Typically, forests are primarily grown for roundwood production. However, Ireland’s forests have the potential to provide large volumes of by-product residues, such as branches and tops, collectively known as brash.

In theory, Irish forests have the potential to produce 3,980 million m3/year of residues, of which 700 million m3/year remains unused.

This is seen by many as a huge potential energy resource, with Bord na Móna, among others, aiming to tap into this.

However, brash is often used to make mats or roadways for machinery to get into and out of forests during felling, making it unusable as an energy source.

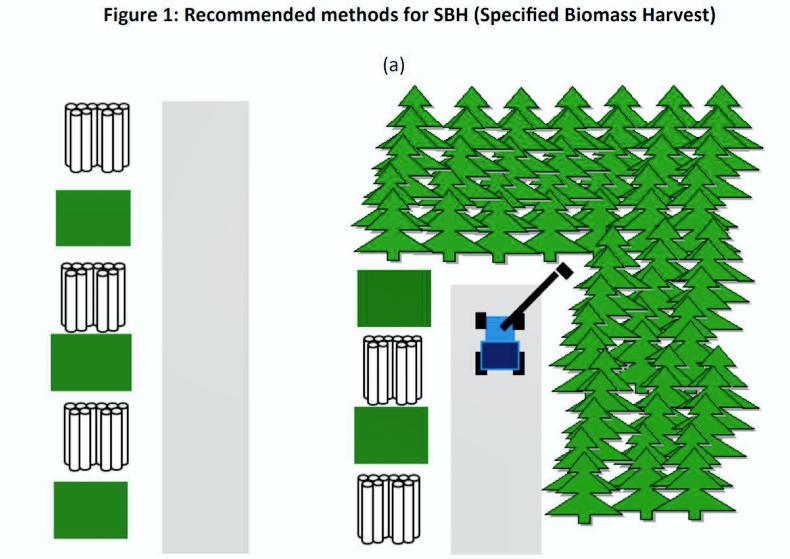

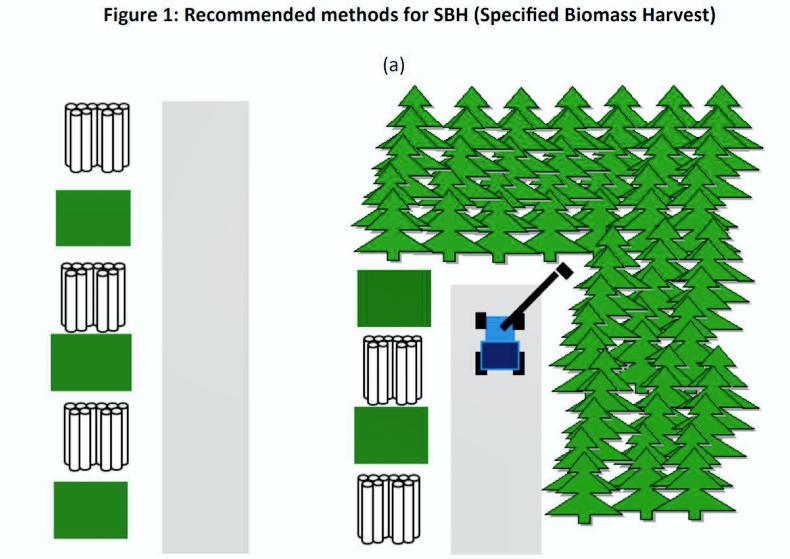

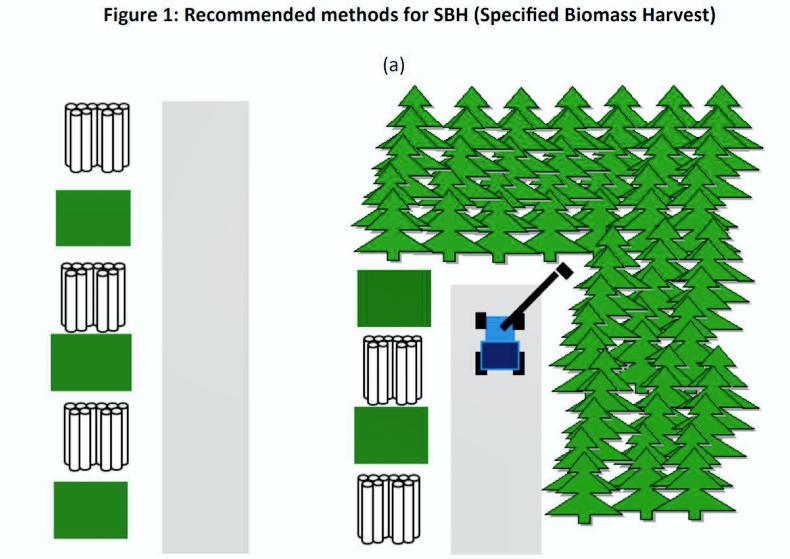

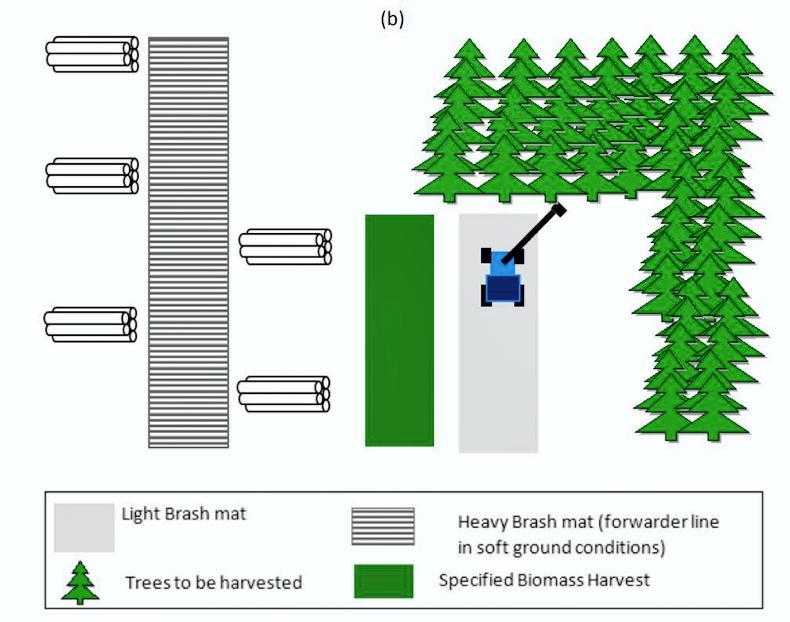

1. Good ground conditions with optional brash mat.

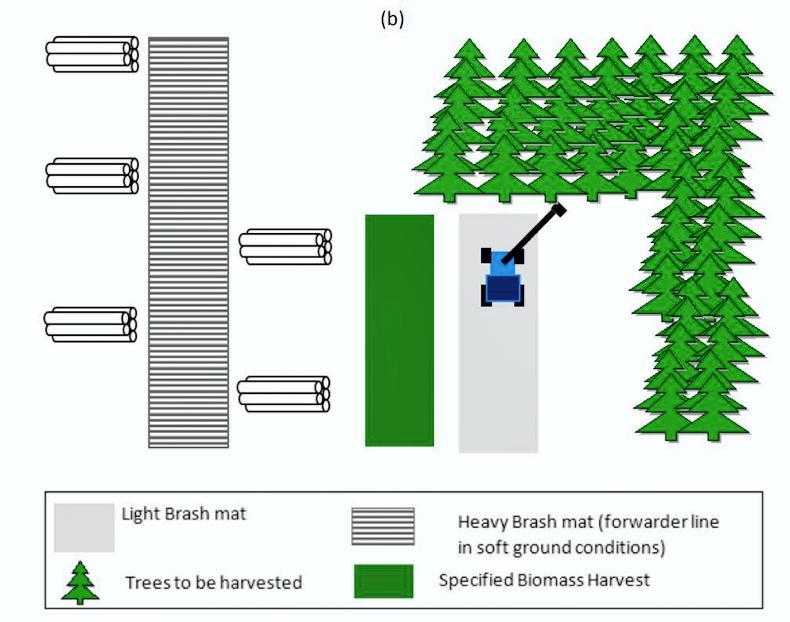

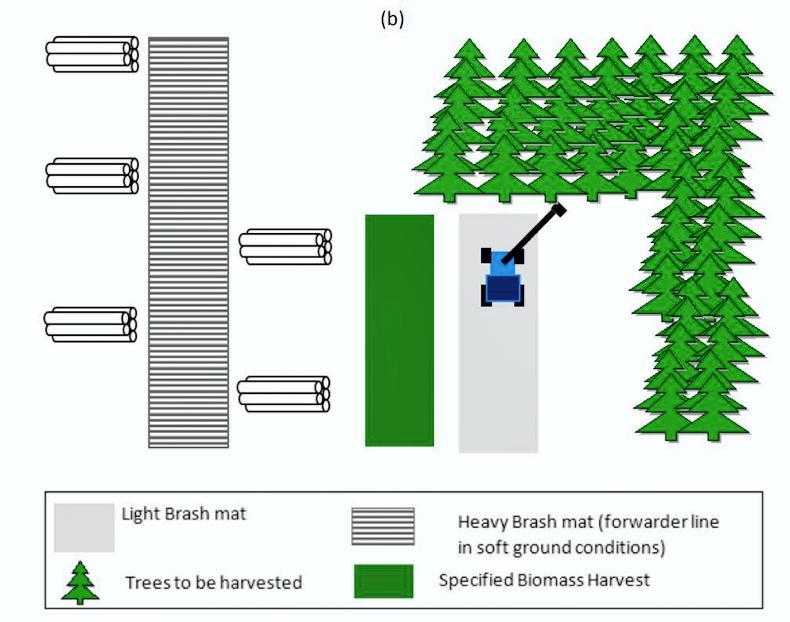

2. Soft ground conditions with heavy brash mat on every second harvesting line to facilitate extraction vehicles. Note the heavy brash mat is left in situ and is not removed.

For brash material to be used for energy, it must be harvested and kept separate from brash mats, a process called specified biomass harvesting (SBH).

SBH refers to the planned and specified harvesting of tops and branches which are removed during normal felling operations for use in energy.

The tops and branches are removed during roundwood harvest and piled in situ on the forest floor adjacent to extraction racks, and left for a sufficient time to allow needle and leaf fall before collection (see Figure 1 and 2).

By harvesting this material through SBH, it is possible to generate large volumes of useful biomass while improving the sustainable forest management practices. SBH also facilitates forest regeneration, more efficient subsequent crop management, and more uniform and higher quality crops in future cycles.

The Irish BioEnergy Association (IrBEA) recently published a technical guide aimed at foresters, forest owners and environmentalists, to outline how SBH should be practised in a cost-effective and sustainable way.

Advantages

SBH material has advantages as a biomass fuel, due to significant greenhouse gas savings when used to replace fossil fuels. This is due in part to the avoidance of emissions from the decaying of these residues when left in the forest.

Furthermore, where clearfell logging residues are removed, reforestation costs can be lowered.

Regeneration is more uniform, as brash, logging debris and potentially soil are not scraped into windrows.

Windrowing has been shown to lead to uneven crop growth, as trees grow faster closer to the windrows, due to higher levels of soil nutrients and better shelter.

The guide outlines four best practices for SBH as below:

