A quarter of a century ago, popstar Jamiroquai penned his famous tune Virtual Reality about the dangers of becoming too immersed in the digital world and not connected enough to the real one. For better or worse, the world has moved on considerably in that time and the use of technology is now part and parcel of our daily lives.

At the Northern Ireland (NI) College of Agriculture, Food and Rural Enterprise (CAFRE) Food Technology Centre (FTC) and Food Innovation Centre (FIC), the focus is on future food technology.

Client companies

Head of technology, Peter Simpson, says this means helping companies become more efficient, produce less waste, less packaging and use more renewable sources. It is also around food reformulation, ie food for health.

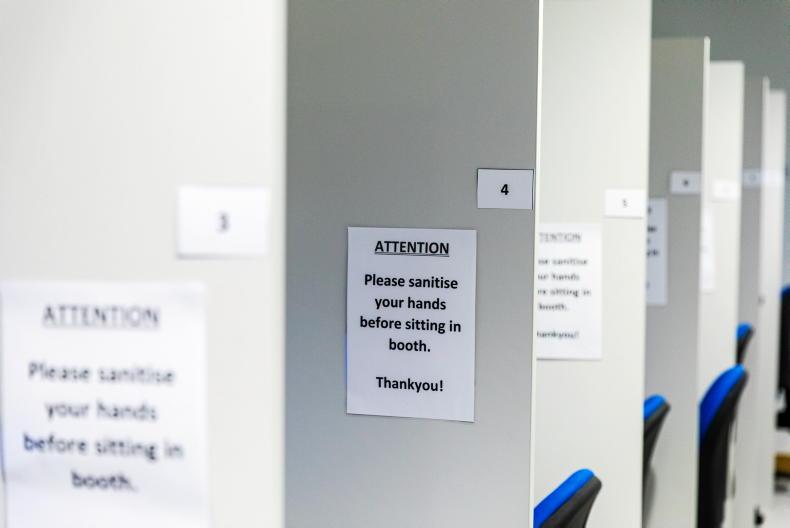

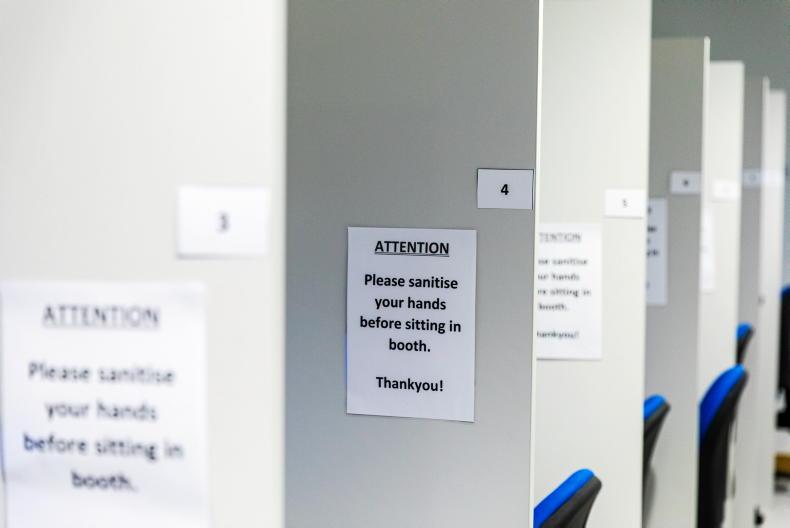

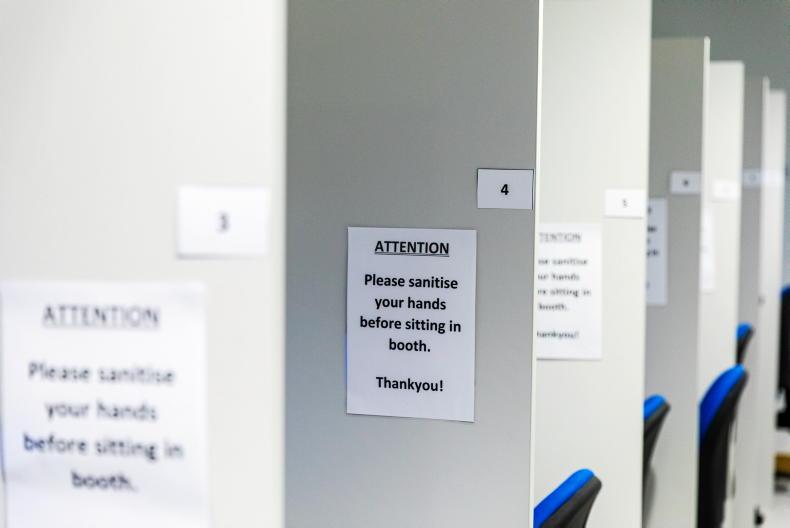

A full suite of focus group facilities are avaialble in Loughry

“Our big selling point is that we can take companies on an innovation pathway from entrepreneur through recipe formulation, to pilot stage production and product launch. We have incubation facilities where companies can start manufacturing on a small scale to see if the product can take off commercially. That’s our unique selling point (USP).”

Head of Food Technology Peter Simpson

Innovation vouchers, where Invest Northern Ireland funds a company or Knowledge Transfer Partnerships* (KTP) – where CAFRE team with a university partner such as Queens – are the funding vehicles used to progress projects.

Robotics laboratory

One such KTP project is CAFRE’s first tentative steps into robotics. A purpose-built lab houses the college’s robot. It was purchased so students could do some basic programming, but, in industry, it could replace a person.

With the industry in a crisis in terms of staffing shortages, Peter remarks that: “They’ve [food manufacturing] gone from not one bit interested in robotics to being really interested. There was no real labour shortage problems until BREXIT and COVID and since then it’s really hard. One of the potential solutions is to put in more automation and robotics to make processes more efficient with less people.”

Russell Ramage was on hand to demo some product reformulation projects.

As the college doesn’t have robotics expertise, they have partnered with Queen’s University, Belfast, through their Northern Ireland Technology Centre (NITC). The NITC have been working on aeronautical and automotive automation projects for over 20 years.

Peter asserts that this vast knowledge is easily transferred to food manufacturing, which makes the partnership a “really good double act”.

Meat curing room in the CAFRE Loughry Food Technology Centre

“We’ve got food technologists working with the NITC. They just want data, data, data, but they have no practical concept of how a food factory actually works. The value is in teaming up together,” he explains.

Furthermore, as well as helping the industry solve a labour problem, robotics is embedded in the curriculum, supporting the next generation of CAFRE food technologists to understand what a robot could do in the factories they will work in.

Where robots can help

Ciara Kane, who herself graduated with a BSc in Food Technology in 2013, works on the robotic and automation project.

Ciara Kane ran the robotics demo.

“Companies are quite traditional with bespoke systems. Currently a lot of the work that could be done by robotics is ‘pick and pack’ where somebody packs a pallet, lifts 12kg boxes and builds that up throughout the day. It’s a repetitive tasks that’s not adding any value. The workforce for these unskilled jobs doesn’t exist here anymore. This is where robotics comes in.”

Ciara Kane guides Amii McKeever along the factory line as part of the VR demo at Loughry.

CAFRE’s robot is a cobot – a collaborative robot – designed to work alongside a human being. If a human being gets in its way, it will stop. This is different to the big, rapid, pick-and-place robots that need to be behind cages. A cobot can be put to work alongside people in the line, rather than replacing them completely. It’s to free people up to work on more value-added activities.

Modelling

The technology is getting really affordable, with the main barrier being a shortage of people who know how to use it. The projects aim to avoid companies spending thousands of pounds on unproven technology, Peter explains.

“Part of the work is in creating virtual simulations of a factory and saying: ‘Here’s your factory at the moment, here’s how it flows, here’s all the data and if we put a robot in there, this is the difference.’ So they have proof before they invest.”

Amii McKeever was given the opportunity to walk the floor of a factory, virtually at least, in the CAFRE robotics lab.

The bottom line in CAFRE is they can model your production line and then let you walk up and down it virtually. With that comment, the only thing was for Irish Country Living to don the virtual reality glasses and walk the factory floor ourselves.

student experience

Finally, how does innovation at CAFRE benefit the student population?

Fiona Dickson, head of learner services, explains.

Head of Learner services Fiona Dickson

“They are on a journey here going from being a student at this level, into the supply chain to the development stage and to the actual processing stage to being in industry. We are trying to emulate in this building what students would actually see in real life”.

* Knowledge Transfer Partnerships (KTPs) link forward thinking businesses with the UK’s world class knowledge bases to deliver innovation projects led by inspired graduates

Read more

Agri Careers: more to CAFRE than students

Catch, cook and craic in Howth

A quarter of a century ago, popstar Jamiroquai penned his famous tune Virtual Reality about the dangers of becoming too immersed in the digital world and not connected enough to the real one. For better or worse, the world has moved on considerably in that time and the use of technology is now part and parcel of our daily lives.

At the Northern Ireland (NI) College of Agriculture, Food and Rural Enterprise (CAFRE) Food Technology Centre (FTC) and Food Innovation Centre (FIC), the focus is on future food technology.

Client companies

Head of technology, Peter Simpson, says this means helping companies become more efficient, produce less waste, less packaging and use more renewable sources. It is also around food reformulation, ie food for health.

A full suite of focus group facilities are avaialble in Loughry

“Our big selling point is that we can take companies on an innovation pathway from entrepreneur through recipe formulation, to pilot stage production and product launch. We have incubation facilities where companies can start manufacturing on a small scale to see if the product can take off commercially. That’s our unique selling point (USP).”

Head of Food Technology Peter Simpson

Innovation vouchers, where Invest Northern Ireland funds a company or Knowledge Transfer Partnerships* (KTP) – where CAFRE team with a university partner such as Queens – are the funding vehicles used to progress projects.

Robotics laboratory

One such KTP project is CAFRE’s first tentative steps into robotics. A purpose-built lab houses the college’s robot. It was purchased so students could do some basic programming, but, in industry, it could replace a person.

With the industry in a crisis in terms of staffing shortages, Peter remarks that: “They’ve [food manufacturing] gone from not one bit interested in robotics to being really interested. There was no real labour shortage problems until BREXIT and COVID and since then it’s really hard. One of the potential solutions is to put in more automation and robotics to make processes more efficient with less people.”

Russell Ramage was on hand to demo some product reformulation projects.

As the college doesn’t have robotics expertise, they have partnered with Queen’s University, Belfast, through their Northern Ireland Technology Centre (NITC). The NITC have been working on aeronautical and automotive automation projects for over 20 years.

Peter asserts that this vast knowledge is easily transferred to food manufacturing, which makes the partnership a “really good double act”.

Meat curing room in the CAFRE Loughry Food Technology Centre

“We’ve got food technologists working with the NITC. They just want data, data, data, but they have no practical concept of how a food factory actually works. The value is in teaming up together,” he explains.

Furthermore, as well as helping the industry solve a labour problem, robotics is embedded in the curriculum, supporting the next generation of CAFRE food technologists to understand what a robot could do in the factories they will work in.

Where robots can help

Ciara Kane, who herself graduated with a BSc in Food Technology in 2013, works on the robotic and automation project.

Ciara Kane ran the robotics demo.

“Companies are quite traditional with bespoke systems. Currently a lot of the work that could be done by robotics is ‘pick and pack’ where somebody packs a pallet, lifts 12kg boxes and builds that up throughout the day. It’s a repetitive tasks that’s not adding any value. The workforce for these unskilled jobs doesn’t exist here anymore. This is where robotics comes in.”

Ciara Kane guides Amii McKeever along the factory line as part of the VR demo at Loughry.

CAFRE’s robot is a cobot – a collaborative robot – designed to work alongside a human being. If a human being gets in its way, it will stop. This is different to the big, rapid, pick-and-place robots that need to be behind cages. A cobot can be put to work alongside people in the line, rather than replacing them completely. It’s to free people up to work on more value-added activities.

Modelling

The technology is getting really affordable, with the main barrier being a shortage of people who know how to use it. The projects aim to avoid companies spending thousands of pounds on unproven technology, Peter explains.

“Part of the work is in creating virtual simulations of a factory and saying: ‘Here’s your factory at the moment, here’s how it flows, here’s all the data and if we put a robot in there, this is the difference.’ So they have proof before they invest.”

Amii McKeever was given the opportunity to walk the floor of a factory, virtually at least, in the CAFRE robotics lab.

The bottom line in CAFRE is they can model your production line and then let you walk up and down it virtually. With that comment, the only thing was for Irish Country Living to don the virtual reality glasses and walk the factory floor ourselves.

student experience

Finally, how does innovation at CAFRE benefit the student population?

Fiona Dickson, head of learner services, explains.

Head of Learner services Fiona Dickson

“They are on a journey here going from being a student at this level, into the supply chain to the development stage and to the actual processing stage to being in industry. We are trying to emulate in this building what students would actually see in real life”.

* Knowledge Transfer Partnerships (KTPs) link forward thinking businesses with the UK’s world class knowledge bases to deliver innovation projects led by inspired graduates

Read more

Agri Careers: more to CAFRE than students

Catch, cook and craic in Howth

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: