With current ground conditions deteriorating in areas of higher rainfall and heavier soils, stock will begin to be housed in the coming weeks. As such, air temperatures are still relatively high for the year, with conditions ideal for the spread of pneumonia in cattle sheds.

The power of ventilation

Preventing pneumonia and other airborne diseases requires a multi-factorial approach, with ventilation being one of them. When we talk about ventilation, the simplest way to look at it is removing warm, stale air from the shed and replacing it with cool, fresh air, hopefully without creating draughts in the process.

To ascertain whether or not you have good ventilation in a shed, look for the tell-tale signs of poor ventilation. Cobwebs, mould growth on sheeting or timbers, or the presence of condensation or foul odours in sheds where cattle are housed.

Air temperature is also a good indication of ventilation. When you walk into a shed full of cattle, the air temperature should be equal to the outside air temperature.

Ventilation can also be tested by using a smoke machine or a smoke bomb to create a plume of smoke in a shed. Viewing the movement of the smoke will give an indication to the farmer as to how air flows within their shed.

Air flow

Many farmers are under the illusion that air flow is down to the stack effect – when air warms, its pressure increases and it rises. This is true to a certain extent, but in a windy nation like Ireland, our ability to improve airflow is hugely dependent on utilising ventilation.

Ventilation is dictated by two main things; inlet and outlet spacing. A rule of thumb is that there should be 0.1m² of outlet space for each animal housed.

Where the outlet space is too small, warm, stale air will rise up to the ridge point, but will be unable to escape. This warm, stale air will then cool and fall back down, bringing any dust or pathogens with it.

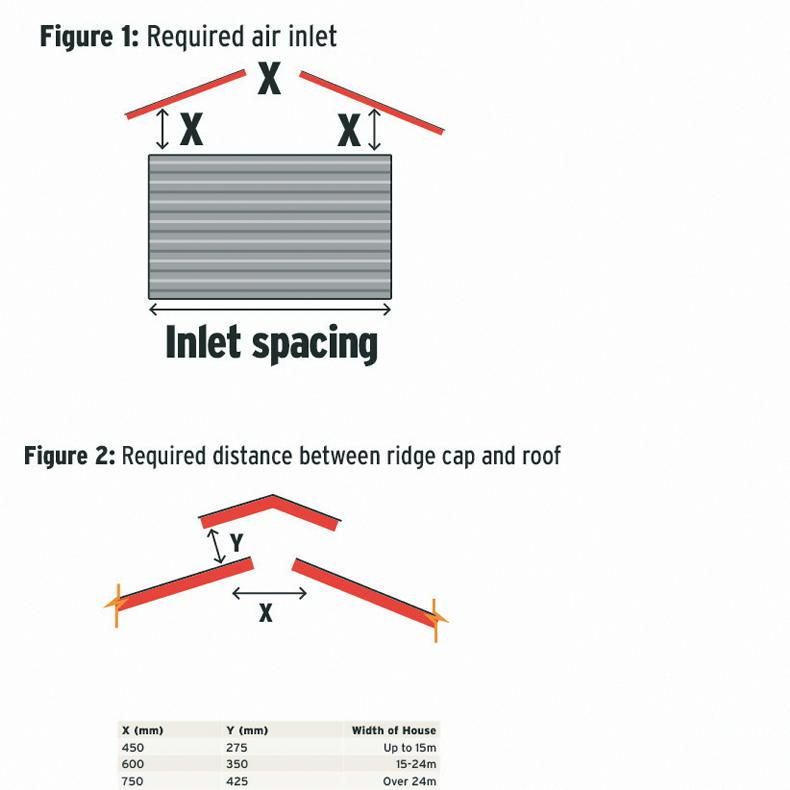

An outlet 450mm in width is recommended for buildings less than 15m in width, increasing to 600mm for buildings between 15-24m width and 750mm for buildings larger than 24m.

Ridge caps are not recommended, although many farmers choose to install them to prevent rainfall entering sheds. Where they are installed, they should be fully clear of the shed by 275mm, 350mm or 425mm for the above respective shed sizes.

The inlet is recommended to be twice the size of the outlet, i.e 0.2m² per animal. This ensures enough clean, cool air enters the building, but also creates a ‘suck’ effect with the outlet.

The smaller outlet area will pull the cool air from the inlet into the shed with a vacuum effect. It is recommended, however, to stick to the above outlet areas that are dictated by shed width to avoid creating draughts in sheds. Roof pitch will also have an affect on air flow, with a recommended pitch of 12-15° allowing for improved funnelling of stale air towards the outlet.

Example

A three-bay double slatted shed is 12m in width and 14.4m in length, comprising a central passage of 4m width with pens either side of 4m in depth. The shed holds 48 store heifers.

With a space opening of 450mm along the ridge running 14.4m, the outlet area equals 6.48m², suitable for just under 64 cattle.

To ensure adequate inflow of air, our inlet space should be double this, i.e 12.96m². If we have a gap of 450mm (the same as our outlet) between the side sheeting and the eaves, running along the full length of the shed on both sides, we will achieve this.

Where vented sheeting or space boarding is used in lieu of a clear inlet, it should extend 1.5m below the height of the eaves along the full length of the shed, as per Department recommendations.

SHARING OPTIONS