Brash mats: Brash mats have been shown to be extremely useful in protecting vulnerable forest soils from physical damage. Where brash mats have become depleted since the roundwood harvest, and as a result soil damage could be expected, the SBH pile should be used to replenish the mat in front of the machine.Fertility: Excessive removal of needles or foliage at harvest can have negative impacts through a reduction in soil fertility and associated site productivity. For best practice, tops and green material should be left onsite to allow needles and foliage sufficient time to fall off and return to the litter pool. Most of the tree nutrients are in the foliage and small branches, and their full removal can result in two to three times the losses of nitrogen and phosphorus.Acidification: Soil acidification can be induced on poorly buffered soils when excessive amounts of base cations such as potassium, calcium, and magnesium are removed in foliage and small branch wood. These sites are generally in nutrient-poor areas. On very poor shallow soils, SBH removal is best avoided, unless wood ash, which can raise pH, can be applied prior to regeneration.Retention: The importance of the retention of wildlife habitats at clearfelling, as set out in the DAFM Standards for Felling and Reforestation, extends to deadwood and branches. These provide habitat for specialist decay organisms and for some bird species and mammals. For deadwood specifically, the recommendation is for the retention of 5m3/ha on clearfell sites and 2m3/ha on thinning sites.

Typically, forests are primarily grown for roundwood production. However, Ireland’s forests have the potential to provide large volumes of by-product residues, such as branches and tops, collectively known as brash.

In theory, Irish forests have the potential to produce 3,980 million m3/year of residues, of which 700 million m3/year remains unused.

This is seen by many as a huge potential energy resource, with Bord na Móna, among others, aiming to tap into this.

However, brash is often used to make mats or roadways for machinery to get into and out of forests during felling, making it unusable as an energy source.

1. Good ground conditions with optional brash mat.

2. Soft ground conditions with heavy brash mat on every second harvesting line to facilitate extraction vehicles. Note the heavy brash mat is left in situ and is not removed.

For brash material to be used for energy, it must be harvested and kept separate from brash mats, a process called specified biomass harvesting (SBH).

SBH refers to the planned and specified harvesting of tops and branches which are removed during normal felling operations for use in energy.

The tops and branches are removed during roundwood harvest and piled in situ on the forest floor adjacent to extraction racks, and left for a sufficient time to allow needle and leaf fall before collection (see Figure 1 and 2).

By harvesting this material through SBH, it is possible to generate large volumes of useful biomass while improving the sustainable forest management practices. SBH also facilitates forest regeneration, more efficient subsequent crop management, and more uniform and higher quality crops in future cycles.

The Irish BioEnergy Association (IrBEA) recently published a technical guide aimed at foresters, forest owners and environmentalists, to outline how SBH should be practised in a cost-effective and sustainable way.

Advantages

SBH material has advantages as a biomass fuel, due to significant greenhouse gas savings when used to replace fossil fuels. This is due in part to the avoidance of emissions from the decaying of these residues when left in the forest.

Furthermore, where clearfell logging residues are removed, reforestation costs can be lowered.

Regeneration is more uniform, as brash, logging debris and potentially soil are not scraped into windrows.

Windrowing has been shown to lead to uneven crop growth, as trees grow faster closer to the windrows, due to higher levels of soil nutrients and better shelter.

The guide outlines four best practices for SBH as below:

Brash mats: Brash mats have been shown to be extremely useful in protecting vulnerable forest soils from physical damage. Where brash mats have become depleted since the roundwood harvest, and as a result soil damage could be expected, the SBH pile should be used to replenish the mat in front of the machine.Fertility: Excessive removal of needles or foliage at harvest can have negative impacts through a reduction in soil fertility and associated site productivity. For best practice, tops and green material should be left onsite to allow needles and foliage sufficient time to fall off and return to the litter pool. Most of the tree nutrients are in the foliage and small branches, and their full removal can result in two to three times the losses of nitrogen and phosphorus.Acidification: Soil acidification can be induced on poorly buffered soils when excessive amounts of base cations such as potassium, calcium, and magnesium are removed in foliage and small branch wood. These sites are generally in nutrient-poor areas. On very poor shallow soils, SBH removal is best avoided, unless wood ash, which can raise pH, can be applied prior to regeneration.Retention: The importance of the retention of wildlife habitats at clearfelling, as set out in the DAFM Standards for Felling and Reforestation, extends to deadwood and branches. These provide habitat for specialist decay organisms and for some bird species and mammals. For deadwood specifically, the recommendation is for the retention of 5m3/ha on clearfell sites and 2m3/ha on thinning sites.

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: