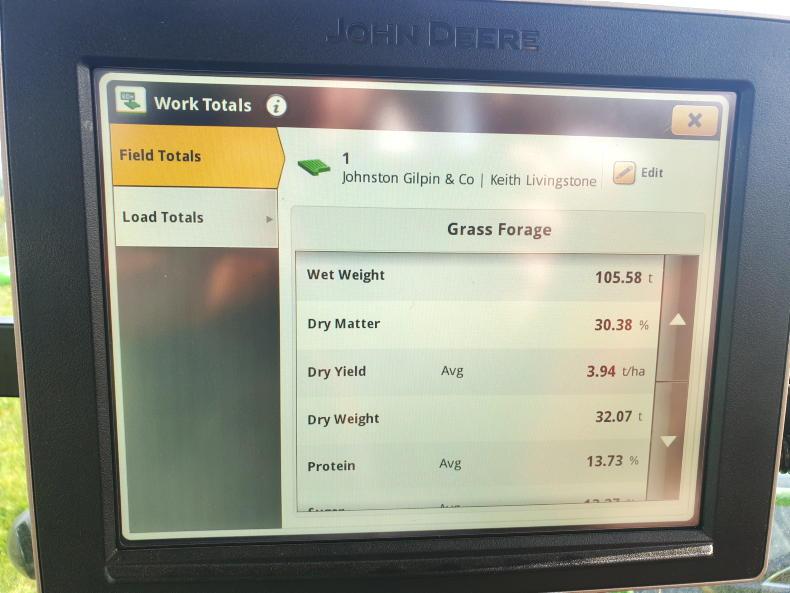

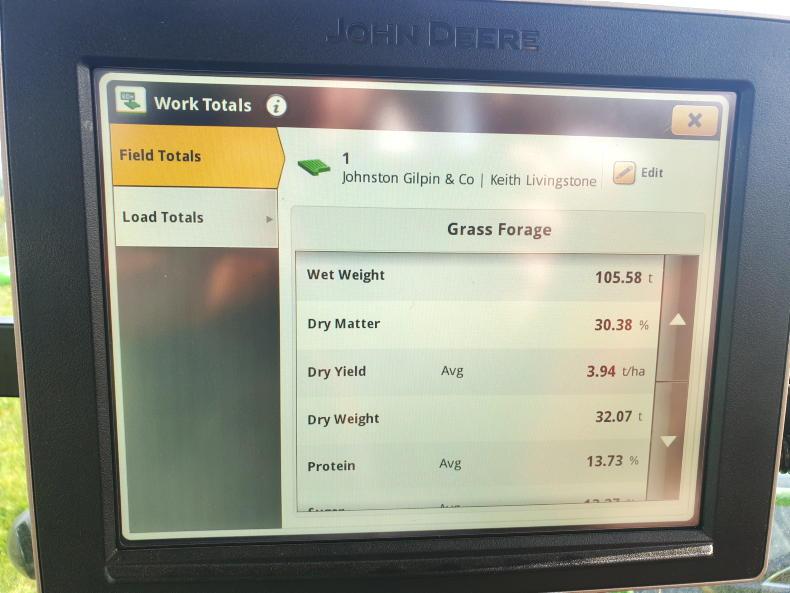

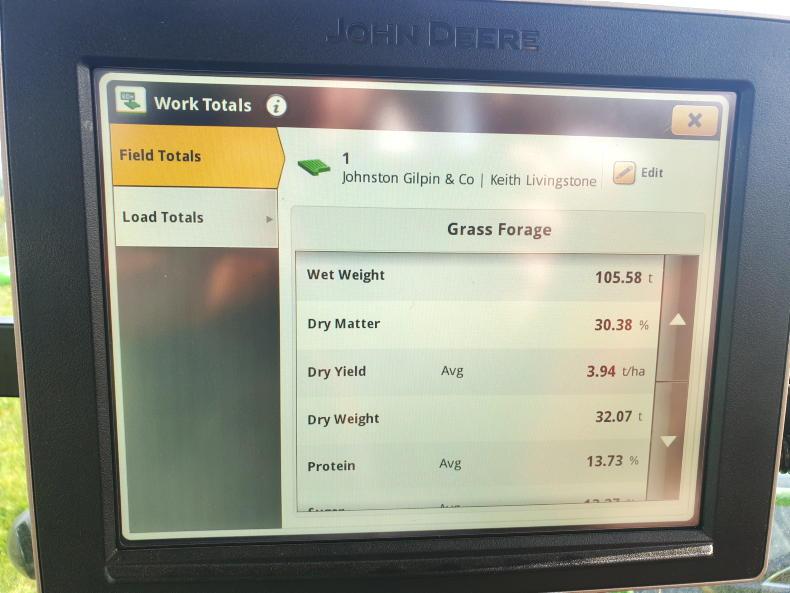

Precision agriculture tools, along with fleet management, allow agricultural machinery to not only harvest crops, but also gather real-time data to give a very accurate insight into a machine’s true performance – and potentially a field’s true yield, along with DMD, crude protein and sugar content.

Allowing users to remotely connect to their machines helps with performance and better planning.

Shorter weather windows, large capital investment and lack of labour mean farmers are often reliant on contractors for certain work, like silage and grain harvesting tasks and, on some farms, they may perform nearly all machinery-related work.

John Deere, famous for its green tractors and harvesting equipment is at the forefront in precision agriculture and telematics, a system that allows John Deere equipment (like tractors, combines, and other machinery) to collect and transmit data to a central platform, like a phone app or dealer centre.

This then helps farmers, contractors and dealers track the performance remotely of their machines in real-time, monitor their location and ensure everything is running smoothly.

The contractor’s opinion

Liam Whyte is an agricultural contractor based in Shinrone, Co Offaly. He has guidance systems, Isobus and John Deere’s fleet management, on his John Deere 6155R, 6215R and fleet management on his John Deere 8500i self-propelled forage harvester.

Liam has dealt with Templetuohy Farm Machinery (TFM) for a good few years and is absolutely delighted with the service.

“I’m genuinely delighted with the John Deere fleet management and the guidance system. To be perfectly honest, I don’t see it as a cost anymore, the technology on the machine is a saving to me now.”

Liam gives examples and says during silage it’s obviously a very busy time with a lot of organising going on.

“I load the silage myself and I can monitor off the phone the diesel level of the harvester from the pit. I don’t fill diesel from a fuel bowser, but a truck comes every day to the different farmers’ yards we are working out of.”

He explains how he can organise the time the truck needs to come, what machine needs diesel more urgently and where each machine is for the truck driver to fill via GPS. It’s a simple thing, but it takes pressure off and keeps us moving when we need to be. Liam says the telematics on the John Deeres don’t just help with maintenance, but it’s the predictive maintenance now, which is super impressive.

“Last year, just before a busy bank holiday weekend, the silage harvester took a sudden dip in power and TFM picked up an error code straight away and it looked like a turbo issue. To be on the safe side, they ordered up a turbo as they knew we would be under pressure that weekend and couldn’t afford to be stopped.

“We kept going as the machine just worked away and there were no other issues with it afterwards, and once it started raining and we got a chance to stop, they properly investigated it.

“This gives me great peace of mind that my equipment and its in-field performance is being monitored remotely, to make sure it’s working at its optimum and parts are available if ever needed.”

Liam can also watch drivers working from his yard, to see how they are doing when the tractors are out spreading fertiliser or sowing corn, for example. He can see the output, idle times, fuel usage, Ad Blue levels and much more. It helps him plan, as he can contact farmers and tell them when they will be on and helps with efficiency gains, such as laying out fields optimally.

“You just scribe an A/B line and work your widths off that, it really is that simple to use once it’s set up.”

Another interesting point he mentions is how much fresher you feel after a long day’s work getting off the tractor, as it lets you relax more and you don’t have to concentrate or focus as intensely. This he says takes the strain out of the long days on both him and the other drivers.

“It helps keep you more alert during busy harvest periods and no doubt this helps with farm safety overall.”

When Liam is pushed on other technologies, such as John Deere’s Harvest Lab, the remote crop-sensing tool that analyses crop nutrients in real time, he says it’s the future.

“It’s a brilliant piece of technology, but a serious cost and Government support is needed more to help all stakeholders in meeting the emissions targets coming from Europe, we simply can’t justify paying out continuously for everything, we operate a business at the end of the day and need to cover our overheads.

“This data could be very valuable to farmers here in Ireland in numerous ways for record keeping and better farm management decisions by calculating the inputs of nutrients, versus the outputs in silage or tillage crops, along with soil analysis.”

The John Deere Harvest Lab NIR sensing system.

The farmer’s take

Nelius Irwin, along with his brother Peter and father Liam, are dairy farmers miliking 420 cows, based in Kilmeedy, Co Limerick.

Nelius runs a 2023 John Deere 6130M with guidance and Isobus. He openly says it’s easily been the best investment on the farm when asked about the technology.

“We are not machinery people to be honest, but our John Deere dealer advised us to be more open minded around technology, so we ordered the tractor with full GPS plus Isobus from the factory.”

He explains how the headland management feature is outstanding, along with section control and the savings it is making.

“Colin from Geary’s Garage helped us set it all up at the start and we simply couldn’t do without Isobus and the GPS section control for spreading now.”

Nelius got the TAMS grant for the fertiliser spreader. At the time, he wouldn’t have made the investment without grant aid, he said.

However, having witnessed the extent of which the spreader and technology have saved fertiliser, he is now of the opinion that the investment is still justified without grant aid based on the savings alone.

“We can now spread very accurately all the time and are never short fertiliser or waste time going back to the yard for a bag to finish off a field. We know when it’s done that it’s done right.”

Nelius feels the Department of Agriculture must now look at grant-aiding the agricultural contractors in Ireland for the other technologies available to help complete the nutrient cycle.

“We can record cow performance accurately on-farm and control the inputs precisely onto the land. What would be great is analysing the yield and quality in the field at silage time as well as slurry going out.

"If contractors were supported, then farmers would indirectly be supported with invaluable information through the service they provide back to us.”

Most farmers are not realistically able to own large silage harvesters or combines for several reasons and cost is the main reason.

Farmers simply don’t have the financial resources, the knowledge, time or labour, so they are very reliant on their local agricultural contractors for this service. He agrees they are the missing piece of the puzzle in many cases to help take Irish agriculture forward.

“That sure would allow us to further improve on utilising yield mapping and targeting inputs more accurately going forward.”

All GPS systems require a receiver and display screen.

The machinery dealer’s view

Johnny Corkery from Geary’s Garage in Co Limerick believes there are very clear advantages to all this technology.

“Obviously, we can remotely connect to the tractor without leaving the yard here. That gives the lads in service a serious headstart for diagnosing issues. Sometimes the issue can be solved by an update or something simple and we just log in to the customer’s screen and the necessary adjustments are made or software updated.

"If that doesn’t work, we can analyse error codes and zone into a particular sensor or whatever. The lads in the workshop can load anything they feel necessary into the van and are prepared even before they arrive to the farmer and pop up the bonnet.”

He highlights when it comes to selling second-hand equipment, good data potentially gives a true breakdown of the machine’s history, if that’s what is desired.

Johnny gives an example of a seven-year-old tractor with 6,500 hours which might seem high to someone scrolling DoneDeal, but he explains by analysing the data here the tractor could be reasonably fresh.

“When tractors are properly analysed, we find 10% of the hours logged might be at idle, 50% of those hours when examined might be at about 20-25% engine load, like doing loader work or raking silage, then another 30% at around 50% engine load or thereabouts. The remaining 10% then may be averaging around 80% engine load.”

Johnny also feels that contractors here do need more consideration with funding from the Government for technology, as Irish farms and stocking rates, along with the wetter climate, make us an outlier in Europe.

In essence, he explains, it’s all about using technology to make farming more efficient and environmentally friendly, helping reduce costs and increase productivity, there is no point in having it but not using it.

Precision agriculture tools such as NIR crop sensing gathers valuable data surrounding crop yield and quality.

*Fergal O’Sullivan, is an agricultural engineering lecturer at Munster Technological University.

Precision agriculture tools, along with fleet management, allow agricultural machinery to not only harvest crops, but also gather real-time data to give a very accurate insight into a machine’s true performance – and potentially a field’s true yield, along with DMD, crude protein and sugar content.

Allowing users to remotely connect to their machines helps with performance and better planning.

Shorter weather windows, large capital investment and lack of labour mean farmers are often reliant on contractors for certain work, like silage and grain harvesting tasks and, on some farms, they may perform nearly all machinery-related work.

John Deere, famous for its green tractors and harvesting equipment is at the forefront in precision agriculture and telematics, a system that allows John Deere equipment (like tractors, combines, and other machinery) to collect and transmit data to a central platform, like a phone app or dealer centre.

This then helps farmers, contractors and dealers track the performance remotely of their machines in real-time, monitor their location and ensure everything is running smoothly.

The contractor’s opinion

Liam Whyte is an agricultural contractor based in Shinrone, Co Offaly. He has guidance systems, Isobus and John Deere’s fleet management, on his John Deere 6155R, 6215R and fleet management on his John Deere 8500i self-propelled forage harvester.

Liam has dealt with Templetuohy Farm Machinery (TFM) for a good few years and is absolutely delighted with the service.

“I’m genuinely delighted with the John Deere fleet management and the guidance system. To be perfectly honest, I don’t see it as a cost anymore, the technology on the machine is a saving to me now.”

Liam gives examples and says during silage it’s obviously a very busy time with a lot of organising going on.

“I load the silage myself and I can monitor off the phone the diesel level of the harvester from the pit. I don’t fill diesel from a fuel bowser, but a truck comes every day to the different farmers’ yards we are working out of.”

He explains how he can organise the time the truck needs to come, what machine needs diesel more urgently and where each machine is for the truck driver to fill via GPS. It’s a simple thing, but it takes pressure off and keeps us moving when we need to be. Liam says the telematics on the John Deeres don’t just help with maintenance, but it’s the predictive maintenance now, which is super impressive.

“Last year, just before a busy bank holiday weekend, the silage harvester took a sudden dip in power and TFM picked up an error code straight away and it looked like a turbo issue. To be on the safe side, they ordered up a turbo as they knew we would be under pressure that weekend and couldn’t afford to be stopped.

“We kept going as the machine just worked away and there were no other issues with it afterwards, and once it started raining and we got a chance to stop, they properly investigated it.

“This gives me great peace of mind that my equipment and its in-field performance is being monitored remotely, to make sure it’s working at its optimum and parts are available if ever needed.”

Liam can also watch drivers working from his yard, to see how they are doing when the tractors are out spreading fertiliser or sowing corn, for example. He can see the output, idle times, fuel usage, Ad Blue levels and much more. It helps him plan, as he can contact farmers and tell them when they will be on and helps with efficiency gains, such as laying out fields optimally.

“You just scribe an A/B line and work your widths off that, it really is that simple to use once it’s set up.”

Another interesting point he mentions is how much fresher you feel after a long day’s work getting off the tractor, as it lets you relax more and you don’t have to concentrate or focus as intensely. This he says takes the strain out of the long days on both him and the other drivers.

“It helps keep you more alert during busy harvest periods and no doubt this helps with farm safety overall.”

When Liam is pushed on other technologies, such as John Deere’s Harvest Lab, the remote crop-sensing tool that analyses crop nutrients in real time, he says it’s the future.

“It’s a brilliant piece of technology, but a serious cost and Government support is needed more to help all stakeholders in meeting the emissions targets coming from Europe, we simply can’t justify paying out continuously for everything, we operate a business at the end of the day and need to cover our overheads.

“This data could be very valuable to farmers here in Ireland in numerous ways for record keeping and better farm management decisions by calculating the inputs of nutrients, versus the outputs in silage or tillage crops, along with soil analysis.”

The John Deere Harvest Lab NIR sensing system.

The farmer’s take

Nelius Irwin, along with his brother Peter and father Liam, are dairy farmers miliking 420 cows, based in Kilmeedy, Co Limerick.

Nelius runs a 2023 John Deere 6130M with guidance and Isobus. He openly says it’s easily been the best investment on the farm when asked about the technology.

“We are not machinery people to be honest, but our John Deere dealer advised us to be more open minded around technology, so we ordered the tractor with full GPS plus Isobus from the factory.”

He explains how the headland management feature is outstanding, along with section control and the savings it is making.

“Colin from Geary’s Garage helped us set it all up at the start and we simply couldn’t do without Isobus and the GPS section control for spreading now.”

Nelius got the TAMS grant for the fertiliser spreader. At the time, he wouldn’t have made the investment without grant aid, he said.

However, having witnessed the extent of which the spreader and technology have saved fertiliser, he is now of the opinion that the investment is still justified without grant aid based on the savings alone.

“We can now spread very accurately all the time and are never short fertiliser or waste time going back to the yard for a bag to finish off a field. We know when it’s done that it’s done right.”

Nelius feels the Department of Agriculture must now look at grant-aiding the agricultural contractors in Ireland for the other technologies available to help complete the nutrient cycle.

“We can record cow performance accurately on-farm and control the inputs precisely onto the land. What would be great is analysing the yield and quality in the field at silage time as well as slurry going out.

"If contractors were supported, then farmers would indirectly be supported with invaluable information through the service they provide back to us.”

Most farmers are not realistically able to own large silage harvesters or combines for several reasons and cost is the main reason.

Farmers simply don’t have the financial resources, the knowledge, time or labour, so they are very reliant on their local agricultural contractors for this service. He agrees they are the missing piece of the puzzle in many cases to help take Irish agriculture forward.

“That sure would allow us to further improve on utilising yield mapping and targeting inputs more accurately going forward.”

All GPS systems require a receiver and display screen.

The machinery dealer’s view

Johnny Corkery from Geary’s Garage in Co Limerick believes there are very clear advantages to all this technology.

“Obviously, we can remotely connect to the tractor without leaving the yard here. That gives the lads in service a serious headstart for diagnosing issues. Sometimes the issue can be solved by an update or something simple and we just log in to the customer’s screen and the necessary adjustments are made or software updated.

"If that doesn’t work, we can analyse error codes and zone into a particular sensor or whatever. The lads in the workshop can load anything they feel necessary into the van and are prepared even before they arrive to the farmer and pop up the bonnet.”

He highlights when it comes to selling second-hand equipment, good data potentially gives a true breakdown of the machine’s history, if that’s what is desired.

Johnny gives an example of a seven-year-old tractor with 6,500 hours which might seem high to someone scrolling DoneDeal, but he explains by analysing the data here the tractor could be reasonably fresh.

“When tractors are properly analysed, we find 10% of the hours logged might be at idle, 50% of those hours when examined might be at about 20-25% engine load, like doing loader work or raking silage, then another 30% at around 50% engine load or thereabouts. The remaining 10% then may be averaging around 80% engine load.”

Johnny also feels that contractors here do need more consideration with funding from the Government for technology, as Irish farms and stocking rates, along with the wetter climate, make us an outlier in Europe.

In essence, he explains, it’s all about using technology to make farming more efficient and environmentally friendly, helping reduce costs and increase productivity, there is no point in having it but not using it.

Precision agriculture tools such as NIR crop sensing gathers valuable data surrounding crop yield and quality.

*Fergal O’Sullivan, is an agricultural engineering lecturer at Munster Technological University.

SHARING OPTIONS