When did you set up your business and why?

Palm Free Irish Soap started trading in 2015, but we have actually been making soap for just over 26 years now.

It all began back in 1996 when we arrived here from the UK when reading the ingredients that were listed on a well-known baby soap.

We began researching what they were, bearing in mind there was limited internet available at the time, so a trip to the library and O’Mahony’s Bookshop was the only way forward, and we were surprised to find that this well-known brand was made up of a plethora of chemicals.

It was then that we decided to try to make our own soap using food-safe vegetable oils and pure essential oils as the main ingredients.

We still remain a small family-run business, but now employ eight full-time staff, four of which are family members.

When doing our research for raw materials for Palm Free Irish Soap, we were already very much aware of the effects that mass palm oil production was having on the environment, so we opted to avoid using it in any of our recipes.

Palm oil itself is a beautiful oil, but it’s the whole environmental impact of the production methods that caused us to take a step back and search for more sustainable alternative oils.

Palm Free Irish Soap have been operating since 1996, based in Co Clare.

Can you explain your process?

Our soap-making process is of a traditional nature, we do not mass produce our products. Instead we rely upon a hands-on approach, which not only creates employment but also keeps us fairly fit too.

Instead of using tap water or water from a municipal supply, we actually collect and filter Irish rainwater. This unique ingredient is then incorporated in the manufacture of our soaps.

We use an energy-saving cold process method, which only requires a gentle heat to melt and saponify the beautiful vegetable oils, such as coconut oil, shea butter, olive oil, castor oil and sunflower oil.

For some of our more delicate recipes, we still use our original 25-year-old oak paddle to gently mix the ingredients.

After saponification, the soaps are then left to set up in their moulds for up to 12 hours before being un-moulded.

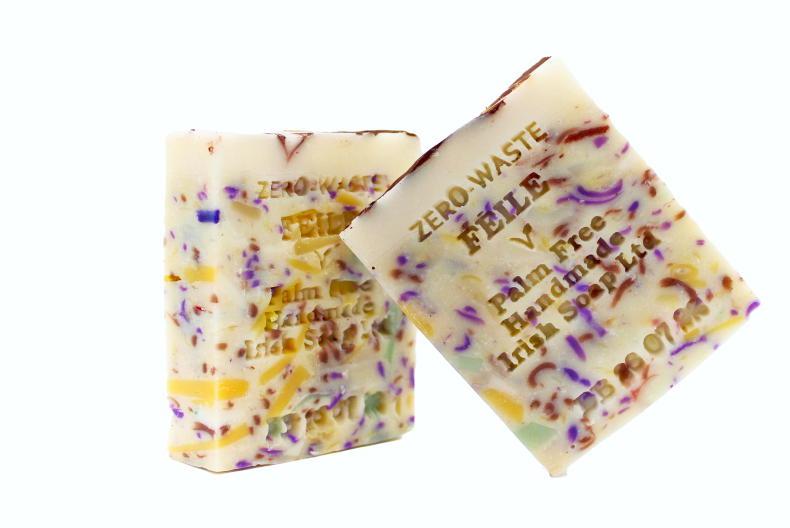

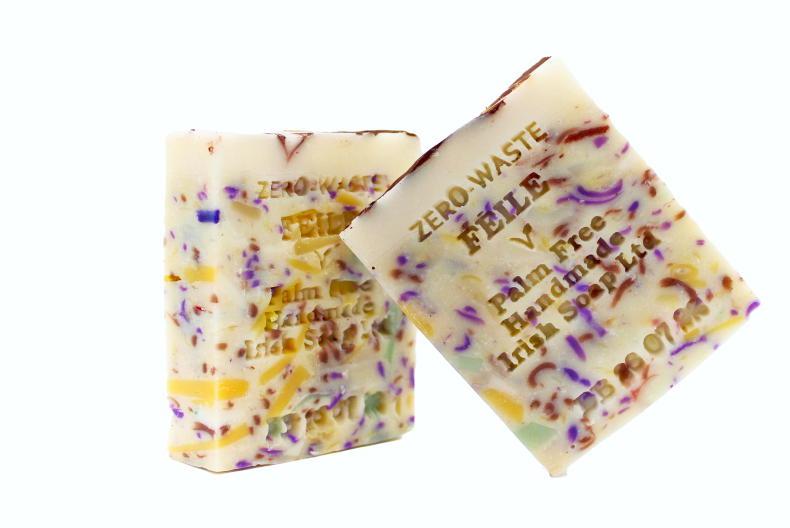

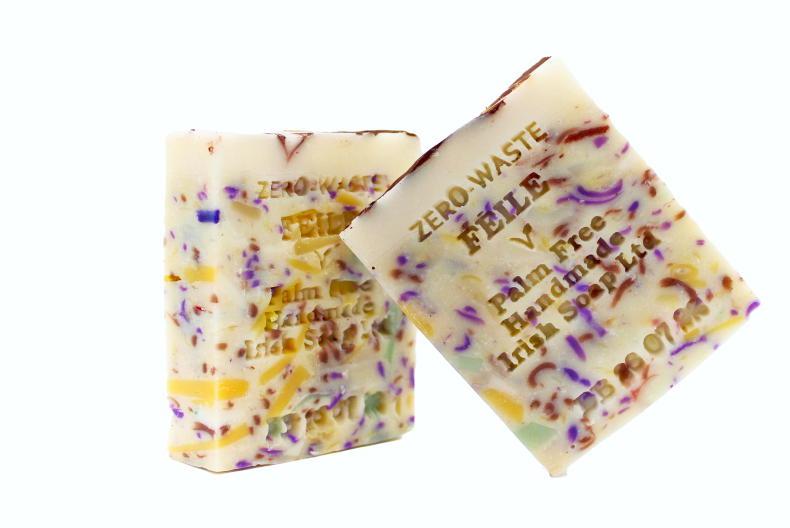

Every soap is then individually hand cut into bars before being hand stamped with our company logo, the type of soap and a totally unique individual batch code, which also relates to the best before date.

We are proud to be the only company in Europe to give each bar of soap its own identity in this way.

The cut soap bars are then stacked and wheeled into a purpose-built drying room, where they are left in a controlled environment for up to six weeks to cure fully, much like a cheese maturing.

We rely heavily on working together as a team and pool our ideas and make concerted efforts to constantly update our processes, minimising any waste and ensuring that we work together economically and effectively.

We have recently availed of a digital start grant from our Local Enterprise Office here in Clare, which has enabled us to begin our journey of being a paperless company.

This has not only cut down our need for reams of triplicate order books, but it has also enabled us to collect data and statistics, as well as adding the security of accountability to our processes.

Our mindset is to grow on a local level, for the common good, maintain our grassroots approach and actively encourage feedback from all of our customers.

What is your best seller?

Throughout our many years of soap making, there is one stand-out product that has consistently out-sold all of the others and that is our classic Irish lavender (dream) soap.

Tony Hoynes and his daughters, Jade and Sorcha, of Palm Free Irish Soap Ltd.

What is it about your business that brings you joy?

Being proud to be the creator of a range of beautiful handmade Irish skincare products.

Knowing that by taking our no-nonsense sustainable approach to business and by producing a range of genuinely sustainable products that will actually make a difference, not only to your skin but also to our planet.

Not losing sight of our vision, despite what some advisers have recommended over the years.

Getting such positive feedback from our customers on the beauty and effectiveness of our products reinforces our beliefs in what we are doing and makes us all smile.

Being recognised for our efforts and achievements in the form of being nominated and winning awards for our manufacturing ethos and sustainability.

We have been fortunate to have won the green award for three consecutive years for green micro business of the year, and at the European Free from Skincare Awards, we won a gold award for our new TLC shampoo bar, as well as a silver for the TLC conditioner, plus another silver for our zesty lemon soap and bronze for our best in brand.

Most recently, we were nominated for and won a Pakman award from Repak for our efforts in waste prevention.

What are your hopes for 2023?

We are exploring new and exciting markets and by investing in technologies and some new machinery, we are ensuring that we are well positioned to increase our output by around 50%.

However, we will continue to maintain our handmade hands-on approach to our manufacturing process.

What advice would you give to another start-up business?

I think the best advice to give to anyone starting out in business is be prepared. Carry out your market research, identify your customers and analyse your competition.

Have a plan and be prepared to put in the hours. When others are planning a weekend away, think about setting out a robust business plan.

Be prepared to make sacrifices, enjoy what you do, be creative and don’t be afraid to think outside the box.

Visit https://palmfreeirishsoap.ie/

Read more

Meet The Maker: Wizard & Grace

Meet The Maker: illustrator Una Heaney

When did you set up your business and why?

Palm Free Irish Soap started trading in 2015, but we have actually been making soap for just over 26 years now.

It all began back in 1996 when we arrived here from the UK when reading the ingredients that were listed on a well-known baby soap.

We began researching what they were, bearing in mind there was limited internet available at the time, so a trip to the library and O’Mahony’s Bookshop was the only way forward, and we were surprised to find that this well-known brand was made up of a plethora of chemicals.

It was then that we decided to try to make our own soap using food-safe vegetable oils and pure essential oils as the main ingredients.

We still remain a small family-run business, but now employ eight full-time staff, four of which are family members.

When doing our research for raw materials for Palm Free Irish Soap, we were already very much aware of the effects that mass palm oil production was having on the environment, so we opted to avoid using it in any of our recipes.

Palm oil itself is a beautiful oil, but it’s the whole environmental impact of the production methods that caused us to take a step back and search for more sustainable alternative oils.

Palm Free Irish Soap have been operating since 1996, based in Co Clare.

Can you explain your process?

Our soap-making process is of a traditional nature, we do not mass produce our products. Instead we rely upon a hands-on approach, which not only creates employment but also keeps us fairly fit too.

Instead of using tap water or water from a municipal supply, we actually collect and filter Irish rainwater. This unique ingredient is then incorporated in the manufacture of our soaps.

We use an energy-saving cold process method, which only requires a gentle heat to melt and saponify the beautiful vegetable oils, such as coconut oil, shea butter, olive oil, castor oil and sunflower oil.

For some of our more delicate recipes, we still use our original 25-year-old oak paddle to gently mix the ingredients.

After saponification, the soaps are then left to set up in their moulds for up to 12 hours before being un-moulded.

Every soap is then individually hand cut into bars before being hand stamped with our company logo, the type of soap and a totally unique individual batch code, which also relates to the best before date.

We are proud to be the only company in Europe to give each bar of soap its own identity in this way.

The cut soap bars are then stacked and wheeled into a purpose-built drying room, where they are left in a controlled environment for up to six weeks to cure fully, much like a cheese maturing.

We rely heavily on working together as a team and pool our ideas and make concerted efforts to constantly update our processes, minimising any waste and ensuring that we work together economically and effectively.

We have recently availed of a digital start grant from our Local Enterprise Office here in Clare, which has enabled us to begin our journey of being a paperless company.

This has not only cut down our need for reams of triplicate order books, but it has also enabled us to collect data and statistics, as well as adding the security of accountability to our processes.

Our mindset is to grow on a local level, for the common good, maintain our grassroots approach and actively encourage feedback from all of our customers.

What is your best seller?

Throughout our many years of soap making, there is one stand-out product that has consistently out-sold all of the others and that is our classic Irish lavender (dream) soap.

Tony Hoynes and his daughters, Jade and Sorcha, of Palm Free Irish Soap Ltd.

What is it about your business that brings you joy?

Being proud to be the creator of a range of beautiful handmade Irish skincare products.

Knowing that by taking our no-nonsense sustainable approach to business and by producing a range of genuinely sustainable products that will actually make a difference, not only to your skin but also to our planet.

Not losing sight of our vision, despite what some advisers have recommended over the years.

Getting such positive feedback from our customers on the beauty and effectiveness of our products reinforces our beliefs in what we are doing and makes us all smile.

Being recognised for our efforts and achievements in the form of being nominated and winning awards for our manufacturing ethos and sustainability.

We have been fortunate to have won the green award for three consecutive years for green micro business of the year, and at the European Free from Skincare Awards, we won a gold award for our new TLC shampoo bar, as well as a silver for the TLC conditioner, plus another silver for our zesty lemon soap and bronze for our best in brand.

Most recently, we were nominated for and won a Pakman award from Repak for our efforts in waste prevention.

What are your hopes for 2023?

We are exploring new and exciting markets and by investing in technologies and some new machinery, we are ensuring that we are well positioned to increase our output by around 50%.

However, we will continue to maintain our handmade hands-on approach to our manufacturing process.

What advice would you give to another start-up business?

I think the best advice to give to anyone starting out in business is be prepared. Carry out your market research, identify your customers and analyse your competition.

Have a plan and be prepared to put in the hours. When others are planning a weekend away, think about setting out a robust business plan.

Be prepared to make sacrifices, enjoy what you do, be creative and don’t be afraid to think outside the box.

Visit https://palmfreeirishsoap.ie/

Read more

Meet The Maker: Wizard & Grace

Meet The Maker: illustrator Una Heaney

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: