The sheds, built by building contractor TJ Garahy, are delivering the goods in terms of adaptability, comfort and labour efficiency.

PICTURE ONE

The distant shed was put up four years ago. It has no tank, a solid floor, and no internal pillars. It is multi-purpose - and in use all year.

The shed on the left was built last autumn. It has a slatted passage at the feed rail. Behind it, and separated by a mass concrete wall, is a bedded area running along the shed’s eight bays.

PICTURE TWO

This first four bay shed was put up with the intention that one end would winter heifer weanlings and the other would house farm yard dung (fym). The fym is now stored in an unused silage pit. Effluent from both the fyn and the sheds are piped to a nearby storage tank.

This shed is used to winter weanlings and calves. In summer it is used to store grain straw and fertilizer. “It’s in use all year round,” John Murphy said.

“That’s the advantage of a solid floor.” Flexibility is helped by the following:

The roof is a portal frame meaning there are no internal pillars, This allows easier storage of straw and parking of machinery, etc.One inch holes, left in the mass concrete walls during construction, are used to hang internal gates. John has set up a system of gates hanging from gates, crossing from the back wall to the feed barrier at the front.All these internal gates swing back to the wall, out of the way for easy cleaning and for quick taking down of pens.

The near gable end of the shed has good access by means of two wide sliding doors. This allows for easy cleaning out of dirty straw from the barrier area each week in winter. John drives the loading shovel in and pulls out the straw with the bucket. The roof spans 50 feet.The shed has lots of ventilation. Air comes in through the open front and through the vented sheeting over the rear wall and at the far gable end. There is a ridge canopy to allow stale air to exit.

PICTURE THREE

With a portal frame, the rafters are supported only by the pillars. Apex bracing at the top of the roof where the two rafters meet, and knee bracing where the rafters sit on the pillars, provide strength. Straw bales can be stacked into the roof, and high machinery or loads can be driven into the shed.

This is a well made roof. The X-shaped cross bracing between rafters is in place the first and last bays. There are two clear sheets per bay for light, two lamps inside and one outside.

PICTURE FOUR

Here, from the rear, we can see the new shed which was finished last autumn. It’s an eight bay single, with a 40 foot span. John Murphy reckons that if he expands cow numbers he may, at some future stage, build a similar shed to face it, making a double, with a roofed feed passage in the centre.

We can see that the drinking troughs in this shed are outside the back wall and there are windows in the wall for the cows to lean out and drink.

PICTURE FIVE

This shed is laid out as a slatted passage beside the feed barrier and a bedded area behind. The shed is used for wintering dairy cows, wean- lings and in calf heifers. Again, there are no internal pillars. John Murphy had stub pillars on to which he hangs barrier gates.

The large sliding door at the gable end allows easy cleaning of the bedded area with the farm’s loading shovel.

John Murphy opted for a concrete wall to separate the bedded and slatted areas. This minimises the amount of straw pulled out through the slats, it allows the cattle to be locked on the slats, when bedding or cleaning out the shed and it also facilitates easy movement of stock between the pens.

In the near future, John reckons that if he expands numbers he may house some cows in this shed right through the summer. He is limited in the amount of grass he has around at the home yeard.

His grazing platform includes leased ground, “but that could go at any time”.

In this scenario he would keep the fresher cows on grass.

PICTURE SIX

There are a number of advantages to drinking troughs sited outside the shed, They stay clean and free of dung. They don’t interfere with cleaning out of the bedding by the loader. There is no drinker or pipes to be broken by cattle and no risk of leaks down into the tank.

PICTURE SEVEN

John Murphy farms in Craanford, Co Wexford. His 90-year-old father Peter is retired but active on the farm. The farm has one full-time employee, Billy Greene, and one part-time, local Dairy farmer, Patrick Kavanagh. John supplies Glanbia and represents north Wexford, east Wicklow on the management board.

Straw bedding works well for John and is readily available in Wexford.

John plans to purchase a straw chopper for next winter, this will result in 30% to 40% less straw usage and bedding can be completed without having to enter the sheds, as the chopper will fire the straw over the tanks and into the bedded area from the feed passage.

John finds les work with the straw system than the cubical system. Cubicals are very labour intensive and they are never really clean. “He has a 160 space cubicle house on the farm for the dairy cows.

The four bay bedded shed cost €50,000 when built four years ago. “We gave away the grant,” he comments.

The metal work of the new shed, finished last autumn, cost €31,000 including VAT. The underground slatted tank had been put in place before hand. Concreting work was completed by A. Waldron and sons.

*This article was first published by the Irish Farmers Journal on 5th May 2012.

The sheds, built by building contractor TJ Garahy, are delivering the goods in terms of adaptability, comfort and labour efficiency.

PICTURE ONE

The distant shed was put up four years ago. It has no tank, a solid floor, and no internal pillars. It is multi-purpose - and in use all year.

The shed on the left was built last autumn. It has a slatted passage at the feed rail. Behind it, and separated by a mass concrete wall, is a bedded area running along the shed’s eight bays.

PICTURE TWO

This first four bay shed was put up with the intention that one end would winter heifer weanlings and the other would house farm yard dung (fym). The fym is now stored in an unused silage pit. Effluent from both the fyn and the sheds are piped to a nearby storage tank.

This shed is used to winter weanlings and calves. In summer it is used to store grain straw and fertilizer. “It’s in use all year round,” John Murphy said.

“That’s the advantage of a solid floor.” Flexibility is helped by the following:

The roof is a portal frame meaning there are no internal pillars, This allows easier storage of straw and parking of machinery, etc.One inch holes, left in the mass concrete walls during construction, are used to hang internal gates. John has set up a system of gates hanging from gates, crossing from the back wall to the feed barrier at the front.All these internal gates swing back to the wall, out of the way for easy cleaning and for quick taking down of pens.

The near gable end of the shed has good access by means of two wide sliding doors. This allows for easy cleaning out of dirty straw from the barrier area each week in winter. John drives the loading shovel in and pulls out the straw with the bucket. The roof spans 50 feet.The shed has lots of ventilation. Air comes in through the open front and through the vented sheeting over the rear wall and at the far gable end. There is a ridge canopy to allow stale air to exit.

PICTURE THREE

With a portal frame, the rafters are supported only by the pillars. Apex bracing at the top of the roof where the two rafters meet, and knee bracing where the rafters sit on the pillars, provide strength. Straw bales can be stacked into the roof, and high machinery or loads can be driven into the shed.

This is a well made roof. The X-shaped cross bracing between rafters is in place the first and last bays. There are two clear sheets per bay for light, two lamps inside and one outside.

PICTURE FOUR

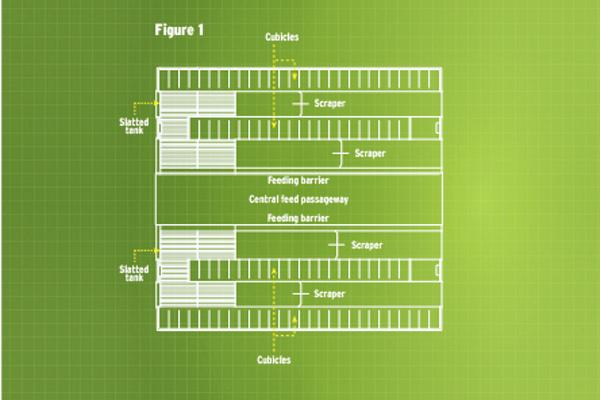

Here, from the rear, we can see the new shed which was finished last autumn. It’s an eight bay single, with a 40 foot span. John Murphy reckons that if he expands cow numbers he may, at some future stage, build a similar shed to face it, making a double, with a roofed feed passage in the centre.

We can see that the drinking troughs in this shed are outside the back wall and there are windows in the wall for the cows to lean out and drink.

PICTURE FIVE

This shed is laid out as a slatted passage beside the feed barrier and a bedded area behind. The shed is used for wintering dairy cows, wean- lings and in calf heifers. Again, there are no internal pillars. John Murphy had stub pillars on to which he hangs barrier gates.

The large sliding door at the gable end allows easy cleaning of the bedded area with the farm’s loading shovel.

John Murphy opted for a concrete wall to separate the bedded and slatted areas. This minimises the amount of straw pulled out through the slats, it allows the cattle to be locked on the slats, when bedding or cleaning out the shed and it also facilitates easy movement of stock between the pens.

In the near future, John reckons that if he expands numbers he may house some cows in this shed right through the summer. He is limited in the amount of grass he has around at the home yeard.

His grazing platform includes leased ground, “but that could go at any time”.

In this scenario he would keep the fresher cows on grass.

PICTURE SIX

There are a number of advantages to drinking troughs sited outside the shed, They stay clean and free of dung. They don’t interfere with cleaning out of the bedding by the loader. There is no drinker or pipes to be broken by cattle and no risk of leaks down into the tank.

PICTURE SEVEN

John Murphy farms in Craanford, Co Wexford. His 90-year-old father Peter is retired but active on the farm. The farm has one full-time employee, Billy Greene, and one part-time, local Dairy farmer, Patrick Kavanagh. John supplies Glanbia and represents north Wexford, east Wicklow on the management board.

Straw bedding works well for John and is readily available in Wexford.

John plans to purchase a straw chopper for next winter, this will result in 30% to 40% less straw usage and bedding can be completed without having to enter the sheds, as the chopper will fire the straw over the tanks and into the bedded area from the feed passage.

John finds les work with the straw system than the cubical system. Cubicals are very labour intensive and they are never really clean. “He has a 160 space cubicle house on the farm for the dairy cows.

The four bay bedded shed cost €50,000 when built four years ago. “We gave away the grant,” he comments.

The metal work of the new shed, finished last autumn, cost €31,000 including VAT. The underground slatted tank had been put in place before hand. Concreting work was completed by A. Waldron and sons.

*This article was first published by the Irish Farmers Journal on 5th May 2012.

SHARING OPTIONS