Poultry farmer Erik van Veldhuisen plans on staying ahead of ever-increasing environmental and animal welfare regulations by future-proofing his facilities.

The farm, located around an hour outside of Amsterdam in the centre of the Netherlands, includes a solar PV on every farm roof and a heat exchange pump, which he says makes the farm carbon-neutral from an energy point of view.

Key to the farm’s planning were these developments, which van Veldhuisen hopes will allow the farm to stay fully stocked amid looming nitrogen emissions reduction plans posed by the Dutch government.

Neighbouring farmers without the same level of investment in facilities may see stock numbers cut by between 12% and 50%, depending on where regional reduction lines are drawn.

Van Veldhuisen keeps 25,000 broilers, having recently expanded the operation by adding another poultry house to the existing operation in a process which took years to progress through local planning and permit regulations.

A key element of ensuring farm margins with the additional costs of these measures is the direct selling of product to customers. Most broilers are sold to a processor for supermarket shelves but a portion of broilers are slaughtered off-farm before returning to the farm to undergo additional processing and retail on-site.

Rising feed costs have not hit Dutch poultry farmers as hard as many of their Irish counterparts, as van Veldhuisen explained that most supply contracts had broiler prices index-linked to feed costs.

The unit had remained empty for a total of 15 weeks this year, after two separate orders not to restock due to bird flu.

Insurance had been taken out by the farmer to cover income losses for this period.

The farm has a number of features that push animal welfare standards beyond the minimum criteria set out under regulations, such as the broilers being stocked at half the maximum stocking rate – 10 birds/m2.

One air filtration unit connected to each broiler house reduced ammonia and particulates to about 30% of the figure allowed in regulations.

The "winter garden" allowing broilers free access to an area with lower housing temperatures and increased airflow from three weeks old. \ Noel Bardon

From three weeks of age, broilers have free access to a “winter garden” - an extension to the housing shed with no heat provided and better air circulation through the mesh sidings to these areas.

Enrichment materials are also provided in the main housing area.

All poultry litter produced on the holding is taken to a composting unit. Given the intensity of livestock farming in the Netherlands, significant volumes of manure from pig and poultry units are not land spread as farmers have sufficient supplies of cattle slurry and digestate from anaerobic digestion plants from which to source nutrients.

Of the litter that does not go for composting and sale to the professional or hobby horticulture sectors, burning in biomass boilers is a popular option.

The Irish Farmers Journal also visited a veal unit just a few kilometres away from the poultry farm where most slurry is sent to a co-operative owned separation facility set up around 30 years ago, when farmers came under nitrates pressure from the government and less organic fertilisers were spread.

With separated slurry, the solids are either incinerated for energy generation or composted, while the liquid fraction has undergone enough processing to be diverted to household sewage treatment facilities.

By entering a contract agreement on the farm expansion late last year, van Veldhuisen estimates that he saved €60,000 in building costs.

Government proposals to cut ammonia emissions by between 12% and 95% in every region of the Netherlands have also slowed construction.

Feed costs have almost doubled in recent months but index pricing broilers against feed costs has cushioned the blow to farmers. \ Noel Bardon

The two largest commercial banks in the Netherlands, ING and Rabobank NL, told the Irish Farmers Journal that lenders faced “additional risks” in approving loans for farmers given the “uncertainty” created by the Dutch government’s nitrogen emissions proposals.

The veal farmer who spoke with the Irish Farmers Journal stated that his 1970s-era facilities were due an upgrade but that he was reluctant to begin preparations for works in case he would be hit with stock reductions as part of these environmental plans.

A €70,000 ammonia and particulate filter, improving animal welfare and lowering emissions, which will prove a crucial investment should the Dutch government progress with nitrogen emission reduction plans. \ Noel Bardon

Why go beyond the bare minimum?

Van Veldhuisen said that over the past few years, farmers saw Dutch supermarkets seeking higher-quality farm goods, citing higher consumer expectations around animal welfare and farm sustainability.

Conventionally produced goods can be easily sold to processors supplying the export market. However, domestic retailers are increasingly upping the standards their suppliers must adhere to.

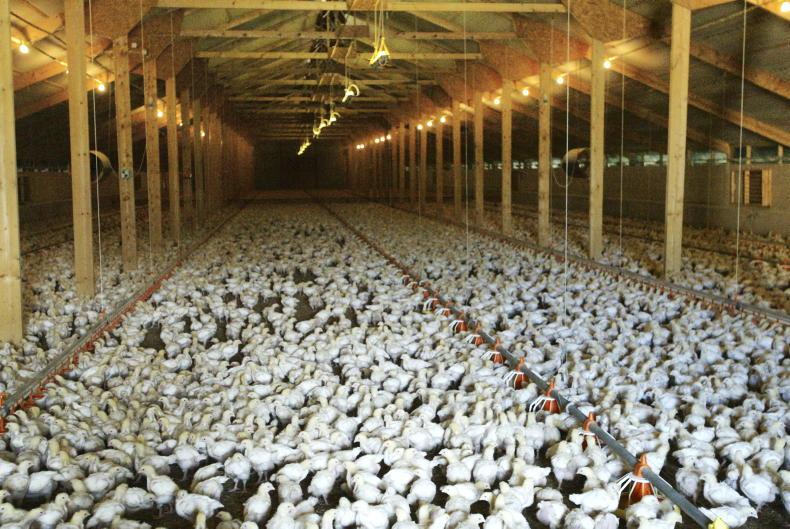

Low stocking density broilers. While animal welfare practices are pushing van Veldhuisen's broiler prices beyond those of conventional chicken, supermarkets have indicated that higher standards may become mandatory in the coming years. / Photo supplied by farmer

He said that by raising his standards, he could stay ahead of the regulations and command higher prices in the marketplace. His aim was to sell all broilers direct, but customer demand is currently limiting this.

Compliant

The sheds covered in solar panels and the €70,000 apiece ammonia filters on the broiler houses were also intended to help keep the farm compliant with emissions rules likely to tighten over the coming years.

The full extent of these tightened nitrogen emissions reduction proposals had not been considered by van Veldhuisen when he drew up the farm’s plans but they may save his operation from stock cuts in the near future, as his fellow Dutch livestock farmers say they are seeking out any investment opportunities that allow them to continue farming productively.

“We receive a higher price for our meat and that has to be [the case].

“The consumer must pay a better price and in 2023, supermarkets are making the step for all chickens to go to the ‘better living’ concept.

“We have extra paperwork but we need the extra prices. The local buyers can come and see around the facilities, see the areas the chickens have. Once they see it, they will pay more. We can explain to them.

“Selling through the ‘better living’ concept, we can get about €1.70/kg. I’m not too sure where normal prices are now, they go up and down a lot – it would probably be €1.05/kg.”

Poultry farmer Erik van Veldhuisen plans on staying ahead of ever-increasing environmental and animal welfare regulations by future-proofing his facilities.

The farm, located around an hour outside of Amsterdam in the centre of the Netherlands, includes a solar PV on every farm roof and a heat exchange pump, which he says makes the farm carbon-neutral from an energy point of view.

Key to the farm’s planning were these developments, which van Veldhuisen hopes will allow the farm to stay fully stocked amid looming nitrogen emissions reduction plans posed by the Dutch government.

Neighbouring farmers without the same level of investment in facilities may see stock numbers cut by between 12% and 50%, depending on where regional reduction lines are drawn.

Van Veldhuisen keeps 25,000 broilers, having recently expanded the operation by adding another poultry house to the existing operation in a process which took years to progress through local planning and permit regulations.

A key element of ensuring farm margins with the additional costs of these measures is the direct selling of product to customers. Most broilers are sold to a processor for supermarket shelves but a portion of broilers are slaughtered off-farm before returning to the farm to undergo additional processing and retail on-site.

Rising feed costs have not hit Dutch poultry farmers as hard as many of their Irish counterparts, as van Veldhuisen explained that most supply contracts had broiler prices index-linked to feed costs.

The unit had remained empty for a total of 15 weeks this year, after two separate orders not to restock due to bird flu.

Insurance had been taken out by the farmer to cover income losses for this period.

The farm has a number of features that push animal welfare standards beyond the minimum criteria set out under regulations, such as the broilers being stocked at half the maximum stocking rate – 10 birds/m2.

One air filtration unit connected to each broiler house reduced ammonia and particulates to about 30% of the figure allowed in regulations.

The "winter garden" allowing broilers free access to an area with lower housing temperatures and increased airflow from three weeks old. \ Noel Bardon

From three weeks of age, broilers have free access to a “winter garden” - an extension to the housing shed with no heat provided and better air circulation through the mesh sidings to these areas.

Enrichment materials are also provided in the main housing area.

All poultry litter produced on the holding is taken to a composting unit. Given the intensity of livestock farming in the Netherlands, significant volumes of manure from pig and poultry units are not land spread as farmers have sufficient supplies of cattle slurry and digestate from anaerobic digestion plants from which to source nutrients.

Of the litter that does not go for composting and sale to the professional or hobby horticulture sectors, burning in biomass boilers is a popular option.

The Irish Farmers Journal also visited a veal unit just a few kilometres away from the poultry farm where most slurry is sent to a co-operative owned separation facility set up around 30 years ago, when farmers came under nitrates pressure from the government and less organic fertilisers were spread.

With separated slurry, the solids are either incinerated for energy generation or composted, while the liquid fraction has undergone enough processing to be diverted to household sewage treatment facilities.

By entering a contract agreement on the farm expansion late last year, van Veldhuisen estimates that he saved €60,000 in building costs.

Government proposals to cut ammonia emissions by between 12% and 95% in every region of the Netherlands have also slowed construction.

Feed costs have almost doubled in recent months but index pricing broilers against feed costs has cushioned the blow to farmers. \ Noel Bardon

The two largest commercial banks in the Netherlands, ING and Rabobank NL, told the Irish Farmers Journal that lenders faced “additional risks” in approving loans for farmers given the “uncertainty” created by the Dutch government’s nitrogen emissions proposals.

The veal farmer who spoke with the Irish Farmers Journal stated that his 1970s-era facilities were due an upgrade but that he was reluctant to begin preparations for works in case he would be hit with stock reductions as part of these environmental plans.

A €70,000 ammonia and particulate filter, improving animal welfare and lowering emissions, which will prove a crucial investment should the Dutch government progress with nitrogen emission reduction plans. \ Noel Bardon

Why go beyond the bare minimum?

Van Veldhuisen said that over the past few years, farmers saw Dutch supermarkets seeking higher-quality farm goods, citing higher consumer expectations around animal welfare and farm sustainability.

Conventionally produced goods can be easily sold to processors supplying the export market. However, domestic retailers are increasingly upping the standards their suppliers must adhere to.

Low stocking density broilers. While animal welfare practices are pushing van Veldhuisen's broiler prices beyond those of conventional chicken, supermarkets have indicated that higher standards may become mandatory in the coming years. / Photo supplied by farmer

He said that by raising his standards, he could stay ahead of the regulations and command higher prices in the marketplace. His aim was to sell all broilers direct, but customer demand is currently limiting this.

Compliant

The sheds covered in solar panels and the €70,000 apiece ammonia filters on the broiler houses were also intended to help keep the farm compliant with emissions rules likely to tighten over the coming years.

The full extent of these tightened nitrogen emissions reduction proposals had not been considered by van Veldhuisen when he drew up the farm’s plans but they may save his operation from stock cuts in the near future, as his fellow Dutch livestock farmers say they are seeking out any investment opportunities that allow them to continue farming productively.

“We receive a higher price for our meat and that has to be [the case].

“The consumer must pay a better price and in 2023, supermarkets are making the step for all chickens to go to the ‘better living’ concept.

“We have extra paperwork but we need the extra prices. The local buyers can come and see around the facilities, see the areas the chickens have. Once they see it, they will pay more. We can explain to them.

“Selling through the ‘better living’ concept, we can get about €1.70/kg. I’m not too sure where normal prices are now, they go up and down a lot – it would probably be €1.05/kg.”

SHARING OPTIONS