extent of the challenges faced by farmers including the limitations of the traditional trailing shoe.

Soon after, Mastek publically presented what it called the FlexiShoe, essentially a hybrid between a rigid trailing shoe and dribble bar. It combined all the features of a dribble bar but with the addition of a steel coulter and rubber boot to split the grass canopy and deposit the slurry onto the surface.

The main difference compared to a trailing shoe is the absence of the steel spring and additional steelwork needed to provide downward force on the coulters.

(1) Both booms are protected with a sprung break back system.

After Mastek debuted its FlexiShoe, which met the criteria outlined by the Department of Agriculture deeming it grant eligible, other manufacturers came forward with their own spin on the hybrid style LESS applicator. To date, Mastek has in the region of 130 units sold and working.

Earlier in the season, Mastek provided us with the opportunity to try out its 7.6m FlexiShoe fitted to a Mastek 1,600 gallon tanker, a well matched duo.

FlexiShoe range

The Mastek standard FlexiShoe range currently includes five models, 7.6m, 8m, 8m (double fold), 9.2m (double fold), 10.2m (double fold) and 12.5m (double fold).

Meanwhile, a heavier duty 10m and 12m model are offered and are available for slurry tanker mounting or umbilical use.

The 7.6m model is available chassis or rear door mounted, the latter in its lightest form weighing 480kg, which is marginally more than a dribble bar of the equivalent working width. Transport height is 3.5m and transport width is 2.7m. Optional equipment includes three point linkage mounting, and a flow meter.

Its design is very similar to Mastek’s Professional Universal Dribble Bar (PUDB) of which units are working in their thousands across the globe. Albeit there are some slight tweaks.

As with the entire Mastek range, all design and fabrication takes place in house in Cootehill, Co Cavan.

Build

Both outer wings and the central piece are formed from a rectangular box section in order to keep weight to a minimum and strength as high as possible.

The very outer ends on each side are further hollowed, again to minimise weight. All steel components are galvanised as standard. A total of 28 brackets evenly spaced at 27cm hold on to the individual outlet hoses.

Unlike most trailing shoes, the FlexiShoe features a mechanical hinged break back protection system. Mastek’s design incorporates an 18mm coil spring which returns back to its working position once tripped.

It can be seen from the design that Mastek has focused on maximising strength within this particular area and around all hinge points through the use of additional steel plating and gussets. All pivots are pinned and bushed with easy to access grease points which we like to see.

(2) The SuperCut 2 macerator is a key selling point on all Mastek LESS aplicators.

Folding of the outer booms is done using two hydraulic cylinders, positioned along the main frame and out of harm’s way. Both rams are protected with check valves to prevent the booms dropping out of transport positon in an event oil pressure is lost.

Being the smaller 7.6m model, our test unit was mounted via the slurry tanker’s rear door, the lighter and more cost effective option for tankers not fitted with brackets. Door and chassis mounting is an option across all models, aside from the heavier duty 10m and 12m machines.

As expected, we had no issues with the rear door mount, especially given the fact it was on a modern tanker that was designed to bear such weight.

The only minor downside was the distance between the FlexiShoe and the rear of the tanker. Could it have been designed to sit a little bit closer to the rear of the tanker? On the flip side, it leaves access to the macerator easy from all angles.

SuperCut 2 Gen 2 macerator

At the heart of all Mastek’s LESS applicators is its patented SuperCut Gen 2 macerator. Features of which include easy access, 2.5m of serrated cutting surface area, double sided internal screens with various hole size options to increase or decrease slurry flow. The macerator is powered using a high torque hydraulic motor, which Mastek states has a hydraulic flow requirement of 35l/min.

As with its PUDB range, Mastek uses 45mm diameter distribution hoses to deliver slurry from the macerator to each of the 28 outlets. The hoses are clamped into the booms using hose clamps.

(3) The diverter valve allows the operator to switch between sending oil to the macerator or the booms.

The outlet side is where things differ from the PUDB. Instead of a straight drop, the brackets have a lower sweeping bend on the outlet side to allow the 50mm polyurethane (PU) hose to trail without restricting slurry flow.

Each hose is fitted with a rubber boot and coulter assembly, identical to what is found on a conventional trailing shoe. The boot and coulter provide enough weight to seperate the grass canopy.

Transport

Once raised into transport position, the PU hoses on the outer booms hang down on themselves and prevent any slurry residue from dripping out. Meanwhile, the central eight outlets are held rigid using a length of tubular box steel.

Chains at either end connected to the outer booms simultaneously raise and lower the central boots and coulters in and out of working/transport position.

Again, once folded the design sees the hoses kink to prevent any slurry residue from leaking out. As standard, all applicators come with the option of fitting two rear fill points.

Both are angled for better access. As standard an upper and lower set of LED tailights are integrated into the design.

In the field

Controls are straightforward. Two double acting spools and a 12v power supply is all that is required to work the raising/lowering of the booms, macerator and gate valve.

A solenoid operated diverter valve switches between the booms and the macerator, while the second service is dedicated to the opening/closing of the gate valve.

The reasoning for having the macerator and booms on the one spool is to prevent the macerator running dry during transport. The simple valve block and solenoid is mounted on the outer side of the central bar below the tanker barrel. Again, access is easy for the purpose of maintenance.

(4) A simple switch operated solenoid valve allows two hydraulic services to be used via the one double acting spool.

Like the dribble bar, the glory of the FlexiShoe is if the tractor happens to roll back or the operator reverses without raising the applicator, then no damage can be done. Instead, the PU hoses kink and the shoes lie over.

Having lost traction on a hilly surface causing the tractor to roll back slightly, we wondered what the outcome would have been if it was a trailing shoe? Would the downwards force on the coulters have resulted in bent springs?

After spreading on a mix of terrain, we found that in hollows and on certain slopes where the boom doesn’t run exactly parallel to the surface, the trailing PU go from a state of tension to compression and need all their rigidity to remain open.

Given that the macerator and boom are worked off the same spool (for good reason), it’s not as straightforward as pulling the spool and raising the boom on the fly.

In the event that the splashplate needs to be used, it can be done by swapping one quick release hose from the macerator inlet gate valve to the splashplate gate valve.

The 7.6m unit folds to 3.5m high and 2.7m wide.

During our time spent with the Mastek 1,600 gallon tanker and 7.6m FlexiShoe, we had it coupled with a New Holland TM 130 which most would consider a good match. The tanker pulled exceptionally well in all scenarios, empty and full.

Although correct slurry consistency is key with all LESS systems, it is especially the case with the Flexi-Shoe given the additional bend and narrower outlet on the rubber boot. Macerator performance and access couldn’t be faulted. The stone trap which opens in a similar manner was also easily accessed.

The FlexiShoe does what it is designed to do and is the best solution for those in areas not really suited towards conventional trailing shoes but yet still wanting to avail of TAMS grant aid. However, in ideal conditions and as expected, a fully-fledged trailing shoe would have the edge in terms of providing a more precise placement of slurry.

Personally, we would opt for an 8m double folding or 9.2m unit on tankers over 1,800 gallon in order to avoid speeds of 10km/h when applying rates as low as 1,500 gallons/ac. Another benefit of the double fold is the lower transport height, reducing the risk of damage.

Model: FlexiShoe. Working width: 7.6m.Transport width: 2.7m.Transport height: 3.5m. Mounting method: Rear door. No of outlets: 28.Weight: 480kg. Price: €18,000-€32,000 Inc VAT. (depending on working width)

Like all Mastek's dribble bars and trailing shoes, they are well designed and well built.

Two rear fill points can be fitted.

An easy access stone trap is built in as standard.

Across the 7.6m workign width there are 28 outlets.

In hollows, the layflat hose can kink and close if the boom is lowered to tis limit.

The FlexiShoe is effective at splitting the grass canopy.

The 7.6m FlexiShoe has 28 outlets.

SHARING OPTIONS